Preparation method for polycarboxylic acid type concrete slump-retaining agent

A technology of slump retaining agent and concrete, which is applied in the field of preparation of polycarboxylate concrete slump retainer, can solve the problems of poor workability of concrete mixture, increase of retarding components, large slump loss, etc., and achieve excellent slump Slump retention ability, good slump retention, simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0037] First add 280g of deionized water to the reactor, start stirring and add 400g of modified polyether, heat up to 60±2°C, add liquid C, stir for 5 minutes, start to add liquid A and liquid B dropwise, of which liquid A: 3.0 hours After the dropwise addition is completed, the dropwise addition of liquid B is completed in 4.0 hours, and the dropwise addition temperature is 60±2°C; after that, keep the temperature for 2 hours, cool down to 50°C, add 80g of 30% liquid caustic soda for neutralization, and control the pH: 6.0~7.0. Adjust the concentration of the system to 40% (preparation of liquid A: dissolve 0.28 g of thioglycolic acid and 1 g of ascorbic acid into 80 g of deionized water for later use; preparation of liquid B: dissolve 45 g of acrylic acid in 15 g of deionized water for later use; preparation of liquid C, Add 6 g of 32.5% hydrogen peroxide into 15 g of deionized water for subsequent use).

example 2

[0039] First add 280g of deionized water into the reactor, start stirring and add 400g of modified polyether, raise the temperature to 70±2°C, add liquid C, and stir for 5 minutes. Start to add liquid A and liquid B dropwise, among which liquid A is added dropwise in 4 hours, and liquid B is added in 3 hours. The dropping temperature is kept at 75±2°C. After that, keep the reaction for 1 hour, lower the temperature to 50°C, add 45g of 30% liquid caustic soda for neutralization, and control the pH: 6.0-7.0. Adjust the concentration of the system to 40% (preparation of liquid A, dissolve 2 g of mercaptopropionic acid, 1 g of thioglycolic acid and 2 g of ascorbic acid into 80 g of deionized water, and set aside; preparation of liquid B: dissolve 45 g of methacrylic acid in 15 g of deionized water ; Standby; C liquid preparation, 32.5% hydrogen peroxide 3g ammonium persulfate 2g was added to 15g deionized water; standby).

example 3

[0041] First add 280g of deionized water into the reactor, start stirring and add 400g of modified polyether, raise the temperature to 65±2°C, add liquid C, stir for 5 minutes, and add liquid A and liquid B dropwise at the same time. Add solution A in 5 hours, add solution B in 4 hours, then keep warm for 2 hours, the reaction temperature is 65±2°C, cool down to 50°C, add 75g of 30% liquid caustic soda for neutralization, and control pH: 6.0~7.0. Adjust the concentration of the system to 40% (preparation of liquid A: dissolve 3 g of sodium bisulfite and 1 g of mercaptopropionic acid in 80 g of deionized water for later use; preparation of liquid B: dissolve 20 g of methacrylic acid and 20 g of maleic anhydride in 40 g of deionized water Standby; 32.5% hydrogen peroxide 6g is dissolved in 15g deionized water for standby).

