Method for improving rolling stability of container thin material

A container and stability technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of affecting the surface quality of strip steel, increasing the rate of scrap and accident, affecting the qualified rate and performance rate of container thin materials, etc. Achieve the effect of reducing accident rate and accident handling workload, improving rolling mill operation rate and rolling efficiency, and improving corporate reputation and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The size of the billet is 230×1200mm, the material is SPA-H, and the specification of the rolled container thin material is 2.0×1100mm. Three heating furnaces are used, and seven finishing mills are used. F6 and F7 indicate that F1-F4 are PC rolling mills.

[0023] In order to ensure that the container thin material is rolled in the best condition of the finishing roll, the container thin material is arranged to be rolled in the middle of the rolling plan, and before the container thin material is rolled, 4 transitional materials are arranged to be intensively rolled. The transition material is 45# high-quality carbon structural steel, and the specifications of the finished products after rolling are two pieces of 2.3×1150mm and two pieces of 2.5×1120mm.

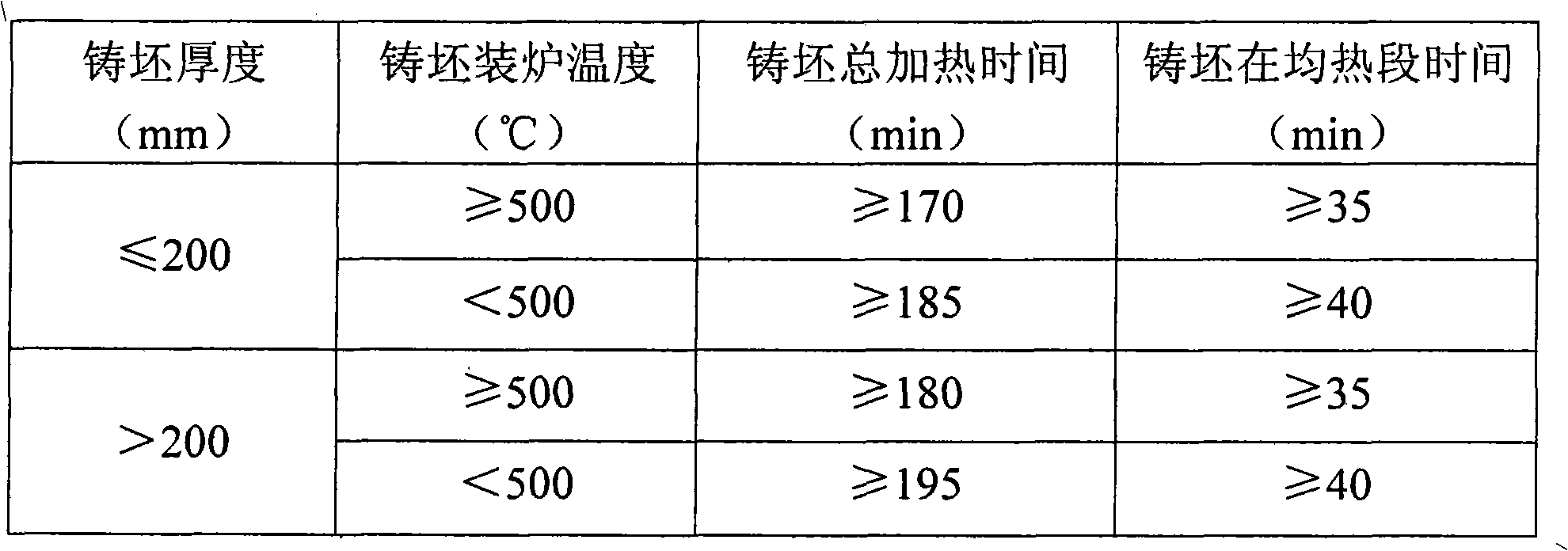

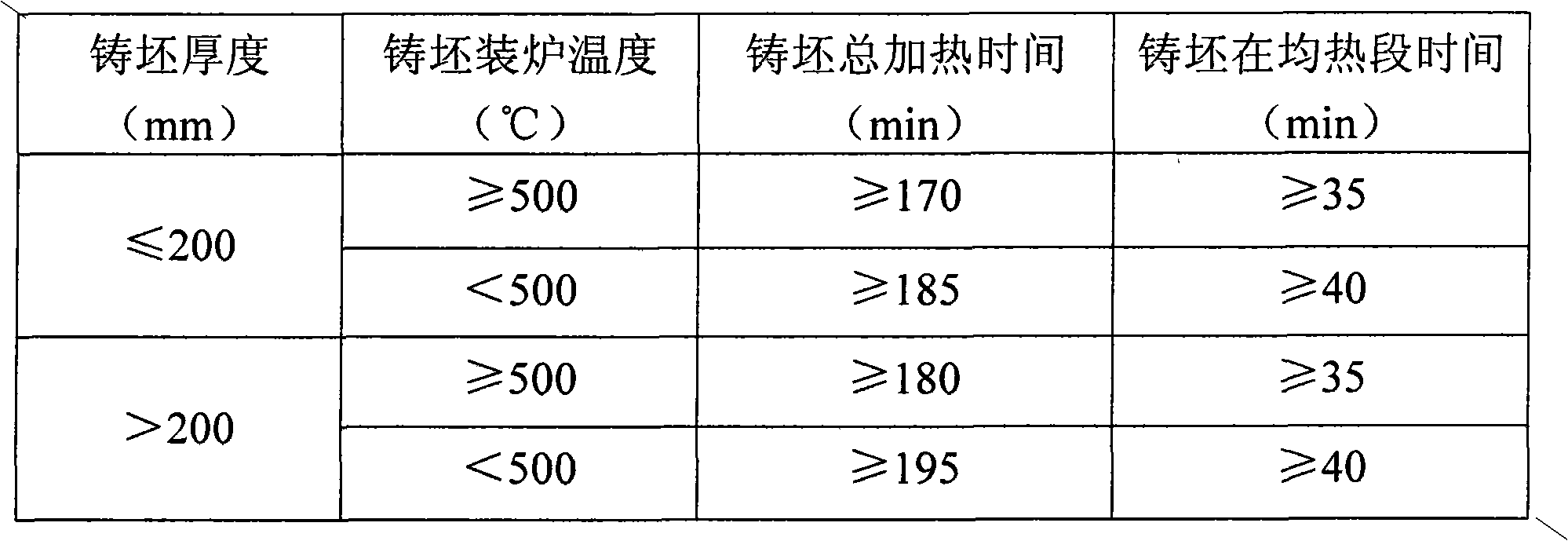

[0024] Heating regime control:

[0025] Considering that the casting slab is thicker and the furnace charging temperature reaches 630°C, it is put into a heating furnace with other hot slabs; the total heating time o...

Embodiment 2

[0036] The size of the billet is 170×1150mm, the material is SPA-H, and the specification of the container thin material after rolling is 1.5×1100mm. Three heating furnaces and seven finishing mills are used. F1~F4 are PC rolling mills.

