High-temperature proton exchange membrane fuel cell membrane electrode and preparation method thereof

A proton exchange membrane and fuel cell membrane technology, applied in battery electrodes, fuel cell components, circuits, etc., can solve the problems of decreased battery stability and uncertain electrode acid content, so as to improve battery performance and ensure certainty , The effect of improving the effective active area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

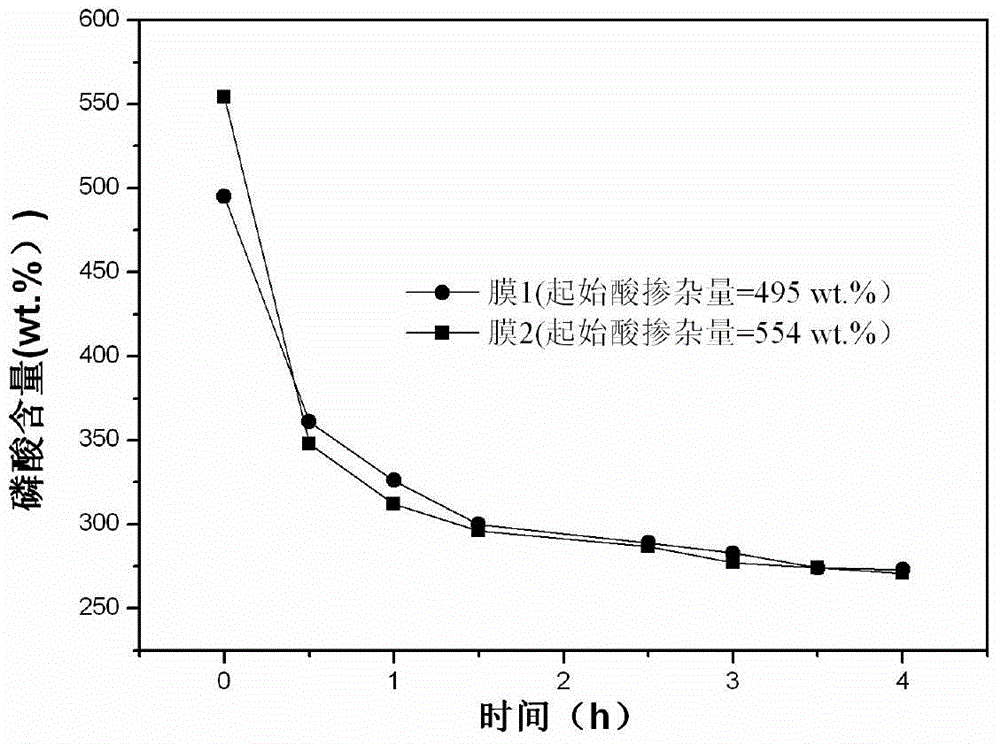

[0037] Treatment of high temperature proton exchange membranes: with figure 1 The ABPBI membrane 1 after 4h equilibration treatment was used as the proton exchange membrane for preparing high-temperature membrane electrodes, and the acid content of the membrane was 182wt.% after equilibration.

[0038] Anode and cathode gas diffusion electrodes: the anode and cathode gas diffusion electrodes use TorayTGP-H-60 as the support layer, and the carbon powder loading in the microporous layer is 1.8mg / cm 2 ; With 60% Pt / C (JM) as the catalyst, the catalyst loading in the catalytic layer is 0.9mgPt / cm 2 . Then according to the electrode area and the required acid content, take a certain amount of 85% concentrated phosphoric acid respectively, add water to dilute to a 40% mass concentration, then add 5 times the volume of ethanol to obtain an acid solution, and finally use a micro-dropper to anode and cathode respectively. The acid solution is spread on the gas diffusion electrode, an...

Embodiment 2

[0042] by figure 1 The ABPBI membrane 2 after 4h equilibration treatment was used as the proton exchange membrane for preparing high-temperature membrane electrodes, and the acid content of the membrane was 181wt.% after equilibration. The microporous layer and the catalytic layer in the anode and cathode gas diffusion electrodes are the same as in Example 1, but the content of phosphoric acid introduced on the anode and cathode gas diffusion electrodes is respectively 3.5 mg / cm 2 and 5.2mg / cm 2 .

