A biomass particle combustion device that can dry raw materials

A biomass particle and combustion device technology, which is applied in the direction of solid fuel combustion, drying, dryer, etc., can solve the problems of incomplete combustion and dense smoke, and achieve simple and efficient arrangement, convenient transportation, and improved utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

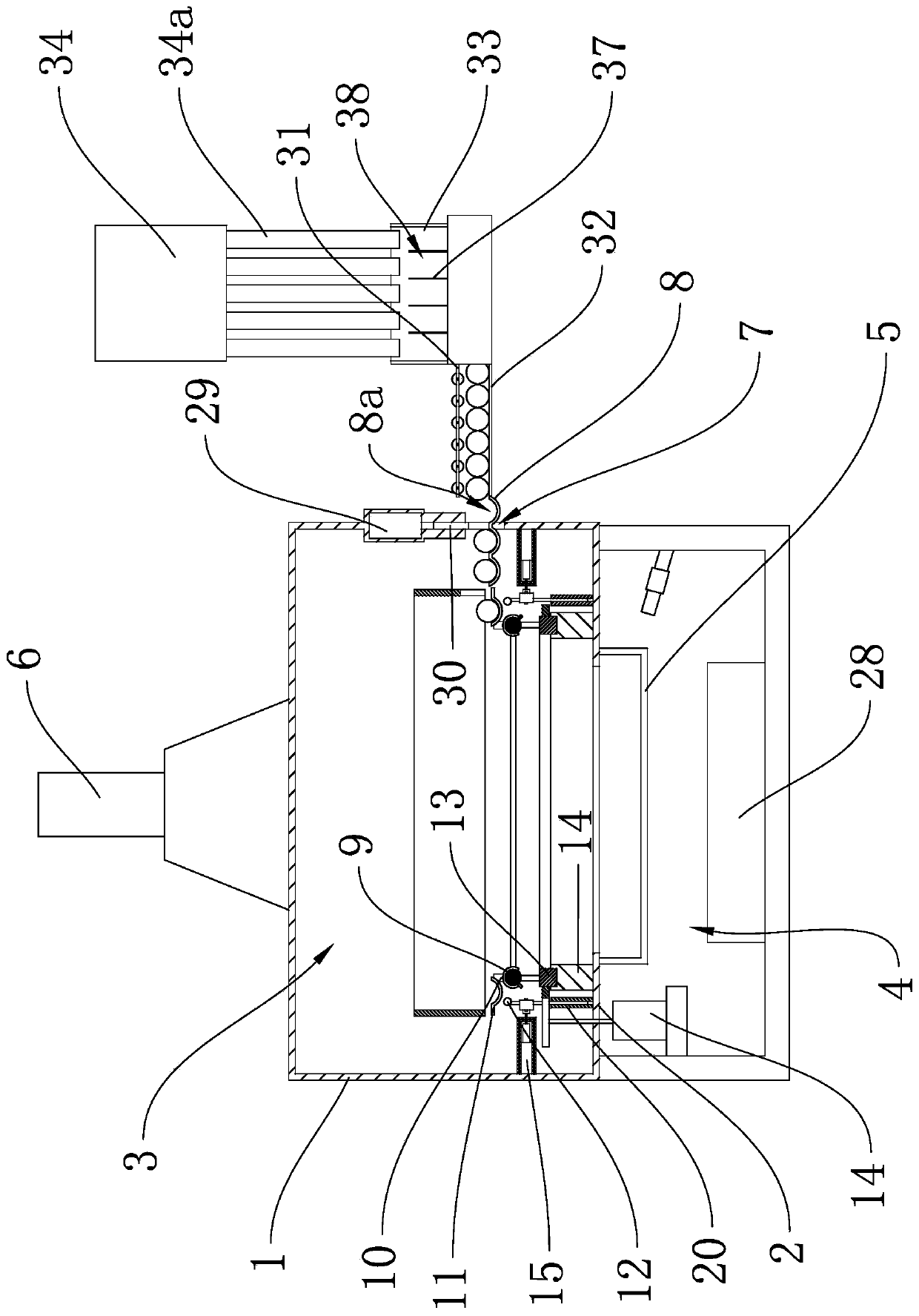