[0037] The transition material is A420LF automobile beam steel, and the finished product specification after rolling is 2.0×1150mm. Before rolling the container thin material, arrange to roll 4 pieces of transition material intensively.

[0038] Heating control: the billet is cold at room temperature; the total heating time in the heating furnace is 220 minutes, the soaking time is 70 minutes, and the temperature of the billet out of the furnace is controlled at 1250°C;

[0039] The slabs near the furnace doors of the three heating furnaces arrive at the tapping position after an interval of 95 seconds.

[0040] Rough rolling control: rough rolling adopts large reduction rolling to reduce descaling cooling water flow, and the rough rolling o...

Embodiment 3

[0046] The specification of casting slab is 200×1000mm, the material is SPA-H, the specification of container thin material is 1.2×900mm, three heating furnaces are used, seven finishing mills are used, and F1~F4 are PC rolling mills.

[0047] 09CuPCrNi-A corrosion-resistant steel is selected as the transition material, and 4 pieces of transition material are rolled intensively first, and the finished product specifications are two pieces of 1.6×950mm and two pieces of 1.4×930mm.

[0048] Heating system: billet charging temperature reaches 500°C, total heating time is 195 minutes, soaking time is 55 minutes, billet exit temperature is controlled at 1250°C; billets near the furnace door reach the tapping position after 97 seconds.

[0049] Rough rolling: Rolling with a large reduction to reduce the number of descaling, and the temperature at the exit of rough rolling is controlled at 1120°C.

[0050] Finish rolling: F1 adopts single-exhaust scale water descaling, all cooling wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com