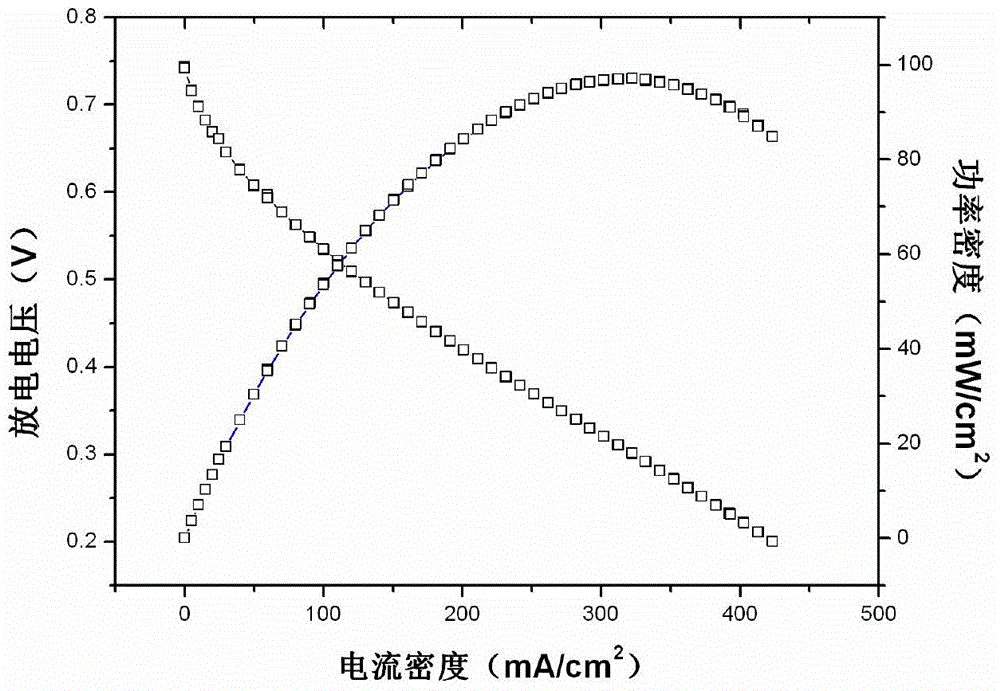

[0043] After the obtained membrane electrode is assembled into a single cell, the test is carried out, the test conditions are the same as in Example 1, and the test results are as follows: Figure 4 shown. It can be seen from the figure that the battery is at 200mA / cm 2 The hourly discharge voltage can reach 653mV, and the maximum power density can reach 302mW / cm 2 .

Embodiment 3

[0045] Adsorb the ABPBI membrane at concentrated phosphoric acid at 40°C for 6 hours to obtain a film with an acid content of 457wt.%, then equilibrate the film at 22°C and a relative humidity of 50% for 8 hours, and finally maintain the acid content at about 177wt.%. , and use this membrane as a proton exchange membrane for preparing high-temperature membrane electrodes. The microporous layer and catalytic layer in the anode and cathode gas diffusion electrodes are the same as in Example 1, but the content of phosphoric acid introduced on the anode and cathode gas diffusion electrodes is respectively 8.2 mg / cm 2 and 9.9mg / cm 2 .

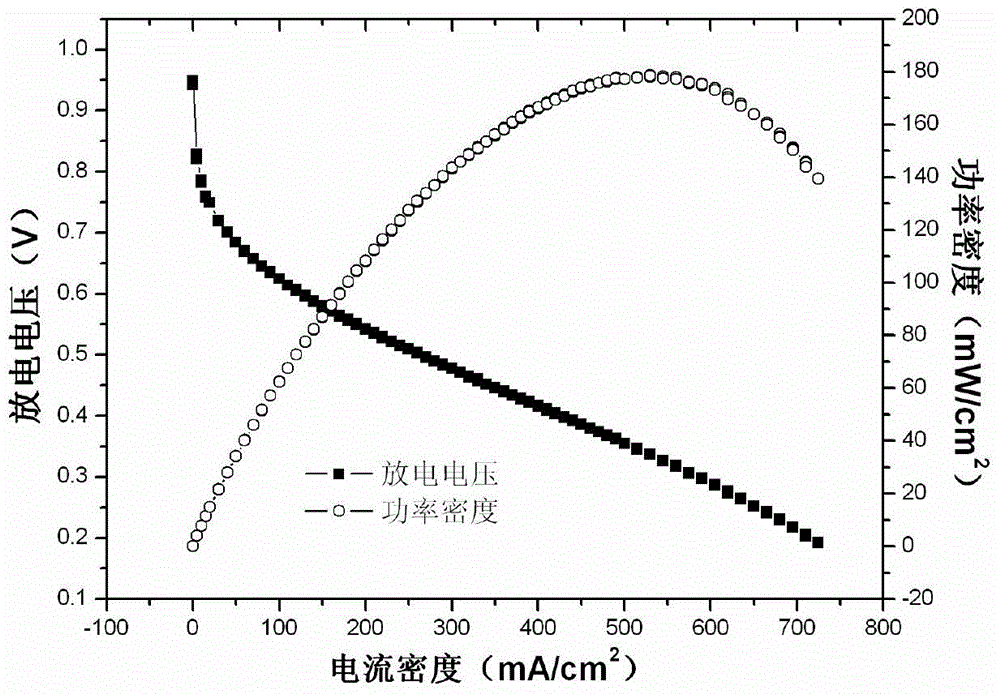

[0046] Gained membrane electrode was assembled into a single cell, and performance characterization was carried out under the same test conditions as in Example 1, and the results were as follows Figure 5 shown. Battery at 200mA / cm 2 The hourly discharge voltage is 610mV, and the maximum power density is 233mW / cm 2 , single cell at high curren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com