Nitrogen-resistant type hydrocracking catalyst carrier and preparation method thereof

A catalyst carrier, hydrocracking technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of poor nitrogen resistance, difficulty in balancing nitrogen resistance performance and cracking activity, and low cracking activity and other problems, to achieve the effect of high nitrogen resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment -1

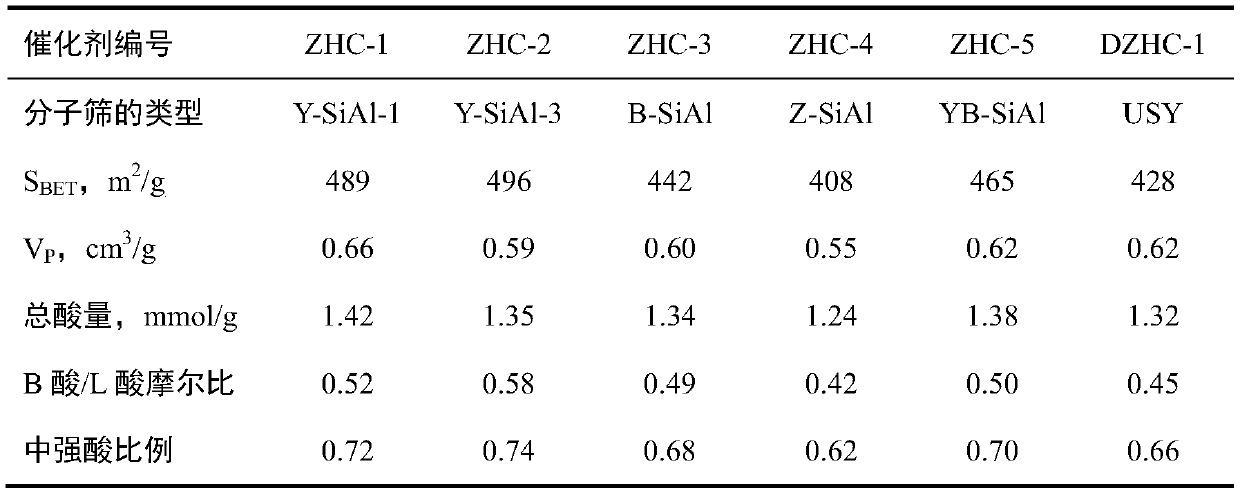

[0022] Example-1 USY / amorphous silicon aluminum (amorphous silicon aluminum SiO 2 Content 30.0wt%)

[0023] Weigh 210.0g TEOS and dissolve it in 250mL deionized water. After hydrolysis, mix it with 1200mL 2.5mol / L aluminum nitrate aqueous solution and stir well, then add 108.0g USY molecular sieve (SiO 2 :Al 2 O 3 The molar ratio is 12, and the particle size is 100 nm) to form a mixed solution. Ammonia with a mass concentration of 12% by weight was added to the mixed solution in drops until the pH of the mixed solution was 9.8. After the addition of ammonia, the mixed glue solution was stirred and aged at 40°C for 4 hours. After the synthesized product is allowed to stand and age for 6 hours, it is filtered and washed to neutrality by suction, and the filter cake is dried at 120°C for 4 hours and calcined at 520°C for 4 hours to obtain 30% USY / amorphous silicon-aluminum composite material, marked with Y- SiAl-1.

Embodiment -2

[0024] Example-2 USY / amorphous silicon aluminum (amorphous silicon aluminum SiO 2 Content 50.0wt%)

[0025] Weigh 340.0g TEOS and dissolve it in 100mL deionized water, mix it with 800mL 2.5mol / L aluminum chloride salt aqueous solution after hydrolysis, and stir well, then add 50.0g USY molecular sieve (SiO 2 :Al 2 O 3 The molar ratio is 15 and the particle size is 100 nm) to form a mixed solution. Ammonia with a mass concentration of 12% by weight was added to the mixed solution in drops until the pH of the mixed solution was 9.8. After the addition of ammonia, the mixed glue solution was stirred and aged at 40°C for 4 hours. After the synthesized product is allowed to stand and age for 6 hours, it is filtered and washed to neutrality by suction, and the filter cake is dried at 120°C for 4 hours and calcined at 520°C for 4 hours to obtain a 20% USY / amorphous silicon-aluminum composite material, marked with Y- SiAl-2.

Embodiment -3

[0026] Example-3 USY / amorphous silicon aluminum (amorphous silicon aluminum SiO 2 Content 30.0wt%)

[0027] Weigh 340.0g TEOS and dissolve it in 100mL deionized water, mix it with 800mL 2.5mol / L aluminum chloride salt aqueous solution after hydrolysis, and stir well, then add 200.0g USY molecular sieve (SiO 2 :Al 2 O 3 The molar ratio is 40, and the particle size is 250 nm) to form a mixed solution. Ammonia with a mass concentration of 12% by weight was added to the mixed solution in drops until the pH of the mixed solution was 9.8. After the addition of ammonia, the mixed glue solution was stirred and aged at 40°C for 4 hours. After the synthesized product is allowed to stand and age for 6 hours, it is filtered and washed to neutrality by suction, and the filter cake is dried at 120°C for 4 hours and calcined at 520°C for 4 hours to obtain a 50% USY / amorphous silicon-aluminum composite material, marked with Y- SiAl-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com