Rotary dryer star and method for treating solid particles

A rotary dryer and star-shaped structure technology, applied in the direction of drying solid materials, chemical instruments and methods, and method combinations to dry solid materials, etc., can solve problems such as low productivity and destroy solid particles, and achieve the effect of improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

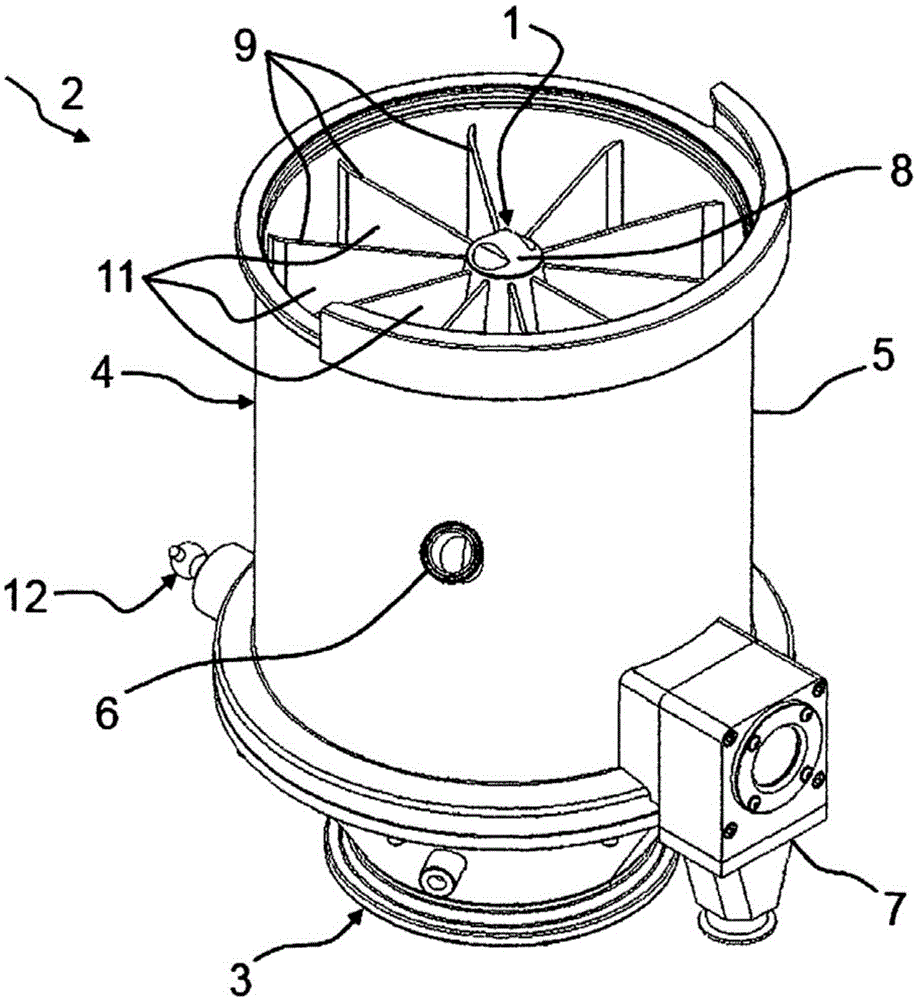

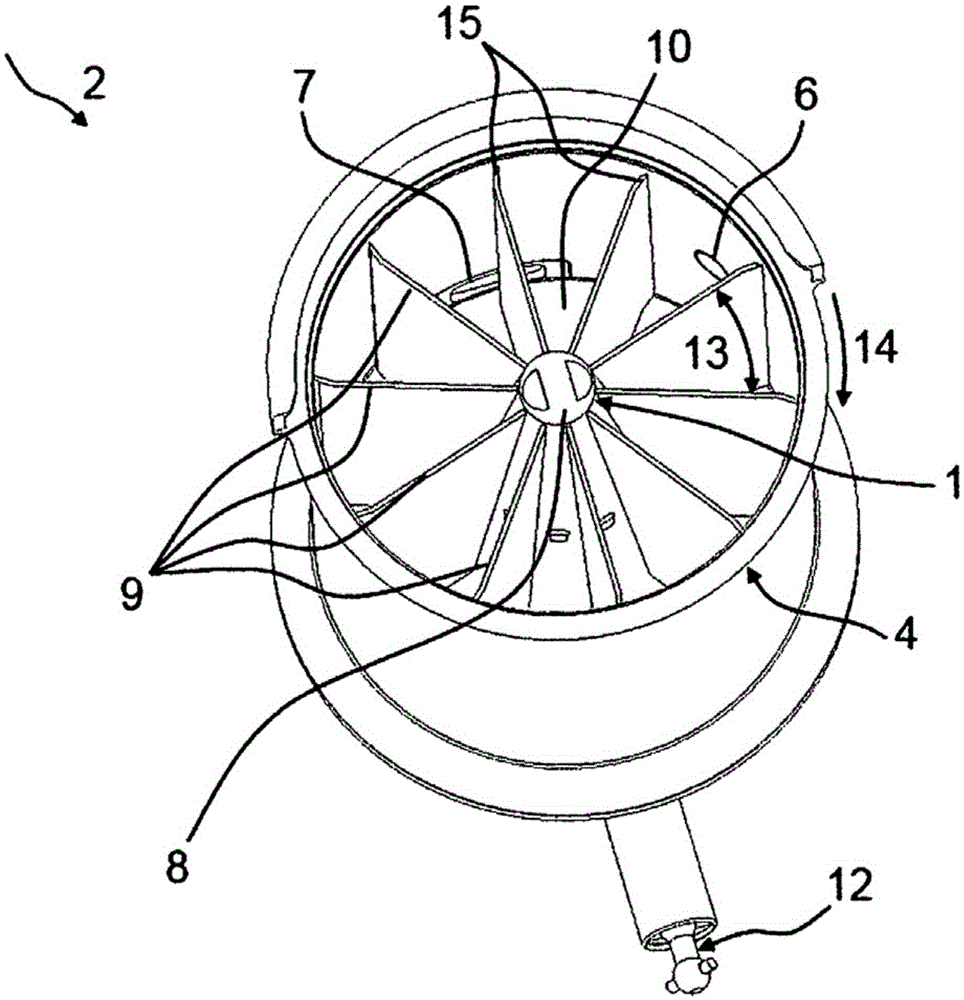

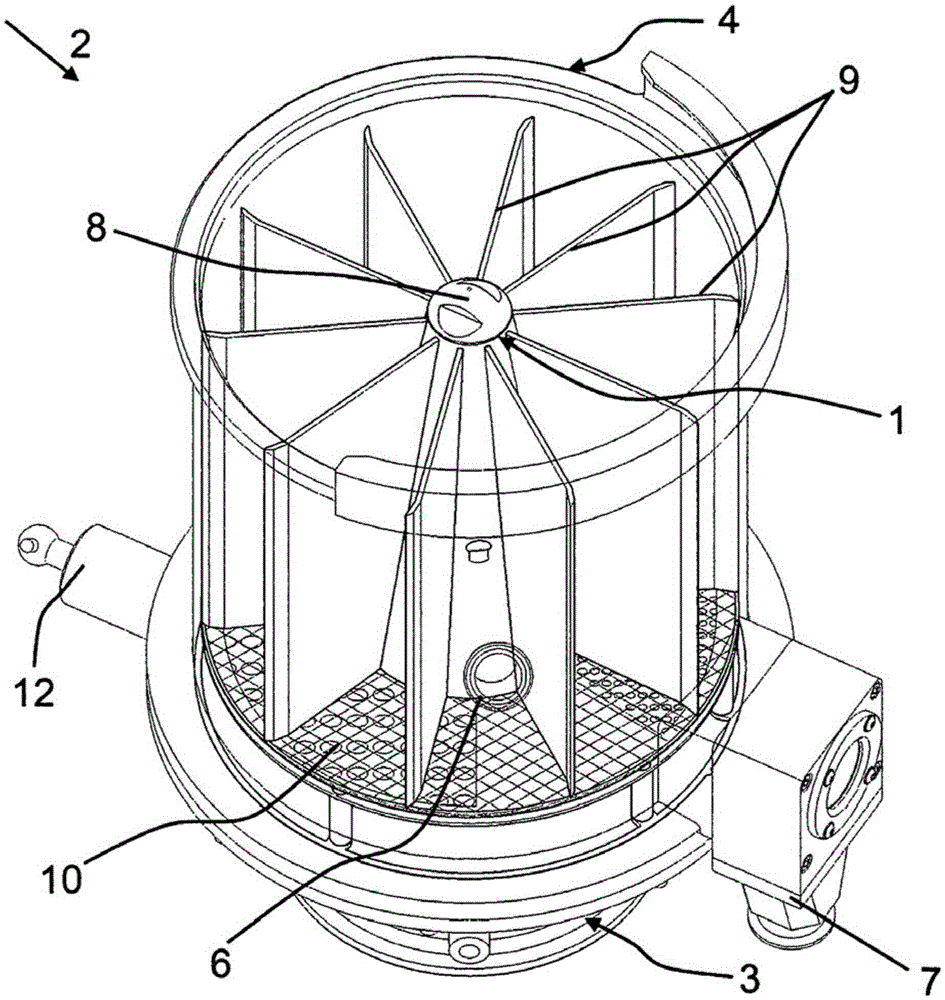

[0034] figure 1 shows a perspective view of an embodiment of a rotary dryer star 1 according to the invention, which is installed in a fluidization device 2 . The vortex chamber 4 arranged above the distributor chamber 3 comprises a housing 5 with a solid particle inlet unit 6 and a solid particle outlet unit 7 and a rotary dryer star 1 according to the invention rotating in the vortex chamber 4 , The star structure of the rotary dryer has a cone 8 and a partition wall 9 arranged on the cone, which is made of sheet metal, aluminum or the like, for example, and which divides the swirl chamber 4 into a plurality of subregions. The partition wall 9 extends over the entire structural height of the eddy chamber 4 . The partition wall 9 of the spin dryer star 1 , the housing 5 , the not shown inflow bottom 10 , eg a grid, and the not shown cover of the swirl chamber 4 enclose a treatment chamber 11 . The rotation of the rotary dryer star 1 according to the invention is generated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com