Waste lithium battery powder iron removal device

A waste lithium battery and powder technology, applied in solid separation, chemical instruments and methods, magnetic separation, etc., can solve the problems of reduced work efficiency, difficulty in collecting iron powder, and poor separation effect, so as to improve work efficiency, save manpower, Easy-to-observe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

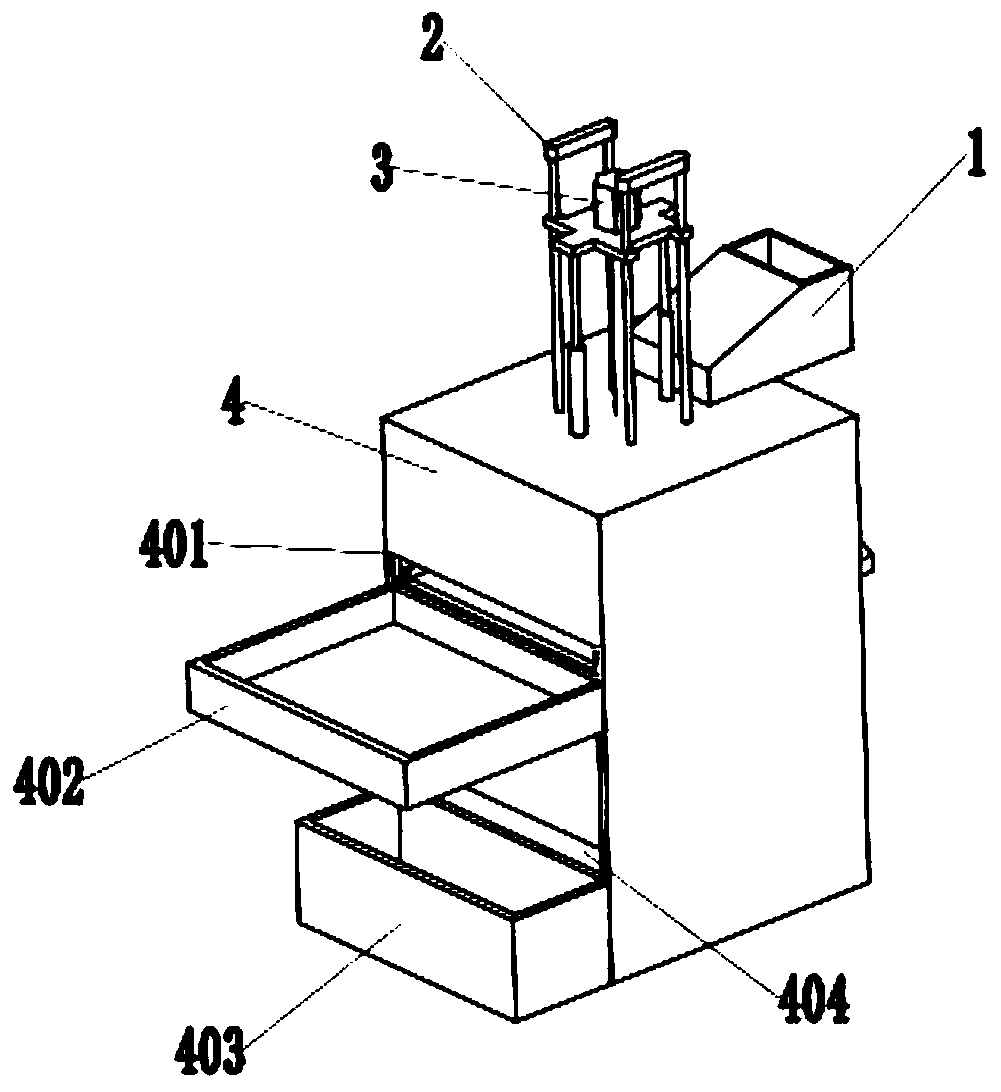

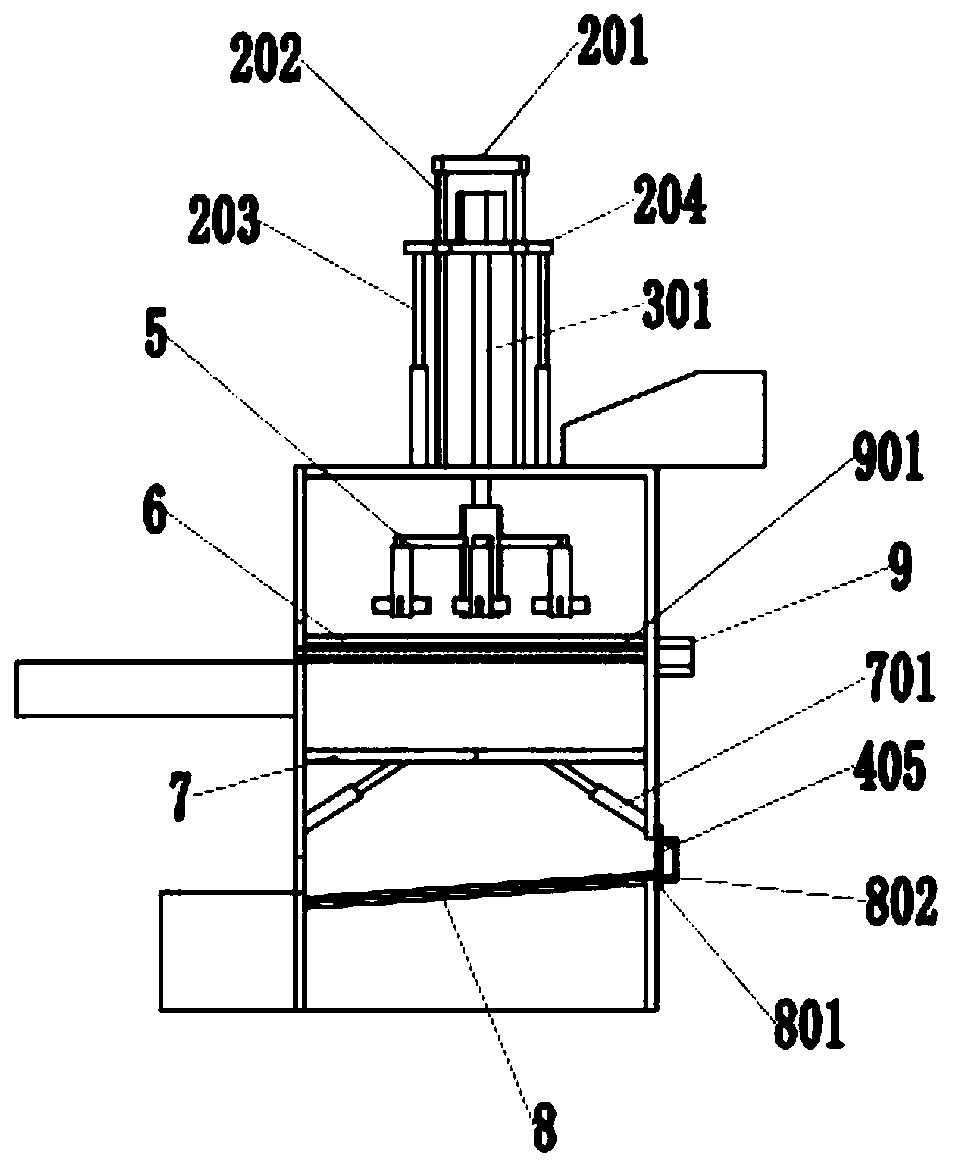

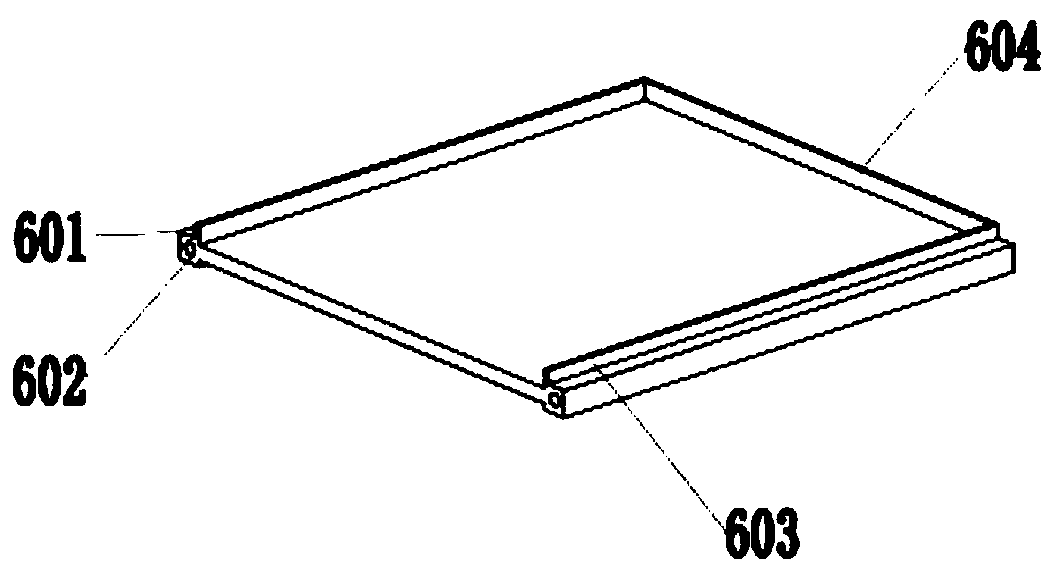

[0026] Such as Figure 1-2 As shown, a waste lithium battery powder iron removal device includes a feed box 1, a support frame 2, a first motor 3, a chassis 4, an electromagnetic iron absorbing device 5, an iron powder collecting plate 6, a separation door 7, and an iron absorbing plate 8. The upper end of the chassis 4 is provided with a support frame 2, the support frame 2 is provided with a lifting plate 204, the lifting plate 204 is provided with a first motor 3, and the first motor 3 is connected with a connecting shaft 301, the end of the connecting shaft 301 is provided with an electromagnetic iron-absorbing device 5, and one side of the