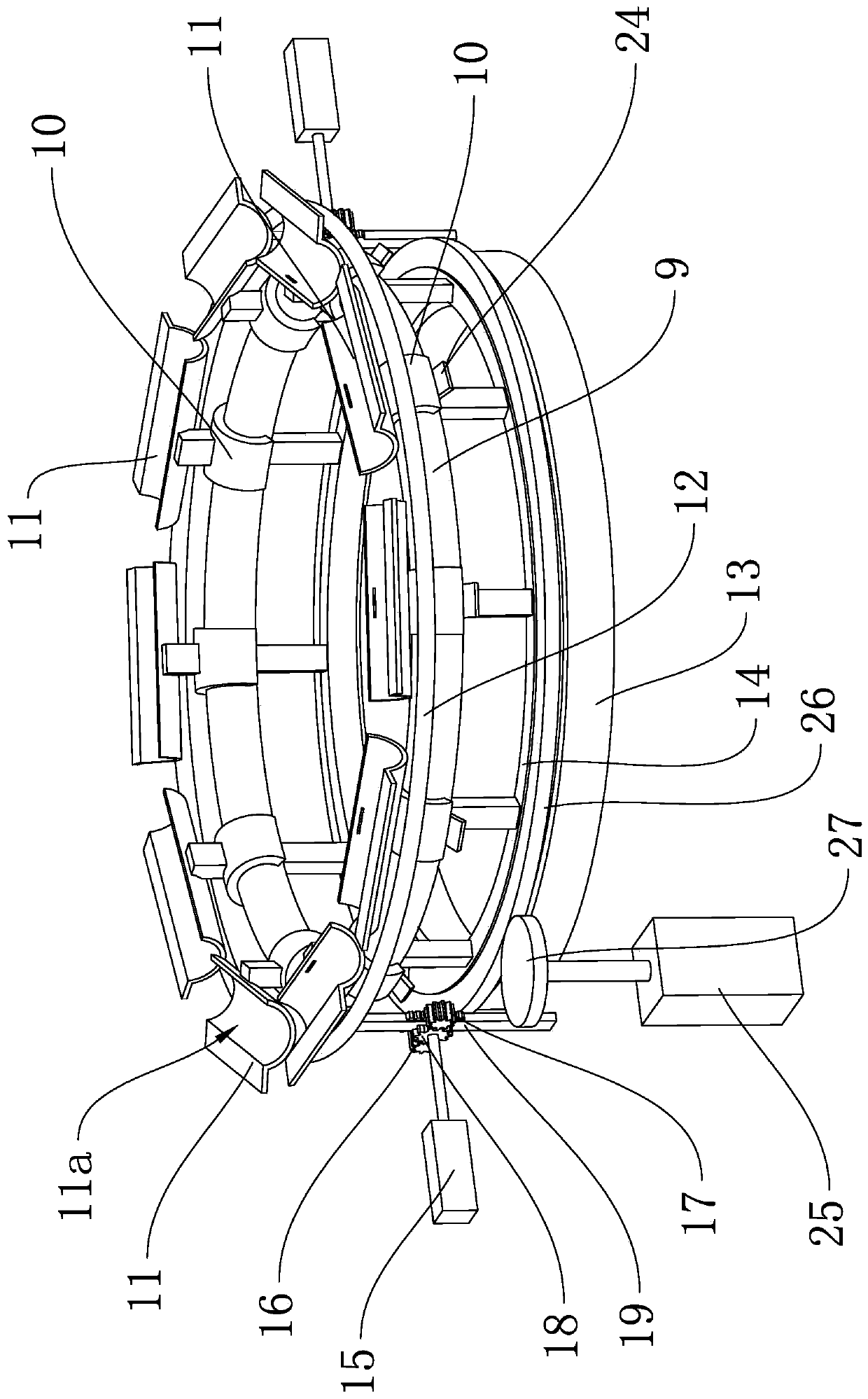

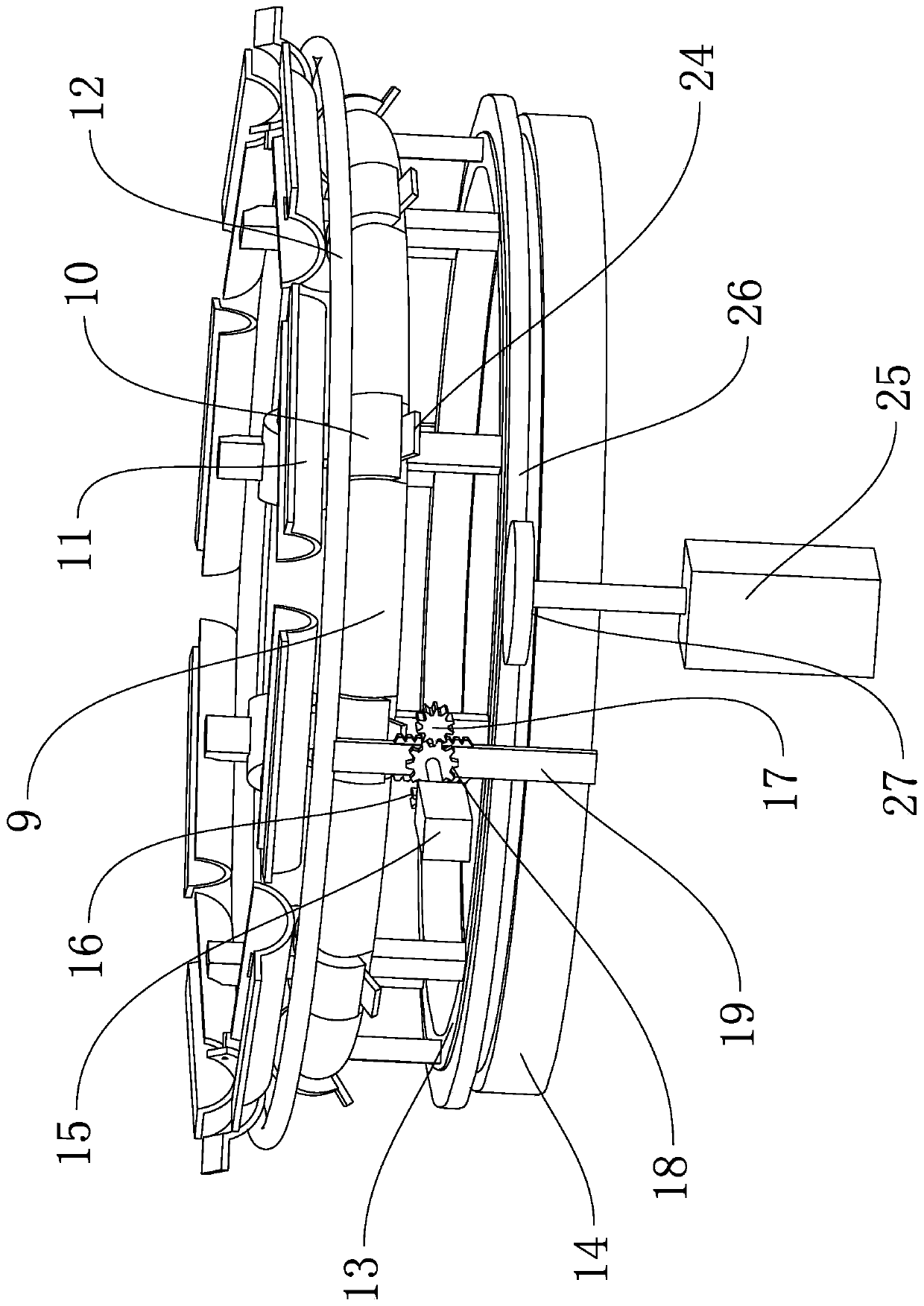

[0042] Such as Figure 1 to Figure 7 As shown, a biomass particle combustion device capable of drying raw materials includes a box body 1, which is characterized in that a partition 2 is fixed inside the box body 1, and the partition board 2 separates the box body 1 into combustion chambers for burning raw materials. chamber 3 and recovery chamber 4 for recovering the burnt ash, the shelf is provided with a through hole, the lower part of the shelf is fixed with a filter burning net 5, the top of the box body 1 is fixed with a fire outlet pipe 6, and the combustion chamber 3 is provided with a The receiving and storing mechanism for receiving and storing raw materials. There is a feeding port 7 on one side of the box body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com