Catalyst for preparing cyclohexanediamine by phenylenediamine hydrogenation under ammonia reaction conditions

A phenylenediamine and catalyst technology, applied in the field of catalysts, can solve the problems of catalyst deactivation, difficulty, low yield of target products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

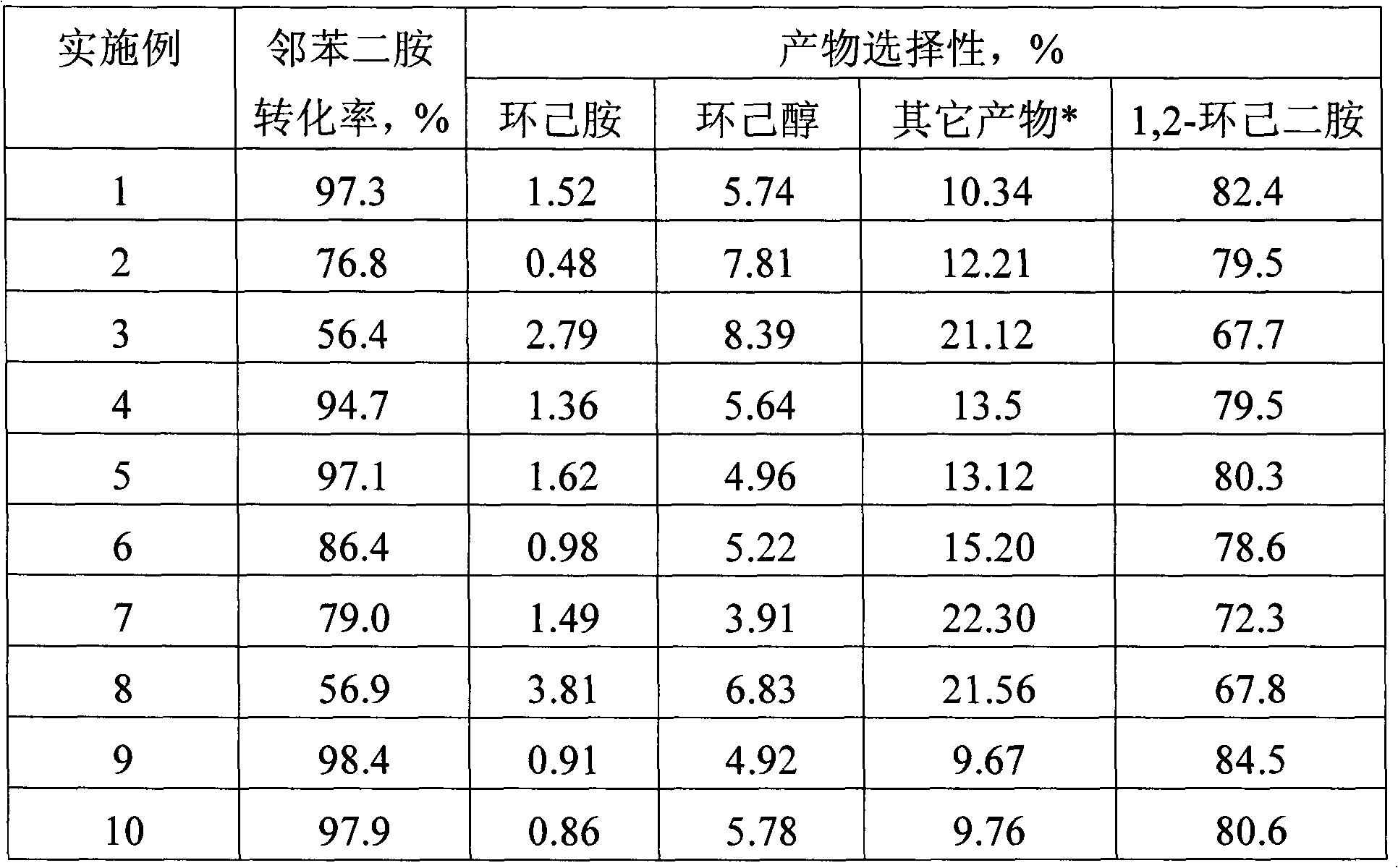

Examples

Embodiment 1

[0022] The catalyst of Example 1 was 5% Ru / coir charcoal. Weigh 9.5 grams of coconut shell charcoal (150-200 mesh), soak and boil in 3% nitric acid for 4 hours before use, wash with distilled water until pH=7.0, dry at 120°C for 6 hours, and configure 15ml containing 1.2935 grams of RuCl 3 .3H 2 O aqueous solution, use this aqueous solution to impregnate the above-mentioned coconut shell charcoal carrier, dry naturally, and dry in an oven at 120 ° C for 4 hours.

Embodiment 2

[0024] Catalyst 5%Ru / Al of embodiment 2 2 o 3 . In addition to weighing 9.5 grams of Al 2 o 3 Except, all the other preparation steps are the same as in Example 1.

Embodiment 3

[0026] Catalyst 5%Ru / SiO of Example 3 2 . In addition to weighing 9.5 g of SiO 2 Except, the rest of the preparation steps are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com