Additive for B-Si containing iron-based amorphous alloy and nanocrystalline alloy

A technology for iron-based amorphous alloys and nanocrystalline alloys, which is applied in the smelting field of amorphous alloys and nanocrystalline alloys, and can solve the problems of limited purification capacity, differences in purification goals, and inapplicability to smelting of iron-based amorphous master alloys. , to achieve the effect of reducing the smelting temperature and reducing the amount of burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The additive according to the present embodiment comprises 70% microcarbon ferrochrome, 8% Sn, 10% Pb and 12% Bi by weight percentage, wherein the microcarbon ferrochrome comprises 70% Cr, 8% by weight, 0.06% carbon, 1.0% Si, the balance being iron and unavoidable impurities.

[0030] The additive according to this embodiment is expressed by m A :m S =1.6:1000 and m A +m O ×3×10 5 Fe 78 Si 9 B 13 Alloy steel water. Among them, Fe 78 Si 9 B 13 The initial oxygen content in alloy steel water m O is 8ppm, the mass m of the additive according to the present embodiment A is 1.6kg, the mass of alloy steel m S It is 1000kg.

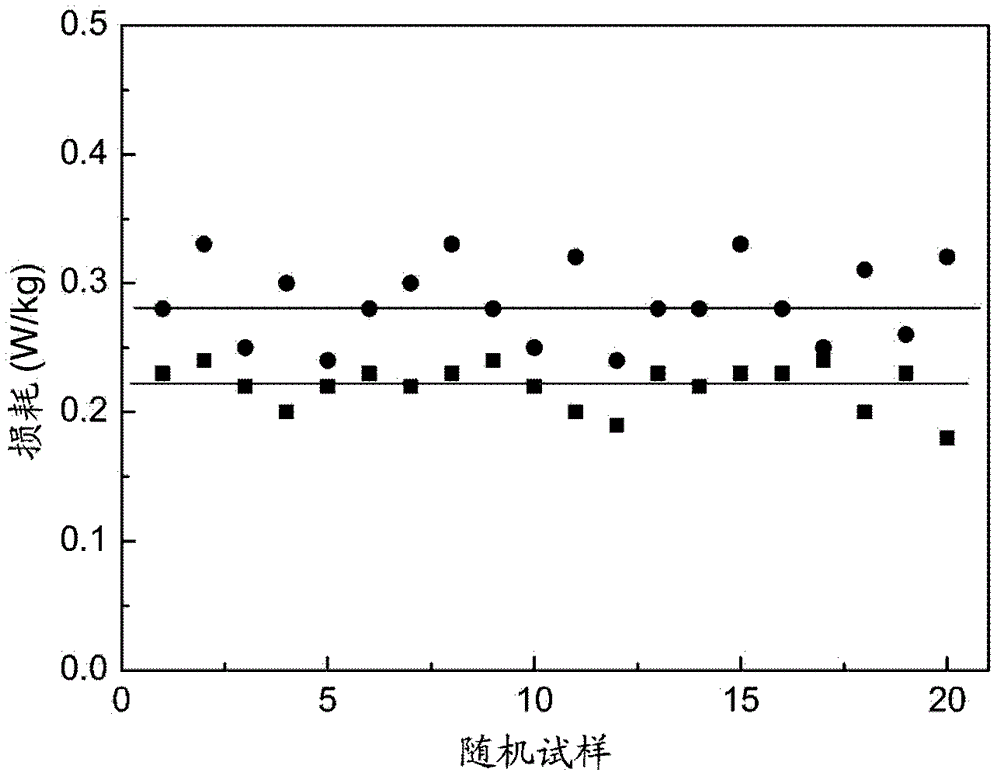

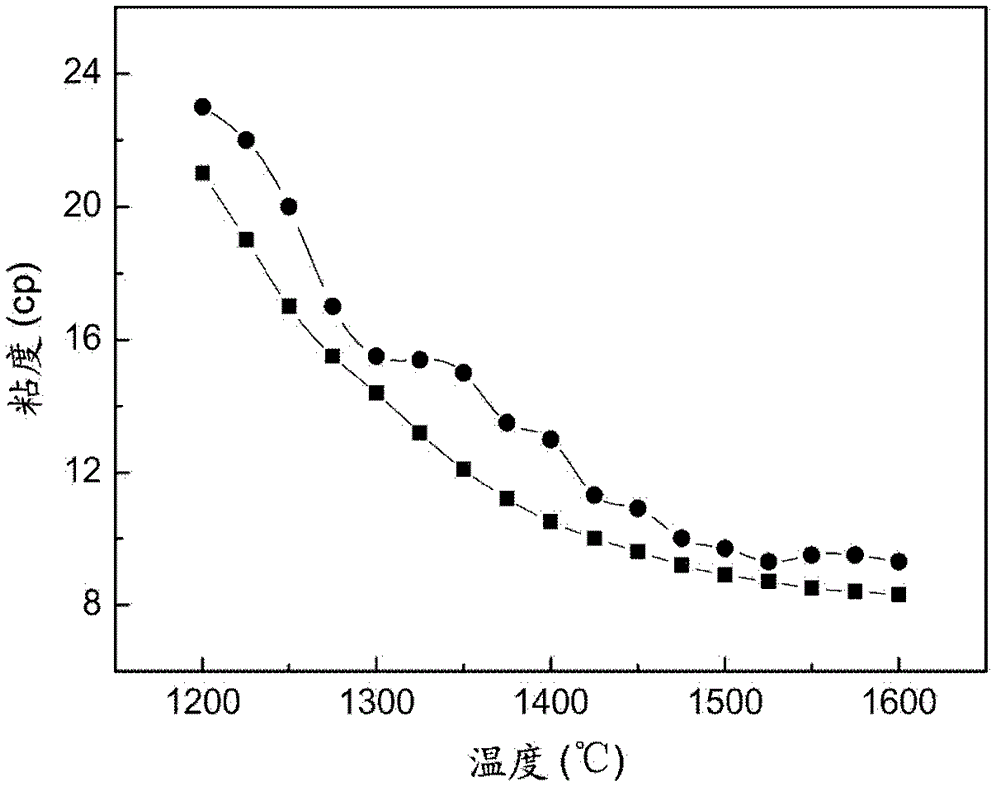

[0031] figure 1 For Fe using additives according to this example 78 Si 9 B 13 Alloy molten steel and Fe without additives according to this embodiment 78 Si 9 B 13 Viscosity-temperature relationship curve of alloy molten steel in the range of 1200°C-1600°C. exist figure 1 , the curve represented by the dots is the viscosity-temperat...

Embodiment 2

[0043] The additive according to the present embodiment comprises 80% micro-carbon ferrochrome, 5% Sn, 5% Pb and 10% Bi by weight percentage, wherein the micro-carbon ferrochrome contains 70% Cr by weight percentage , 0.03% carbon, 1.0% Si, and the balance is iron and unavoidable impurities.

