Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Lower the smelting temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

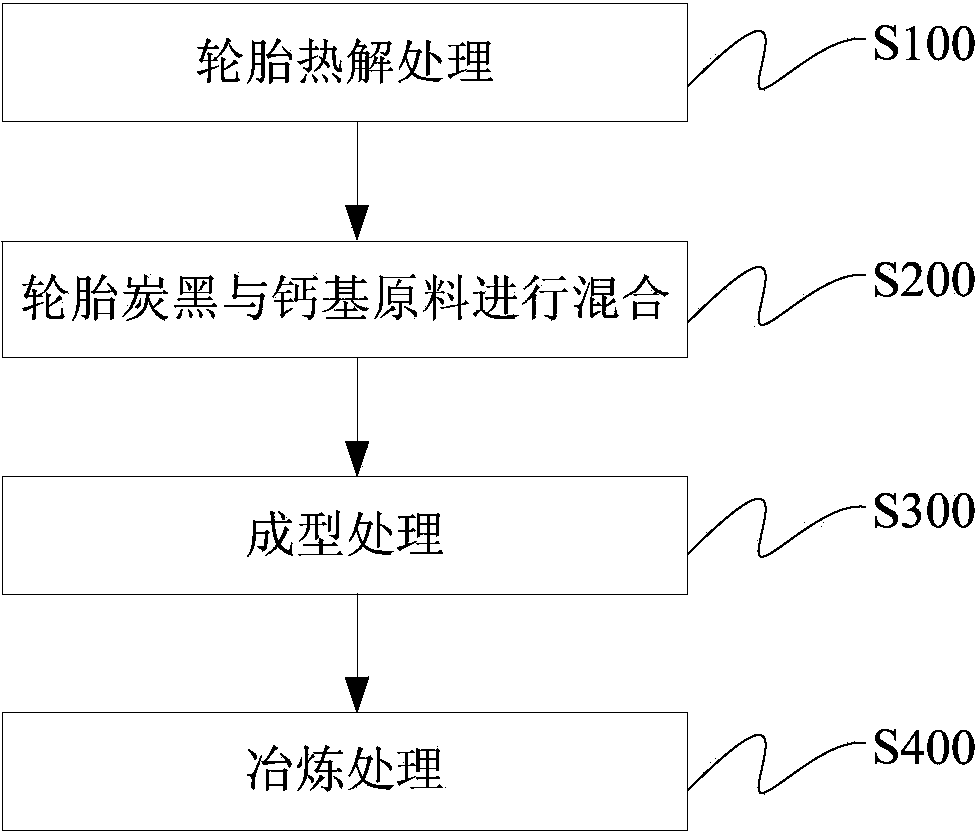

Method for preparing calcium carbide

InactiveCN103708458AReduce manufacturing costLow reaction temperatureCalcium carbideElectric arc furnaceEnergy consumption

The invention discloses a method for preparing calcium carbide, which comprises the following steps: pyrolyzing junked tires to obtain high-temperature oil gas, iron wires and tire carbon black; mixing the tire carbon black with a calcium-base raw material to obtain a mixture; forming the mixture to obtain a massive furnace raw material; and smelting the massive furnace raw material in an arc furnace to obtain the calcium carbide. The technique can obviously lower the temperature and energy consumption, thereby lowering the production cost of the calcium carbide.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

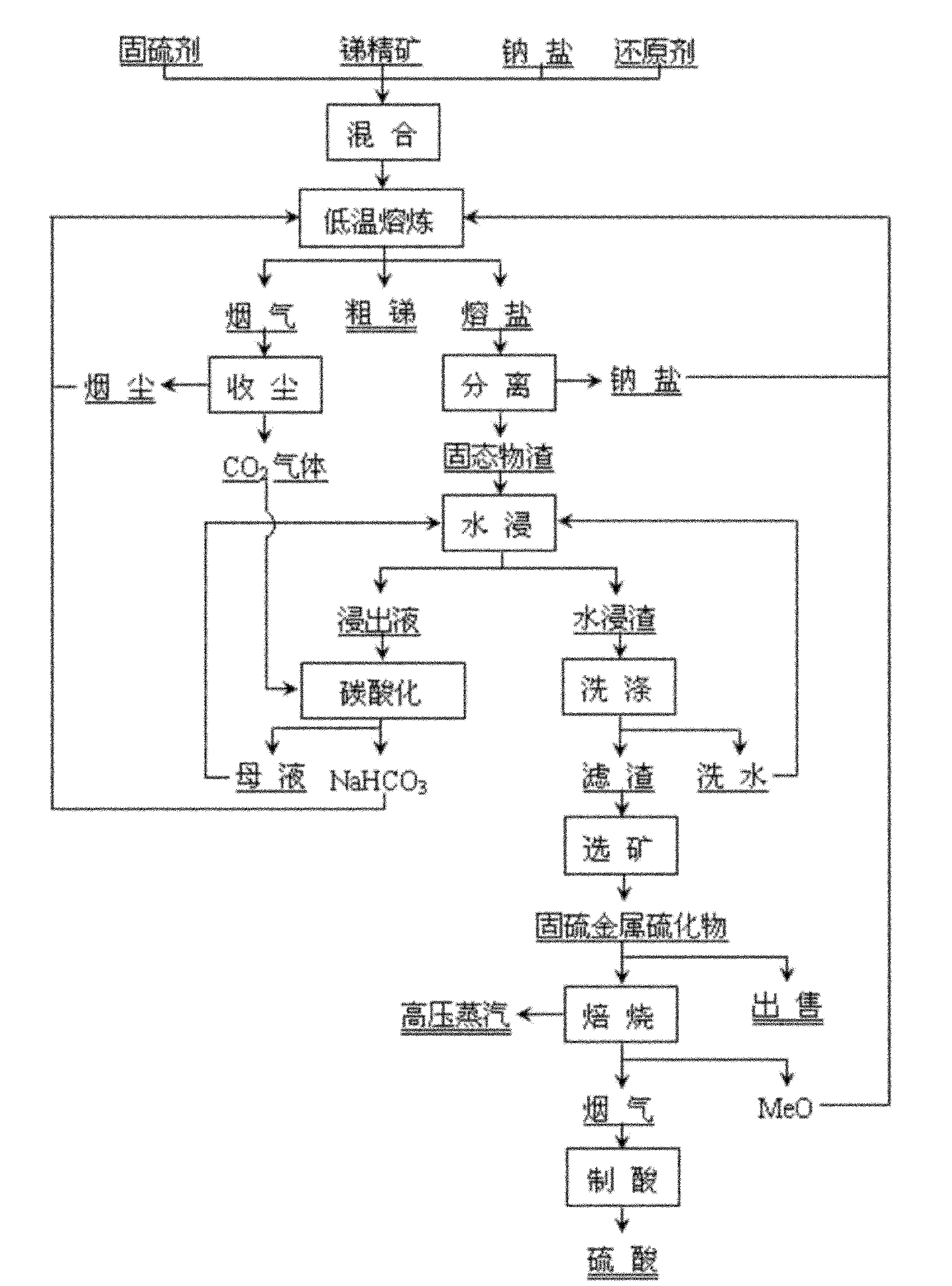

Clean metallurgical method for low-temperature molten salt of antimony

InactiveCN101914693ALower the smelting temperatureImprove direct yieldProcess efficiency improvementSlagSulfide

