Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

151results about How to "Reduce surface recombination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

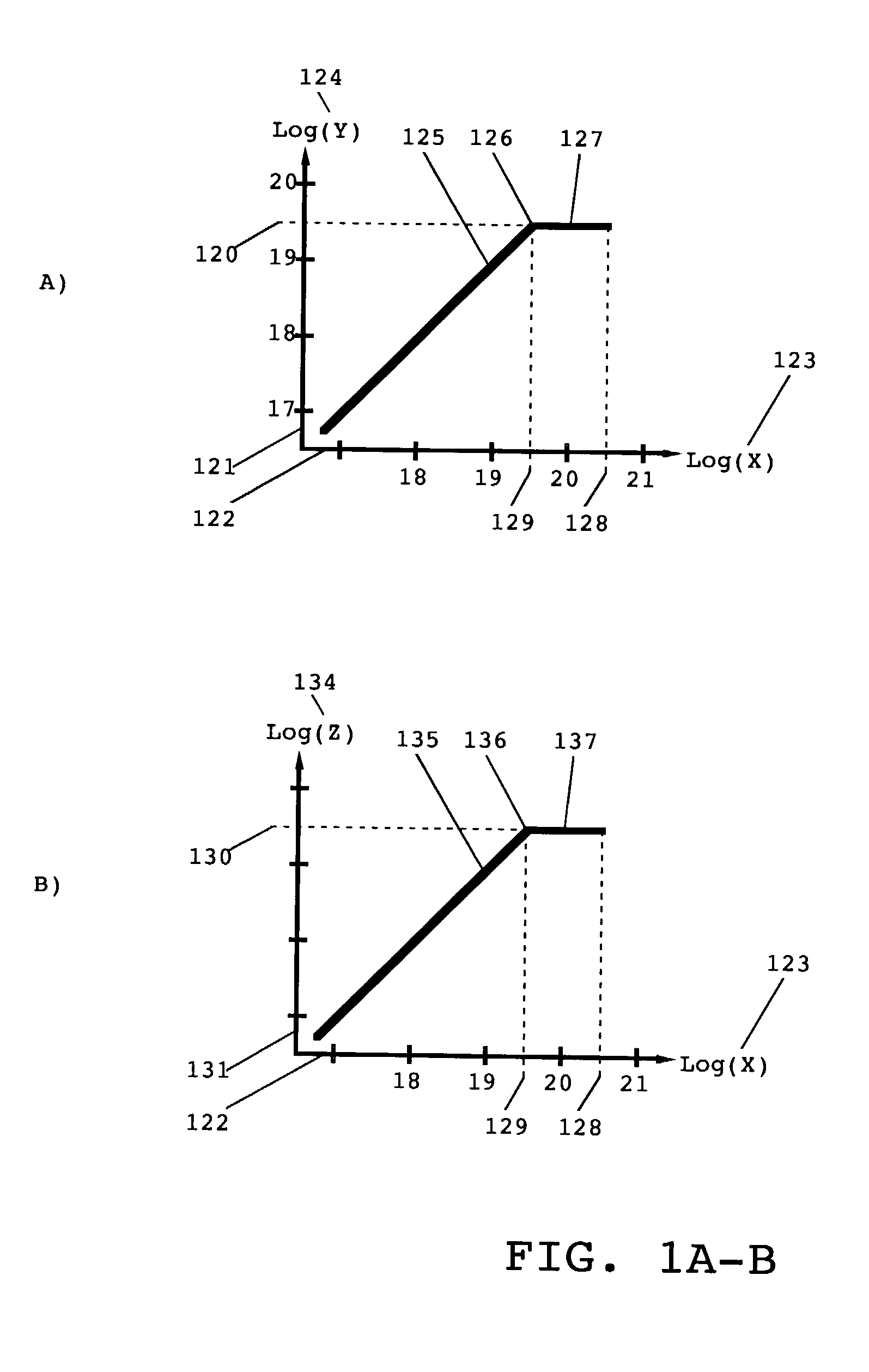

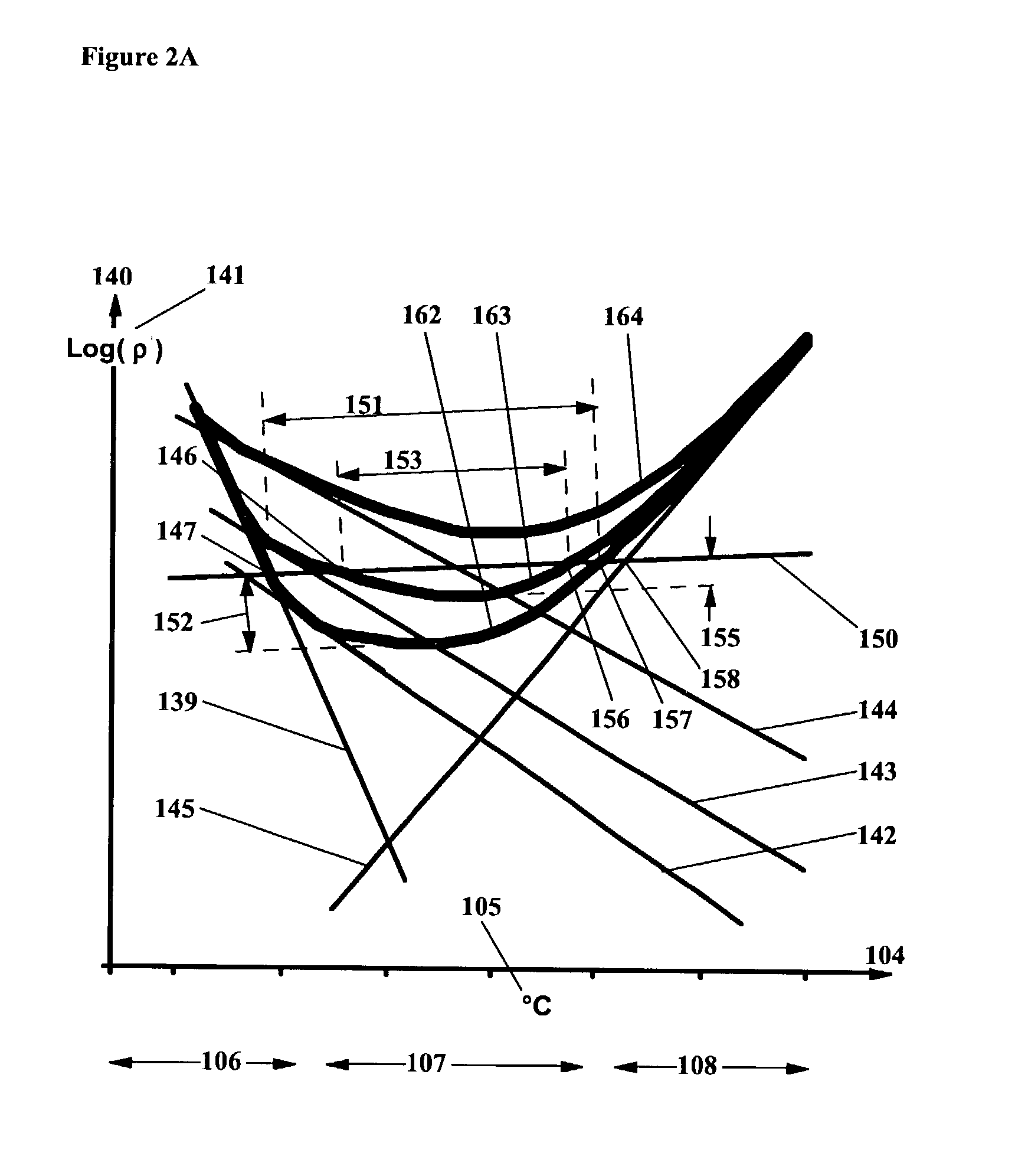

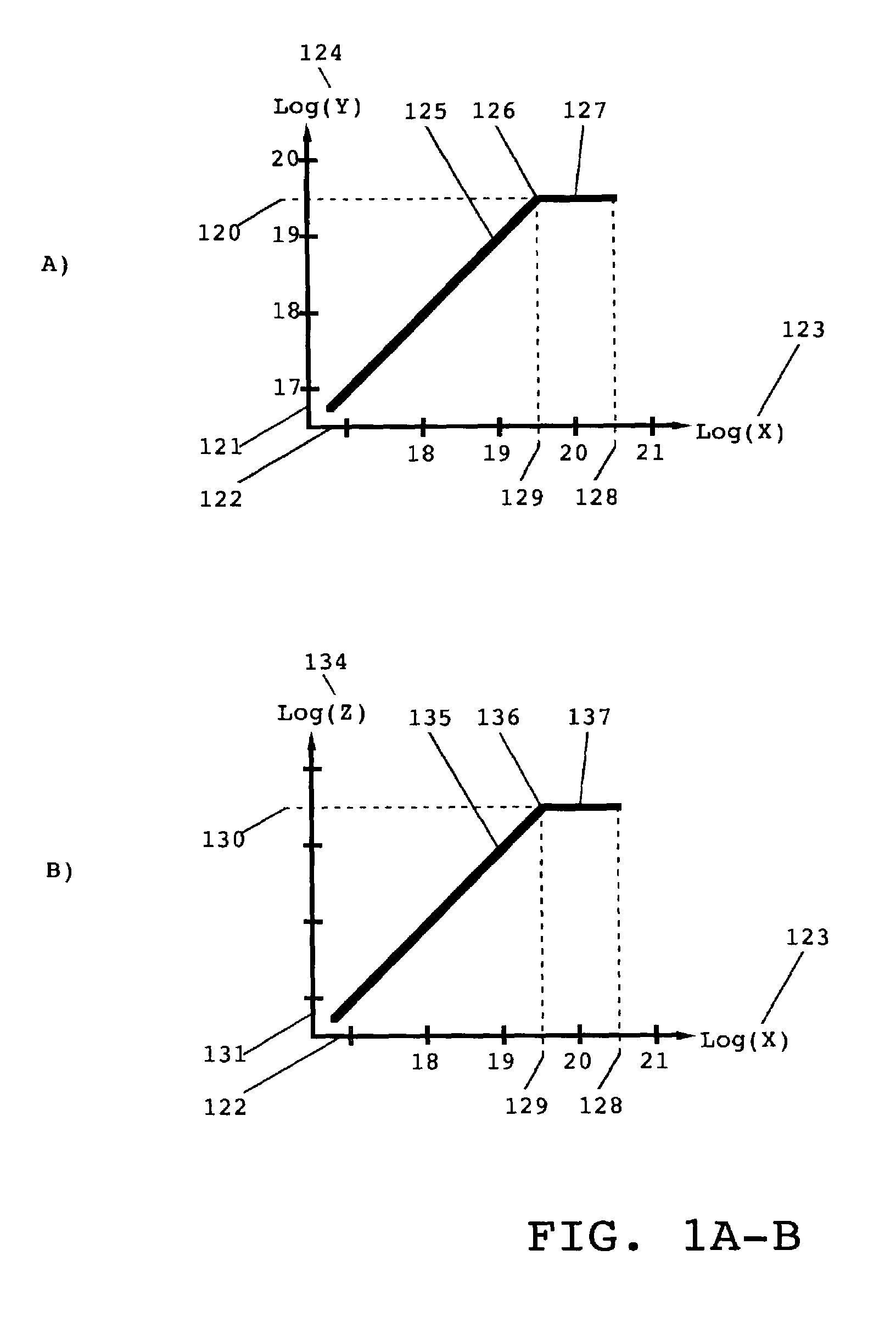

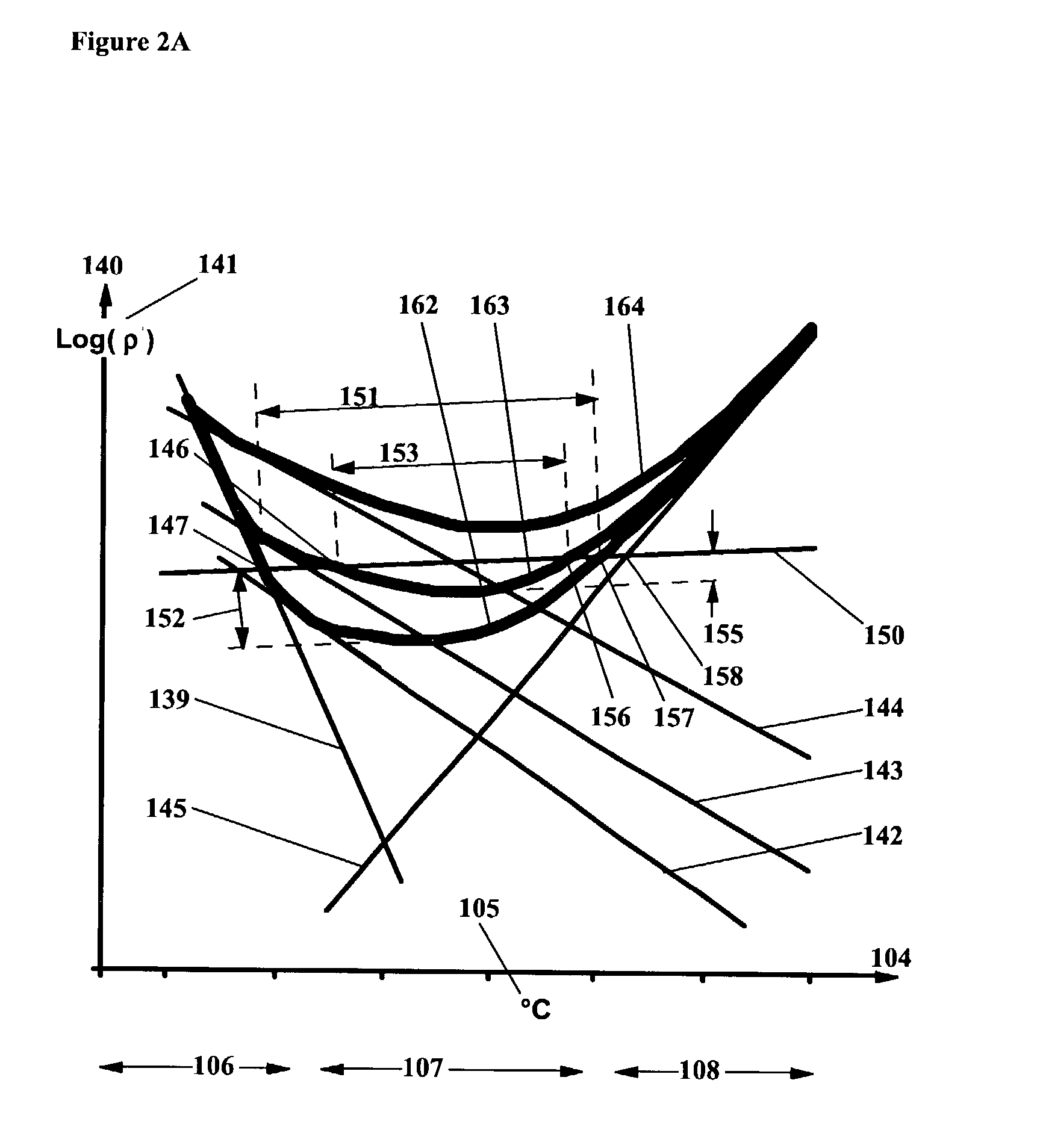

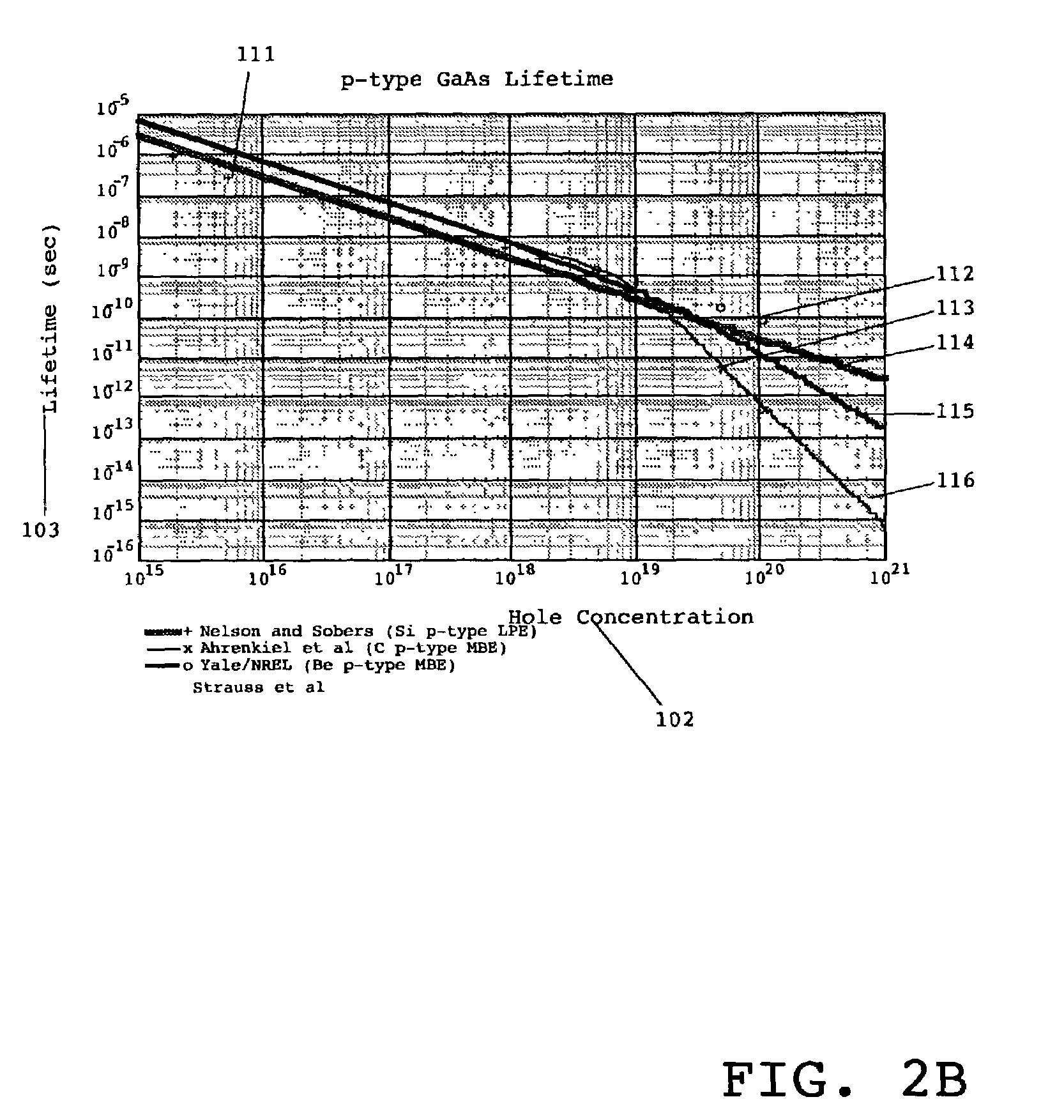

Methods of hyperdoping semiconductor materials and hyperdoped semiconductor materials and devices