[0044] The additive according to this example is represented by m A :m S =1:500 and m A +m O ×3×10 5 = 5 relational formula to add Fe 73.7 CuNb 3 Si 13.3 B 9 Alloy molten steel for smelting. Fe 73.7 CuNb 3 Si 13.3 B 9 The initial oxygen content of alloy molten steel is 10ppm, the mass m of the additive according to this embodiment A is 2kg, the mass of alloy steel m S It is 1000kg.

[0045] image 3 For using the Fe of the additive according to this embodiment 73.7 CuNb 3 Si 13.3 B 9 Alloy molten steel and Fe without additives according to this embodiment 73.7 CuNb 3 Si 13.3 B 9 Viscosity-temperature relationship curve of alloy molten steel in the range of 1200°C-...

Embodiment 3

[0056] The additive according to the present embodiment comprises 85% microcarbon ferrochrome, 2% Sn, 5% Pb and 8% Bi by weight percentage, wherein the microcarbon ferrochrome comprises 70% Cr, 0.03% C, 1.5% Si, and the balance is iron and unavoidable impurities.

[0057] The additive according to this embodiment is expressed by m A :m S =1:1111 and m A +m O ×3×10 5 =3.9 relational formula adds Fe 78 Si 9 B 13 Alloy steel is smelted in water. Among them, different from Examples 1 and 2, here smelting Fe 78 Si 9 B 13 5% of the iron used in alloy molten steel has rust on the surface of the iron, Fe 78 Si 9 B 13 The initial oxygen content in alloy steel water m O is 10ppm, the mass m of the additive according to the present embodiment A is 0.9kg, the mass of alloy steel m S It is 1000kg. Will use the Fe of this embodiment additive 78 Si 9 B 13 Alloy molten steel was heated to 1350°C, and Fe was prepared by single-roll method 78 Si 9 B 13 Amorphous alloy thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com