Method for separating benzene and toluene from hydrocarbon mixture

A hydrocarbon mixture and toluene technology, applied in the chemical industry, can solve problems such as complex processes and high energy consumption, and achieve the effects of simple process flow, convenient operation, and investment cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

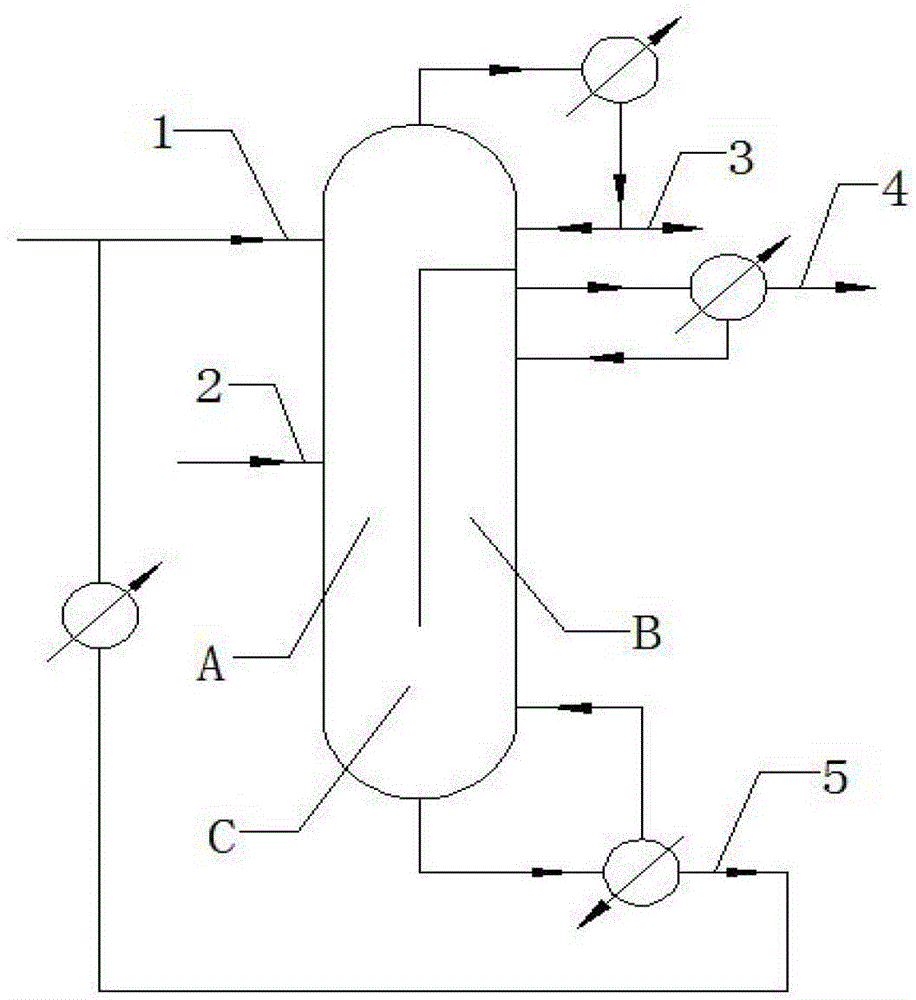

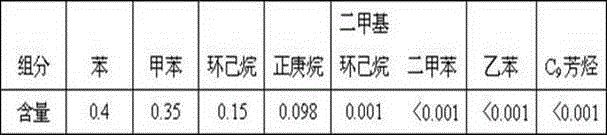

[0017] combine figure 1 As shown, a dividing wall extractive distillation column is used to separate the mixed aromatics of benzene and toluene in the hydrocarbon mixture, packing is installed in the column, and the theoretical plate number of the dividing wall extractive distillation column is 30 plates. The hydrocarbon mixture enters the feed side A of the tower from the hydrocarbon mixture feed port 2 at 100 kmol / hr, and the feed temperature is 95°C; the extractant mainly composed of sulfolane enters the tower from the extractant feed port 1 at 110 kmol / hr Feed side A, feed temperature 90°C. The raw material feed position is the 10th plate and the solvent feed position is the 2nd plate. The solvent ratio is 1.1, the reflux ratio is 0.5, the top pressure of the dividing wall extractive distillation column is 0.1Mpa, the top temperature is 85.0°C, and the bottom temperature is 286°C. Raw materials and extractant are mixed in zone A and the separation of aromatics and non-a...

Embodiment 2

[0019] combine figure 1 As shown, a dividing wall extractive distillation column is used to separate the mixed aromatics of benzene and toluene in the hydrocarbon mixture. Packing is installed in the column, and the theoretical plate number of the column is 29 plates. The raw material enters the feed side A of the tower from the hydrocarbon mixture feed port 2 at 100 kmol / hr, and the feed temperature is 90°C; the extraction agent mainly sulfolane enters the tower from the extractant feed port 1 at 150 kmol / hr. Side A, feed temperature 95°C. The raw material feed position is the 14th plate and the solvent feed position is the 2nd plate. The dividing wall extractive distillation column is operated under normal pressure, the solvent ratio is 1.5, the reflux ratio is 0.9, the temperature at the top of the column is 87.9°C, and the temperature at the bottom of the column is 287.8°C. Raw materials and extractant are mixed in zone A and the separation of aromatics and non-aromatic...

Embodiment 3

[0021] combine figure 1 As shown, a dividing wall extractive distillation column is used to separate the mixed aromatics of benzene and toluene in the hydrocarbon mixture. Packing is installed in the column, and the theoretical plate number of the column is 29 plates. The raw material enters the feed side A of the tower from the hydrocarbon mixture feed port 2 at 100 kmol / hr, and the feed temperature is 90°C; the extraction agent mainly sulfolane enters the tower from the extractant feed port 1 at 200 kmol / hr. Side A, feed temperature 95°C. The raw material feed position is the 12th plate and the solvent feed position is the 2nd plate. The dividing wall extractive distillation column operates under reduced pressure, the top pressure is 0.04Mpa, the solvent ratio is 2, the reflux ratio is 1.5, the top temperature is 58.4°C, and the bottom temperature is 248.6°C. Raw materials and extractant are mixed in zone A and the separation of aromatics and non-aromatics is completed. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com