InactiveUS20030121468A1Avoiding and mitigating formationEasy to operateTransistorPolycrystalline material growthSide effectSemiconductor materials

Methods are disclosed for producing highly doped semiconductor materials. Using the invention, one can achieve doping densities that exceed traditional, established carrier saturation limits without deleterious side effects. Additionally, highly doped semiconductor materials are disclosed, as well as improved electronic and optoelectronic devices / components using said materials. The innovative materials and processes enabled by the invention yield significant performance improvements and / or cost reductions for a wide variety of semiconductor-based microelectronic and optoelectronic devices / systems. Materials are grown in an anion-rich environment, which, in the preferred embodiment, are produced by moderate substrate temperatures during growth in an oxygen-poor environment. The materials exhibit fewer non-radiative recombination centers at higher doping concentrations than prior art materials, and the highly doped state of matter can exhibit a minority carrier lifetime dominated by radiative recombination at higher doping levels and higher majority carrier concentrations than achieved in prior art materials. Important applications enabled by these novel materials include high performance electronic or optoelectronic devices, which can be smaller and faster, yet still capture or emit light efficiently, and high performance electronics, such as transistors, which can be smaller and faster, yet cooler.

Owner:YALE UNIV

Method for preparing N-type crystalline silicon solar cell with aluminum-based local emitters on back side

InactiveCN101853897AAvoid damageAvoid Edge Leakage SituationsFinal product manufactureSemiconductor devicesP–n junctionMaterials science

The invention provides a method for preparing an N-type crystalline silicon solar cell with aluminum-based local emitters on the back side. The method comprises the following steps: firstly, selecting N-type silicon wafers to carry out the surface-textured etching process; further forming a front surface field through phosphorous diffusion; depositing a passivating film on the front surface after the phosphorosilicate glass is formed during the removal of diffused phosphorous; carrying out the back-side chemical polishing process on the silicon wafers to remove the N+ layer formed on the back side during the phosphorous diffusion; then, sequentially printing an aluminum layer or a silver-aluminum layer through the passivating film deposited on the back side, local holes or grooves on the back side and screens on the back side; then, printing silver paste on the front surface; and finally, carrying out the one-step sintering process to form a local P+ layer on the back side and allowing the P+ layer to coming into ohmic contact with the electrodes on the front and back surfaces. By using the N-type substrate, forming local aluminum-based P-N junctions on the back side and further using the back-side chemical polishing process to remove the edge junctions, the invention can substitute for the conventional stacking-type plasma etching process, simplify the technological procedures and further bring a series of performance improvement to cells.

Owner:JA YANGZHOU SOLAR PHOTOVOLTAIC ENG

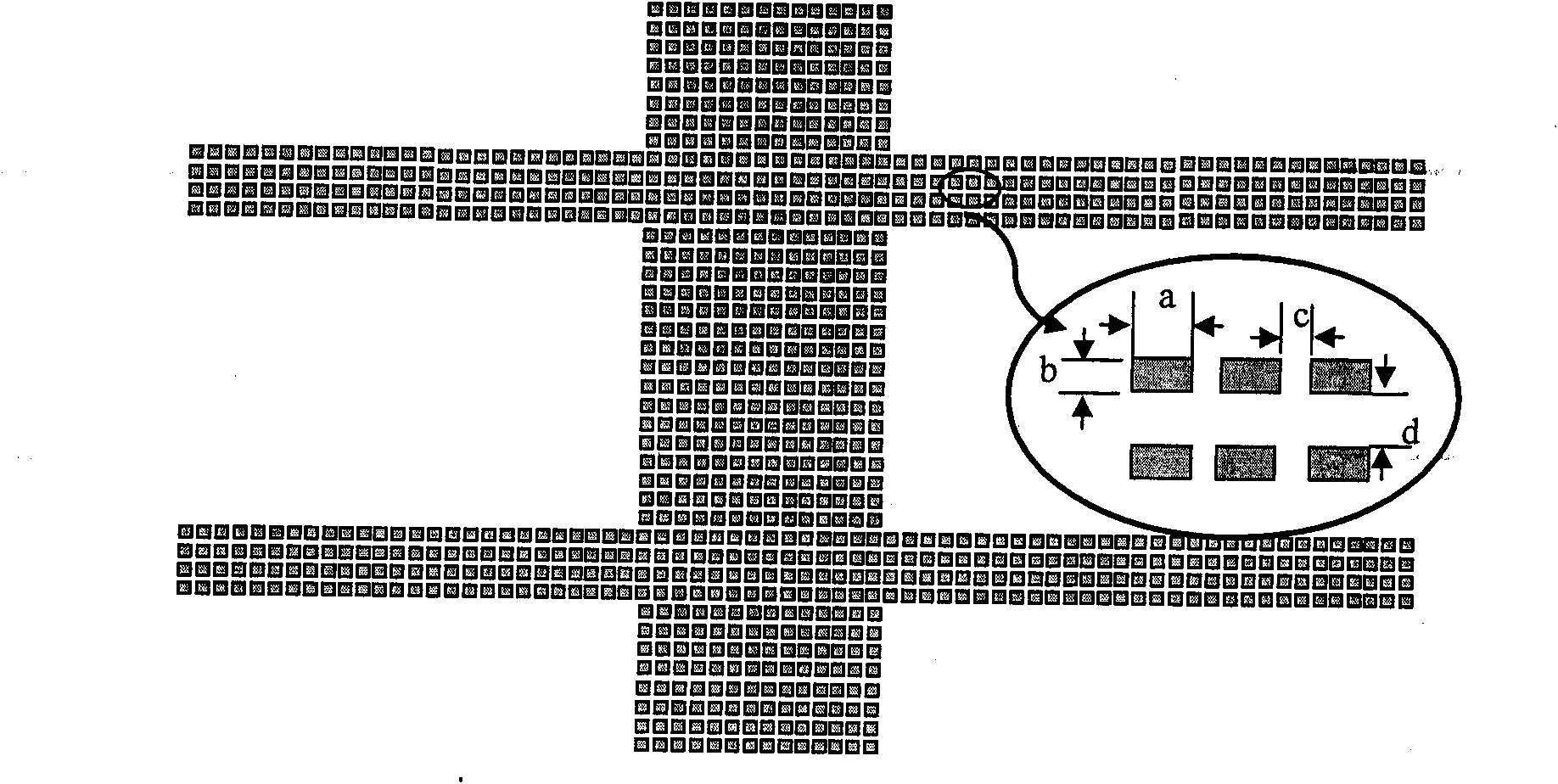

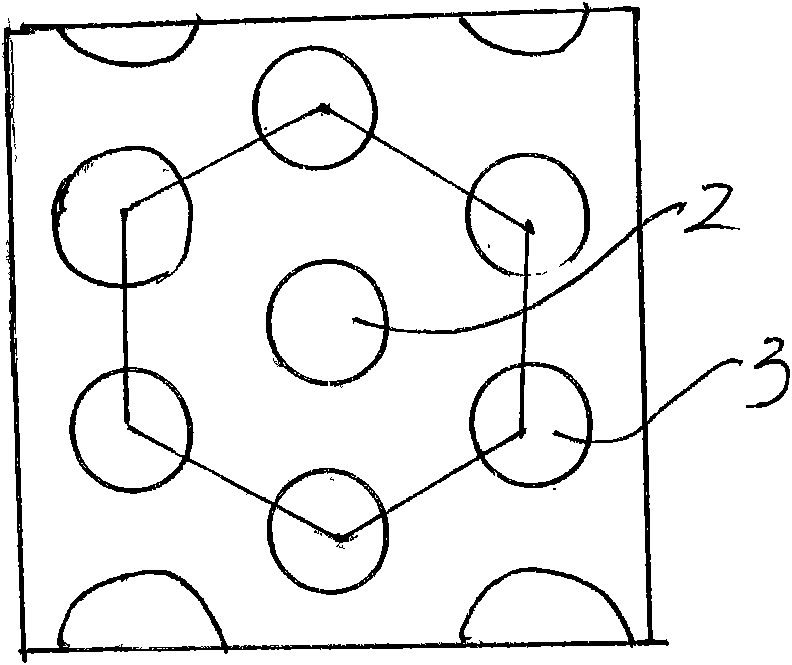

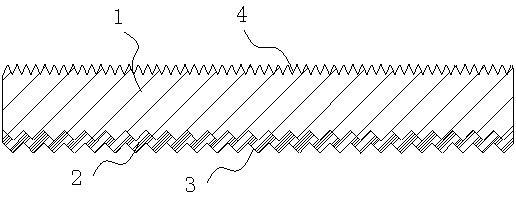

Method for preparing front electrodes of solar cells

InactiveCN101562217AReduce surface recombinationHigh aspect ratioFinal product manufactureSemiconductor devicesStencil printingChemical plating

The invention relates to a method for preparing front electrodes of solar cells, which comprises the following steps: firstly preparing discontinuous dot electrodes; and then connecting the dot electrodes by electroplating technology to realize that the electrodes collect and transport current but dielectric films still exist between the dot electrodes to have the function of passivation. The discontinuous dot electrodes are prepared by photoetching, evaporation and dissection methods, or firstly printed by silkprint, stencil printing or ink jet printing and then prepared by a sintering method. The electroplating is photoinductive electroplating or chemical plating. The dot electrodes effectively reduce surface recombination; and the adopted electroplating technology not only simply and accurately realizes the connection of the dot electrodes, but also effectively reduces the width of grid lines, namely reduces electrode shading areas and further reduces the surface recombination so as to contribute to improving battery efficiency.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

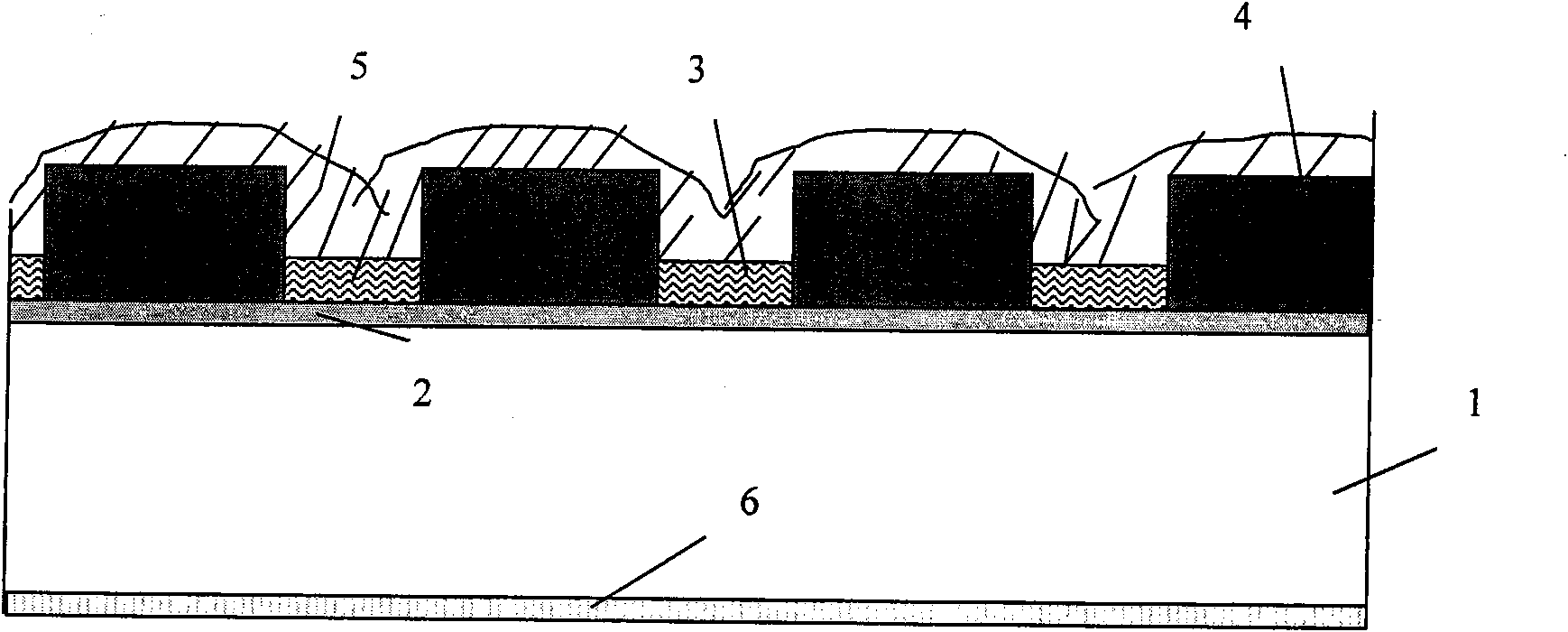

Methods of hyperdoping semiconductor materials and hyperdoped semiconductor materials and devices

InactiveUS7179329B2Easy to operateIncrease computing speedTransistorPolycrystalline material growthSide effectSemiconductor materials

Methods are disclosed for producing highly doped semiconductor materials. Using the invention, one can achieve doping densities that exceed traditional, established carrier saturation limits without deleterious side effects. Additionally, highly doped semiconductor materials are disclosed, as well as improved electronic and optoelectronic devices / components using said materials. The innovative materials and processes enabled by the invention yield significant performance improvements and / or cost reductions for a wide variety of semiconductor-based microelectronic and optoelectronic devices / systems.Materials are grown in an anion-rich environment, which, in the preferred embodiment, are produced by moderate substrate temperatures during growth in an oxygen-poor environment. The materials exhibit fewer non-radiative recombination centers at higher doping concentrations than prior art materials, and the highly doped state of matter can exhibit a minority carrier lifetime dominated by radiative recombination at higher doping levels and higher majority carrier concentrations than achieved in prior art materials. Important applications enabled by these novel materials include high performance electronic or optoelectronic devices, which can be smaller and faster, yet still capture or emit light efficiently, and high performance electronics, such as transistors, which can be smaller and faster, yet cooler.

