Preparation method of catalyst for producing 1,2-cyclohexane dicarboxylic ester through hydrogenation

A cyclohexanedicarboxylate and catalyst technology, applied in the field of catalysis, can solve the problems of complex catalyst preparation process, high reaction temperature, unfavorable reaction progress and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

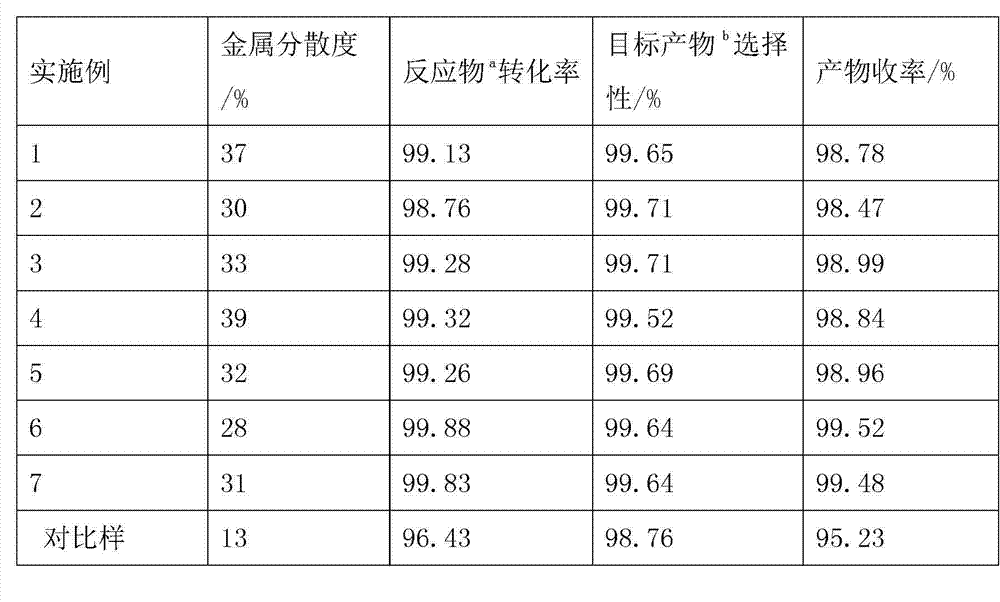

Examples

Embodiment 1

[0027] Take 100g of activated alumina spherical carrier (specific surface 190.34m 2 / g, pore diameter 10.5nm, pore volume 0.51ml / g, ball diameter 5mm), and dried at 110℃ for 12h for later use. RuCl containing 0.1g Ru elemental 3 Impregnate 100 g of the carrier with an equal volume of hydrochloric acid aqueous solution for 3 hours, dry at 110°C for 10 hours after impregnation, and heat up to 300°C for 3 hours. Soak the catalyst with 0.5wt% NaOH aqueous solution, slightly heat, boil and wash 3 times. The catalyst was washed with deionized water, dried in the air, and dried at 120° C. for 10 h. Prepare Ru / Al with 0.1% Ru elemental mass fraction 2 o 3 catalyst.

Embodiment 2

[0029] Take 100g of activated alumina spherical carrier (specific surface 190.34m 2 / g, pore diameter 10.5nm, pore volume 0.51ml / g, ball diameter 5mm), and dried at 110℃ for 12h for later use. RuCl containing 0.5g Ru elemental 3 Impregnate 100 g of the carrier with an equal volume of hydrochloric acid aqueous solution for 5 hours, dry at 110°C for 10 hours after impregnation, and heat up to 300°C for 3 hours. Soak the catalyst with 0.5wt% NaOH aqueous solution, heat slightly, boil and wash 6 times. The catalyst was washed with deionized water, dried in the air, and dried at 120° C. for 10 h. Prepare Ru / Al with 0.5% Ru mass fraction 2 o 3 catalyst.

Embodiment 3

[0031] Take 100g of activated alumina spherical carrier (specific surface 190.34m 2 / g, pore diameter 10.5nm, pore volume 0.51ml / g, ball diameter 5mm), and dried at 110℃ for 12h for later use. Ru(NO 3 ) 3 Impregnate 100 g of the carrier with an equal volume of hydrochloric acid aqueous solution for 8 hours, dry at 110°C for 10 hours after impregnation, and heat up to 300°C for 3 hours. Soak the catalyst with 2.0wt% NaOH aqueous solution, heat slightly, boil and wash 3 times. The catalyst was washed with deionized water, dried in the air, and dried at 120° C. for 10 h. Prepare Ru / Al with 2.0% Ru mass fraction 2 o 3 catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com