Ethers polycarboxylic acid water reducing agent and preparation

A kind of ether polycarboxylate and preparation technology, applied in the field of ether polycarboxylate water reducer and its preparation technology, can solve the problems of difficult control of polymer molecular weight, increase of industrial production cost, low water reducing rate of concrete, etc. Achieve the effect of improving the performance of slump retention, easy control of reaction conditions, and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. The composition and ratio of the monomers used are as follows:

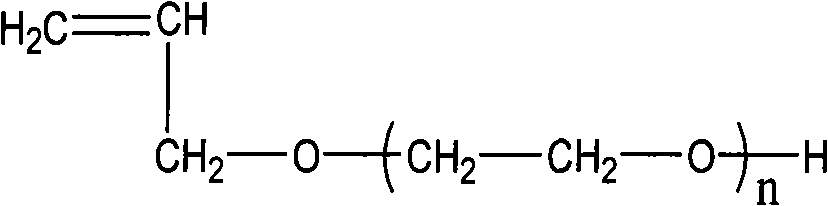

[0035] 1) Monomer A: allyl polyoxyethylene glycol ether (APEG), with a molecular weight of 2000, accounting for 10% of the total monomer weight;

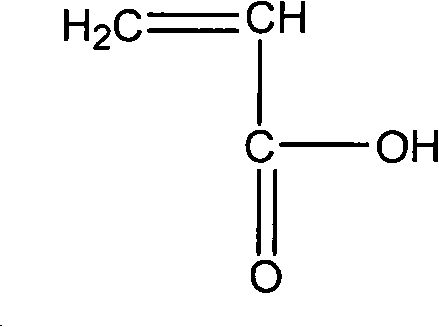

[0036] 2) Monomer B: acrylic acid (AA), accounting for 70% of the total monomer weight;

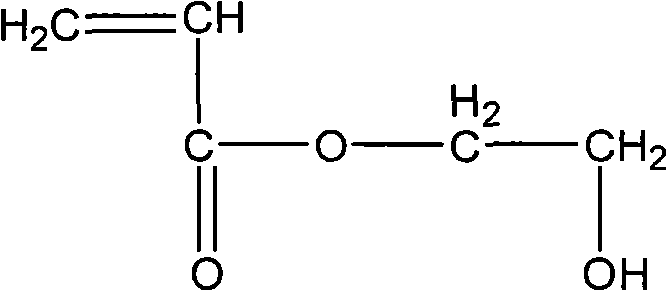

[0037] 3) Monomer C: hydroxyethyl acrylate, accounting for 20% of the total weight of monomers.

[0038] Two, the preparation process is as follows:

[0039] 1) Add 10g of allyl polyoxyethylene glycol ether monomer into the reactor, and add 10g of deionized water to dissolve it;

[0040] 2) Purge the reactor with nitrogen gas while stirring and raising the temperature. When the temperature rises to 60°C, add dropwise a mixed aqueous solution made of 70g of acrylic acid monomer, 20g of hydroxyethyl acrylate monomer and 95g of deionized water and 50g of 10% persulfuric acid Ammonium aqueous solution, ensure that the dropwise addition is completed within 4 hours;

[004...

Embodiment 2

[0043] 1. The composition and ratio of the monomers used are as follows:

[0044] 1) Monomer A: allyl polyoxyethylene glycol ether (APEG), with a molecular weight of 2400, accounting for 40% of the total monomer weight;

[0045] 2) Monomer B: acrylic acid (AA), accounting for 30% of the total monomer weight;

[0046] 3) Monomer C: hydroxyethyl acrylate, accounting for 30% of the total weight of monomers.

[0047] Two, the preparation process is as follows:

[0048] 1) Add 40g of allyl polyoxyethylene glycol ether monomer into the reactor, and add 24g of deionized water to dissolve it;

[0049] 2) Purge the reactor with nitrogen gas while stirring and heating up. When the temperature rises to 90°C, add dropwise a mixed aqueous solution made of 30g acrylic acid monomer, 30g hydroxyethyl acrylate monomer and 99g deionized water and 30g10% persulfuric acid Ammonium aqueous solution, ensure that the dropwise addition is completed within 4 hours;

[0050] 3) After dropping, keep...

Embodiment 3

[0052] 1. The composition and ratio of the monomers used are as follows:

[0053] 1) Monomer A: allyl polyoxyethylene glycol ether (APEG), with a molecular weight of 3000, accounting for 70% of the total monomer weight;

[0054] 2) Monomer B: acrylic acid (AA), accounting for 20% of the total monomer weight;

[0055] 3) Monomer C: hydroxyethyl acrylate, accounting for 10% of the total weight of monomers.

[0056] Two, the preparation process is as follows:

[0057] 1) Add 70g of allyl polyoxyethylene alcohol ether monomer into the reactor, and add 25g of deionized water to dissolve it;

[0058] 2) Purging the reactor with nitrogen while stirring and raising the temperature, when the temperature rises to 120°C, add dropwise the mixed aqueous solution made of 20g acrylic acid monomer, 10g hydroxyethyl acrylate monomer and 80g deionized water and 50g 10% superhydrogen Aqueous ammonium sulfate solution, ensure that the dropwise addition is completed within 4 hours;

[0059]3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com