Method for producing cold-formed steel of U-shaped davit arm

A technology of cold-formed steel and production methods, which is applied in the field of hot roll bending-stretching composite forming of U-shaped booms, can solve the problems of high-strength steel for plates, achieve the goals of reducing the yield point, expanding the strength level, and improving the forming performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

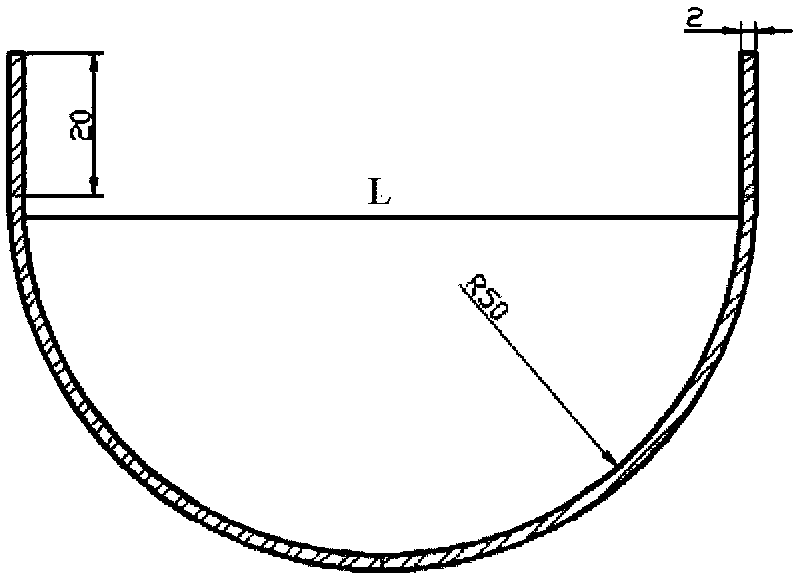

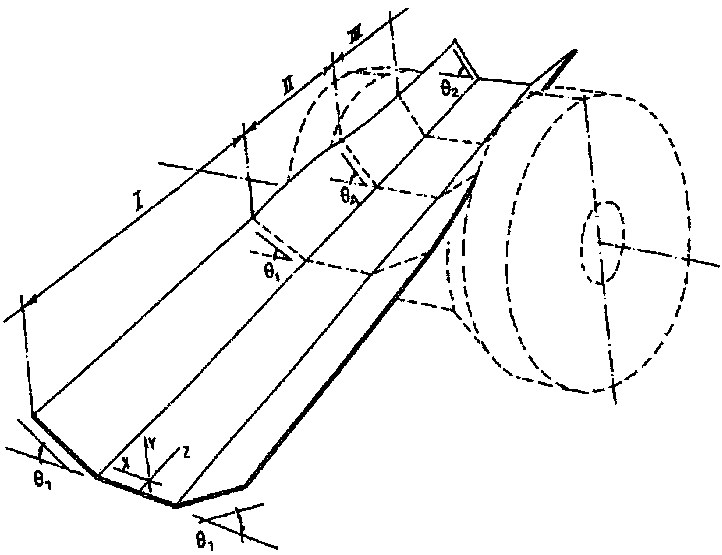

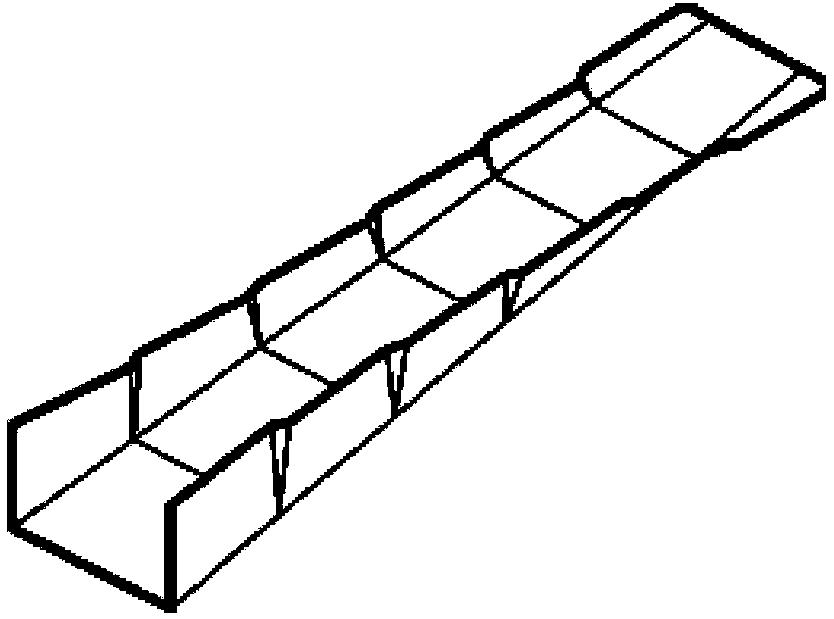

[0040] 1) Prepare a high-strength steel sheet with a length of 2000mm, a width of 200mm, and a thickness of 2mm. The front end of the sheet must have a certain slope; 2) The sheet advances in the roll at a feed speed of v=20m|min; The increase in the diameter of the rolls between times is 0.5 mm. 3) After the sheet passes through the first pass, an induction heating device is installed between the first and second passes, and the induction coil heats the sheet to a temperature of 500°C with power P, and the heating time is 10s; 4) Using 6 Each pass rolls the sheet material, and the bending angle of each pass is 12°→27°→45°→65°→81°→90° (this parameter is based on the conditions of the production equipment itself, and according to the formed The requirements of the product, such as surface quality, dimensional accuracy, etc., and the characteristics of the corresponding materials, such as the yield strength and tensile strength of the material, are given by the engineering and t...

Embodiment approach 2

[0043] 1) Prepare a high-strength steel sheet with a length of 2000mm, a width of 200mm, and a thickness of 2mm. The front end of the sheet must have a certain slope; 2) The sheet advances in the roll at a feed speed of v=15m|min; The increase in the diameter of the rolls between times is 0.5 mm. 3) After the sheet passes through the first pass, an induction heating device is installed between the first and second passes, and the induction coil heats the sheet to a temperature of 700°C with power P, and the heating time is 15s; 4) Using 6 Roll forming is performed on the sheet material in each pass, and the bending angle of each pass is 12°→27°→45°→65°→81°→90°; 5) The transition sheet passes through the forming roller in the last pass to obtain a Symmetrical sheet material with U-shaped section, and due to the tension stretching between the racks, the sheet material will be straightened to ensure the shape of the longitudinal section; 6) It will have the symmetry of U-shaped s...

Embodiment approach 3

[0046] 1) Prepare a high-strength steel sheet with a length of 2000mm, a width of 200mm, and a thickness of 2mm. The front end of the sheet must have a certain slope; 2) The sheet advances in the roll at a feed speed of v=10m|min; The increase in the diameter of the rolls between times is 0.5 mm. 3) After the sheet passes through the first pass, an induction heating device is installed between the first and second passes, and the induction coil heats the sheet to a temperature of 900°C with power P, and the heating time is 18s; 4) Using 6 Roll forming is performed on the sheet material in each pass, and the bending angle of each pass is 12°→27°→45°→65°→81°→90°; 5) The transition sheet passes through the forming roller in the last pass to obtain a Symmetrical sheet material with U-shaped section, and due to the tension stretching between the racks, the sheet material will be straightened to ensure the shape of the longitudinal section; 6) It will have the symmetry of U-shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com