The invention discloses a clean metallurgical method for low-temperature molten salt of antimony, and belongs to the metallurgical field of non-ferrous metals. The method is characterized by comprising the following steps of: performing reductive sulfur-fixing melting on antimony concentrate and oxide of metal with higher sulfur affinity compared with the antimony in low-temperature inert molten salt to generate liquid metal antimony and sulfur-fixed metal sulfide, and forming molten salt slag by using the sulfur-fixed metal sulfide and non-reacted substances as solid substances; and separating most inert molten salt from the solid substances and then thermally returning the most inert molten salt to the melting process, regenerating NaHCO3 for recycling by using the molten salt slag through a 'water leaching-carbonated precipitation' process, reclaiming the sulfur-fixed metal sulfide concentrate for selling from the leached residue by ore dressing, or performing roasting desulfuration on the leached residue for heat energy utilization and smoke acid making, and returning oxide roasting sand serving as a sulfur-fixing agent to the melting process. The method greatly reduces the antimony melting temperature, produces the crude antimony at one step, realizes reclamation of sulfur and energy utilization of sulfide, thoroughly eliminates environmental pollution of low-concentration SO2 smoke at the same time of simplifying the flow, reducing the cost and greatly improving the direct yield of the antimony, and has the advantages of low carbon, cleanness and high efficiency.

Owner:CENT SOUTH UNIV

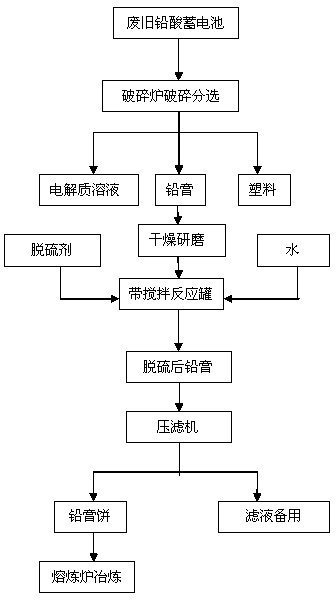

Waste diachylon desulphurization method

InactiveCN103633394AEmission reductionReduce pollutionWaste accumulators reclaimingProcess efficiency improvementProcess engineeringFilter press

The invention discloses a waste diachylon desulphurization method which comprises the following steps: A, adding waste lead-acid storage batteries into crushing and sorting system equipment to carry out crushing and sorting; B, drying sorted diachylon at a temperature of 120 DEG C for later use; C, carrying out grinding and screening on the dried diachylon; D, adding diachylon particles with the uniform size, which are obtained in the step C, into a canned reactor, then adding a desulfurizer and water and stirring to perform the reaction for certain time; E, transporting a mixture in a can, which is obtained after reaction, to a filter press to carry out filter pressing and carrying out separation to obtain a diachylon cake and a filtrate. The method disclosed by the invention has a high lead recovery rate, is low in cost, has low energy consumption and is short in time consumption.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Process for abstracting bismuth by low-temperature alkaline fusion metallurgy of bismuth clean ore

InactiveCN101289710ALower the smelting temperatureSimple processProcess efficiency improvementSlagSodium carbonate

The invention provides a method for extracting bismuth from low temperature caustic fusion bismuth refined ores. In the method, under conditions of the low temperature of between 600 and 900 DEG C and the alkalinity, crude bismuth is extracted from bismuth refined ores by smelting and fusion, and sodium carbonate is leached out by ball-milling slag and sulphonium. The method comprises main steps of the caustic fusion, the milling-leaching and the regeneration of alkali. Due to the adoption of the caustic fusion, the method of has the advantages that the temperature of smelting bismuth is greatly lowered, iron filings and reduction coal are not necessary to add, and particularly low-priced sodium carbonate replaces the majority of sodium hydroxide which lowers smelting cost; directly smelting crude bismuth and regenerating sodium hydroxide greatly simplify the whole process and improve the recovery rate, and the environmental pollution of sulfur dioxide is eliminated. The method is very important to the bismuth smelting and the energy conservation and emission reduction.

