Quaternary platinum-based catalyst for propane dehydrogenation to propylene, preparation method and application thereof

A propane dehydrogenation and catalyst technology, which is applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of catalyst activity, selectivity, high catalyst manufacturing cost, and high content of metal components. To achieve the effect of improving the degree of reduction and utilization efficiency, less carbon deposition, and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

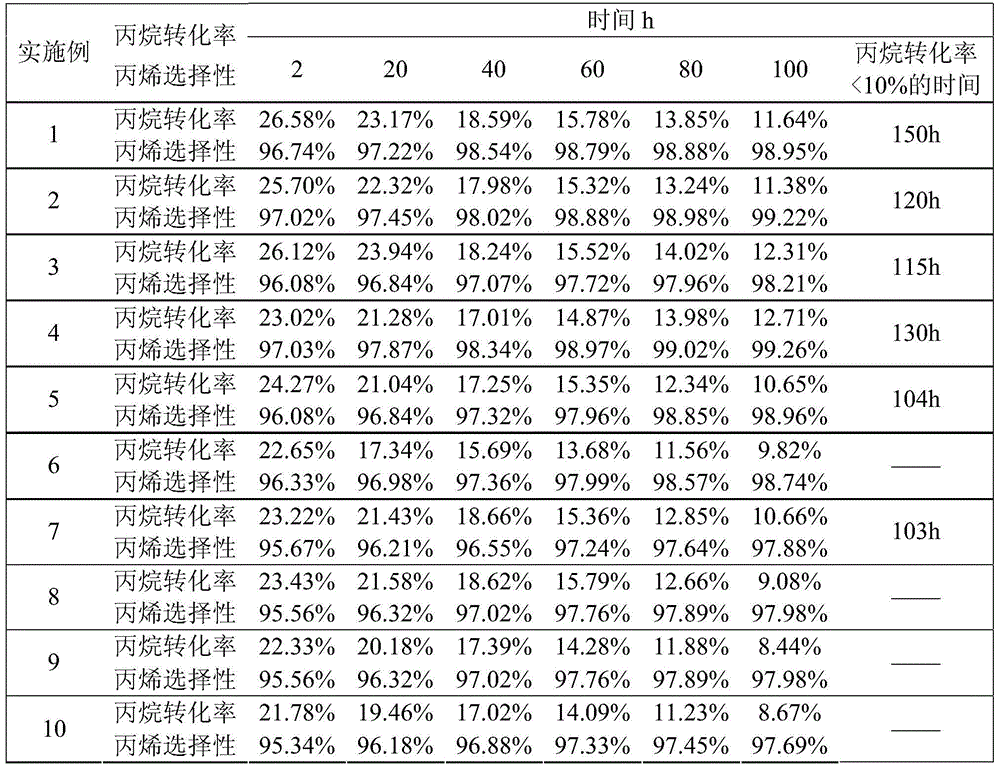

Examples

Embodiment 1

[0031] Select spherical γ-Al with a diameter of 1.5-3mm 2 o 3 The carrier is pretreated, and the carrier is loaded into the constant temperature zone of the quartz reactor. After the temperature is raised to 600°C, the PH 3 , kept for 3 hours, and then placed in a muffle furnace, baked at 540°C for 3 hours.

[0032] It is the platinum nitrate that Pt content is 0.25g, the tin protochloride that Sn content is 0.3g, the potassium chloride that K content is 0.8g and the cerium nitrate that Ce content is 0.6g are mixed uniformly, and above-mentioned mixed solution is poured into 98.05 g the treated alumina carrier, then heated to 90°C and stirred for 3h, dried at 100°C for 5h, placed in a muffle furnace and calcined at 550°C for 6h to obtain a catalyst.

[0033] The catalytic activity of propane dehydrogenation to propylene was determined in a fixed bed reactor. Concrete reaction condition is as follows: catalyst consumption is 0.5g, and reaction pressure is normal pressure, an...

Embodiment 2

[0035] Select spherical γ-Al with a diameter of 1.5-3mm 2 o 3 The carrier is pretreated, and the carrier is loaded into the constant temperature zone of the quartz reactor. After the temperature is raised to 650°C, the PH 3 , kept for 3 hours, and then placed in a muffle furnace, baked at 540°C for 3 hours.

[0036] Pour the sodium chloride solution containing 0.7g of Na into 97.25g of the treated alumina carrier, then heat to 95°C and stir for 3h, then place in an oven, dry at 100°C for 6h, and finally roast at 550°C for 5h to obtain the catalyst precursor body.

[0037] According to the above method, Zn is impregnated on the catalyst precursor, Zn comes from zinc nitrate, and its Zn content is 1.3g; then Pt is impregnated on the catalyst precursor of the previous step, Pt comes from platinum nitrate, and its Pt content is 0.25g; Finally, Sn is impregnated, the Sn source is stannous chloride, and its Sn content is 0.5g to obtain the catalyst.

[0038] Utilize the method o...

Embodiment 3

[0040] Select spherical γ-Al with a diameter of 1.5-3mm 2 o 3 The carrier is pretreated, and the carrier is loaded into the constant temperature zone of the quartz reactor. After the temperature is raised to 600 ° C, NH is injected at normal pressure. 3 , kept for 3 hours, and then placed in a muffle furnace, baked at 600°C for 3 hours.

[0041] Mix platinum nitrate with a Pt content of 0.2g, stannous chloride with a Sn content of 0.3g, calcium nitrate with a Ca content of 1.0g, and lanthanum nitrate with a La content of 0.9g, and pour the above mixed solution into 97.6g The treated alumina carrier was then heated to 95° C. and stirred for 4 hours, dried at 100° C. for 6 hours, and finally placed in a muffle furnace for calcination at 550° C. for 6 hours to obtain a catalyst.

[0042] Utilize the method of embodiment 1 to measure its catalytic activity of propane dehydrogenation to propylene reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com