support frame 2 is provided with a feed box 1, and the feed box 1 is arranged at the upper end of the chassis 4 and is connected to the interior of the chassis 4 Connected, the electromagnetic iron-absorbing device 5 is arranged inside the cabinet 4, and the iron powder collecting plate 6 that is slidingly connected is arranged in the c...

Embodiment 2

[0028] Such as Figure 1-2 As shown, a waste lithium battery powder iron removal device includes a feed box 1, a support frame 2, a first motor 3, a chassis 4, an electromagnetic iron absorbing device 5, an iron powder collecting plate 6, a separation door 7, and an iron absorbing plate 8. The upper end of the chassis 4 is provided with a support frame 2, the support frame 2 is provided with a lifting plate 204, the lifting plate 204 is provided with a first motor 3, and the first motor 3 is connected with a connecting shaft 301, the end of the connecting shaft 301 is provided with an electromagnetic iron-absorbing device 5, and one side of the support frame 2 is provided with a feed box 1, and the feed box 1 is arranged at the upper end of the chassis 4 and is connected to the interior of the chassis 4 Connected, the electromagnetic iron-absorbing device 5 is arranged inside the cabinet 4, and the iron powder collecting plate 6 that is slidingly connected is arranged in the c...

Embodiment 3

[0032] Such as Figure 1-2 As shown, a waste lithium battery powder iron removal device includes a feed box 1, a support frame 2, a first motor 3, a chassis 4, an electromagnetic iron absorbing device 5, an iron powder collecting plate 6, a separation door 7, and an iron absorbing plate 8. The upper end of the chassis 4 is provided with a support frame 2, the support frame 2 is provided with a lifting plate 204, the lifting plate 204 is provided with a first motor 3, and the first motor 3 is connected with a connecting shaft 301, the end of the connecting shaft 301 is provided with an electromagnetic iron-absorbing device 5, and one side of the support frame 2 is provided with a feed box 1, and the feed box 1 is arranged at the upper end of the chassis 4 and is connected to the interior of the chassis 4 Connected, the electromagnetic iron-absorbing device 5 is arranged inside the cabinet 4, and the iron powder collecting plate 6 that is slidingly connected is arranged in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com