Owner:CENT SOUTH UNIV

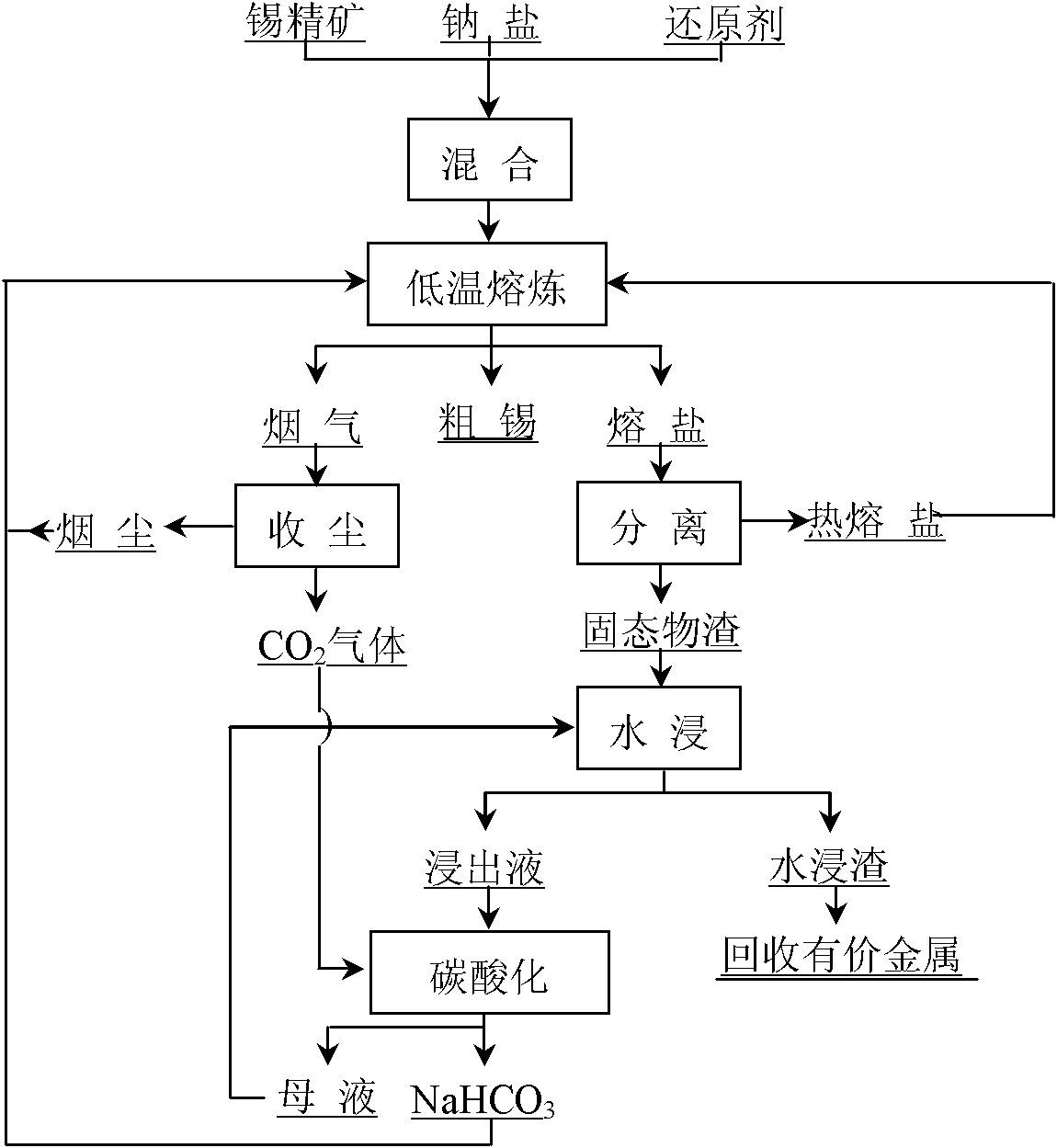

Low-temperature fused salt clean smelting method for tin

The invention discloses a low-temperature fused salt clean smelting method for tin, which is to produce coarse tin by one step of placing tin concentrate or tin-containing material in sodium fused salt for low-temperature reduction smelting. The smelted product also comprises unreacted solid materials such as a gangue component and generated solid products. After the reaction is finished, a major part of inert fused salt separated from the solid materials is returned to a smelting process in a hot state, and the minor part of inert fused salt bonded with the solid materials is recycled after being treated by a wet process. The solid materials obtained after removing the fused slat by dissolving can be treated for recovering valuable metals. The method greatly lowers a tin smelting temperature, can produce coarse tin by one step, solve a tin-iron separation problem, shorten a process flow, reduce cost, greatly improve tin recovery rate and is a new low-carbon, clean and high-efficiency tin smelting method.

Owner:CENT SOUTH UNIV

Preparation method of boron carbide superfine powder

ActiveCN107758670ADifficult to operateLarge controllable difficultyCarbon compoundsBrickBoron carbide

The invention discloses a preparation method of boron carbide superfine powder. The preparation method is based on a boron carbide smelting device which comprises a smelting furnace body built with refractory bricks and a sunken cover plate buckled at a top opening of the smelting furnace body, wherein a positive pole and a negative pole communicating a power supply are inserted into the side wallof the smelting furnace body. The preparation method comprises the following steps: S1, mixing a boron source with a carbon source fully to obtain a smelting raw material; S2, fully filling the smelting furnace body with the smelting raw material and covering the furnace with the sunken cover plate; and S3, applying a voltage to heat the smelting raw material to 1500-1900 DEG C and keeping the temperature for 24-48h to obtain the boron carbide superfine powder. Boron carbide is prepared by means of a nearly closed high-temperature treatment method according to the preparation method disclosedby the invention, so that impurity pollution is reduced, the product is good in crystallinity, the primary content of the obtained boron carbide superfine powder is greater than 96%, and the productgraded meets the demand of an abrasive material, and meets the quality demand on boron carbide powder in the field of grinding industry or engineering ceramics.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

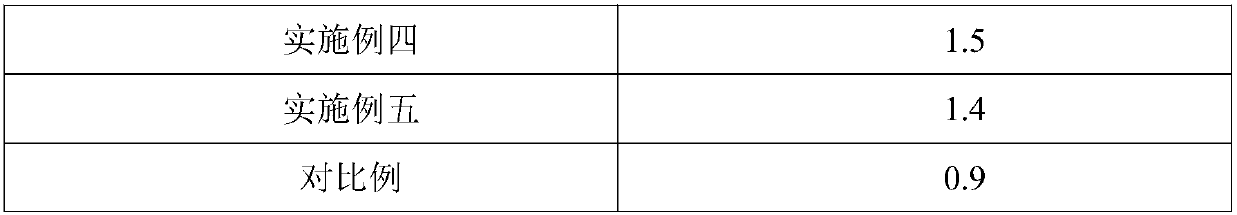

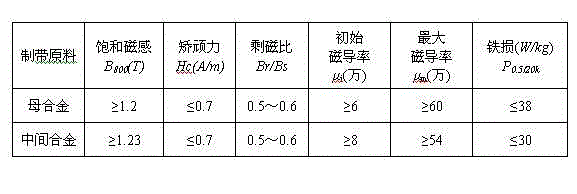

Special intermediate alloy for iron base amorphous nanocrystalline alloy and smelting method thereof

Special intermediate alloy for iron base amorphous nanocrystalline alloy belongs to the field of metallurgy. The alloy comprises the following chemical components: 15.7 wt% of Si, 3.8 wt% of B, 11 wt% of Nb, 2.4 wt% of Cu and the balance of Fe. A smelting method is as below: successively adding industrial pure iron, niobium iron, industrial silicon and electrolytic copper ferroboron into an intermediate frequency smelting furnace; (2) preheating with a small power and heating with high power; (3) completely fusing the raw materials, stirring alternatively with high and low power, at the same time carrying out furnace rocking with small to middle amplitude; and heating to 1400 DEG C and insulating for 5 min; and (4) finally carrying out dedrossing and tapping. The invention solves the problems of raw material burning loss and hard fusion of high-melting-point alloy. The amorphous nanocrystalline alloy strip produced from the intermediate alloy has multiple advantages including uniform composition, good toughness, significantly improved magnetic property and the reduced manufacturing cost.

Owner:太原钢铁(集团)有限公司

Process for preparing deoxidant used in smelting steel and its composite rare-earth deoxidant

A process for prepairng the deoxidant used in steel-smelting procedure includes such steps as proportioning the raw ores, adding carbon as reductor, crushing, continuously loading to horizontal reverberatory furnace, heating to 1300-1450 deg.C by spraying heavy oil and air or oxygen-enriched air into the furnace for 25-100 min, and continuously discharging the finished deoxidant. A composite rare-earth deoxidant prepared by said process contains Fe (20-60%), Al (5-20), Si (2-15), Ca (5-25), Mn (1-15), Ba (0-25) and Re (3-20).

