Selective hydrodesulfurization catalyst and preparation method thereof

A hydrogenation catalyst and hydrodesulfurization technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of high octane number loss and achieve octane Small loss of alkane number, good chemical stability and thermal stability, and improved interaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

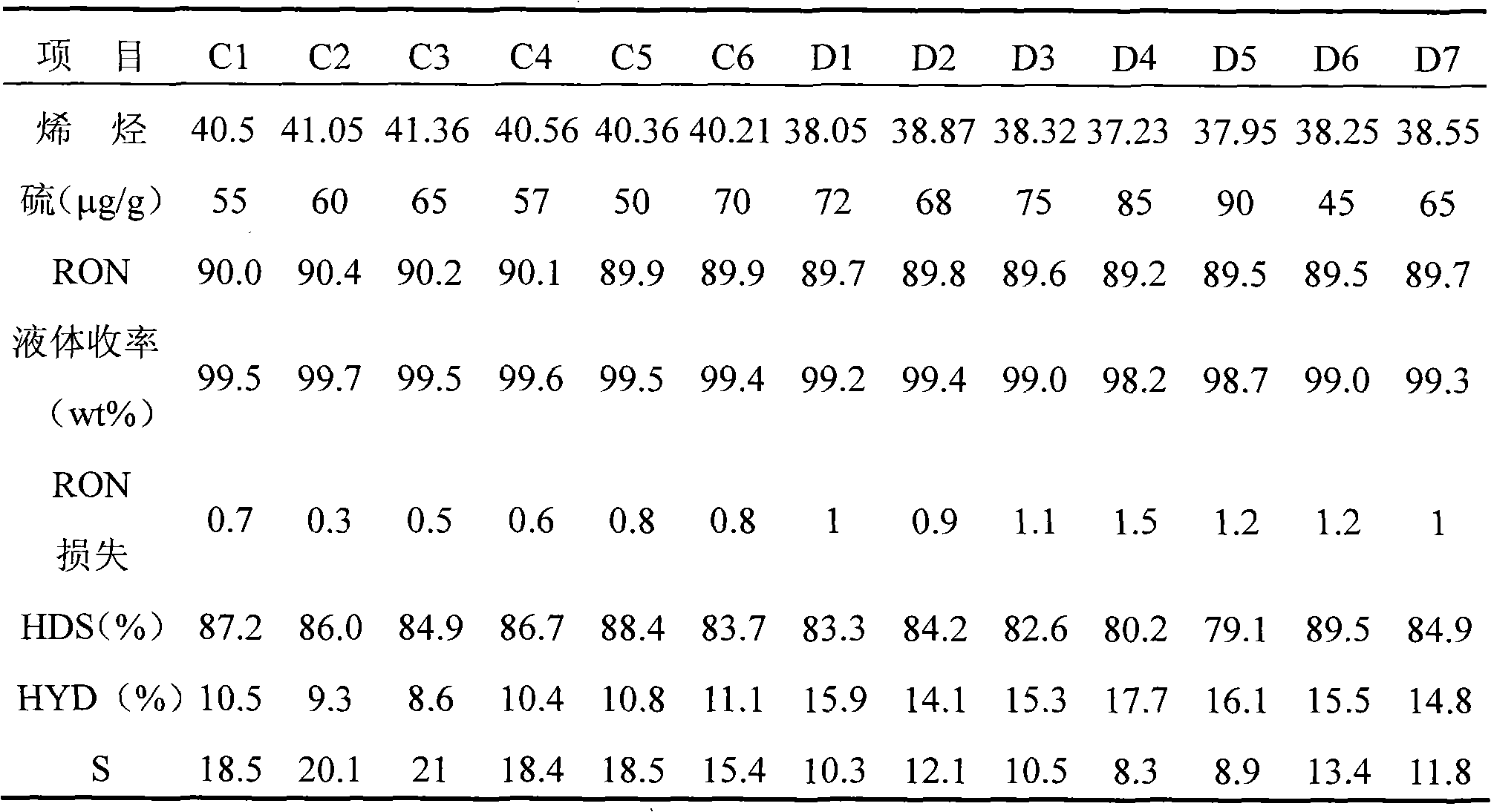

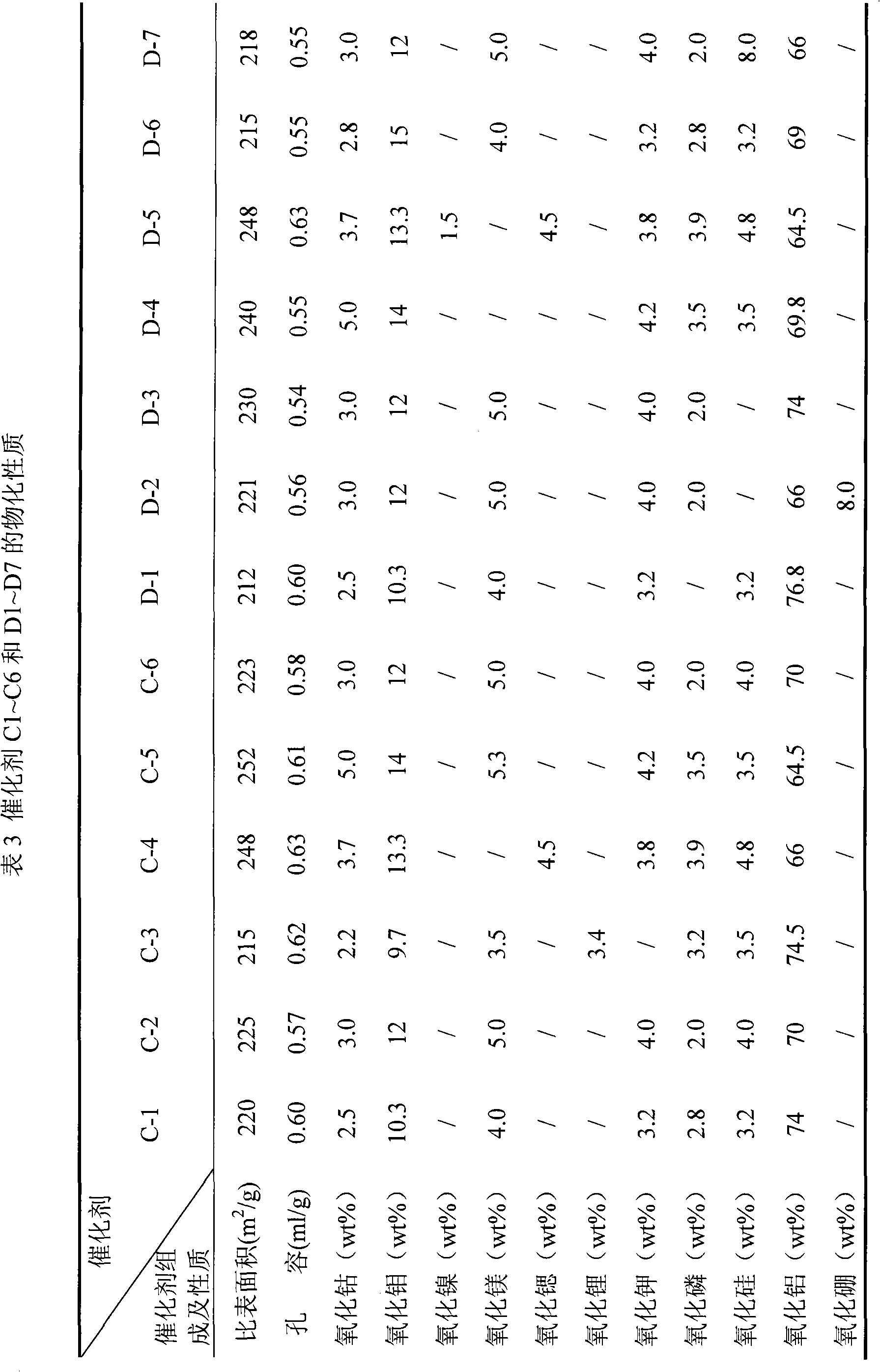

Embodiment 1

[0045] Mix and knead pseudo-boehmite, silica sol, nitric acid and water, extrude, dry at 120°C, and bake at 500°C for 4 hours to obtain a composite carrier of silica and alumina; then impregnate 100g of the composite carrier in magnesium nitrate , potassium nitrate and diammonium hydrogen phosphate, aged at 20-30°C for 5h, dried at 120°C, and calcined at 480°C for 5h to prepare a catalyst carrier containing additives magnesium, potassium and phosphorus; finally prepare nitric acid A mixed solution of cobalt and ammonium molybdate, impregnated on a catalyst carrier, aged at 20-30°C for 5h, dried at 120°C, and calcined at 500°C for 4h to obtain 2.5wt% cobalt oxide, 10.3wt% molybdenum oxide, magnesium oxide 4.0wt%, potassium oxide 3.2wt%, phosphorus oxide 2.8wt%, silicon oxide 3.2wt%, alumina 74wt% finished catalyst C1.

Embodiment 2