Owner:YALE UNIV

Glass powder and silver aluminum paste comprising glass powder and used on positive side of N-type double-sided solar cell

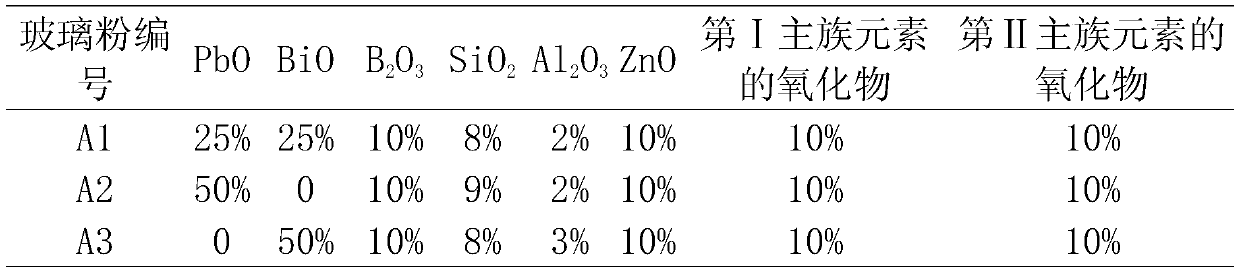

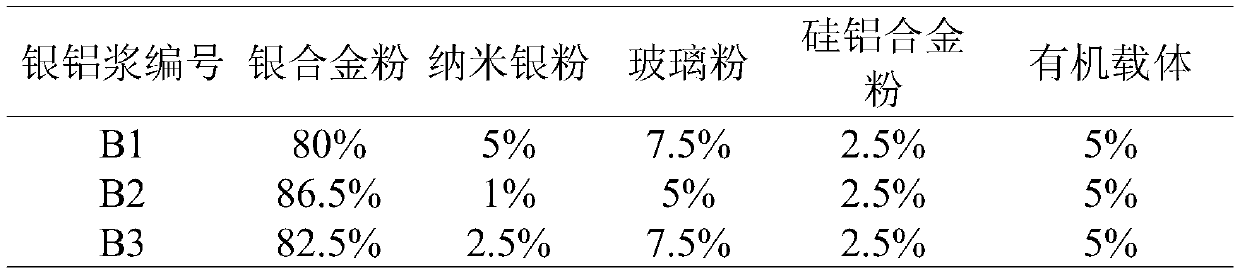

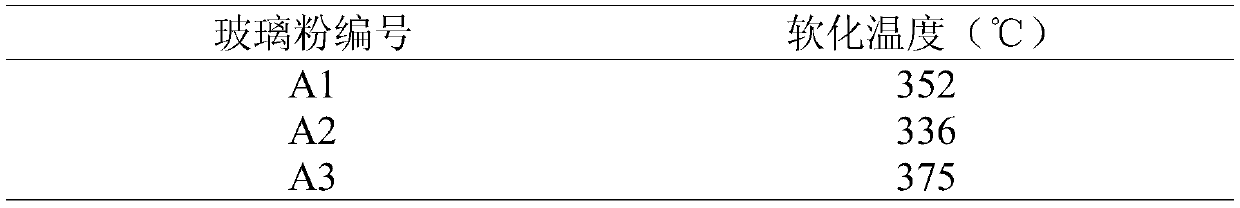

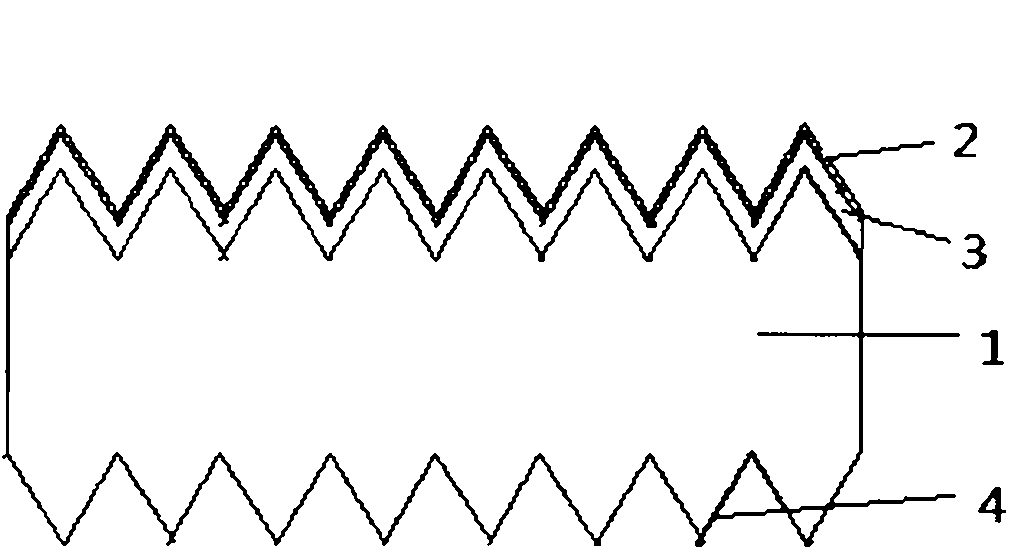

PendingCN110040968ALow softening temperatureIncrease the degree of vitrificationTransportation and packagingMetal-working apparatusMass ratioSilicon solar cell

The invention discloses glass powder and silver aluminum paste which comprises the glass powder and used on the positive side of an N-type double-sided solar cell. The silver aluminum paste comprisesconductive silver powder, silicon aluminum alloy powder, the glass powder and an organic carrier, wherein the glass powder is prepared from the following components in percentage by weight: 0-50% of PbO, 0-50% of BiO, 5-15% B2O3, 8-9% of SiO2, 2-3% of Al2O3 and 5-15% of ZnO; the mass ratio of silicon to aluminum in the glass powder is (4-5) to 1; the content of the conductive silver powder is 80wt% to 90wt%; the conductive silver powder comprises nano silver powder and silver alloy powder in a mass ratio of 1 to (18-90). The glass powder not only guarantees the corrosiveness of SiNx, but alsodoes not cause relatively strong metallized composition. The silver aluminum paste prepared by using the glass powder solves the problem of the contradiction between contact resistance and open circuit voltage when the silver aluminum paste is printed on the positive side of an N-type crystalline silicon solar cell.

Owner:NANTONG T SUN NEW ENERGY CO LTD

Method for passivating back of crystal silicon solar cell

InactiveCN101916795AEnhanced back reflectionImproved long-wavelength spectral responseFinal product manufactureSemiconductor devicesScreen printingLaser etching

The invention discloses a method for passivating the back of a crystal silicon solar cell. The method comprises the following steps of: depositing a SiN* anti-reflection film on the front of the solar cell, corroding the back of the solar cell in heated alkali liquor by using the SiN* anti-reflection film as a mask to obtain a polished surface required by passivation, then depositing double film passivation layers on the polished surface to form a back passivation layer, forming an electrode window on the back passivation layer by adopting laser etching or screen printing of corrosive slurry, and finally forming a local contact back electrode on the electrode window by adopting a screen printing or sputtering method. The method greatly improves the long wave response of the solar cell and improves the conversion efficiency of the solar cell; moreover, a full-aluminum back field structure is canceled, so the method reduces the bending of the solar cell and is more adaptive to the thinning tendency of the solar cell.

Owner:JA SOLAR

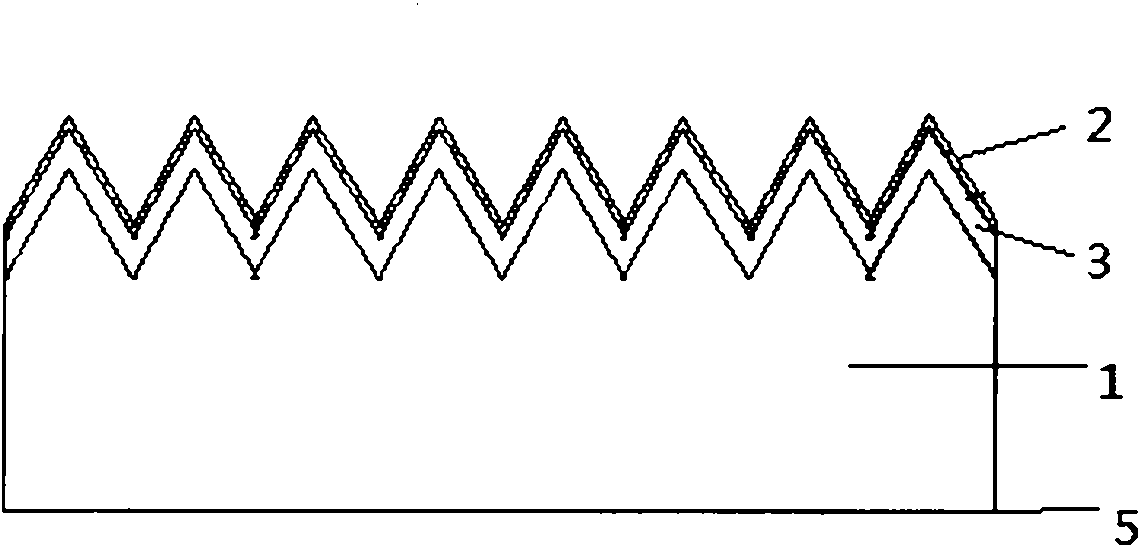

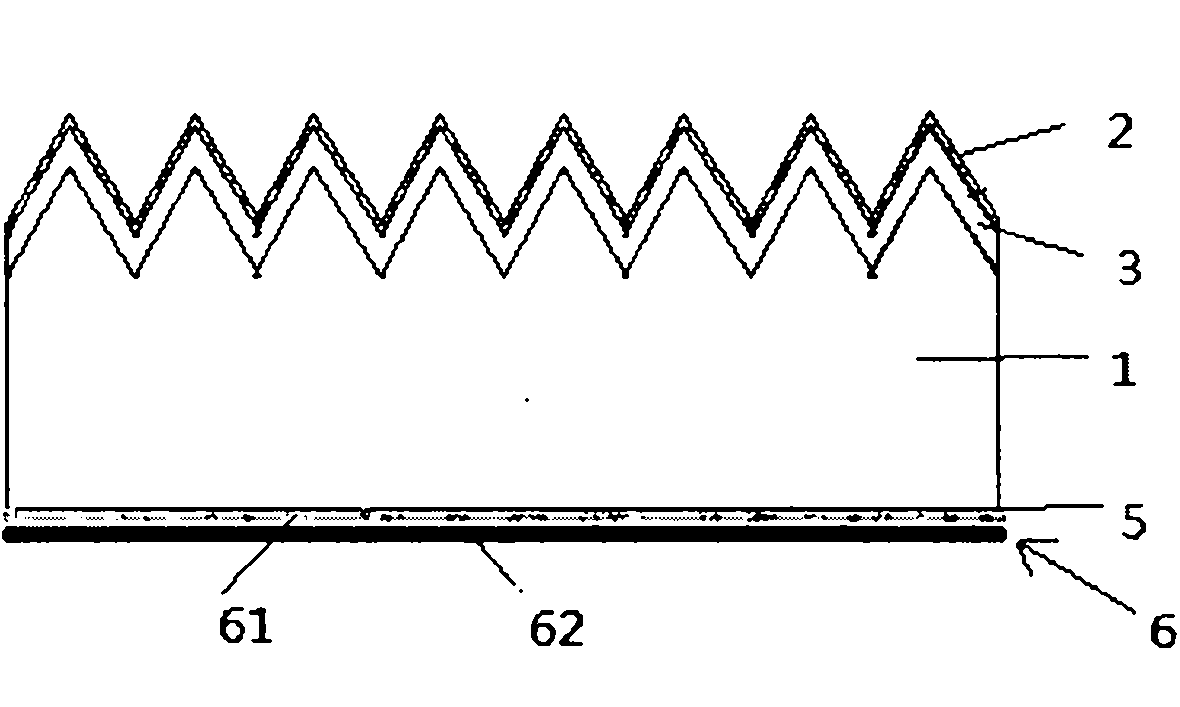

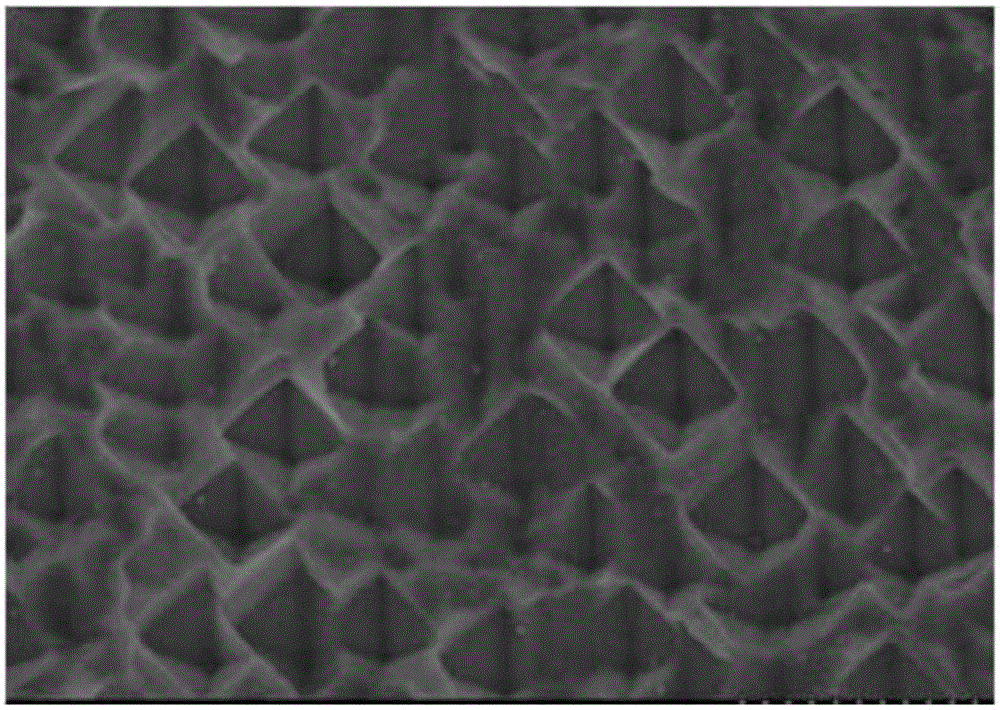

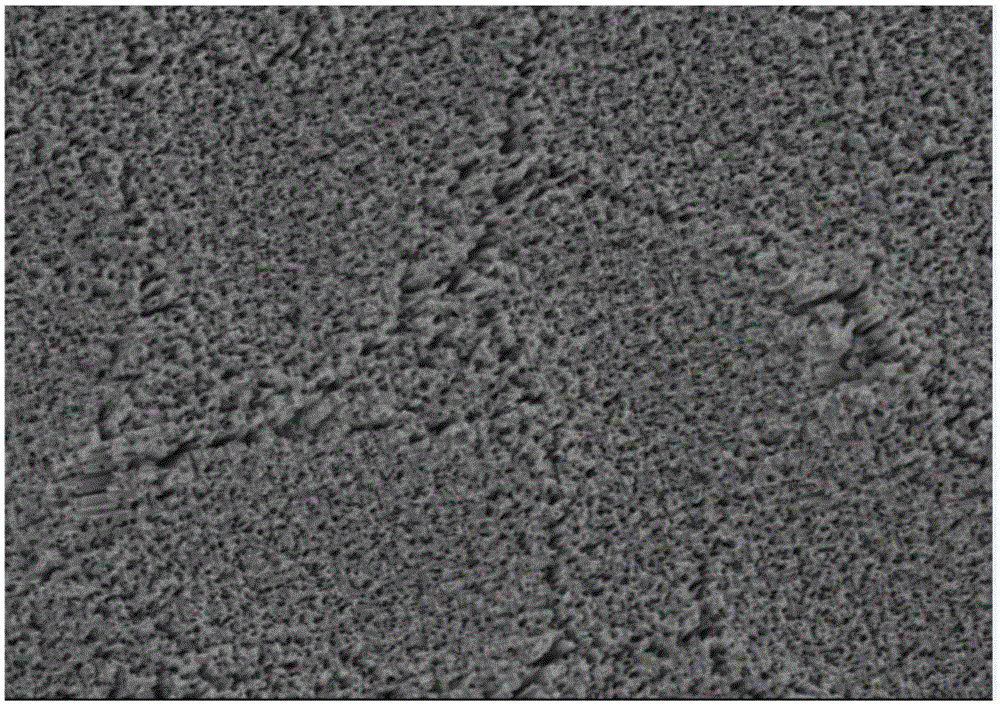

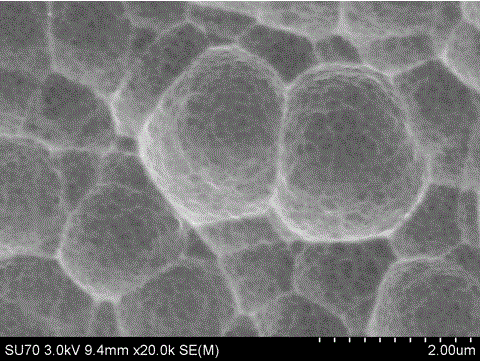

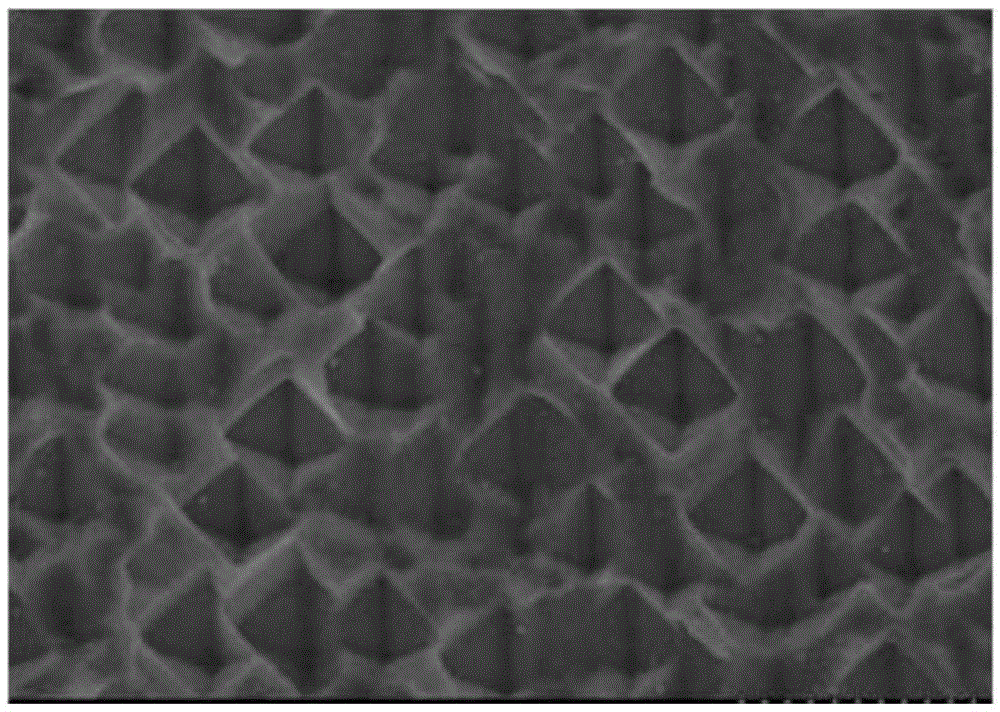

Inverted pyramid structure of polysilicon surface and fabrication method of inverted pyramid structure