Owner:薛国南

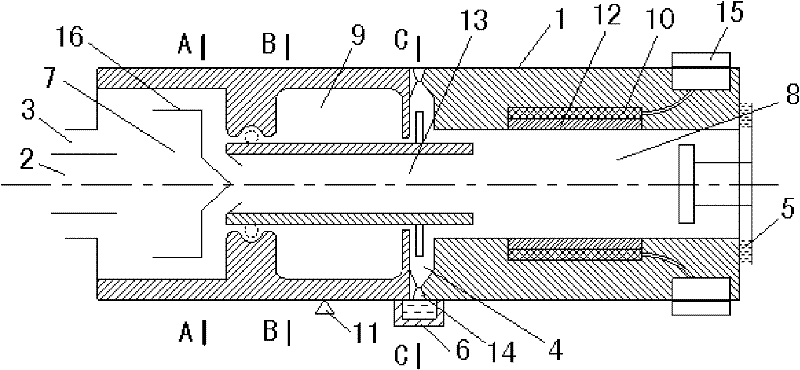

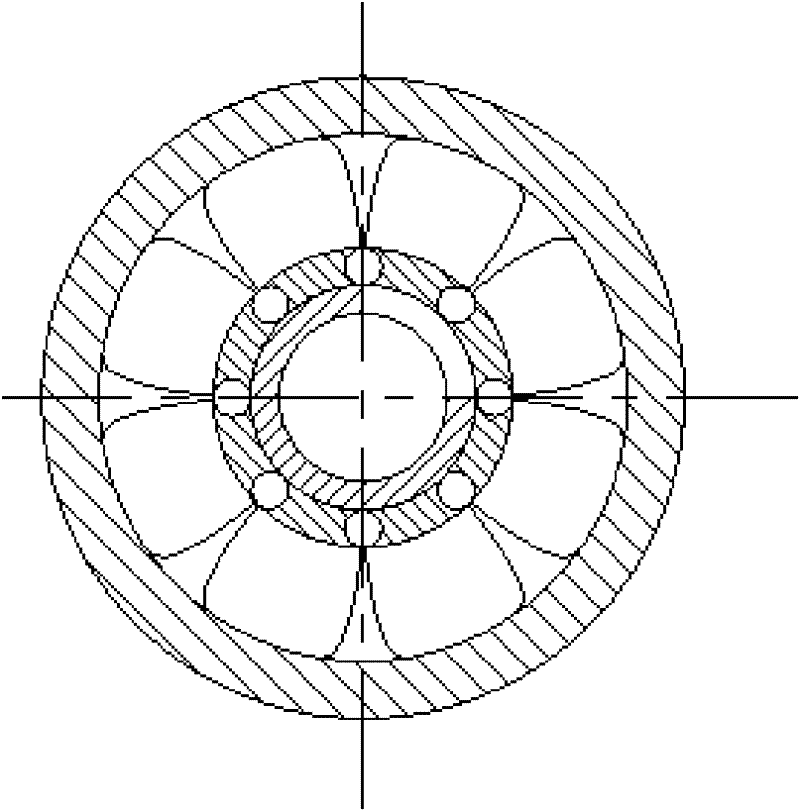

Crude zinc smelting method and smelting kiln used thereby

InactiveCN101665879AHigh recovery rateReduce lossRotary drum furnacesNon-ferrous extractive metallurgySmall footprint

The invention discloses a crude zinc smelting method and a smelting kiln used thereby. The method comprises the following steps: a pyrometallury technique is adopted for smelting and the smelting steps comprise loading, preheating, high-temperature smelting and condensing; the smelting kiln is internally provided with a preheating section, a high-temperature smelting section and a condenser; the raw materials are loaded into the smelting kiln by a feed inlet of the smelting kiln, and then enter the high-temperature smelting section for heating after the preheating section is preheated, and thegenerated zinc steam enters the condenser for condensation; the condensed waste gas enters the preheating section to preheat the raw material, and is exhausted out the smelting kiln by a gas outlet arranged on the smelting kiln, and the waste gas uses a cloth bag for removing dust; and the zinc solution generated by condensation is discharged to a zinc storing tank by a liquid outlet arranged onthe smelting kiln, and the waste residue is discharged out the smelting kiln by a spiral residue-discharging device arranged at the tail part of the smelting kiln. The invention is characterized by small occupied area, large yield, high heat utilization ratio, high recovery ratio, low production cost, capability of treating various renewable zinc ash raw materials and the like, not only is suitable for crude zinc smelting, but also is suitable for smelting other similar non-ferrous metals.

Owner:徐建成

Low-temperature fused salt electrolytic cleaning metallurgy method and device for antimony

ActiveCN107326400AEfficient separationReduce pyro-smelting temperatureCellsElectrodesEnvironmentally friendlyPulse current

The invention relates to a low-temperature fused salt electrolytic cleaning metallurgy method and device for antimony. The method comprises the steps that antimony-containing materials and inert molten salt are mixed and arranged in a low-temperature fused salt electrolyzer in a certain material arrangement mode, and low-temperature fused salt electrolytic smelting is conducted under the certain temperature and pulse current conditions. Along with low-temperature fused salt electrolysis, mixed molten salt in a hearth gradually forms a three-layer melt structure. The antimony-containing materials can be added from an antimony-containing material charging port, and obtained liquid antimony can be discharged from an antimony discharging port formed in the lower portion. Accordingly, the existing antimony concentrate pyrogenic attack temperature is greatly lowered, and high-grade antimony is produced through one step; compared with an existing antimony concentrate pyrometallurgy technology, the method has the advantages of being low in energy consumption, high in direct recovery rate of antimony, clean and environmentally friendly. The device is simple and practical, and a good antimony extraction metallurgy effect can be obtained by using the device in a matched mode.

Owner:CENT SOUTH UNIV

Process for smelting aluminium by carbon reduction method via adding sodium chloride-alumina molten salt

A method for aluminum annealing technology using natrium muriaticum-aluminium oxide fused salt carbon reduction method, contains the following methods and steps: crushing calcined oil coke metallurgical coke to 1-0mm or powder, adding aluminium oxide into hydrochloric acid solution with concentration of 0.5 ~ 20% for immersion of 4-24 hours; oven-drying the aluminium oxide at 100-500 DEG C, adding 174kg+-0.1g carbon into per ton aluminium oxide, mixing and putting into smelting furnace at a temperature of 800-820DEG C, sodium chloride staiting to melt,adding aluminium oxide into sodium chloride fused salt by fractionation, the first time adding 0.5-1.0% alumina, 1.0-3.0% for each subsequent adding. The invention uses sodium chloride as the solventand also as a catalyst, adopts carbon reduction method for luminium extracting, has the advantages of less investment and quick, large production capacity for a single furnace and reduces the cost of production.

Owner:钟群标

Recycling method of valuable metal from copper-cobalt white alloy

ActiveCN109182780ALower the smelting temperatureLower requirementProcess efficiency improvementSlagOxygen

The invention discloses a recycling method of valuable metal from copper-cobalt white alloy, comprising the following steps: (1) adding one or several of matte, copper-nickel matte and scrap copper into a converter together with copper-cobalt white alloy; (2) controlling smelting temperature in the converter to be 1150-1400 DEG C, and blowing oxygen-containing gas into the converter, so that material in the converter reacts in an oxidizing atmosphere, to produce crude copper, cobalt-containing slag and flue gas; (3) separating the crude copper from the cobalt-containing slag, and recycling cobalt from the cobalt-containing slag. According to the method disclosed by the invention, by mixing and smelting the copper-cobalt white alloy with high melting point with matte / copper-nickel matte / scrap copper with low melting point, smelting temperature needed for independently smelting iron-cobalt-copper alloy is effective lowered, the energy consumption advantage of the process is prominent, the requirement of the refractory material is reduced, the process economic benefit is increased, the use amount of a slag forming constituent is small, and the method is relatively economical and environment-friendly.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for preparing calcium carbide

