Method for preparing calcium carbide

A technology of calcium carbide and quicklime powder, applied in the chemical industry, can solve the problems of slow reaction rate, large power consumption and high reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

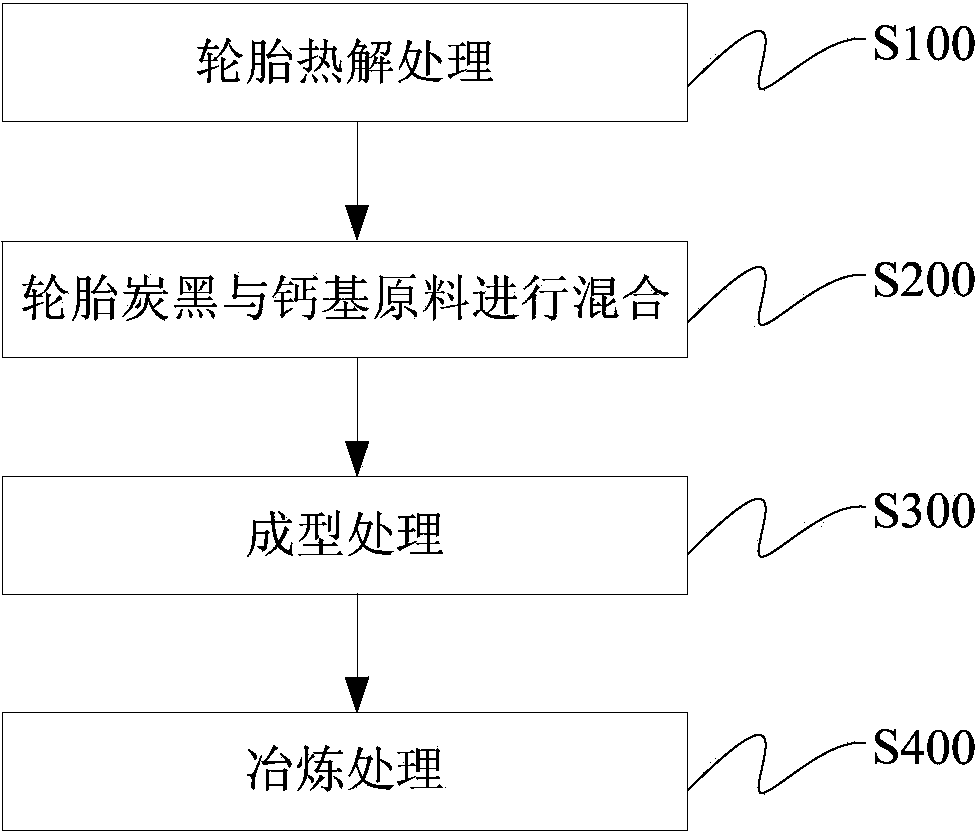

Image

Examples

preparation example Construction

[0036] According to the method for preparing calcium carbide in the embodiment of the present invention, waste tires are pyrolyzed to obtain high calorific value synthesis gas, tar, iron wire and carbon black products, which can realize clean and efficient utilization of waste tires;

[0037] According to the method for preparing calcium carbide in the embodiment of the present invention, the coke production process is a process with high energy consumption and high pollution, while tire carbon black can partially or completely replace high-priced coke to produce calcium carbide, realize energy saving and emission reduction, and reduce the production cost of calcium carbide ;

[0038] According to the method for preparing calcium carbide according to the embodiment of the present invention, the tire carbon black has a small particle size and a large specific surface area, and can be fully mixed with the calcium-based powder, which is beneficial to the efficient progress of the ...

Embodiment

[0043] The waste tires are crushed to less than 50mm, and the quicklime is crushed by a crusher to obtain quicklime particles with a particle size of less than 3mm; the crushed waste tire particles are input into a non-heat carrier regenerative rotary bed, and the pyrolysis pressure is 550 degrees Celsius at a temperature of 550 degrees Celsius. Carry out pyrolysis reaction at 100Pa for 1 hour to obtain high-temperature oil gas, solid pyrolysis products including iron wire and tire carbon black. After the high-temperature oil gas produced is condensed, separated, and purified in sequence, high-calorific value tar and synthetic gas products can be obtained respectively. , the solid pyrolysis product containing iron wire and tire carbon black is separated and processed by a magnetic separator, and tire carbon black and iron wire can be obtained respectively; the obtained tire carbon black is hot and has a particle size of nanoscale, and then mixed with quicklime particles ( The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com