Preparation of magnesium metal modified low-silicon SSZ-13 molecular sieve and MTO reaction performance thereof

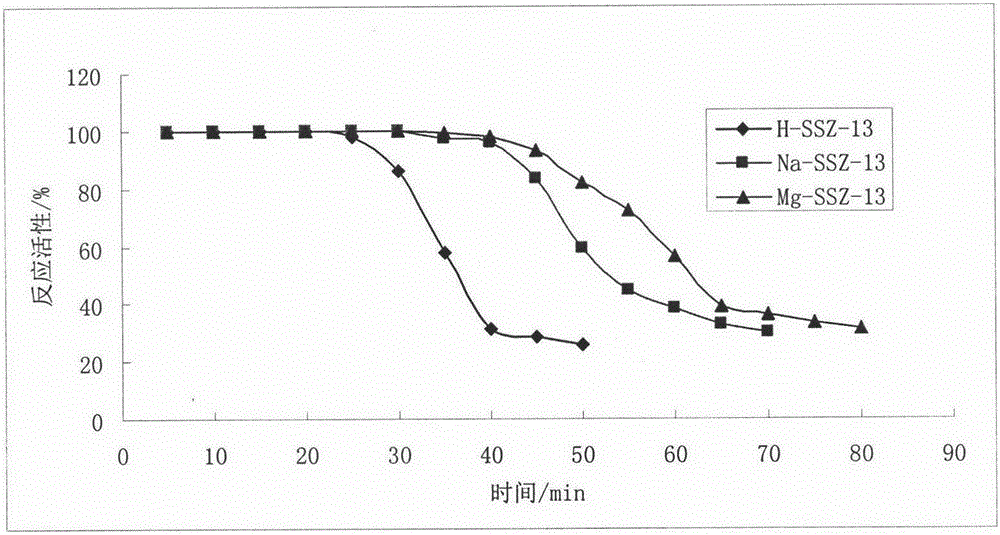

A molecular sieve, metal magnesium technology, applied in the direction of molecular sieve catalyst, molecular sieve and alkali exchange compounds, non-metallic elements, etc., can solve the problems of acid enhancement, molecular sieve product specific surface area decrease, crystallinity decrease, etc., to achieve low acid strength, superior MTO The effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1: Preparation of Mg-SSZ-13 by Magnesium Nitrate Exchange

[0045] Preparation of lye: add 0.83g of sodium hydroxide to 18g of water, stir until the sodium hydroxide is dissolved, add 3.43g of N,N,N-trimethyladamantane ammonium hydroxide (template agent), and stir until a homogeneous solution.

[0046] Preparation of gel: Add 13.05g of silica sol to the reaction kettle, stir in a water bath at room temperature, then add lye, stir evenly, add 3.25g of aluminum sulfate, stir evenly, add 0.16g of molecular sieve of chabazite (CHA) crystal phase as crystal species, and stirred at room temperature for 4 hours to obtain a homogeneous gel.

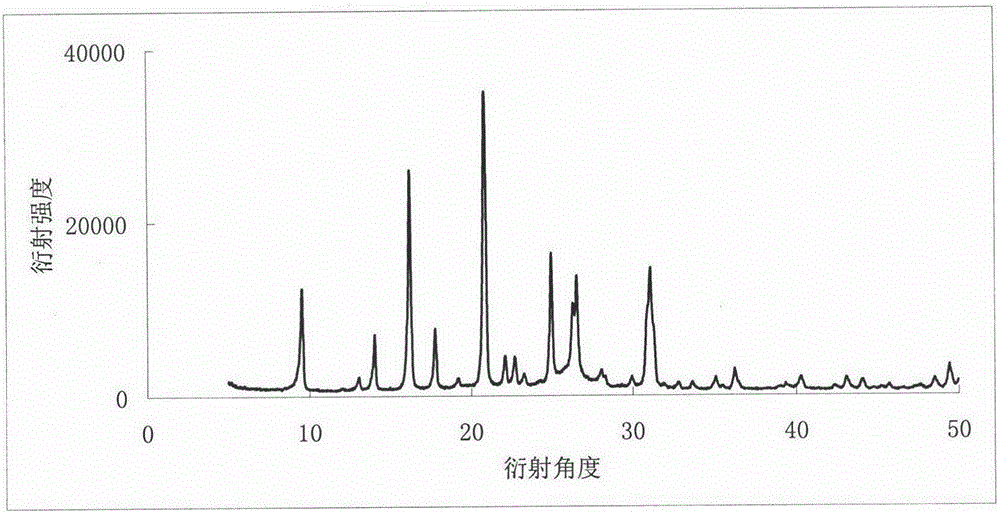

[0047] Crystallization: Put the initial gel into a PTFE autoclave and crystallize at 165°C for 2-4 days. After the crystallization is complete, wash the product with deionized water until the filtrate is neutral, and dry at 100°C 12h.

[0048] Calcination: The dried samples were heated up to 600°C under an air atmosphere for 4 hour...

Embodiment 2

[0051] Example 2: Preparation of Mg-SSZ-13 by Magnesium Acetate Exchange

[0052] Preparation of lye: add 0.83g of sodium hydroxide to 18g of water, stir until the sodium hydroxide is dissolved, add 3.43g of N,N,N-trimethyladamantane ammonium hydroxide (template agent), and stir until a homogeneous solution.

[0053] Preparation of gel: Add 13.05g of silica sol into a beaker, stir in a water bath at room temperature, add lye, stir evenly, add 3.25g of aluminum sulfate, stir evenly, add 0.16g of chabazite (CHA) crystal phase molecular sieve as a seed crystal, and After stirring for 4 hours, a homogeneous gel was obtained.

[0054] Crystallization: Put the initial gel into a PTFE high-pressure reactor and crystallize at 165°C for 2-4 days. After the crystallization is complete, wash the product with deionized water until the filtrate is neutral, and dry at 100°C 12h.

[0055] Calcination: The dried samples were heated to 600°C for 4 hours in the air atmosphere, kept for 4 hour...

Embodiment example 3

[0057] Example 3: One-step synthesis of Mg-SSZ-13 using magnesium nitrate

[0058] Preparation of lye: add 0.83g of sodium hydroxide to 18g of water, stir until the sodium hydroxide is dissolved, add 3.43g of N,N,N-trimethyladamantane ammonium hydroxide (template agent), and stir until a homogeneous solution.

[0059] Preparation of gel: Add 13.05g of silica sol into a beaker, stir in a water bath at room temperature, then add lye, stir evenly, add 3.25g of aluminum sulfate, stir evenly, add 1.47g of magnesium nitrate, add 0.16g of chabazite (CHA) crystal Phase molecular sieves were used as seed crystals, and stirred at room temperature for 4 hours to obtain a uniform gel.

[0060] Crystallization: Put the initial gel into a PTFE high-pressure reactor and crystallize at 165°C for 2-4 days. After the crystallization is complete, wash the product with deionized water until the filtrate is neutral, and dry at 100°C 12h.

[0061] Calcination: The dried samples were heated to 600...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com