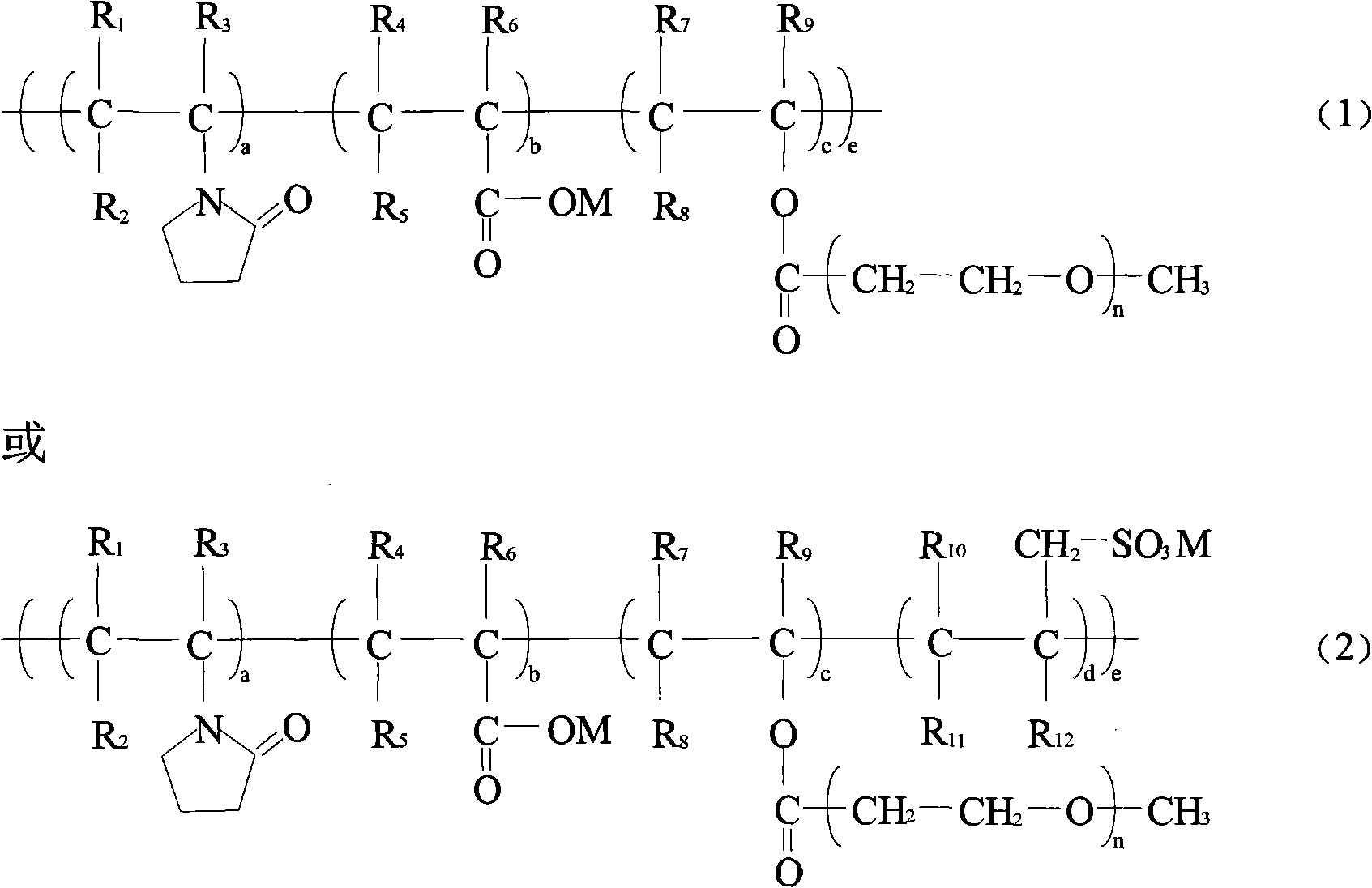

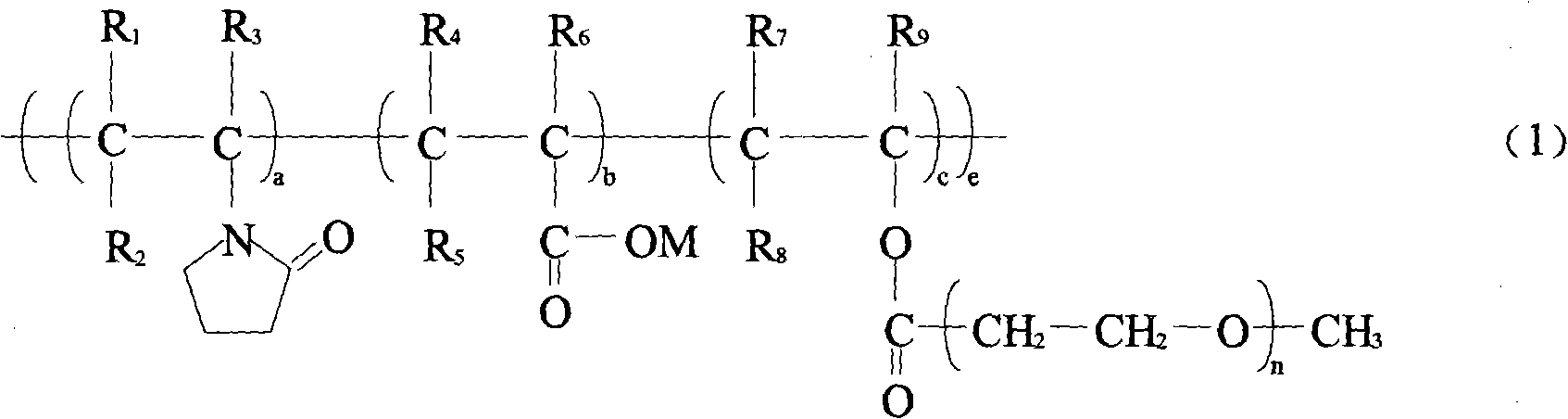

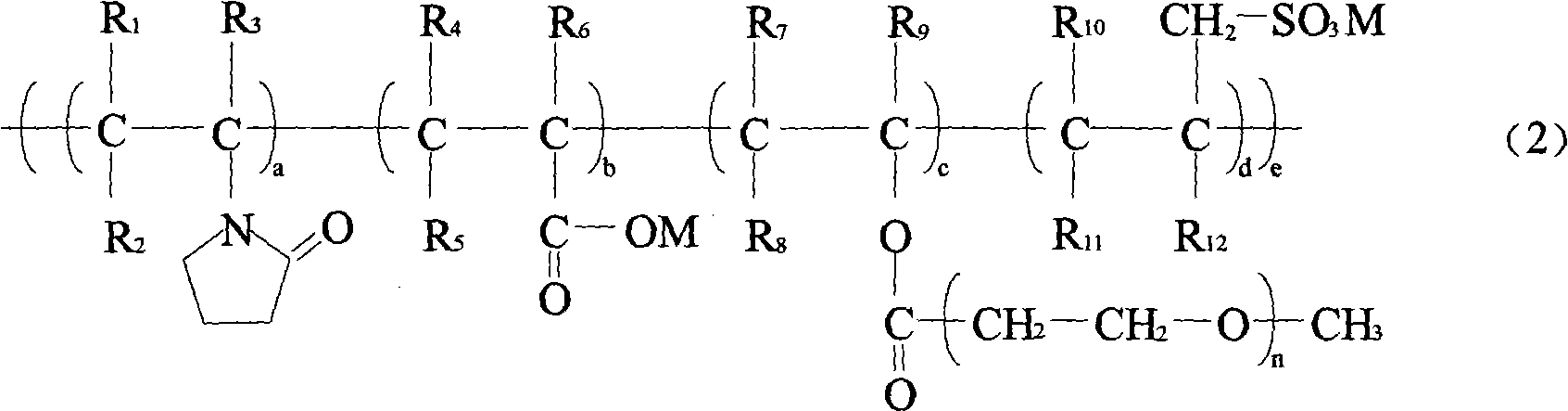

Cement concrete superplasticizer and method for preparing same

A technology of cement concrete and superplasticizer, applied in the field of cement concrete superplasticizer, can solve the problems of harsh reaction conditions, complex production process, long production time, etc., and achieve easy control of reaction conditions, simple synthesis process and low equipment investment little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Add 132g of water into the reaction kettle equipped with a thermometer, agitator, feeding port, reflux condenser, and nitrogen gas inlet pipe, pass in nitrogen gas to purge for 30min, heat in a water bath to 60°C, and then add 5.5g of methacrylic acid Sodium made the primer solution. The stirring speed is 60-100 rpm. Weigh 8.4g of acrylic acid, 30.9g of methoxypolyethylene glycol acrylate (n=9) and 2.1g of vinylpyrrolidone, and then add 15g of water to form a mixed monomer solution. Weigh 3.6g of ammonium persulfate and 3.6g of sodium bisulfite, add 68g of water to make an initiator. The configured mixed monomer solution and the initiator were purged with nitrogen for 30 minutes, and were added dropwise to the reaction bottle with a feeding pump, and the dropping time was controlled at 3 hours. The adding time is controlled at 1 hour, and the temperature is raised to 95°C after dripping, and after 2 hours of heat preservation, the temperature is lowered to below 40°C,...

Embodiment 2

