High service strength enameled steel plate and preparation method thereof

A manufacturing method and technology for steel plates, applied to the steel plate for enamel and its manufacturing field, can solve the problems of lack of steel plates for enamel, low yield strength, etc., and achieve the effects of high strength level, reduced wear, and good anti-scalding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

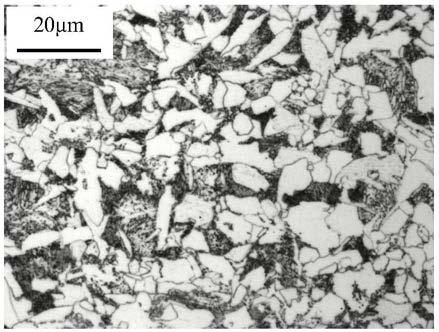

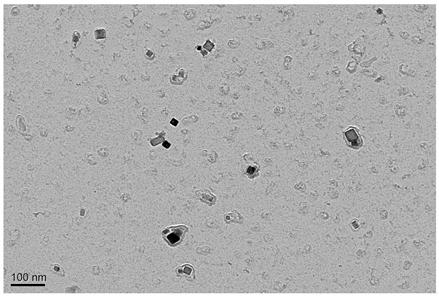

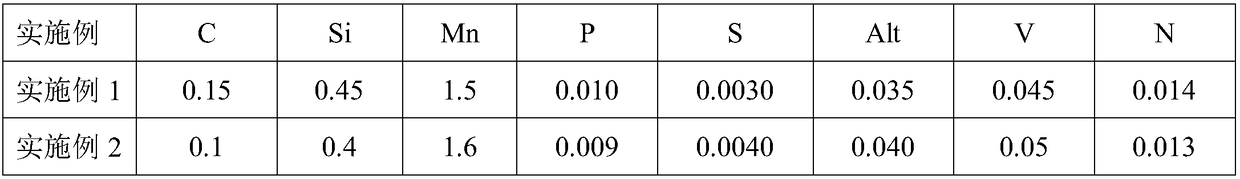

[0042] A steel plate for enameling with high strength after enamel firing, its chemical composition is shown in Table 1 by weight percentage, and its thickness is 11 mm.

[0043] The preparation method of above-mentioned steel plate for enamelling comprises the following steps:

[0044] Step 1, the molten iron is pretreated, converted into steel and refined to obtain the molten iron with the composition ratio of the steel plate for enameling, wherein the chemical composition of the steel plate for enameling is shown in Table 1 by weight percentage;

[0045] Step 2, continuous casting: continuous casting of the refined molten iron to obtain a billet;

[0046]Step 3, heating the slab: controlling the temperature of the slab to 1220°C by heating;

[0047] Step 4, two-stage hot rolling: 6 passes of rough rolling, followed by 7 passes of finish rolling, with a final rolling temperature of 860°C;

[0048] Step 5, coiling: the finished rolled plate is cooled by laminar flow and the...

Embodiment 2

[0057] A steel plate for enameling with high strength after enamel firing, its chemical composition is shown in Table 1 by weight percentage, and its thickness is 13 mm.

[0058] The preparation method of above-mentioned steel plate for enamelling comprises the following steps:

[0059] Step 1, the molten iron is pretreated, converted into steel and refined to obtain the molten iron with the composition ratio of the steel plate for enameling, wherein the chemical composition of the steel plate for enameling is shown in Table 1 by weight percentage;

[0060] Step 2, continuous casting: continuous casting of the refined molten iron to obtain a billet;

[0061] Step 3, heating the slab: controlling the temperature of the slab to 1230°C by heating;

[0062] Step 4, two-stage hot rolling: 6 passes of rough rolling, followed by 7 passes of finish rolling, with a final rolling temperature of 840°C;

[0063] Step 5, coiling: the finished rolled plate is cooled by laminar flow and th...

Embodiment 3

[0072] A steel plate for enameling with high strength after enamel firing, its chemical composition is shown in Table 1 by weight percentage, and its thickness is 14mm.

[0073] The preparation method of above-mentioned steel plate for enamelling comprises the following steps:

[0074] Step 1, the molten iron is pretreated, converted into steel and refined to obtain the molten iron with the composition ratio of the steel plate for enameling, wherein the chemical composition of the steel plate for enameling is shown in Table 1 by weight percentage;

[0075] Step 2, continuous casting: continuous casting of the refined molten iron to obtain a billet;

[0076] Step 3, heating the slab: controlling the temperature of the slab to 1210°C by heating;

[0077] Step 4, two-stage hot rolling: 6 passes of rough rolling, followed by 7 passes of finish rolling, with a final rolling temperature of 840°C;

[0078] Step 5, coiling: the finished rolled plate is cooled by laminar flow and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com