InactiveCN105047734AReduce reflectivityImprove trapping effectFinal product manufacturePhotovoltaic energy generationNano structuringTrapping

The invention discloses an inverted pyramid structure of a polysilicon surface and a fabrication method of the inverted pyramid structure. The method comprises the following steps: preparing black silicon by different methods; rinsing a sample in a mixed liquid of hydrogen peroxide and ethanol amine; and carrying out retreatment on the washed black silicon in a mixed liquid of hydrogen peroxide, hydrofluoric acid, metaphosphoric acid and ammonium fluoride, so as to form the inverted pyramid structure of the polysilicon surface. A wet-chemical method which is different from acid and alkaline corrosion is adopted. According to the method, the effects of anisotropy can be reduced to the maximal extent; and the black silicon with different nano-structures can be corroded into a nano textured structure with a regular inverted pyramid structure through oxidation. Compared with the traditional polycrystalline silicon texture, the polysilicon inverted pyramid light-trapping structure disclosed by the invention is relatively high in light utilization rate and relatively low in reflectivity, so that the polysilicon inverted pyramid light-trapping structure has the characteristics of the inverted pyramid structure; compared with the traditional high surface recombination of a small and dense structure of the black silicon, the surface recombination is obviously reduced; and the efficiency of a solar cell is higher.

Owner:江苏辉伦太阳能科技有限公司

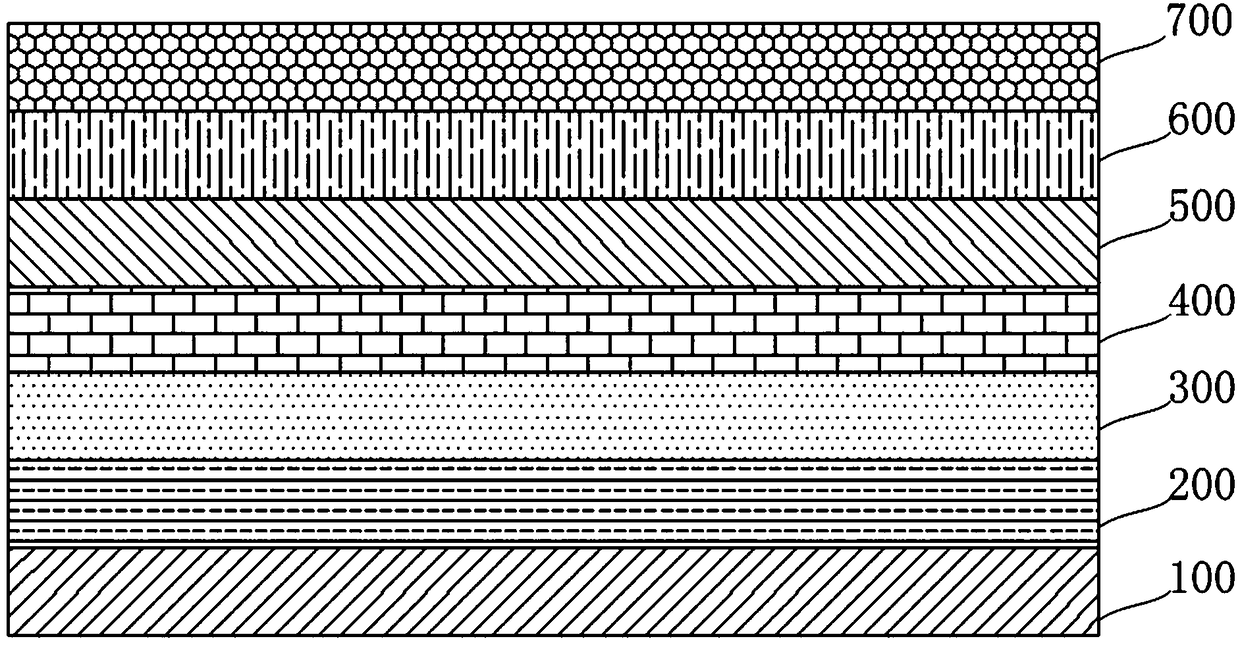

Film solar cell

InactiveCN108269868AIncrease the open circuit voltageImprove photoelectric conversion efficiencyPhotovoltaic energy generationSemiconductor devicesElectronic structureIon exchange

The invention discloses a film solar cell, and the cell comprises a substrate on which a molybdenum layer, a first alkaline element layer, a light absorbing layer, a second alkaline element layer, a buffering layer and a transparent conductive layer are sequentially disposed. According to the invention, alkali metal elements in the second alkaline element layer and the elements in the light absorbing layer are enabled to react to form a film layer containing the alkali metal elements through the setting of the second alkaline element layer, thereby changing the components of the surface of thelight absorbing layer, further changing the electronic structure of the light absorbing layer through ion exchange, reduces the surface recombination of carriers between layers, enabling the post-preparation processing technology to increase a battery open-circuit voltage, and improving the photoelectric conversion efficiency of the cell.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

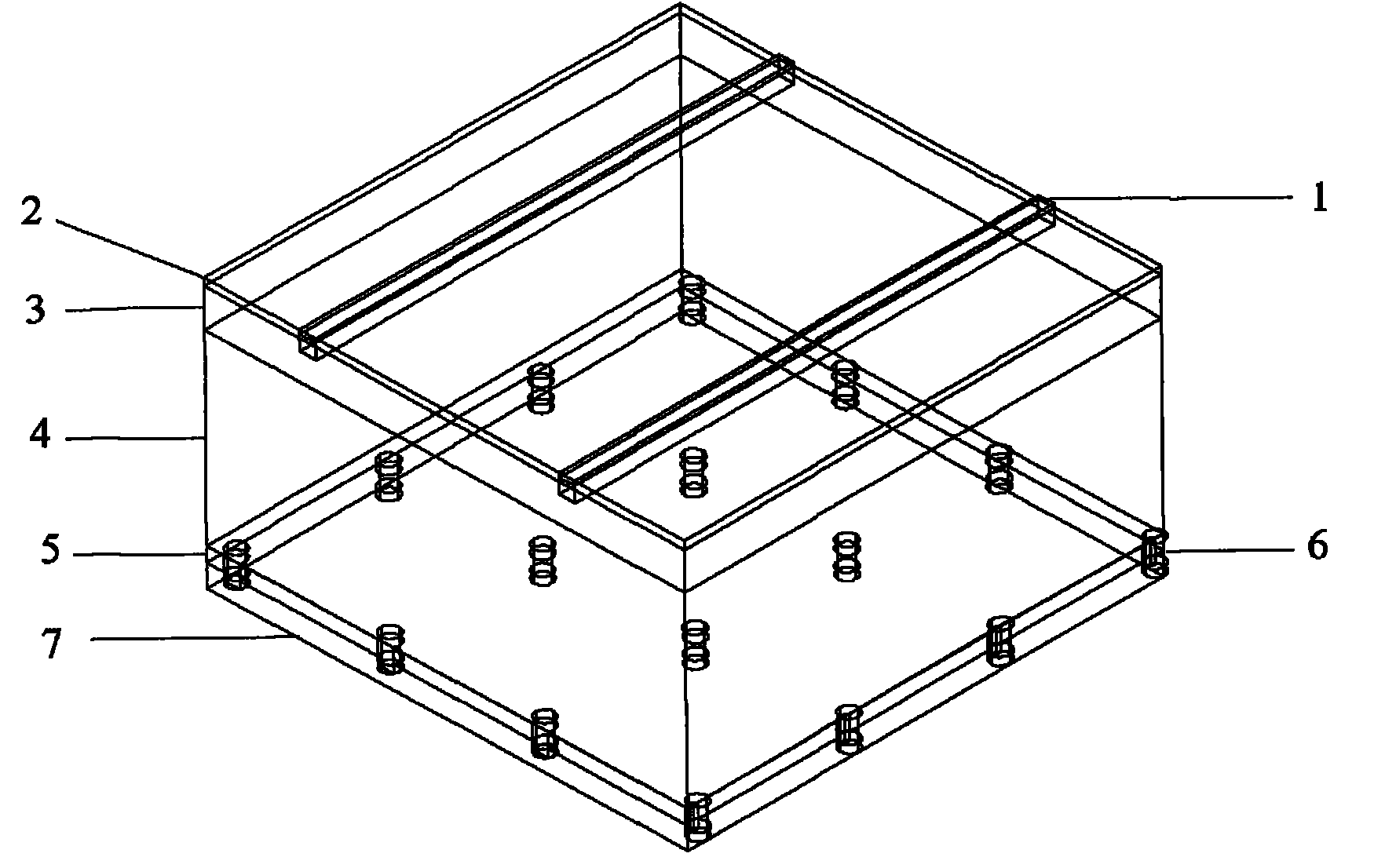

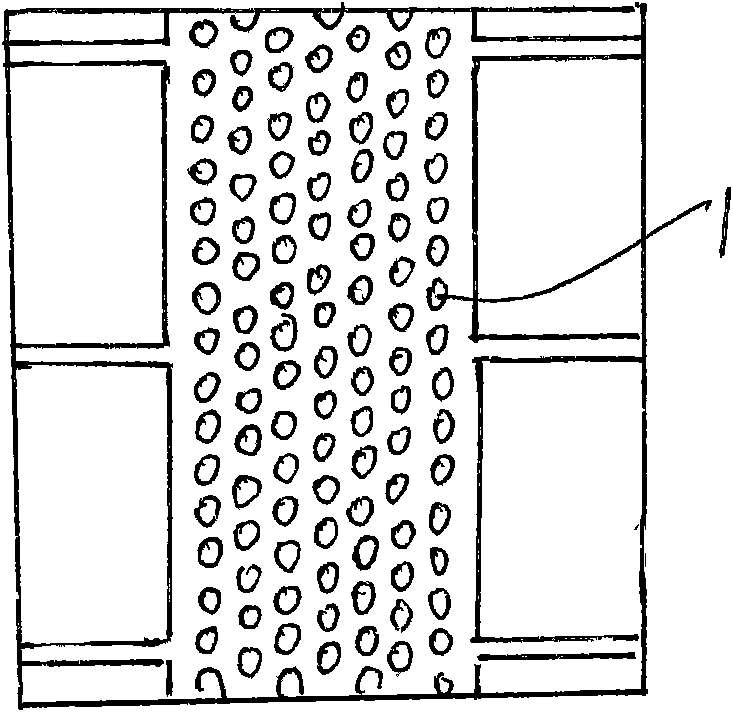

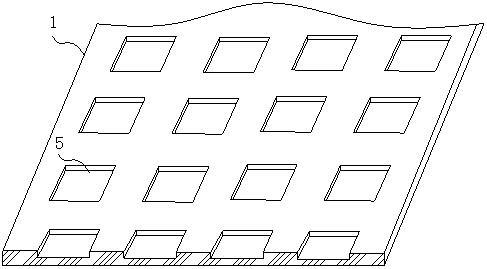

Front and back surface electrodes of screen printing crystalline silicon solar cell and manufacturing method thereof

ActiveCN101609848AStress reliefLess bendingFinal product manufactureSemiconductor devicesScreen printingConductive paste

The invention discloses front and back surface electrodes of a screen printing crystalline silicon solar cell and a manufacturing method thereof; array points which are not printed into conductive paste are manufactured in an electrode main gate line; and the graphics of each array point is in a closed type. The manufacturing method comprises the step of arranging latex film array points on the screen printing plate electrode main gate line for blocking the conductive paste. The positive and back surface electrodes of the screen printing crystalline silicon solar cell and the manufacturing method thereof can effectively save the conductive paste on the positive and back surfaces of the crystalline silicon solar cell, and effectively eliminate the stress caused by different expansion coefficients of silver silicon alloy and silicon, thereby reducing the bending rate of a cell film and the welding debris rate of a component; the invention can enhance the adhesion firmness of the main gate line conductive paste on the silicon surface after being sintered and effectively solve the falling-off problem of a silver main gate line; and the invention reduces the surface contact area of the conductive paste and the silicon, and increases the open-circuit voltage and the short-circuit current.