[0047] The preparation method of the silica and alumina composite carrier is the same as in Example 1. Immerse 100g of composite carrier in a mixed solution of magnesium nitrate, potassium carbonate and ammonium dihydrogen phosphate, age at 20-30°C for 6 hours, dry at 120°C, and roast at 450°C for 6 hours to obtain magnesium, potassium and phosphorus-containing additives catalyst carrier; finally prepare a mixed solution of cobalt nitrate and ammonium molybdate, impregnate it on the catalyst carrier, age at 20-30°C for 5h, dry at 120°C, and roast at 520°C for 4h to obtain 3.0wt% cobalt oxide, Finished catalyst C2 comprising 12 wt% of molybdenum oxide, 5.0 wt% of magnesium oxide, 4.0 wt% of potassium oxide, 2.0 wt% of phosphorus oxide, 4.0 wt% of silicon oxide and 70 wt% of alumina.

Embodiment 3

[0049] Mix and knead pseudo-boehmite, nano-silica (6-100nm particle size), nitric acid and water, extrude, dry at 120°C, and roast at 550°C for 4 hours to obtain a composite carrier of silica and alumina ; then 100g of the composite carrier is immersed in the mixed solution of magnesium nitrate, lithium nitrate and ammonium dihydrogen phosphate, aged at 20-30°C for 5h, dried at 120°C, and calcined at 500°C for 5h to obtain magnesium and potassium additives and phosphorus catalyst carrier; finally prepare a mixed solution of cobalt acetate and ammonium molybdate, impregnate it on the catalyst carrier, age at 20-30°C for 5h, dry at 120°C, and roast at 560°C for 3h to obtain 2.2wt cobalt oxide %, molybdenum oxide 9.7wt%, magnesium oxide 3.5wt%, lithium oxide 3.4wt%, phosphorus oxide 3.2wt%, silicon oxide 3.5wt%, aluminum oxide 74.5wt% finished catalyst C3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com