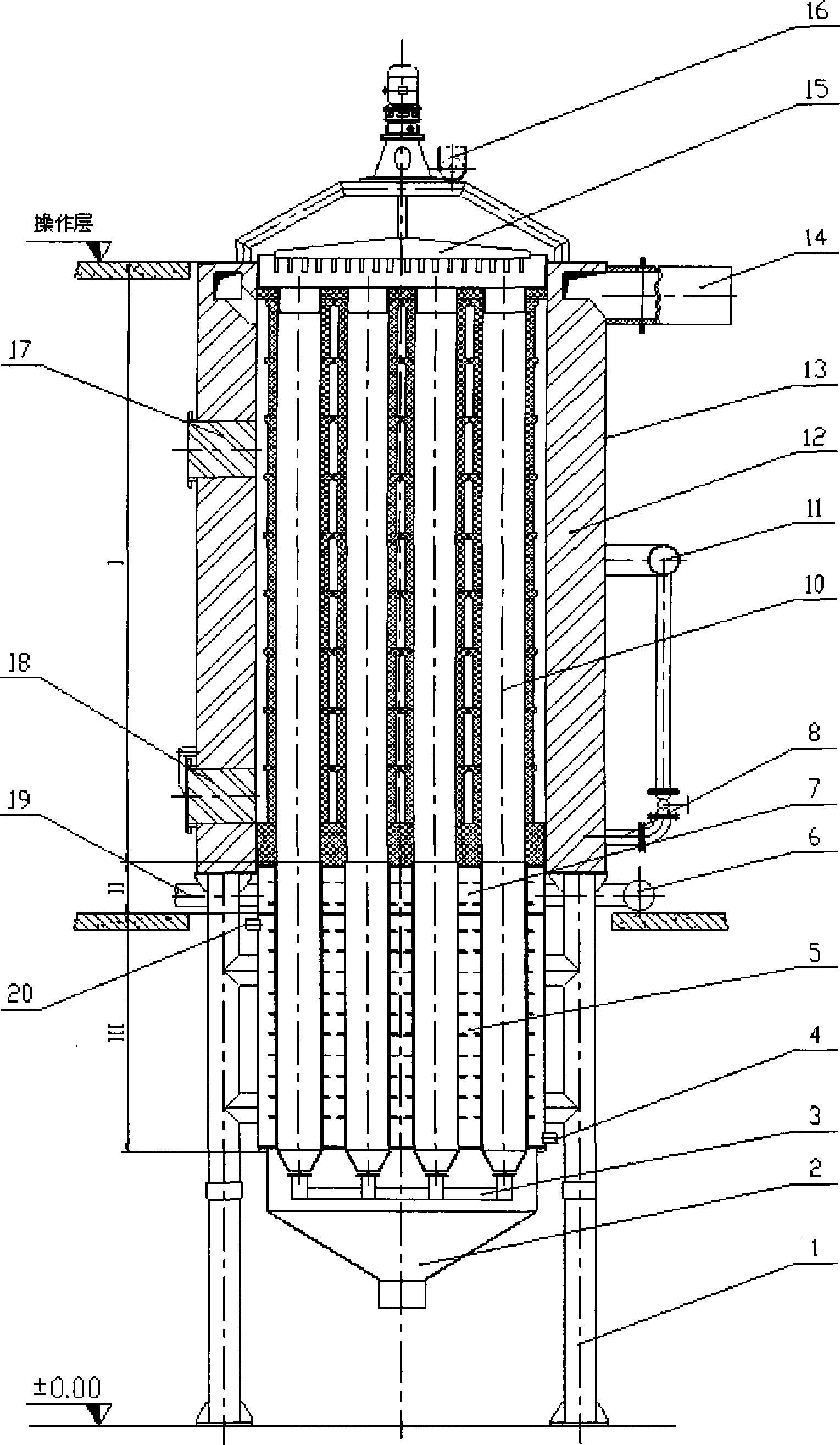

Manganese ore reduction calcination method and apparatus

A manganese ore and roasting technology is applied in the field of manganese dioxide ore reduction roasting into manganese monoxide, which can solve the problems of unreasonable design of roasting chamber and incomplete reaction of manganese dioxide, so as to achieve the same quality, production cost and roasting time , Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] After drying, the manganese dioxide ore particle size <15mm and coke powder are evenly stirred at a ratio of 10:0.5, and then transported to the feeding bin at the top of the roasting chamber, and continuously and slowly enter the tubular roasting under the action of the automatic disc feeding device and gravity. inside the barrel. Manganese dioxide ore and reduced powder are heated and roasted to 920°C-950°C in a closed roasting cylinder, then cooled to about 250°C in a closed "oxygen-free" air waste heat recovery section, and then enter a closed "oxygen-free" water cooling section Medium cooling below 60°C, and finally discharged out of the furnace by an automatic discharge device with stepless speed regulation, and enters the next process. . Since the roasting material is not in contact with the external air in the waste heat recovery section and cooling section, it can effectively prevent the roasted manganese monoxide ore powder from reacting with the oxygen in th...

Embodiment 2

[0046] The dried manganese dioxide ore particle size <15mm and the reduced anthracite pulverized coal are evenly stirred at a ratio of 10:1, and are transported to the feeding bin at the top of the roasting chamber, and are continuously and slowly fed by the automatic disc feeding device and gravity. Inside the tubular roasting cylinder. Manganese dioxide ore and reduced powder are heated and roasted in a closed roasting cylinder to 930°C-970°C, then cooled to about 300°C in a closed "oxygen-free" air waste heat recovery section, and then enter a closed "oxygen-free" water cooling section Medium cooling below 60°C, and finally discharged out of the furnace by an automatic discharge device with stepless speed regulation, and enters the next process. . Since the roasting material is not in contact with the external air in the waste heat recovery section and cooling section, it can effectively prevent the roasted manganese monoxide ore powder from reacting with the oxygen in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com