Owner:HANWHA SOLARONE QIDONG

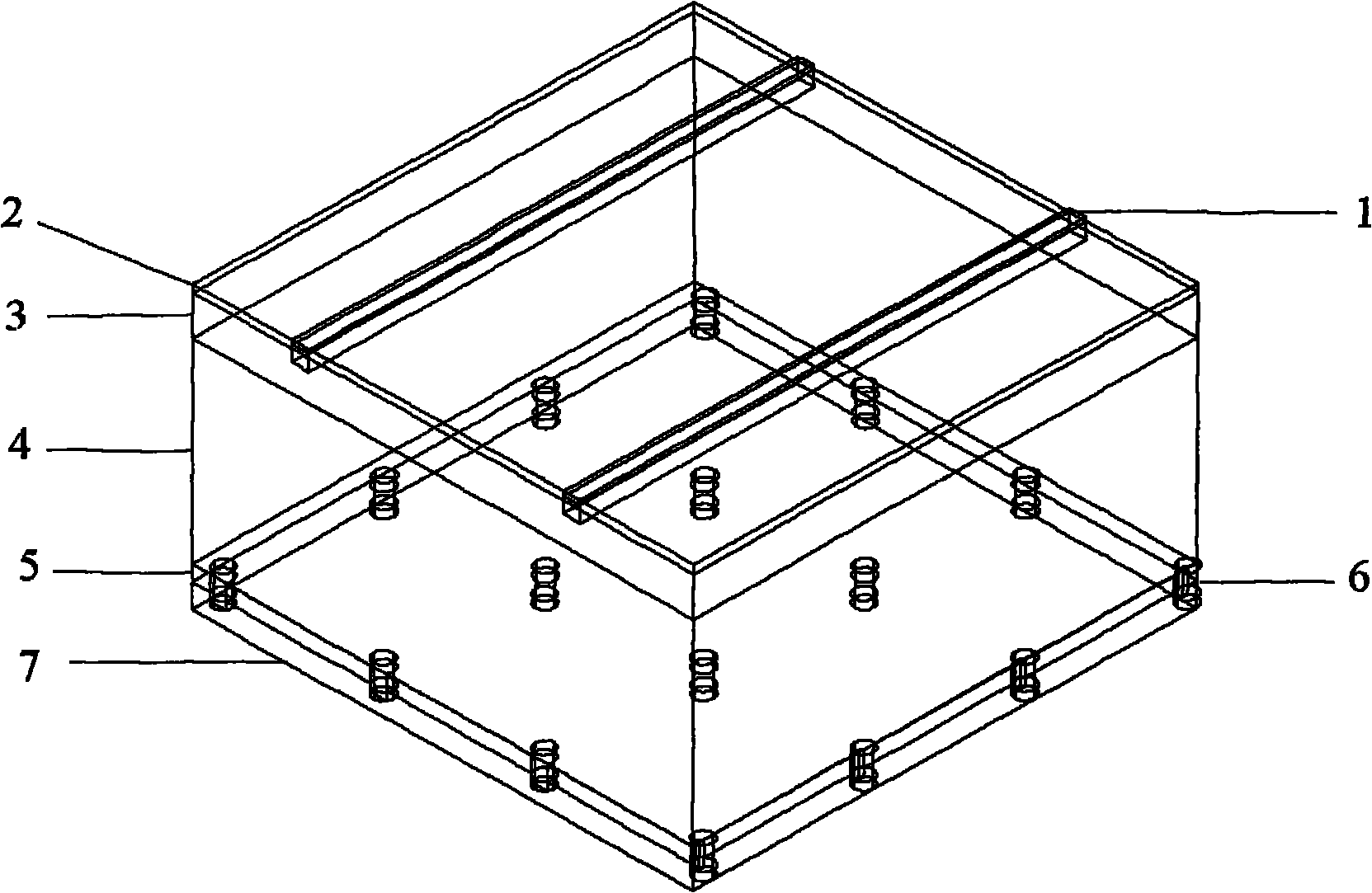

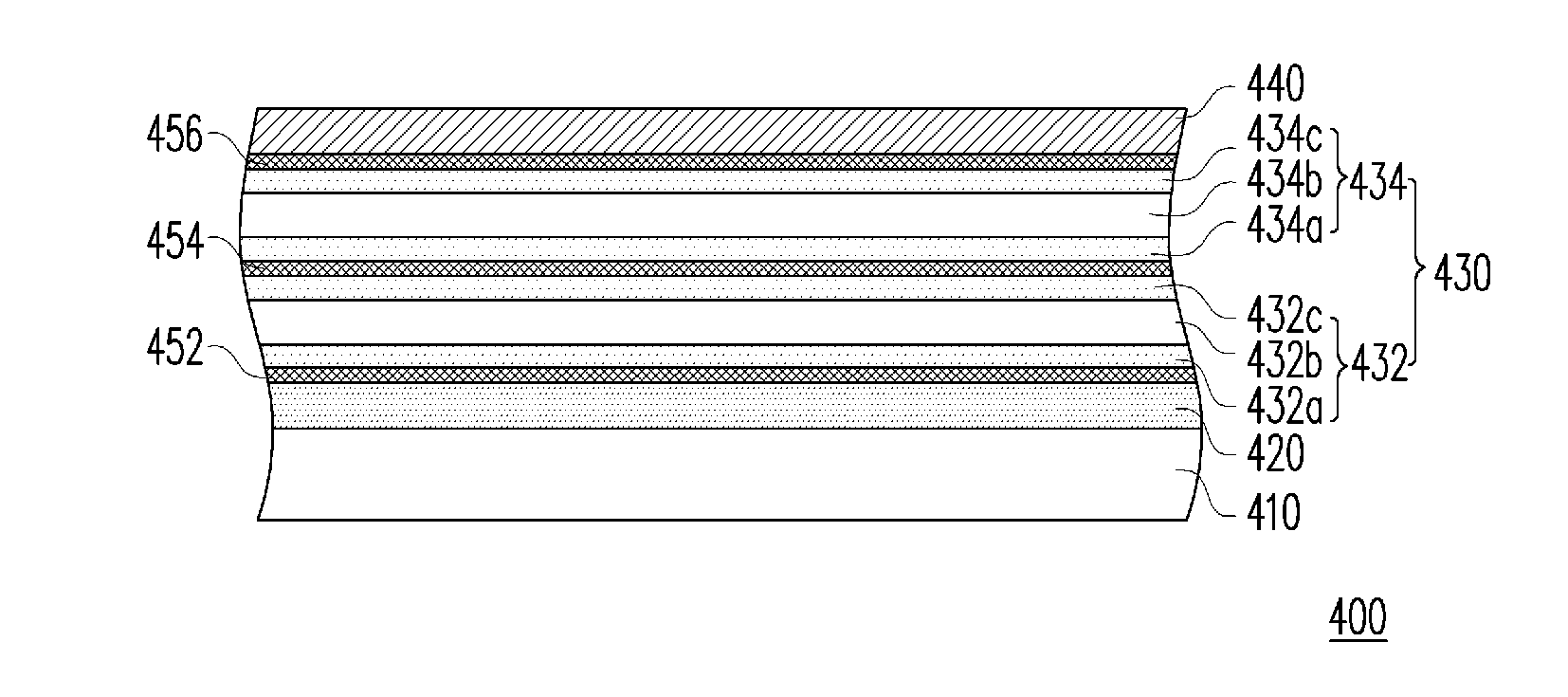

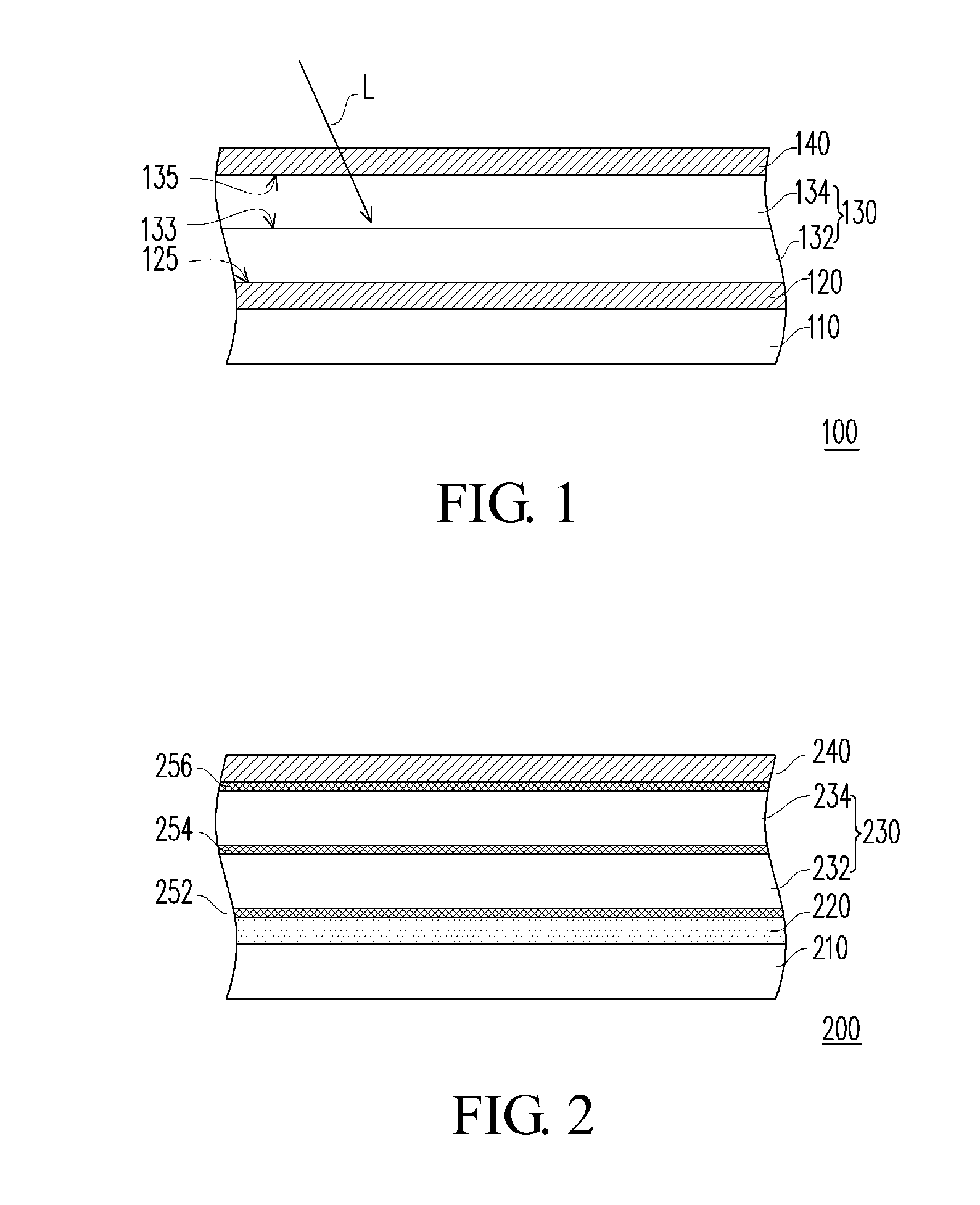

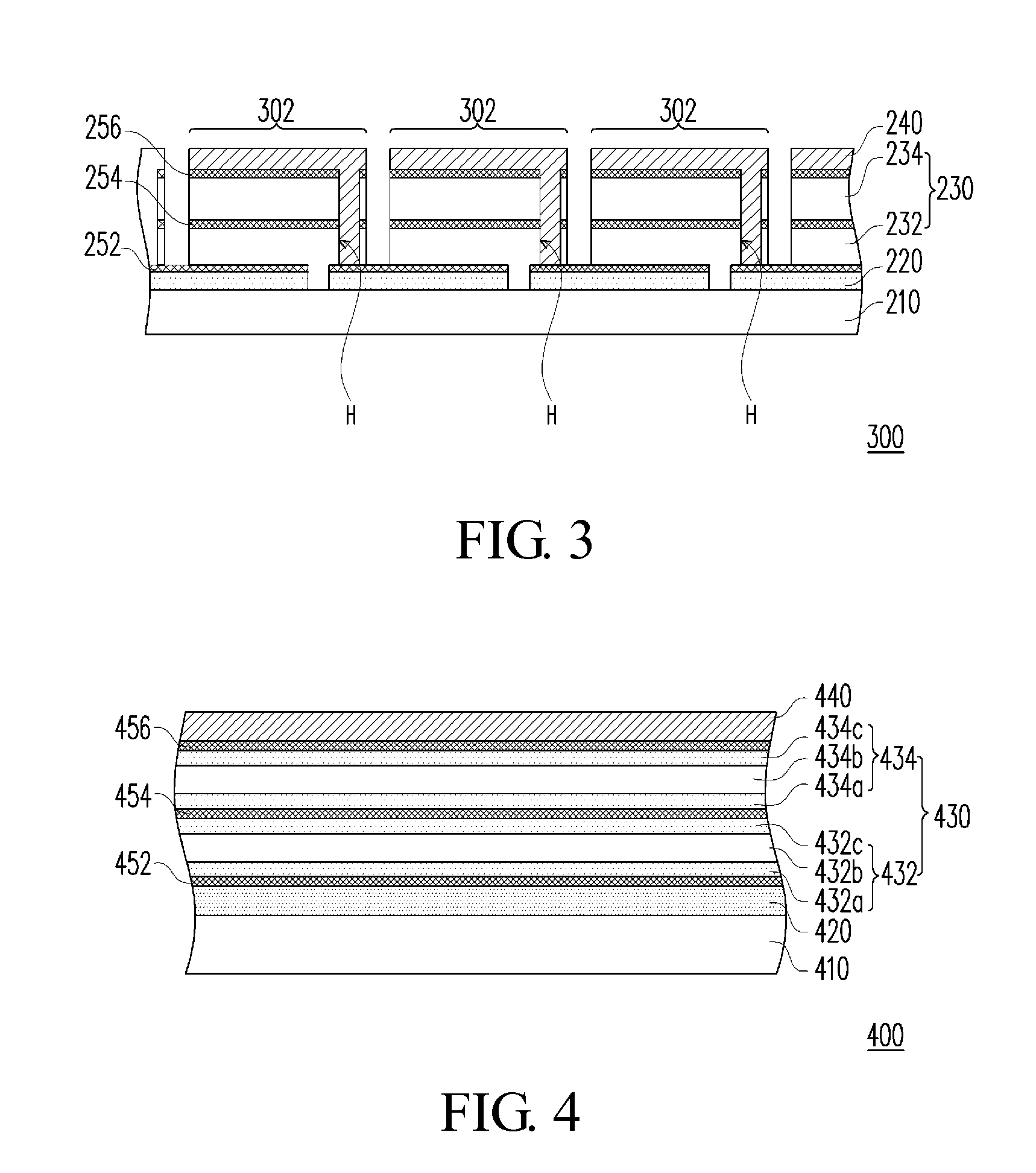

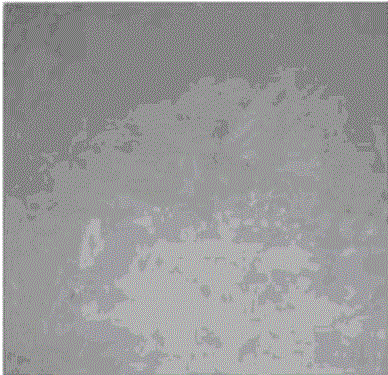

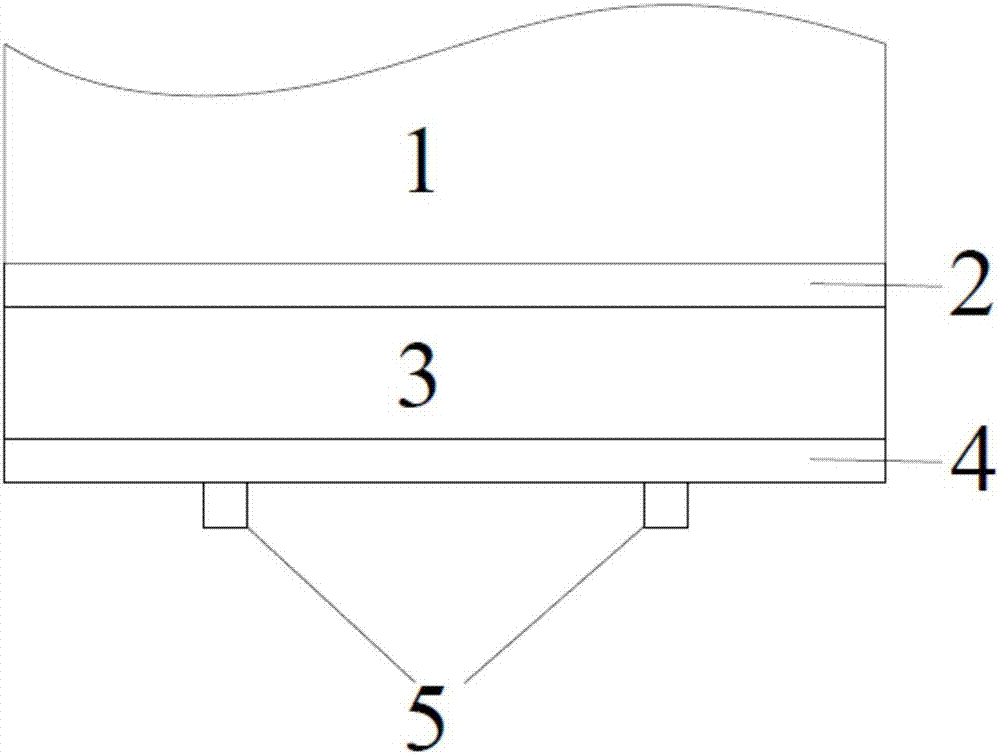

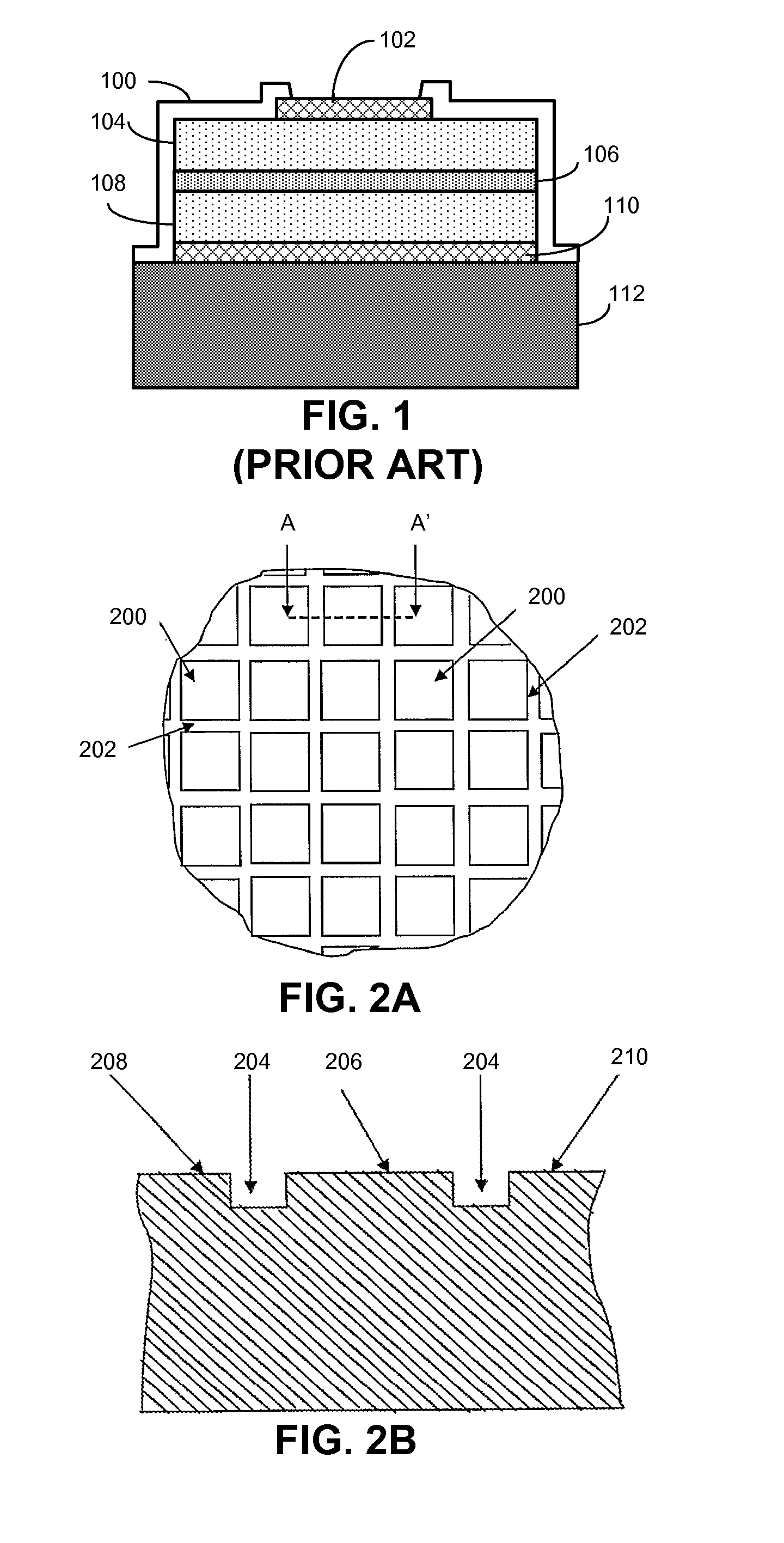

Solar cell and manufacturing method thereof

InactiveUS20110088764A1Reduce chanceImprove conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingSolar cellPhotovoltaics