[0057] In a four-neck flask of a reaction kettle equipped with a thermometer, a stirrer, a dropping funnel, a reflux condenser, and a nitrogen inlet pipe, first replace the air in the bottle with nitrogen, and then add 6.5 g of sodium propylene sulfonate and 86 g of water to the bottle. A primer solution was formed and heated to 70°C in a water bath. The stirring speed is 60-100 rpm. Weigh 9.98g of methacrylic acid, 28.84g of methoxypolyoxyethylene methacrylate (n=23) and 3.3g of vinylpyrrolidone, and then add 15g of water to form a mixed monomer solution. Weigh 9.98g of methacrylic acid and 28.84g of methoxypolyoxyethylene methacrylate (n=23), add 45g of water to form a mixed monomer solution. Weigh 3.6g of ammonium persulfate and add 68g of water to make an initiator. After the configured mixed monomer solution and the initiator were purged with nitrogen for 30 minutes, they were added dropwise to the reaction flask with a feeding pump, and the dropping time was controlled...

Embodiment 3

[0059] In the reaction kettle four-necked bottle equipped with a thermometer, agitator, dropping funnel, reflux condenser, and nitrogen inlet pipe, first replace the air in the bottle with nitrogen, add 17g of water to the bottle as a base material solution, and heat it in a water bath to 80°C. The stirring speed is 60-100 rpm. Take by weighing 35.67g methoxypolyethylene glycol methacrylate (n=35), 4.97g methacrylic acid, 1.02g vinylpyrrolidone and 2.4g mercaptopropionic acid, add 163g water again and be made into containing chain transfer agent The monomer solution was mixed, and then adjusted to pH=5.0 of the mixed monomer solution with sodium bicarbonate. Weigh 3.6g of ammonium persulfate and add 68g of water to make an initiator. After the configured mixed monomer solution and initiator were purged with nitrogen for 30 minutes, they were added dropwise to the reaction bottle with a feeding pump, and the dropping time was controlled at 5 hours. After the dropping, continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com