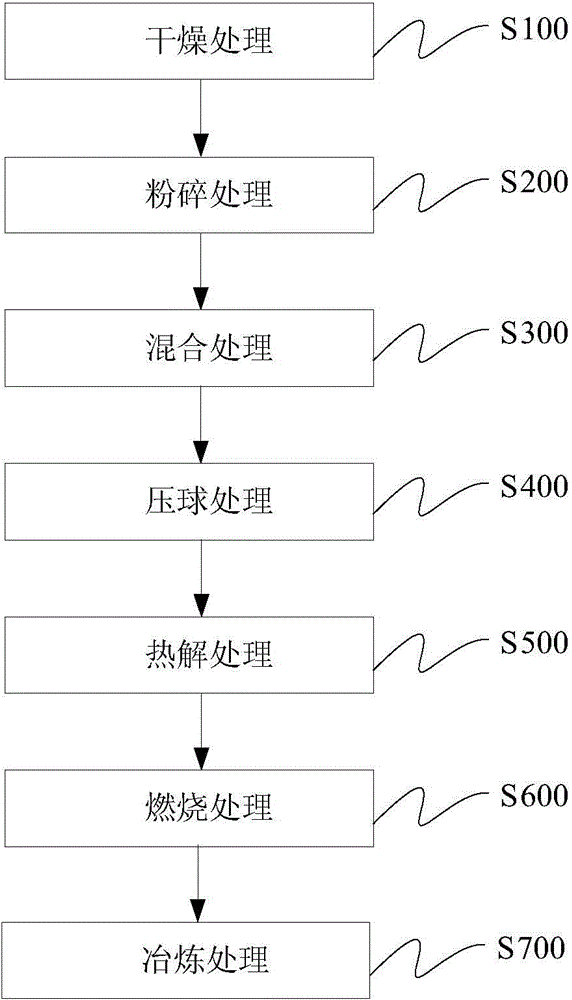

InactiveCN104528723ALower the smelting temperatureShorten smelting timeCalcium carbideMixed materialsPetroleum

The invention provides a method for preparing calcium carbide. The method comprises the steps that raw coal is subjected to drying processing, and dry raw coal is obtained conveniently; the dry raw coal and lime are subjected to smashing respectively, so that raw coal powder and lime powder are obtained conveniently; excess raw coal powder and the lime powder are mixed, so that mixed materials are obtained conveniently; the mixed materials are subjected to ball pressing, so that palletizing materials are obtained conveniently; the palletizing materials are subjected to pyrolysis treatment, so that artificial petroleum, artificial natural gas and pyrolysis solid products are obtained conveniently, wherein the pyrolysis solid products have semicoke and lime; the pyrolysis solid products are conveyed into a burning bin for burning processing in a hot mode, so that pyrolysis solid is obtained conveniently; and the pyrolysis solid is conveyed into a sealed electric furnace for smelting processing, and the calcium carbide is obtained conveniently. According to the method, smelting energy loss and production cost can be lowered obviously, and meanwhile calcium carbide production efficiency can be further improved.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

Raw material formulation of ladle heat insulation cover and preparation method of ladle heat insulation cover

The invention discloses a raw material formulation of a ladle heat insulation cover, which consists of the following components in percentage by weight: 40 to 60 percent of brown fused alumina hollow sphere, 10 to 20 percent of brown fused alumina, 15 to 30 percent of mullite, 1 to 10 percent of alumina micro powder, 1 to 10 percent of silicon micro powder, 1 to 5 percent of Rho-Al2O3 powder, and0.1 to 0.2 percent of dispersant. The method for preparing the ladle heat insulation cover according to the raw material formulation comprises the following steps: 1) stirring the prepared raw materials evenly; 2) adding water which is 6 to 8 percent of the total weight of the raw materials into the well-stirred raw materials, and mixing and stirring the mixture for 3 to 5 minutes; 3) pouring and forming the mixture, and mold unloading after 8 to 12 hours of maintenance; and 4) drying the product at a temperature of between 100 and 120 DEG C. The ladle heat insulation cover prepared by adopting the raw material formulation of the ladle heat insulation cover has the advantages of small stacking density, low heat conductivity, good thermal shock resistance stability, erosion resistance, good workability, low price, and long service life.

Owner:陈红良

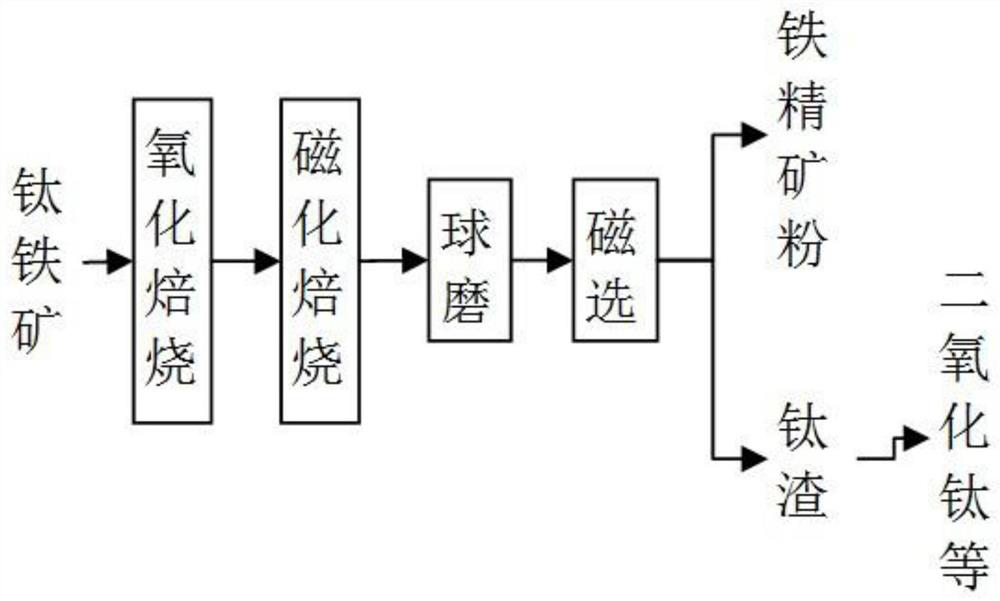

Ilmenite treatment method

ActiveCN111944991AShort processEasy to operateMagnetic separationProcess efficiency improvementIlmeniteRoasting

The invention provides an ilmenite treatment method. The method comprises the following steps: roasting ilmenite in an oxidizing atmosphere to obtain oxidized titanium-iron mixed ore; mixing the oxidized titanium-iron mixed ore with pulverized coal, controlling the temperature to be 1050 DEG C to 1150 DEG C, carrying out magnetizing roasting for 1.5 hours to 2.5 hours, and obtaining reduced titanium-iron mixed ore after the magnetizing roasting is finished; and carrying out ball milling and magnetic separation on the reduced titanium-iron mixed ore, and obtaining iron ore concentrate powder and titanium slag. The treatment method is short in flow, convenient to operate and capable of realizing industrial production easily. Meanwhile, the treatment method is low in energy consumption, low in smelting temperature, small in pollution and environmentally friendly.