A solar cell including a substrate, a first conductive layer, a photovoltaic layer, a second conductive layer and at least one passivation layer is provided. The first conductive layer is disposed on the substrate. The photovoltaic layer generates electron-hole pairs after receiving light, wherein the photovoltaic layer is disposed on the first conductive layer and has a plurality of doped films. The second conductive layer is disposed on the photovoltaic layer. The passivation layer is disposed onto at least one of the positions between the first conductive layer and the photovoltaic layer, between the doped films within the photovoltaic layer, and between the photovoltaic layer and the second conductive layer, so as to reduce the chance for the electron-hole pairs resulting in recombination on at least one of the surfaces of the photovoltaic layer. A manufacturing method of the solar cell is also provided.

Owner:AURIA SOLAR CO LTD

Additive for chambering acid liquid for texturing polycrystal black silicon and application of additive

ActiveCN106119976ACrystal flower improvementReactions become controllablePolycrystalline material growthAfter-treatment detailsPolyvinyl alcoholReaction rate

The invention provides an additive for chambering acid liquid for texturing polycrystal black silicon. The additive comprises the following components in percentage by mass: 0.5%-2% of polyvinyl alcohol, 1%-5% of triethanolamine, 1%-3% of tartaric acid, 0.5%-2% of a silane coupling agent and the balance of water. The invention further provides the chambering acid liquid adopting the additive and a method for texturing polycrystal black silicon. By adding the additive into the chambering acid liquid, the reaction of the chambering treatment can be decelerated, and the reaction rates of the chambering acid liquid on crystal surfaces of the polycrystal black silicon can be furthest kept consistent, so that the anisotropic corrosion is inhibited, crystal patterns of the polycrystal black silicon are obviously improved, and the appearance superiority and the performance superiority of the black silicon are embodied.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

