Ethers polycarboxylic acid water reducing agent and preparation

The invention relates to an ether-based polycarboxylic acid and a preparation process technology, which is applied in the field of ether-based polycarboxylate water-reducing agent and its preparation technology, and can solve the problems of difficult control of polymer molecular weight, increased industrial production cost, low concrete water-reducing rate, and the like, Achieve the effect of improving slump retention performance, easy control of reaction conditions, good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. The composition and ratio of the monomers used are as follows:

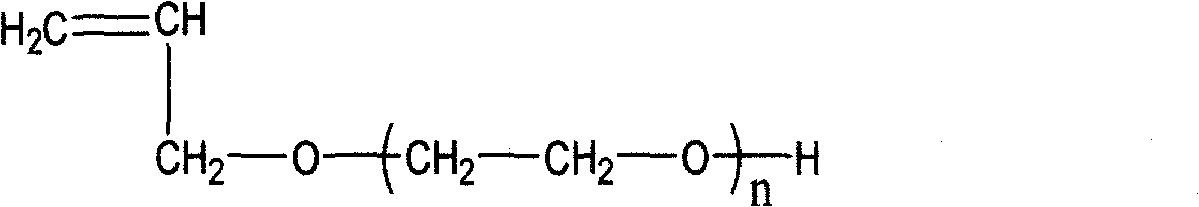

[0035] 1) Monomer A: allyl polyoxyethylene ether (APEG), with a molecular weight of 2000, accounting for 10% of the total monomer weight;

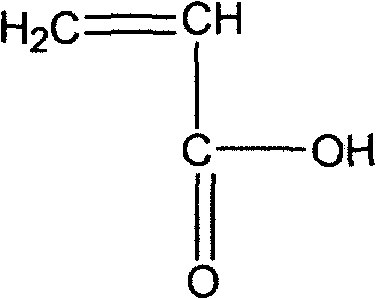

[0036] 2) Monomer B: acrylic acid (AA), accounting for 70% of the total monomer weight;

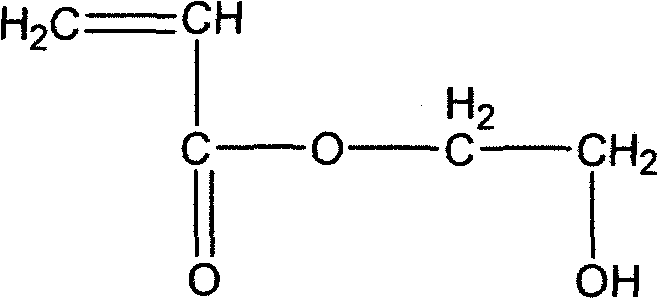

[0037] 3) Monomer C: hydroxyethyl acrylate, accounting for 20% of the total weight of monomers.

[0038] Two, the preparation process is as follows:

[0039] 1) Add 10g of allyl polyoxyethylene ether monomer into the reactor, add 10g of deionized water to dissolve it;

[0040] 2) Purge the reactor with nitrogen gas while stirring and raising the temperature. When the temperature rises to 60°C, add dropwise a mixed aqueous solution made of 70g of acrylic acid monomer, 20g of hydroxyethyl acrylate monomer and 95g of deionized water and 50g of 10% persulfuric acid Ammonium aqueous solution, ensure that the dropwise addition is completed within 4 hours;

[0041] 3) After drippi...

Embodiment 2

[0043] 1. The composition and ratio of the monomers used are as follows:

[0044] 1) Monomer A: allyl polyoxyethylene ether (APEG), with a molecular weight of 2400, accounting for 40% of the total monomer weight;

[0045] 2) Monomer B: acrylic acid (AA), accounting for 30% of the total monomer weight;

[0046] 3) Monomer C: hydroxyethyl acrylate, accounting for 30% of the total weight of monomers.

[0047] Two, the preparation process is as follows:

[0048] 1) Add 40g of allyl polyoxyethylene ether monomer into the reactor, and add 24g of deionized water to dissolve it;

[0049] 2) Purge the reactor with nitrogen gas while stirring and heating up. When the temperature rises to 90°C, add dropwise a mixed aqueous solution made of 30g acrylic acid monomer, 30g hydroxyethyl acrylate monomer and 99g deionized water and 30g10% persulfuric acid Ammonium aqueous solution, ensure that the dropwise addition is completed within 4 hours;

[0050] 3) After dropping, keep warm for 2 ho...

Embodiment 3

[0052] 1. The composition and ratio of the monomers used are as follows:

[0053] 1) Monomer A: allyl polyoxyethylene ether (APEG), with a molecular weight of 3000, accounting for 70% of the total monomer weight;

[0054] 2) Monomer B: acrylic acid (AA), accounting for 20% of the total monomer weight;

[0055] 3) Monomer C: hydroxyethyl acrylate, accounting for 10% of the total weight of monomers.

[0056] Two, the preparation process is as follows:

[0057] 1) Add 70g of allyl polyoxyethylene ether monomer into the reactor, and add 25g of deionized water to dissolve it;

[0058] 2) Purging the reactor with nitrogen while stirring and raising the temperature, when the temperature rises to 120°C, add dropwise the mixed aqueous solution made of 20g acrylic acid monomer, 10g hydroxyethyl acrylate monomer and 80g deionized water and 50g 10% superhydrogen Aqueous ammonium sulfate solution, ensure that the dropwise addition is completed within 4 hours;

[0059]3) After dropping,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com