Owner:重庆优钛实业有限公司 +1

Environment-friendly ferrochrome smelting furnace burden and preparation method thereof

ActiveCN111876592AFacilitate depositionLow melting pointProcess efficiency improvementCokeFerrochrome

The embodiment of the invention discloses an environment-friendly ferrochrome smelting furnace burden and a preparation method thereof in the technical field of ferrochrome smelting. The environment-friendly ferrochrome smelting furnace burden comprises chromium ore powder, coke, serpentine, silica, bluestone and return slag; and the return slag comprises a tundish, furnace slag and iron oxide, wherein the furnace slag and the iron oxide are stored between the tundish and an iron outlet. According to the furnace burden and the method, the iron oxide is added into the furnace burden, so that the melting point of the furnace slag is lowered, and the flowability of the furnace slag is improved; the iron oxide is added into the furnace burden, so that the reducing capacity of the furnace burden is enhanced, and the chromium ore reducing speed is increased; and the iron oxide is added into the furnace burden, so that the activity of the furnace burden is enhanced, the viscosity of the furnace slag is reduced, the slag-metal separation effect is good, and the product purity is high.

Owner:徐州宏阳新材料科技股份有限公司

Method for preparing brown corundum by using powdery bauxite and ash residues

The invention discloses a method for preparing brown corundum by using powdery bauxite and ash residues. The method comprises the following steps: 1) carrying out alkaline leaching on ash residues inan environment of 85-100 DEG C for 5-30 minutes, and filtering out alkali liquor to obtain a product A; 2) mixing the product A with powdery bauxite, and carrying out agglomeration to obtain a productB; 3) preheating the product B in an environment of 50-500 DEG C, then carrying out heating to 900-1150 DEG C, and carrying out calcining and dehydrating for 0.5-2.0 hours to obtain a product C; and4) mixing the product C with coke and scrap iron, feeding the mixture into an electric arc smelting furnace for smelting, and finally, carrying out cooling, grading, crushing and screening to preparethe brown corundum finished product. According to the method disclosed by the invention, the powdery bauxite and the ash residues are used as raw materials, recycling of ash residues is realized, andmeanwhile, the powdery bauxite which is not used as a smelting raw material is effectively utilized, so that production cost of brown corundum is reduced, and the selection range of raw materials is broadened.

Owner:GUIZHOU UNIV +1

Processing process for producing brown fused alumina from bauxite powder ore with reduced grade

PendingCN110436500AEfficient desiliconizationImprove breathabilityAluminium oxide preparationAluminates/aluminium-oxide/aluminium-hydroxide purificationCoesiteLower grade

The invention discloses a processing process for producing brown fused alumina from bauxite powder ore with reduced grade. The processing process comprises: 1) grinding powdery bauxite with low grade,and uniformly mixing to obtain ore powder; 2) adding water to the ore powder until the material can be molded, and pressing into a block to obtain a product A; 3) pre-heat the product A in a 50-500 DEG C environment, placing in a 900-1150 DEG C environment, and dewatering for 0.5-1.5 h to obtain a product B; 4) cooling the product B to a temperature of 150-250 DEG C to obtain a product C; 5) spraying the product C with an alkali liquid, and carrying out desiliconization to obtain a product D; and 6) dewatering the product D again, and carrying out conventional smelting to obtain the brown fused alumina. According to the present invention, the processing process has characteristics of quick desiliconization, good effect, low smelting temperature, short time, low energy consumption and environmental protection, and can easily widen the selection range of bauxite raw materials, improve the quality of brown fused alumina and reduce the production cost.

Owner:GUIZHOU UNIV

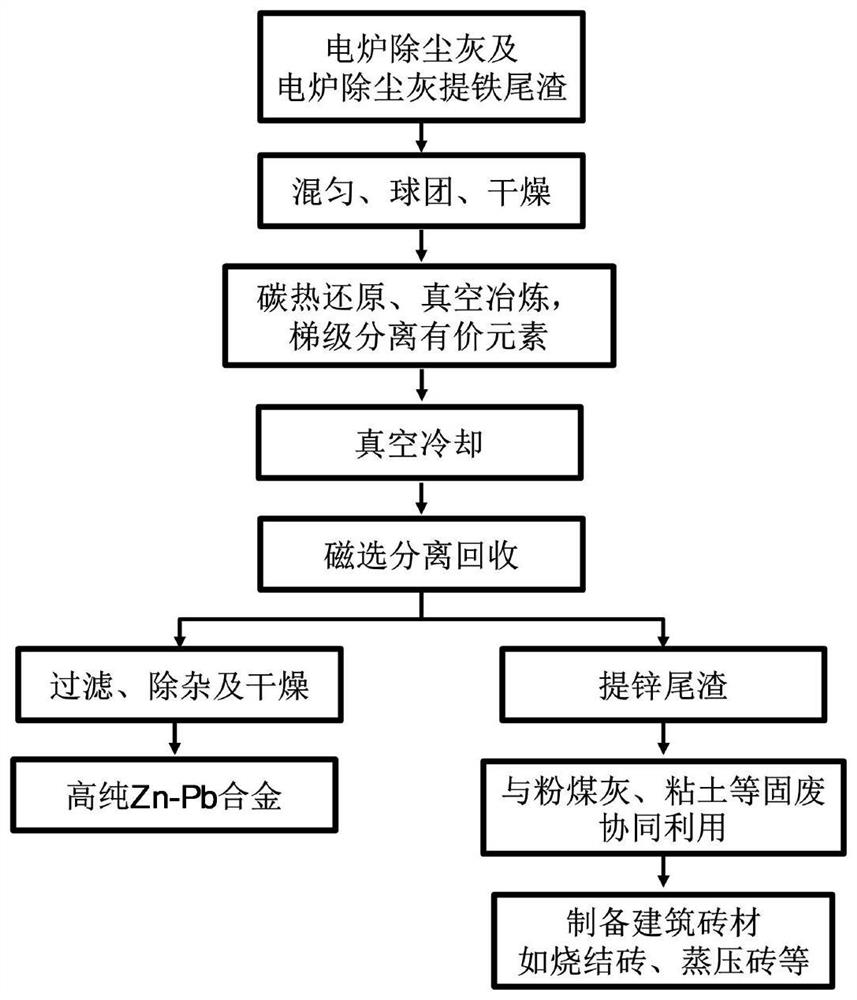

Full-quantification and high-value utilization method of electric furnace fly ash and iron extraction tailings thereof

PendingCN114480841AEmission reductionReduce governance costsMagnetic separationBrickEconomic benefits