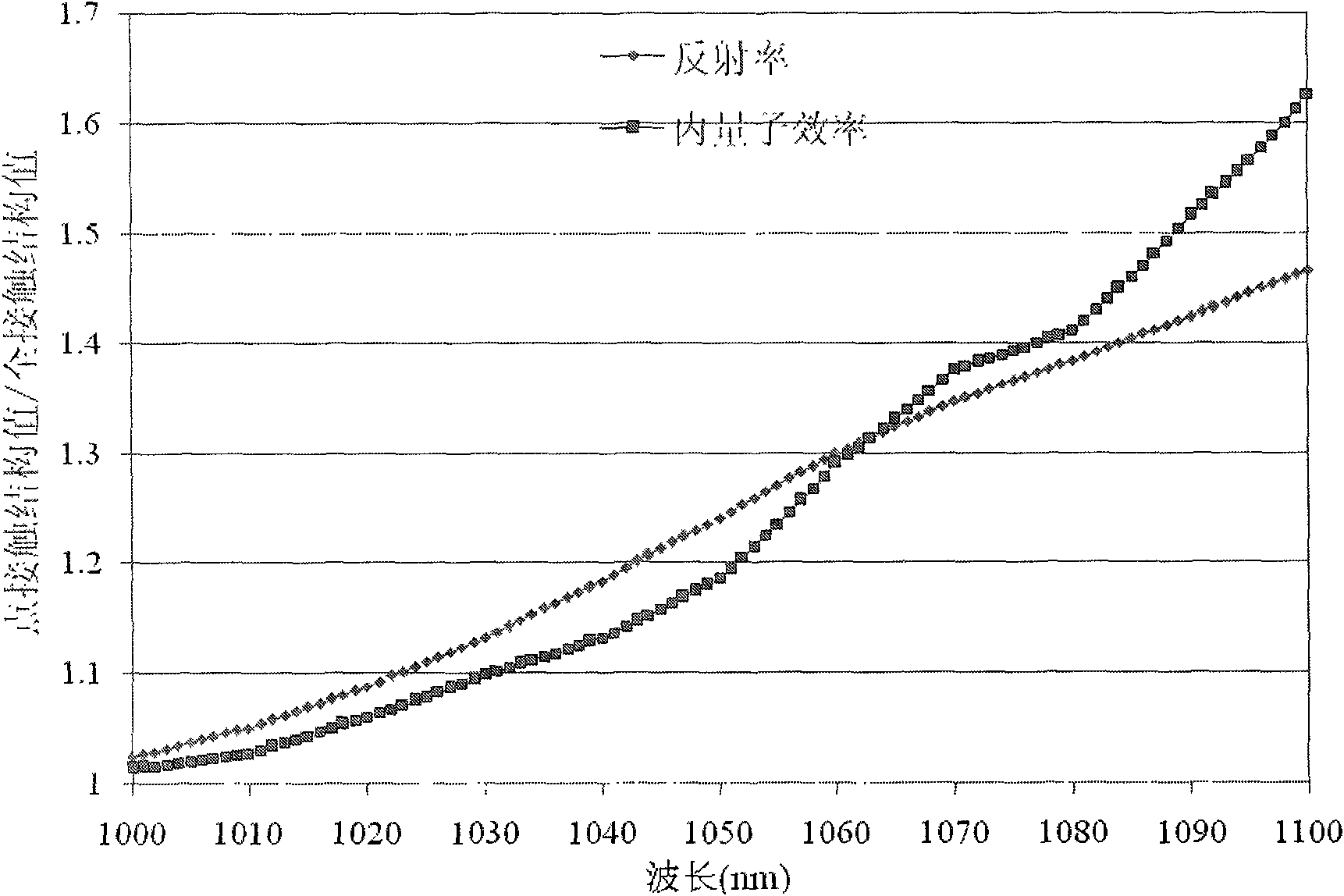

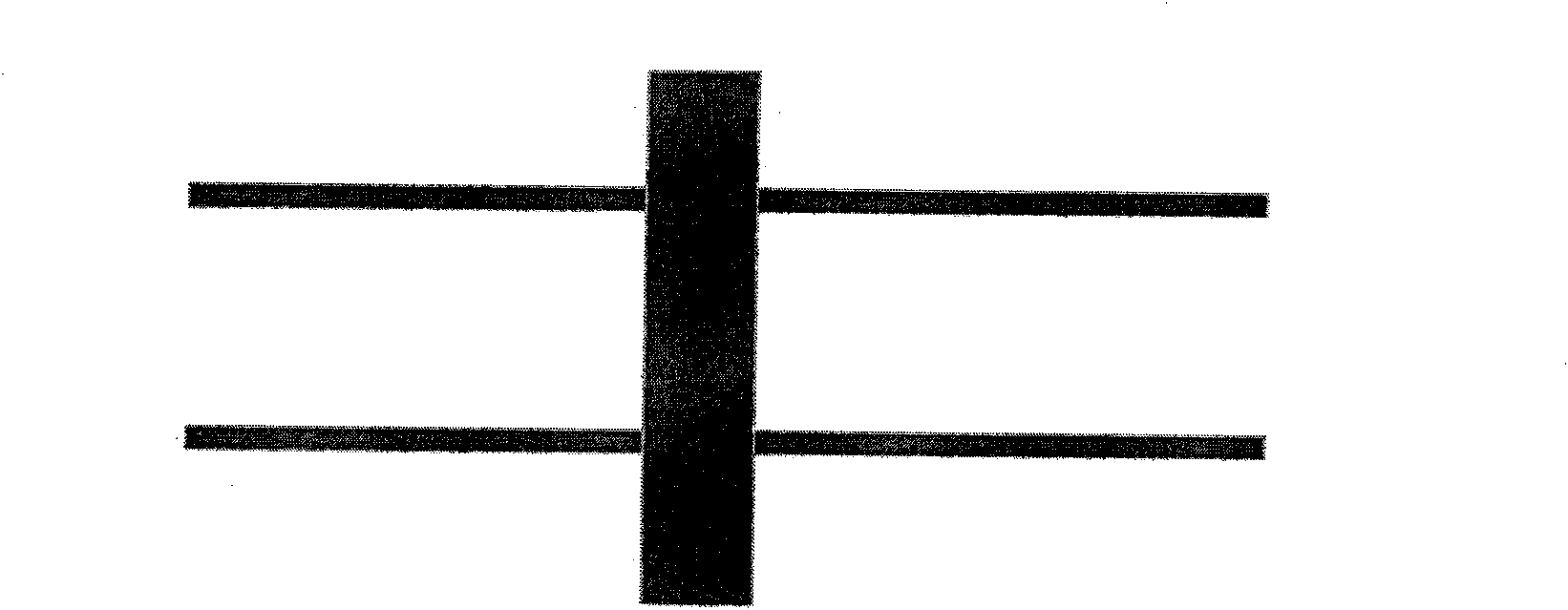

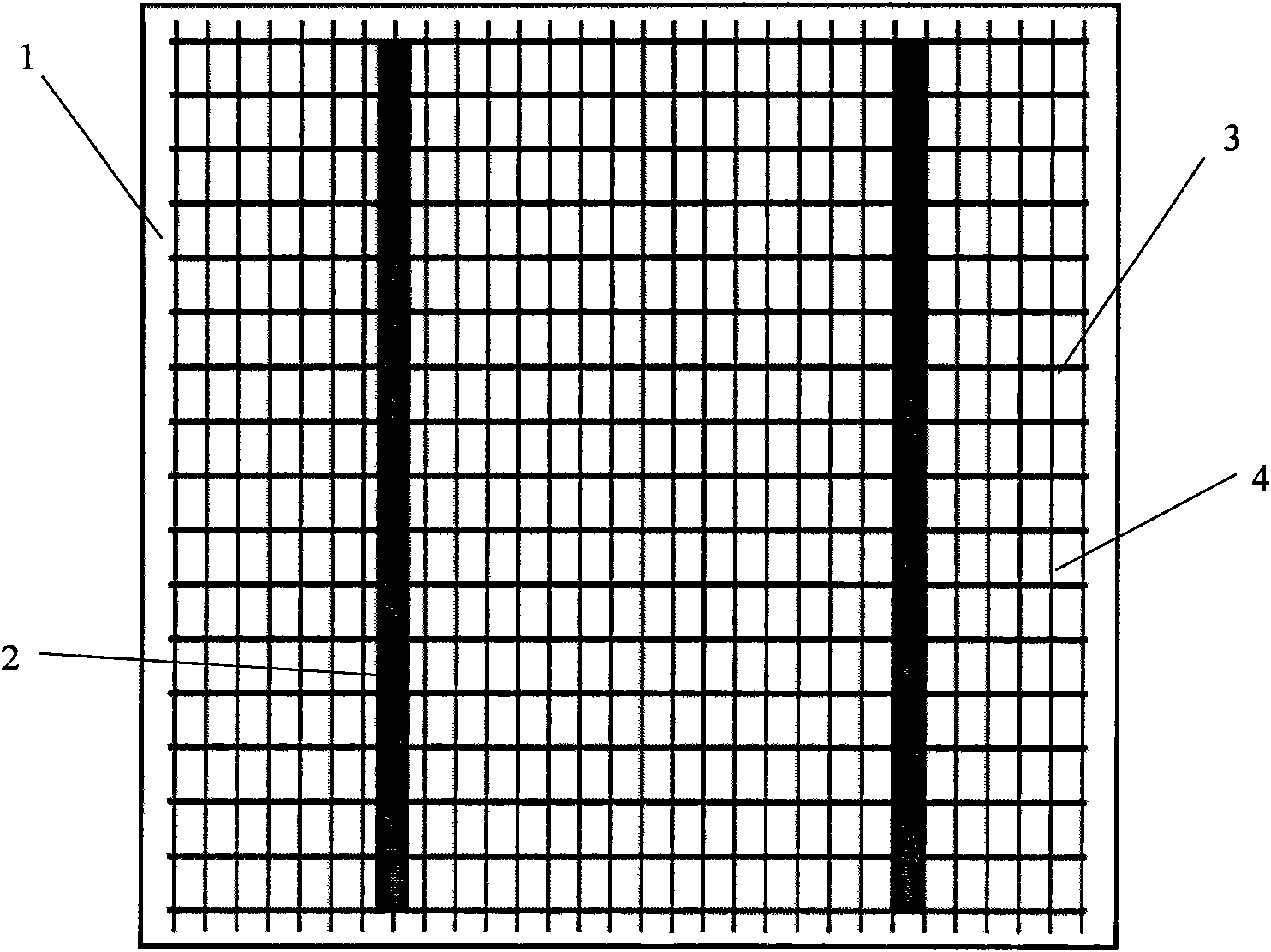

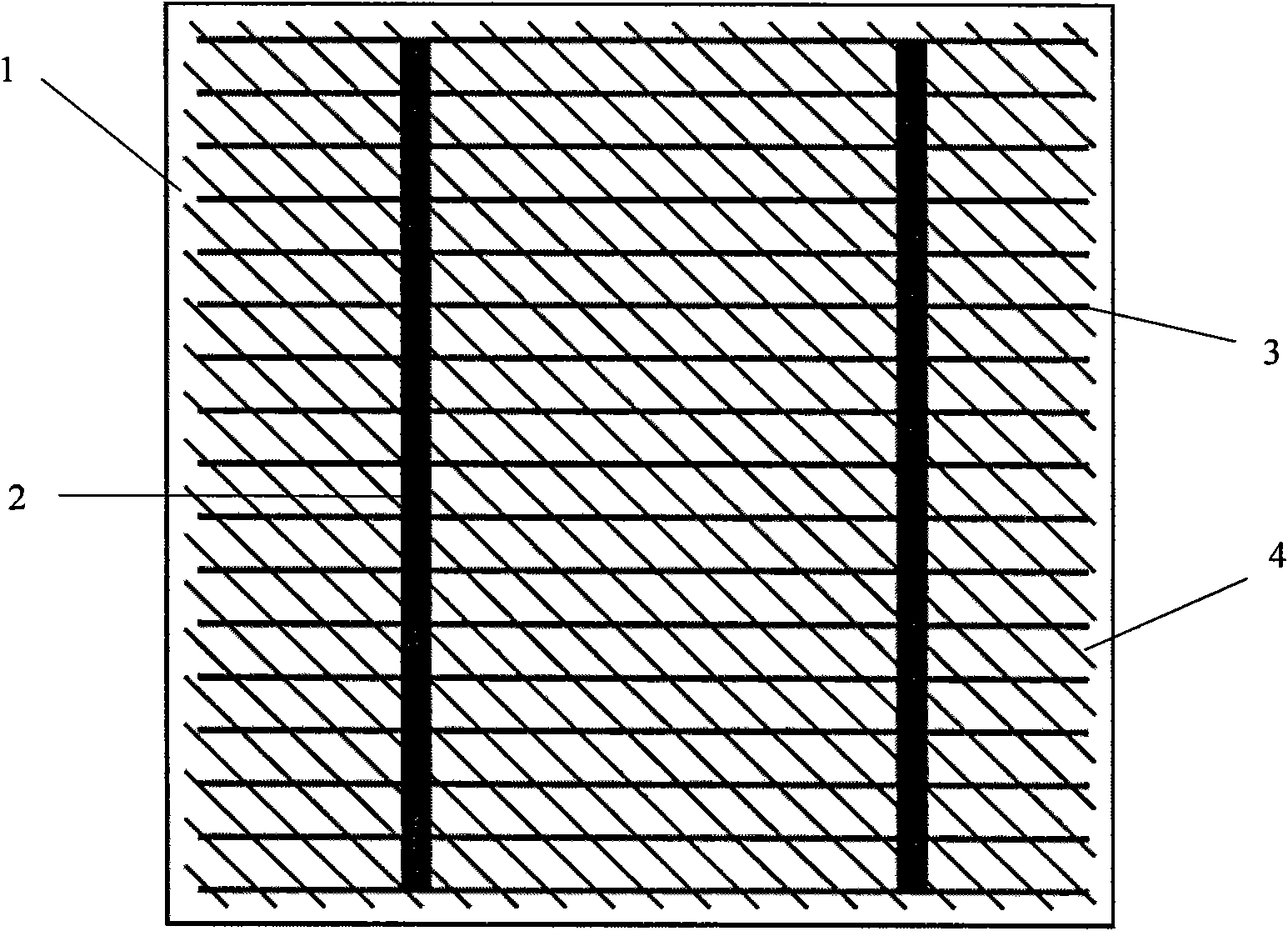

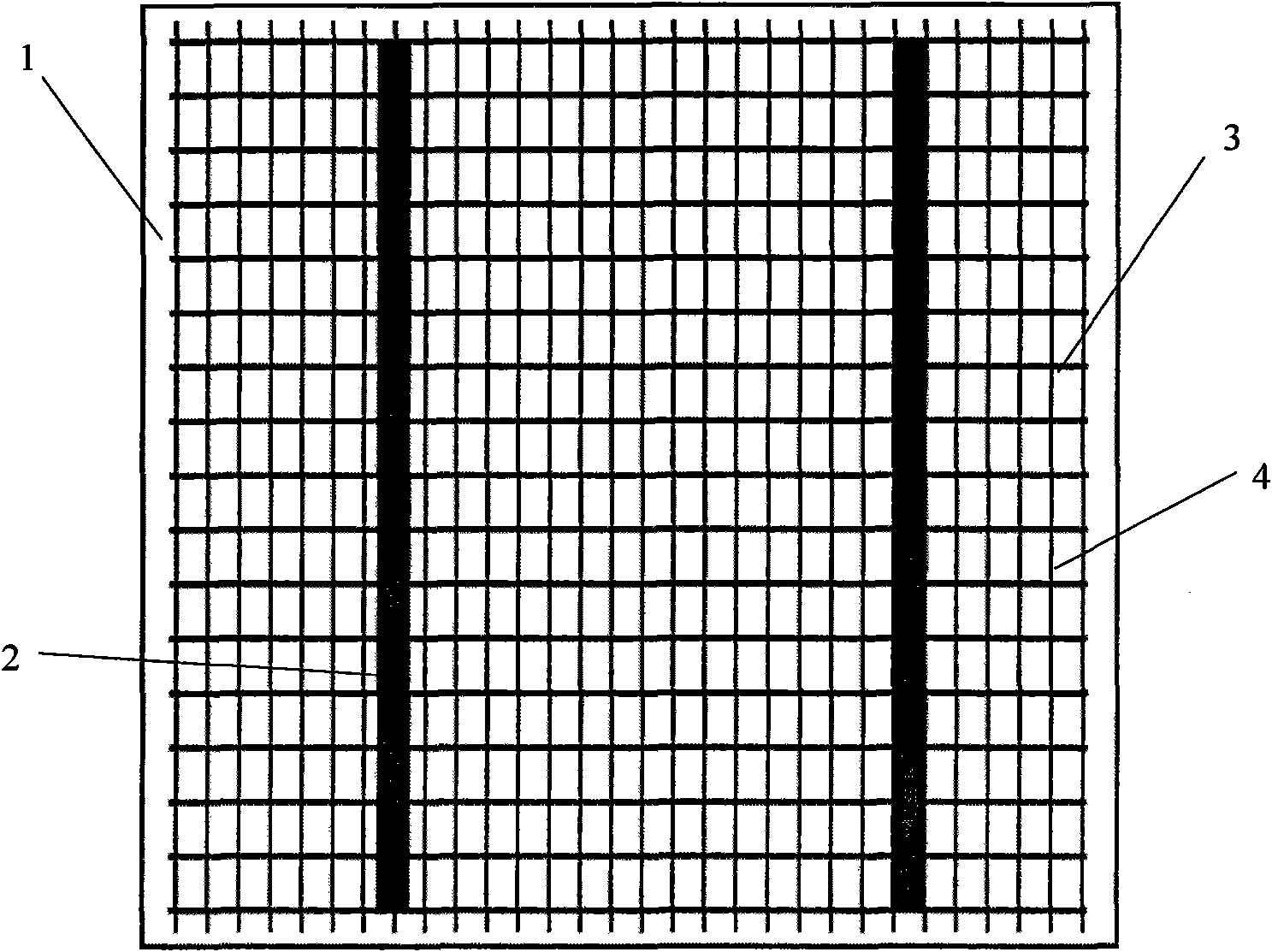

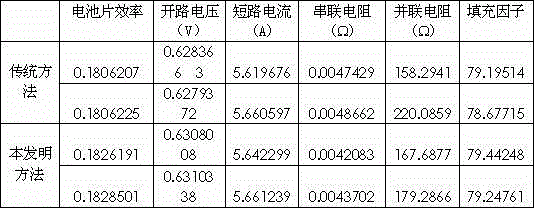

Method for improving photoelectric conversion efficiency of crystal silicon solar battery

InactiveCN101976708AImprove photoelectric conversion efficiencyLess investmentFinal product manufactureSemiconductor devicesProcess equipmentSilicon solar cell

The invention discloses a method for improving photoelectric conversion efficiency of a crystal silicon solar battery. The method is characterized in that: based on the conventional crystal silicon solar battery process, high-doped parallel linear arrays are formed on the surface of an emitter by adopting processes such as screen printing or local laser annealing and the like; and the high-doped parallel linear arrays are crossed with fine grids of a metal electrode in a vertical or certain angle mode. The method improves the ohmic contact of the metal grid electrode and silicon, and meanwhile reduces the number of the required fine grids so as to reduce the shading area and improve the photoelectric conversion efficiency of the crystal silicon solar battery. The method has low equipment investment, does not need to change other conventional process equipment, and is suitable for large-scale industrialized production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

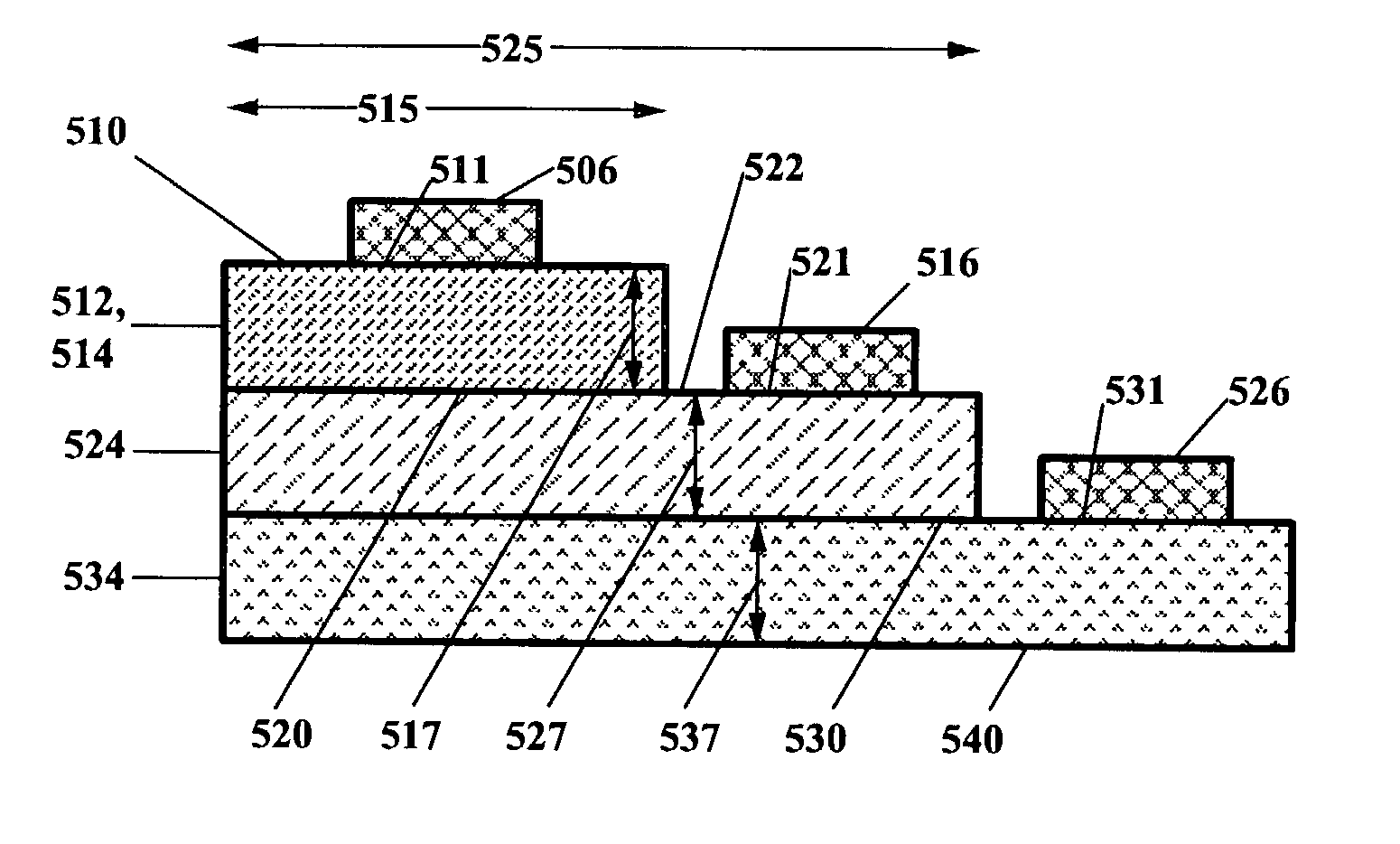

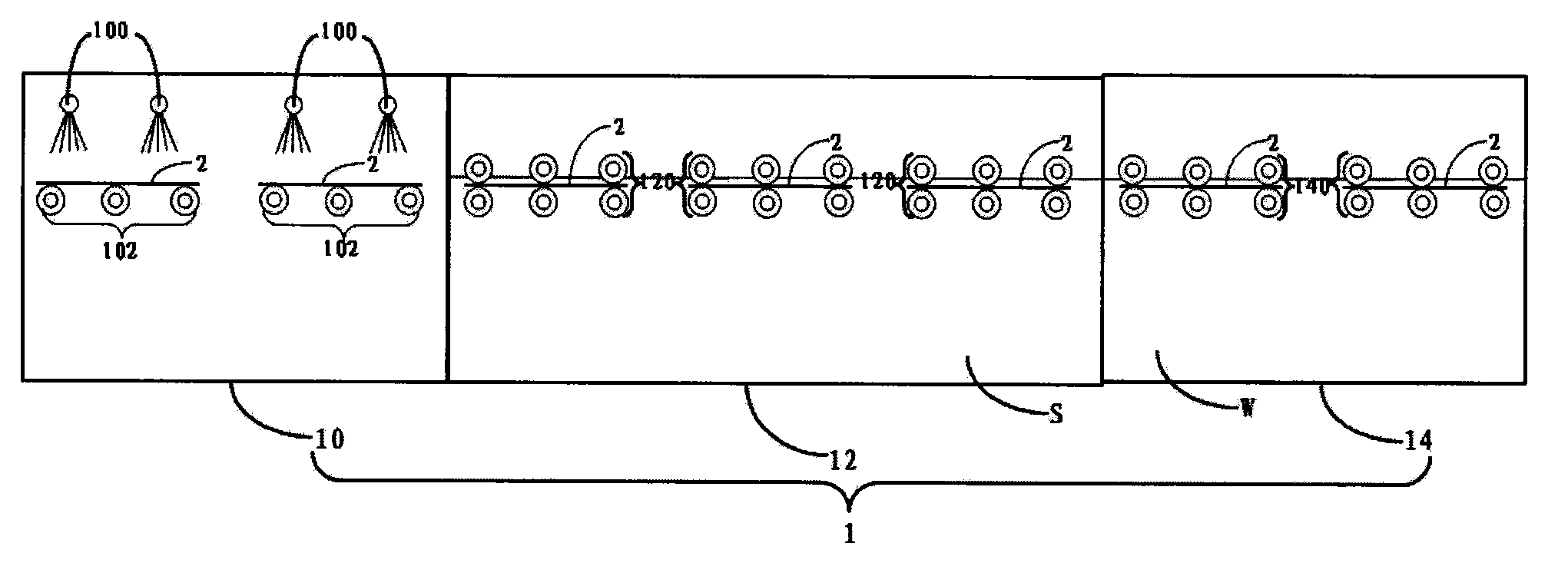

Diffusion Sources From Silicon Based Liquid Precursors

ActiveUS20120052618A1High solar efficiencyReduce contact resistanceSemiconductor/solid-state device manufacturingPhotovoltaic energy generationOligomerDopant

Methods for selectively diffusing dopants into a substrate wafer are provided. A liquid precursor is doped with dopants. The liquid precursor is selected from a group comprising monomers, polymers, and oligomers of silicon and hydrogen. The doped liquid precursor is deposited on a surface of the substrate wafer to create a doped film. The doped film is heated on the substrate wafer for diffusing the dopants from the doped film into the substrate wafer at different diffusion rates to create a heavily diffused region and a lightly diffused region in the substrate wafer. The method disclosed herein further comprises selective curing of the doped film on the surface of the substrate wafer. The selectively cured doped film acts as a diffusion source for selectively diffusing the dopants into the substrate wafer.

Owner:CHEMTRON RES

Solar battery diffusion method

ActiveCN102723266AReduce surface recombination and defect concentrationIncrease widthSemiconductor/solid-state device manufacturingChemistryCrystalline silicon

The invention relates to a solar battery diffusion method which is characterized by comprising a step I of first oxidation, a step II of diffusion and a step III of second oxidation. The step II of diffusion comprises primary diffusion, the secondary diffusion and tertiary diffusion. In the solar battery diffusion method provided by the invention, a P-type silicon wafer is used as a diffusion source substrate; through three sub-steps of diffusion in the diffusion stage, the inlet flow of nitrogen and oxygen turns from large to small, and the inletting time turns from long to short; in the step III, the concentration of a phosphorus source is driven into the substrate from high to low, thus the surface concentration is gradually reduced, and the surface recombination and defect concentration is reduced; gradient doping is formed, the P-N junction area is widened, and the open-circuit voltage is increased; and meanwhile, through the relatively deep junction, the series resistance can be reduced, and the conversion efficiency of a solar battery is improved. The solar battery diffusion method does not need an additional process, is relatively low in cost and can be used for improving the conversion efficiency of the crystalline silicon solar battery.

Owner:JIANGSU HOYI TECH

Wet method etching process

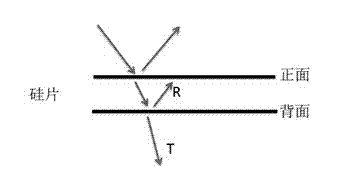

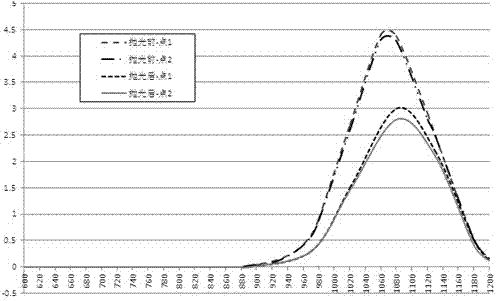

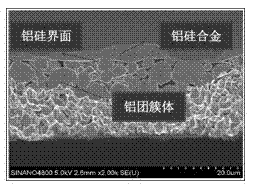

InactiveCN102569502APromote absorptionIncrease IscFinal product manufactureSemiconductor devicesSilicon alloyLight energy

The invention discloses a wet method etching process for crystal silicon wafers, which mainly comprises a back side polishing process. After etching and edge removing, the polishing process performed to the back sides of the crystal silicon wafers through a polishing solution is added, the temperature of the polishing solution in polishing is 5-30 DEG C, the polishing time is 10 seconds to 10 minutes, and the polishing solution contains, by mass, 0.5%-10% of HF, 35%-55% of HNO, 45%-55% of H2SO4 and 5%-30% of acetic acid. By adding the back side polishing process, the back sides of the silicon wafers can be smooth, back reflection of the silicon wafers is strengthened, and absorption of long-wave band spectrums in sunlight is enhanced, thereby improving light energy conversion and short-circuit current (Isc) of a battery and finally improving the conversion efficiency of the battery. In addition, the back of the smooth battery further facilitates combination of follow-up aluminum-silicon alloy and a silicon body, improves ohmic contact, strengthens the light reflection effect of an interface, improves variable output circuit (Voc), and finally improves the conversion efficiency of the battery.

