moving radial bed reactor

A reactor and radial bed technology, applied in the field of reactors, can solve problems such as uneven distribution, catalyst feed blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

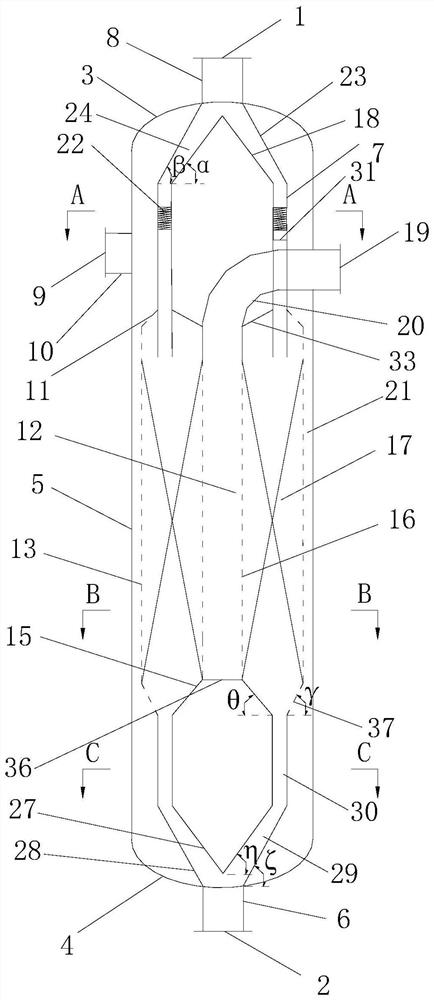

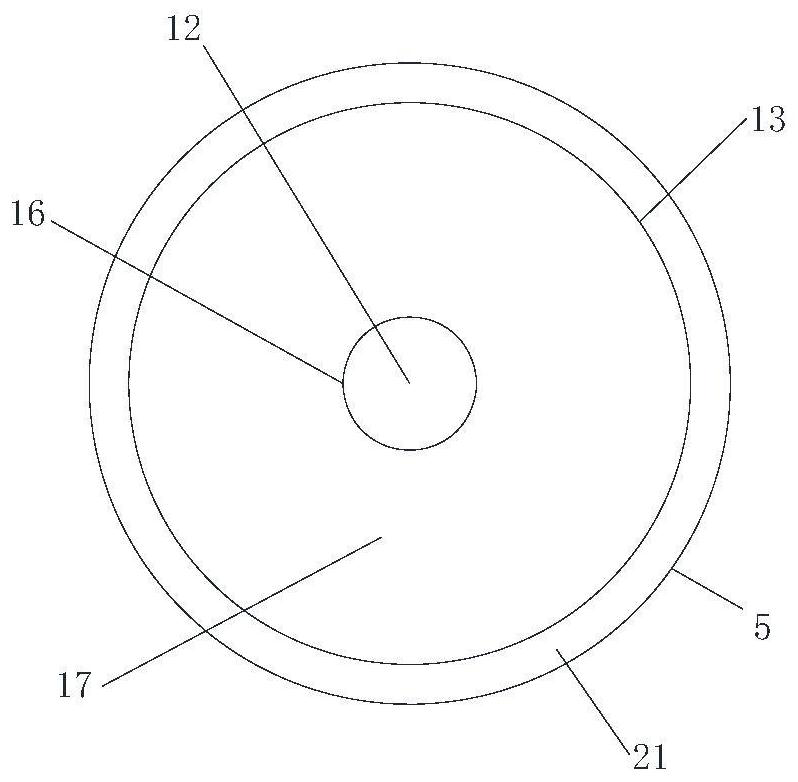

[0086] Such as figure 1 , figure 2 , image 3 , Figure 5 , Image 6 As shown, the reactor used in this embodiment is provided with a catalyst inlet 1 at the top, a catalyst outlet 2 at the bottom, a radial catalytic reaction unit 17, a central tube 12, and a feeder for tangentially feeding the upper part of the shell. Port 9, discharge port 19. The inner diameter of the reactor in this embodiment is 3100mm, the tangent length of the shell is 21500mm, the length of the central tube is 14000mm, the inner diameter of the central tube is 1150mm, the thickness of the catalytic reaction unit is 825mm, the annular gap is 150mm, and the inner diameter of the gas outlet elbow 20 is 900mm. The distance from the apex of the catalyst deflector 31 to the centerline of the gas outlet elbow 20 is 2000 mm, and the inner diameter of the first hollow interlayer cylindrical tube 7 is 2150 mm. The inclination angles of the inner ring plate, the outer ring plate and the horizontal plane are...

Embodiment 2

[0089] Such as figure 1 , figure 2 , Figure 4 , Figure 5 , Image 6 As shown, the reactor used in this embodiment is the same as the reactor used in Example 1 in terms of reactor size, catalyst inlet and outlet system, and raw material inlet and outlet system. The area surrounded by the body is formed, and the catalytic reaction unit is formed by the area between the Johnson net and the central tube to accommodate the passage of the catalyst.

[0090] The reactor of this embodiment is also applied to the continuous reforming process, and the catalyst is a bimetallic Pt-Sn spherical catalyst with a diameter of 2.5-2.8 mm. Reaction raw material is identical with embodiment 1, and reaction pressure is 0.2~1.0MPaG, and the temperature of reaction is 430~550 ℃, and weight hourly space velocity (WHSV) is 0.8~3.0h -1 . The pressure drop of the reactor is less than 10kPa, and the axial temperature difference of the catalytic reaction unit is less than 2°C, which shows that th...

Embodiment 3

[0092] Such as figure 1 , figure 2 , Figure 4 , Figure 5 , Image 6 As shown, the reactor used in this example is the same as the reactor used in Example 2 in terms of reactor size, catalyst inlet and outlet system, raw material inlet and outlet system, annulus and other parameters. The difference is that the reactor is used for methanol to olefins process.

[0093] In this example, the catalyst used for methanol-to-olefins is spherical SAPO-34, the particle diameter of which is 2.1-2.5 mm, and the reaction raw material is H 2 O, CH 3 OH, CH 3 OCH 3 The formed mixture has a reaction pressure of 0.05-0.3MPa and a volumetric space velocity (GHSV) of 0.5-3.2h -1 , The reaction temperature is 405-510°C. The pressure drop of the reactor is less than 20kPa, and the axial temperature difference of the catalytic reaction unit is less than 3.5°C, which shows that the reaction raw materials are evenly distributed in the axial direction, and there is no "cavity" and "sticking"...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com