The invention discloses a full-quantification and high-value utilization method of electric furnace fly ash and iron extraction tailings thereof. The method comprises the following processing procedures: (1) pellet preparation, (2) vacuum smelting, (3) vacuum cooling, (4) magnetic separation and recovery of high-purity Zn-Pb alloy, and (5) preparation of sintered bricks from zinc extraction tailings. According to the method, the Zn-Pb alloy is prepared through carbon thermal reduction and assisted by vacuum smelting of the electric furnace dedusting ash iron extraction tailings, the sintered bricks are prepared through the tailings of the Zn-Pb alloy, the high-purity Zn-Pb alloy product and the sintered brick product with the purity larger than or equal to 96.0% are prepared, full-quantization and high-value utilization of the electric furnace dedusting ash and the iron extraction tailings of the electric furnace dedusting ash are achieved, and economic benefits and environmental benefits are remarkable. The method provided by the invention overcomes the defects of long process flow, high cost, large emission, low added value of products and the like in the prior art, and has wide market popularization and application prospects.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Anti-corrosion alloy sucker rod and manufacturing method thereof

PendingCN111118385AHigh thermodynamic stabilitySpread evenlyDrilling rodsVacuum evaporation coatingThin membraneAlloy

The invention relates to an anti-corrosion alloy sucker rod and a manufacturing method thereof. The anti-corrosion alloy sucker rod comprises a rod body and a joint, and the rod body includes a steelsubstrate, a TiCrN hard thin film, a TiCrSiN anti-corrosion thin film and a polyetheretherketone anti-corrosion coating in sequence from inside to outside. The anti-corrosion properties of the steel substrate are relatively high. The TiCrN hard thin film has relatively high hardness, relatively high working stability and oxidation resistance. The TiCrSiN anti-corrosion thin film has excellent abrasive wear resistance, corrosion resistance and oxidation resistance. The corrosion resistance of the polyetheretherketone anti-corrosion coating is similar to that of nickel steel. In summary, the rodbody of the anti-corrosion alloy sucker rod has excellent anti-corrosion and high-strength performance and a long service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

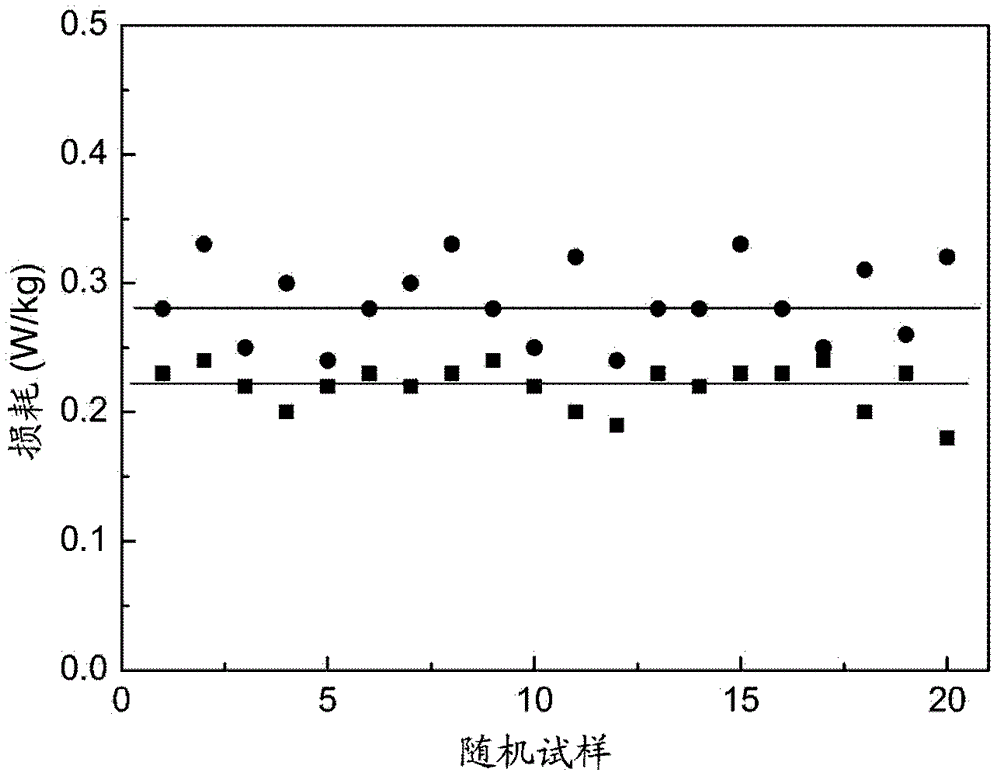

A kind of slagging agent and slagging process for smelting nanocrystalline master alloy

The invention belongs to the technical field of nanocrystalline master alloy smelting, and in particular relates to a slag former for smelting a nanocrystalline master alloy and a slagging process thereof. The slag former is formed by two slag former systems, respectively, a first slag former system and a second slag former system. The slagging process comprises the steps of slag former preparation and secondary slagging during the smelting of a master alloy. According to the slag former and the slagging process provided by the invention, the content of aluminum in the nanocrystalline master alloy can be effectively decreased.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

A kind of preparation method of boron carbide ultrafine powder

ActiveCN107758670BDifficult to operateLarge controllable difficultyCarbon compoundsFire brickCrystallinity

The invention discloses a preparation method of boron carbide superfine powder. The preparation method is based on a boron carbide smelting device which comprises a smelting furnace body built with refractory bricks and a sunken cover plate buckled at a top opening of the smelting furnace body, wherein a positive pole and a negative pole communicating a power supply are inserted into the side wallof the smelting furnace body. The preparation method comprises the following steps: S1, mixing a boron source with a carbon source fully to obtain a smelting raw material; S2, fully filling the smelting furnace body with the smelting raw material and covering the furnace with the sunken cover plate; and S3, applying a voltage to heat the smelting raw material to 1500-1900 DEG C and keeping the temperature for 24-48h to obtain the boron carbide superfine powder. Boron carbide is prepared by means of a nearly closed high-temperature treatment method according to the preparation method disclosedby the invention, so that impurity pollution is reduced, the product is good in crystallinity, the primary content of the obtained boron carbide superfine powder is greater than 96%, and the productgraded meets the demand of an abrasive material, and meets the quality demand on boron carbide powder in the field of grinding industry or engineering ceramics.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Clean metallurgical method for low-temperature molten salt of lead

The invention discloses a clean metallurgical method for low-temperature molten salt of lead. Lead sulfide concentrate, secondary lead raw material or secondary material of lead is smelted in low-temperature inertial molten salt and rough lead is refined in one step; and a metal oxide is used as a sulfur fixing agent, wherein the smelted product comprises liquid metal lead and solid sulfur-fixingmetal sulfide and the solid sulfur-fixing metal sulfide and solid unreacted material are together called solid matter; the majority of the inertial molten salt is separated from the solid matter to return the smelting process in hot state; a small part of the inertial molten salt adhered by the solid matter is processed by a wet method for recycling; the solid matter after the molten salt is removed by soaking is subjected to ore dressing to recover associated metal and the sulfur-fixing metal sulfide; the sulfide is baked for desulfurization; the smoke is used for making acid; and the oxide is calcined and returned to the smelting process and used as the sulfur fixing agent. The method greatly reduces the metallurgical temperature of the lead, produces the rough lead in one step, realizes the recovery of the sulfur and the utilization of the sulfide energy source, has simple flow and low cost, greatly improves the yield of the vertical force and completely eliminates the lead steam produced during the metallurgical process and the pollution caused by the SO2 smoke to the environment.