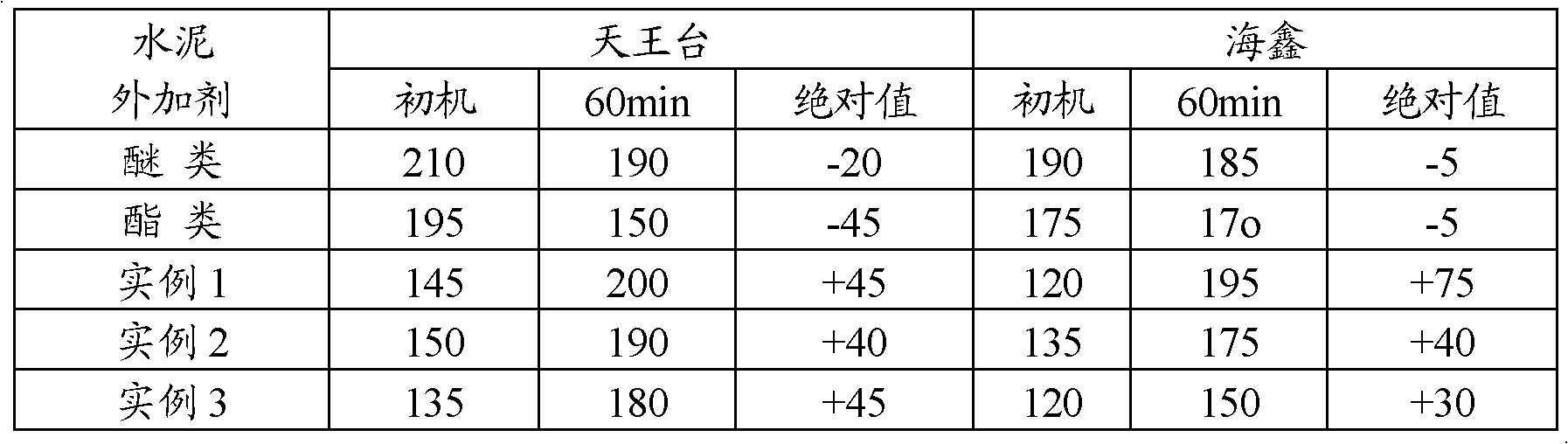

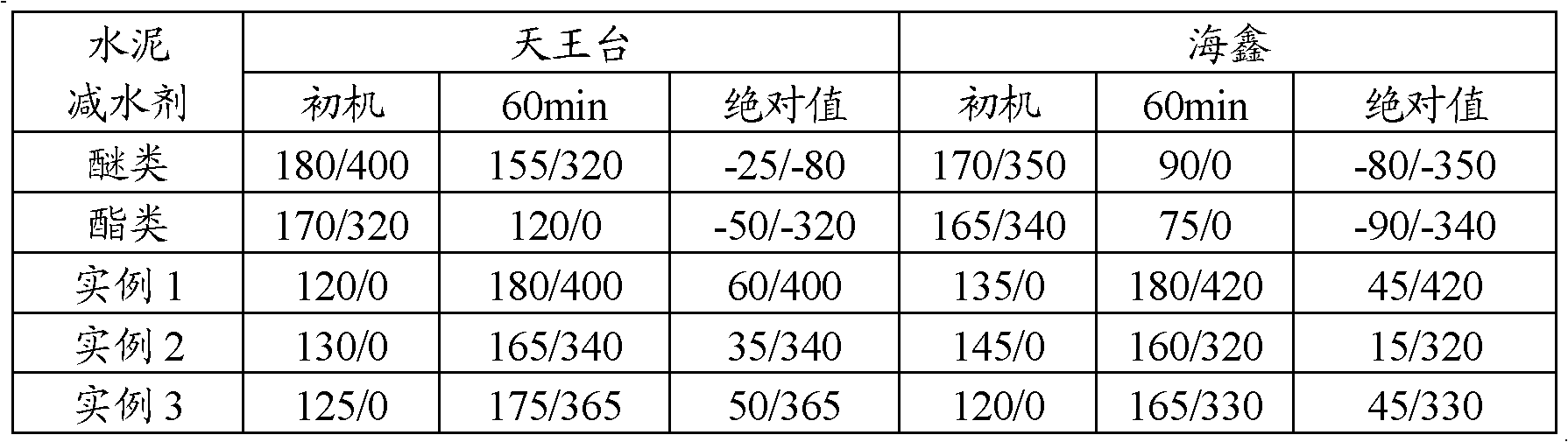

[0042] The comparison results of polycarboxylic acid slump-retaining agent of the present invention with ester water reducer and ether water reducer are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com