Tilted plate separator with variable inclination

A separator and inclined plate technology, applied in liquid separation, separation methods, grease/oily substance/float removal devices, etc., can solve the problems of inability to adjust coalescence efficiency and processing capacity, structure fixation, etc., and achieve good separation effect. , Guarantee the separation effect, improve the effect of process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

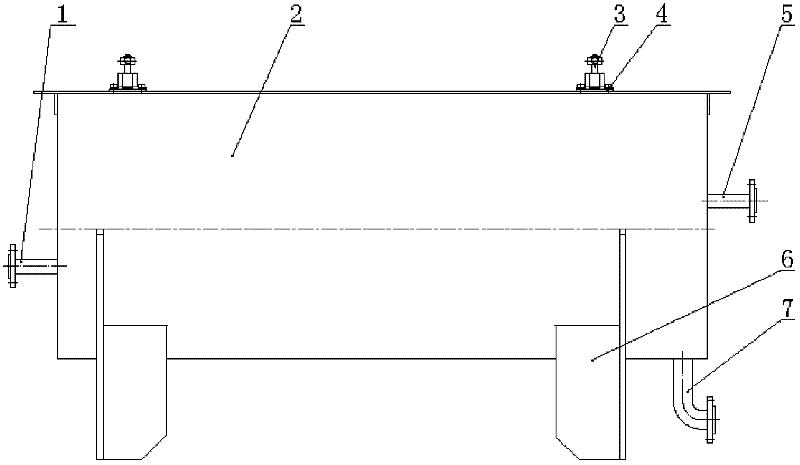

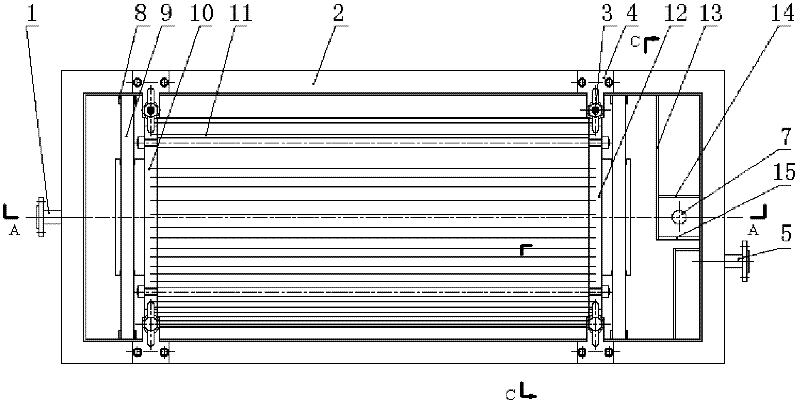

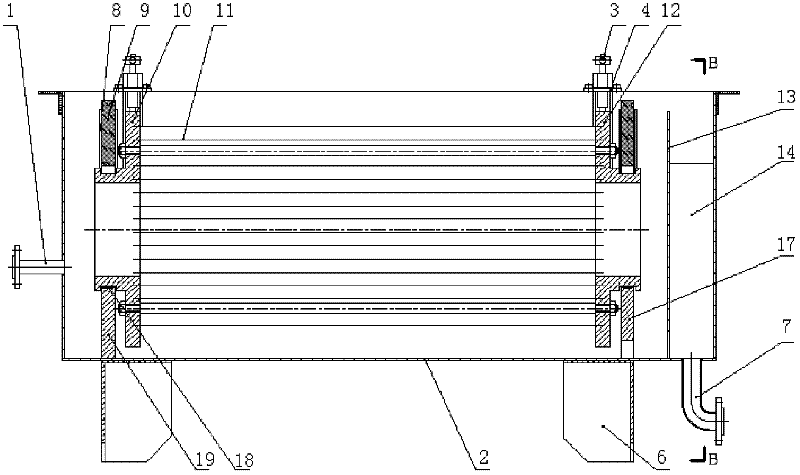

[0033] A slant plate separator with a variable inclination angle, comprising a shell 2, a base 6, a left baffle 19, a right baffle 17, a slant plate assembly, a feed pipe 1, a light phase outlet pipe 5 and a heavy phase outlet pipe 7, the The shell is coaxially fixed on the base, the feed pipe is fixed in the middle of the front end plate of the shell, the light phase outlet pipe is fixed on one side of the rear end plate of the shell, and the heavy phase outlet pipe is fixed in the bottom of the rear end of the shell , a left baffle and a right baffle are radially installed inside the casing, and a slant plate assembly is installed between the left baffle and the right baffle, and its innovative poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com