Owner:CENT SOUTH UNIV

Special intermediate alloy for iron base amorphous nanocrystalline alloy and smelting method thereof

The iron-based amorphous nano master alloy belongs to the field of metallurgy, and its chemical composition mass percentage is: Si is 15.7, B is 3.8, Nb is 11, Cu is 2.4, and the balance is Fe. The smelting method is: add industrial pure iron - ferroniobium - industrial silicon - electrolytic copper boron iron into the intermediate frequency smelting furnace in sequence; (2) preheat with low power first, and then heat with high power; (3) wait After the raw materials are completely melted, carry out alternating stirring with large and small power, and at the same time cooperate with the shaking furnace with medium and small range; when the temperature rises to 1400 ° C, keep it warm for 5 minutes; (4) Finally, slag and tap. The invention solves the problems of burning loss of raw materials, difficulty of melting high-melting point alloys and the like. The amorphous and nanocrystalline strips produced by using the master alloy have multiple advantages such as uniform composition, good toughness, significantly improved magnetic properties, and reduced manufacturing costs.

Owner:太原钢铁(集团)有限公司

A low-temperature molten salt electrolytic clean metallurgy method and device for bismuth

The invention discloses a low-temperature fused salt electrolytic cleaning metallurgy method and device for bismuth. The method comprises the following steps: mixing a bismuth-containing material withinertia fused salt, putting the mixture into a low-temperature fused salt electrolysis device in a certain material distribution manner, and performing low-temperature fused salt electrolytic smelting under certain temperature and pulse current conditions; and along with low-temperature fused salt electrolysis, gradually forming a "three-layer melt" structure by the mixed fused salt in a furnacehearth, wherein the bismuth-containing material can be continuously added from a feeding port, and obtained liquid bismuth can be discharged from a lower bismuth discharging port. According to the low-temperature fused salt electrolytic cleaning metallurgy method, the treatment temperature of an existing bismuth concentrate pyrogenic process is substantially reduced; high-quality bismuth can be produced by one step; and compared with a smelting process of the existing bismuth concentrate pyrogenic process, the low-temperature fused salt electrolytic cleaning metallurgy method has the advantages of low energy consumption and high direct bismuth recovery rate. The device disclosed by the invention is simple and practical; and by cooperative use, the device can achieve a good bismuth extraction metallurgy effect.

Owner:YIYANG SHENGLI CHEM IND

Additive for B-Si containing iron-based amorphous alloy and nanocrystalline alloy

The invention discloses an additive for a B-Si containing iron-based amorphous alloy and a nanocrystalline alloy. The additive comprises the following components by weight percent: 70%-90% of low-carbon ferrochromium, 0-10% of Sn, 0-20% of Pb and 0-20% of Bi, wherein the low-carbon ferrochromium comprises the following elements by weight percent: 63%-75% of Cr, 0.03%-0.15% of C, 1.0%-1.5% of Si and the balance Fe and inevitable impurities. By adopting the additive for the iron-based amorphous alloy and the nanocrystalline alloy, the homogenization of molten steel can be promoted and the soft magnetic property of the alloy can be improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

A method for recovering valuable metals from an alloy containing iron, cobalt and copper

ActiveCN109022819BLower the smelting temperatureLower requirementProcess efficiency improvementSlagFlue gas

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method and device for molten salt electrolysis of materials containing antimony sulfide

ActiveCN111172563BEnhanced mass transferPromote "coagulation and sedimentationElectrolysis componentsElectrolysisMolten bath

The invention discloses a method and device for molten salt electrolysis of materials containing antimony sulfide. The materials containing antimony sulfide and inert molten salt are mixed and put into an electrolysis device for heating electrolysis smelting, inert gas is blown in the smelting process to stir a molten pool, a liquid antimony melt layer is obtained through gradual enrichment on thelower layer in the device along with proceeding of low-temperature molten salt electrolysis, and the elementary substance sulphur is obtained in a smoke collecting device through gradual enrichment.According to the method and the device, molten salt ion mass transfer is enhanced, high-quality antimony and the elementary substance sulphur are produced by one step, and the issue that low-concentration SO2 pollutes the environment in traditional antimony pyrometallurgy is avoided. The method and the device have the advantages of being low in energy consumption, high in antimony direct yield, clean and environmentally friendly. The device is simple and practical, and good antimony and sulphur extractive metallurgy effects can be obtained when the device is used for treating antimony sulfideconcentrate in cooperation.

Owner:CENT SOUTH UNIV

Crude zinc smelting method and smelting kiln used thereby

InactiveCN101665879BHigh recovery rateReduce lossRotary drum furnacesNon-ferrous extractive metallurgySmall footprint

The invention discloses a crude zinc smelting method and a smelting kiln used thereby. The method comprises the following steps: a pyrometallury technique is adopted for smelting and the smelting steps comprise loading, preheating, high-temperature smelting and condensing; the smelting kiln is internally provided with a preheating section, a high-temperature smelting section and a condenser; the raw materials are loaded into the smelting kiln by a feed inlet of the smelting kiln, and then enter the high-temperature smelting section for heating after the preheating section is preheated, and the generated zinc steam enters the condenser for condensation; the condensed waste gas enters the preheating section to preheat the raw material, and is exhausted out the smelting kiln by a gas outlet arranged on the smelting kiln, and the waste gas uses a cloth bag for removing dust; and the zinc solution generated by condensation is discharged to a zinc storing tank by a liquid outlet arranged onthe smelting kiln, and the waste residue is discharged out the smelting kiln by a spiral residue-discharging device arranged at the tail part of the smelting kiln. The invention is characterized by small occupied area, large yield, high heat utilization ratio, high recovery ratio, low production cost, capability of treating various renewable zinc ash raw materials and the like, not only is suitable for crude zinc smelting, but also is suitable for smelting other similar non-ferrous metals.

Owner:徐建成

A low-temperature molten salt electrolytic clean metallurgy method and device for antimony

The invention relates to a low-temperature fused salt electrolytic cleaning metallurgy method and device for antimony. The method comprises the steps that antimony-containing materials and inert molten salt are mixed and arranged in a low-temperature fused salt electrolyzer in a certain material arrangement mode, and low-temperature fused salt electrolytic smelting is conducted under the certain temperature and pulse current conditions. Along with low-temperature fused salt electrolysis, mixed molten salt in a hearth gradually forms a three-layer melt structure. The antimony-containing materials can be added from an antimony-containing material charging port, and obtained liquid antimony can be discharged from an antimony discharging port formed in the lower portion. Accordingly, the existing antimony concentrate pyrogenic attack temperature is greatly lowered, and high-grade antimony is produced through one step; compared with an existing antimony concentrate pyrometallurgy technology, the method has the advantages of being low in energy consumption, high in direct recovery rate of antimony, clean and environmentally friendly. The device is simple and practical, and a good antimony extraction metallurgy effect can be obtained by using the device in a matched mode.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com