Owner:HEFEI & SOLAR TECH

Photoluminescent wafer as well as preparation method and application thereof

InactiveCN102140690ALattice integrityReduce surface recombinationPolycrystalline material growthSolid-state devicesRare-earth elementWafering

The invention relates to the manufacturing field of light emitting diodes (LED), in particular to a photoluminescent wafer for the LED as well as preparation method and application thereof. The photoluminescent wafer is a slice-shaped crystal in a garnet structure with a general formula of A3B5O12 without doping any resins and other bonding agents, the thickness of the photoluminescent wafer is not less than 20 um, and the size of the crystal particle is not less than 10 um; moreover, the photoluminescent wafer comprises a first element A, a second element B and an active element, wherein thefirst element A is at least one of rare-earth elements Y, Lu, La, Gd or Sm; the second element B is at least one of the elements Al, Ga or In; and the active element is at least one of the rare-earthelements Ce, Pr, Tb and Dy. The photoluminescent wafer has the characteristics of high light emitting efficiency and good light emitting uniformity; the light transmission of the light emitting layercan not be reduced by light adsorption of the bonding agent; and the surface of the photoluminescent wafer is easy for people to carry out various optical treatments.

Owner:ZHEJIANG SHENDU LIGHTING

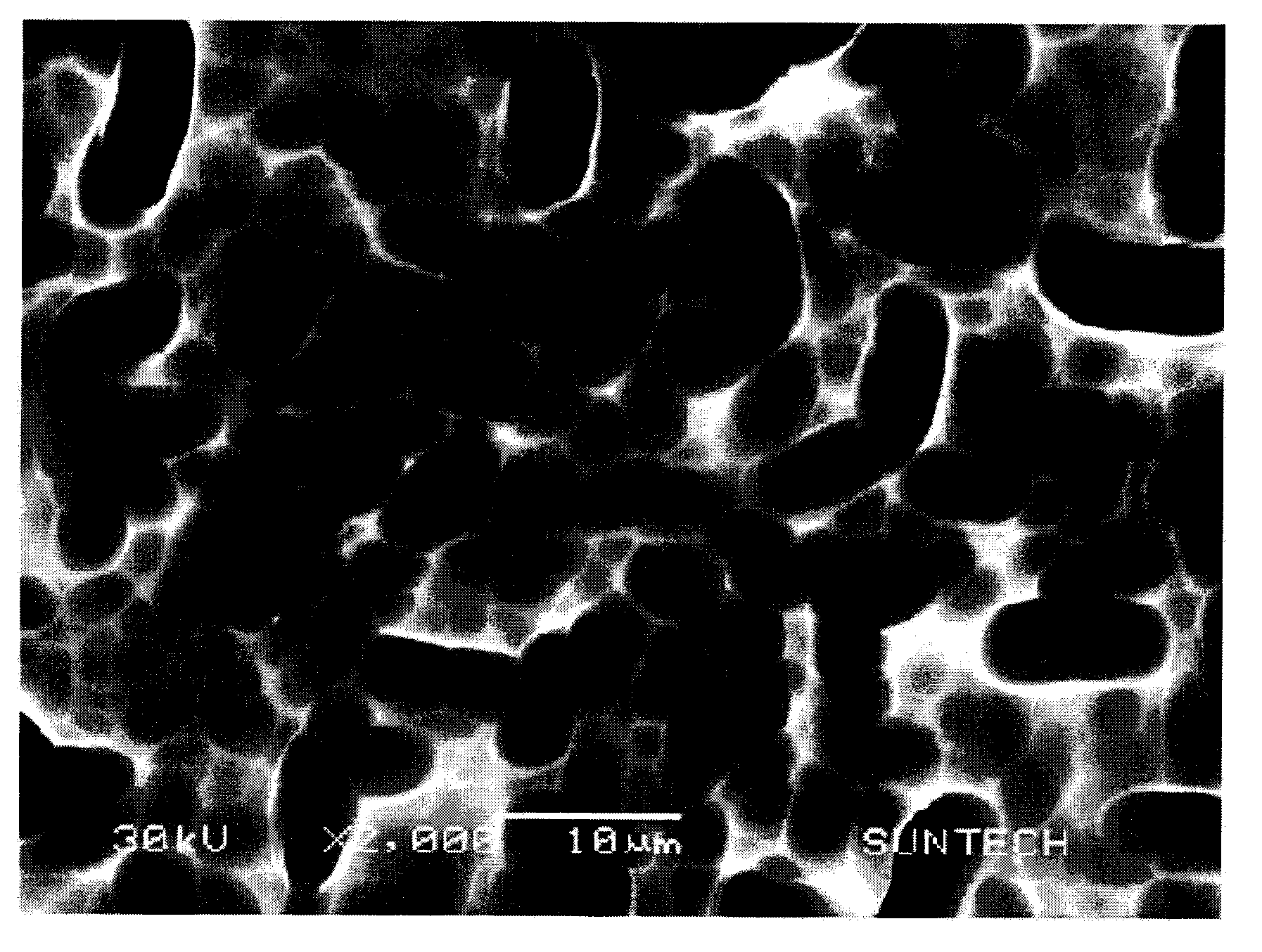

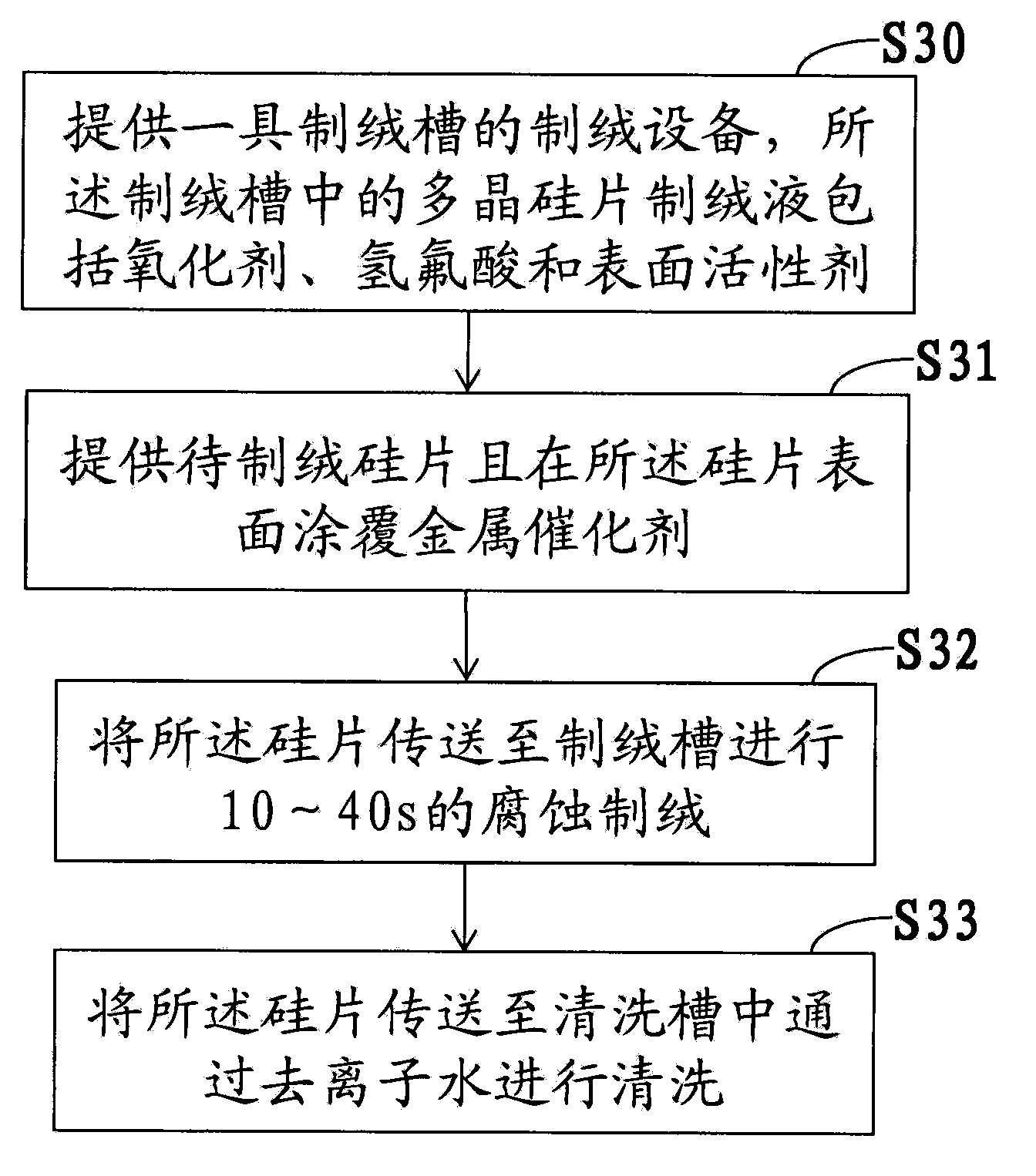

Polycrystalline silicon chip texturing liquid and texturing method

InactiveCN103668466AIncreased texturing speedProcess stabilityAfter-treatment detailsHydrofluoric acidMetal catalyst

The invention provides a polycrystalline silicon chip texturing liquid and a texturing method. The polycrystalline silicon chip texturing liquid in the prior art only contains oxidant and hydrofluoric acid, so that the reaction speed is slow, the area with multiple flaws can be excessively corroded to form the corrosion pit or burrs, the surface of the textured silicon chip is unsmooth, the textured surface is non-uniform, and the silicon chip is easy to break in the subsequent silk printing process. The polycrystalline silicon chip texturing liquid comprises oxidant, hydrofluoric acid and surface active agent. The polycrystalline silicon chip texturing method comprises the steps of firstly providing a texturing device with a texturing trough, placing the polycrystalline silicon chip texturing liquid in the texturing trough, then providing the textured silicon chip, coating the surface of the silicon chip with metal catalyst, and transferring the silicon chip into the texturing trough to be textured in a corrosion manner for 10s to 40s. By adopting the texturing liquid and the texturing method, the texturing speed of the polycrystalline silicon chip is increased, the surface of the polycrystalline silicon chip after being textured is smooth, the textured surface is uniform, the surface has no obvious black silk and crystal interface, so that the breaking rate of the subsequent process can be effectively reduced, the surface compounding is reduced, and the battery efficiency can be improved.

Owner:WUXI SUNTECH POWER CO LTD

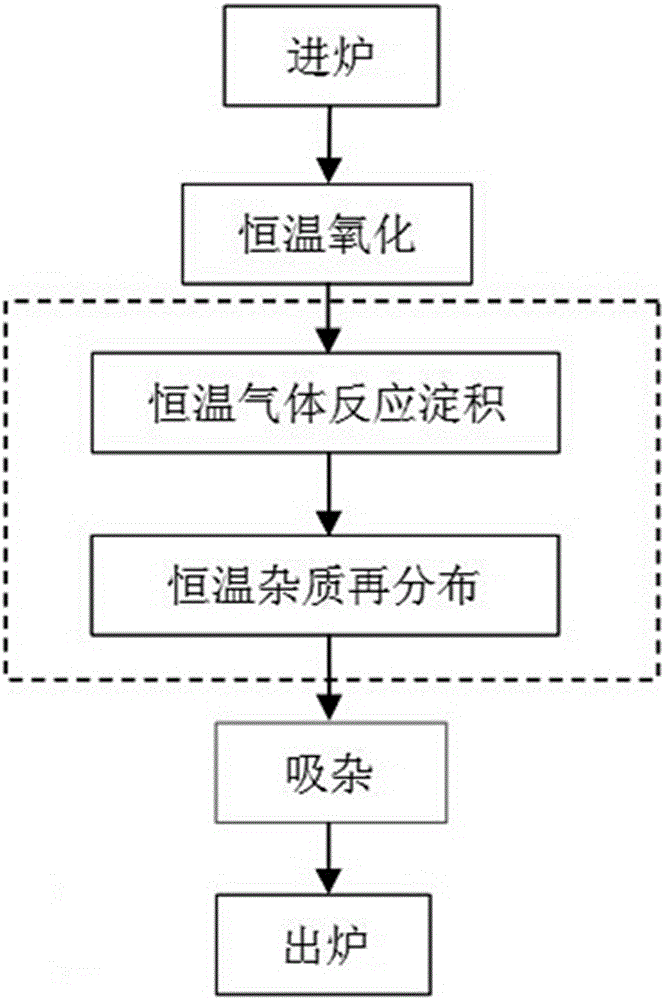

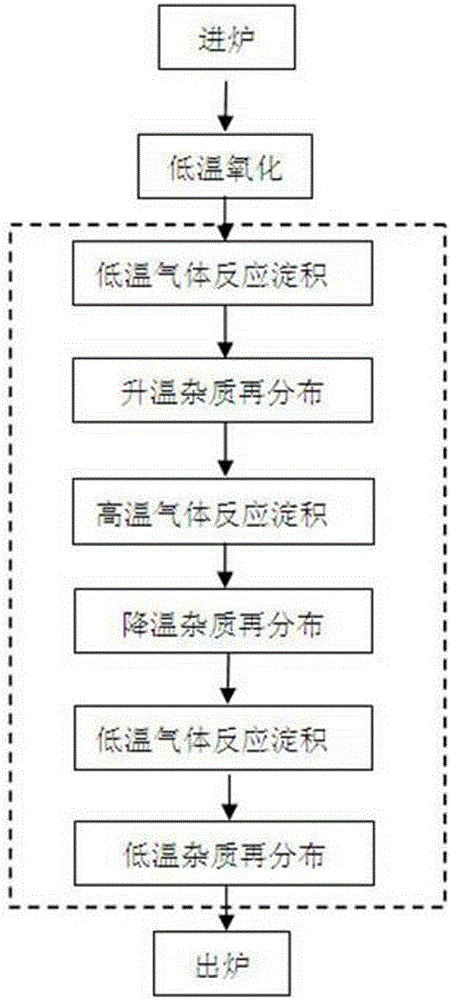

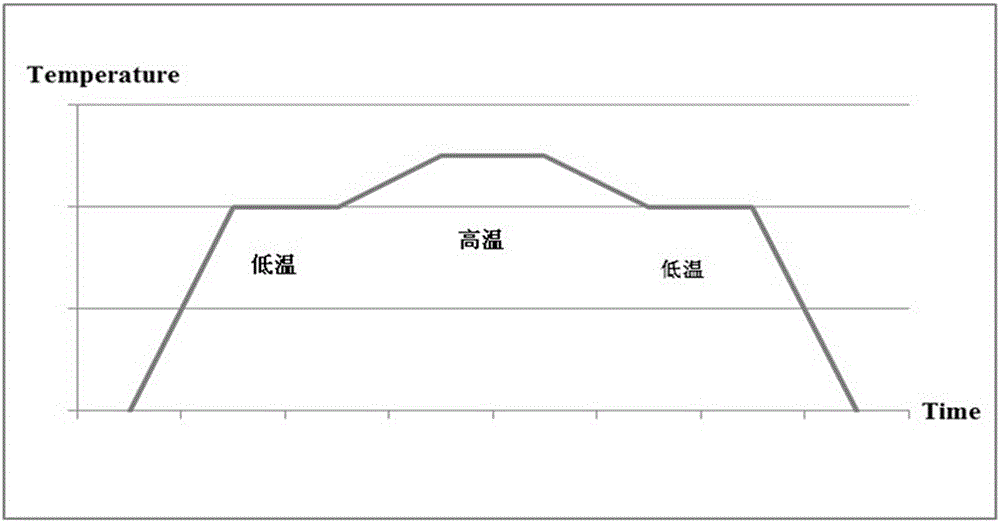

Diffusion technique of crystal-silicon efficient high-sheet-resistance battery piece

ActiveCN105280484AImprove photoelectric conversion rateReduce surface recombinationFinal product manufactureSemiconductor/solid-state device manufacturingDopantEngineering

The present invention relates to a diffusion technique of a crystal-silicon efficient high-sheet-resistance battery piece. The diffusion technique comprises the steps of furnace entering, low-temperature oxidation, low temperature gas reaction deposition, low temperature dopant redistribution, high temperature gas reaction deposition, cooling dopant redistribution, low temperature gas reaction deposition, low temperature dopant redistribution and discharge. With adoption of the diffusion technique provided by the present invention, photoelectric conversion efficiency of the battery pieces can be raised, the production time is shortened, and the production efficiency is raised.

Owner:TRINA SOLAR CO LTD +1

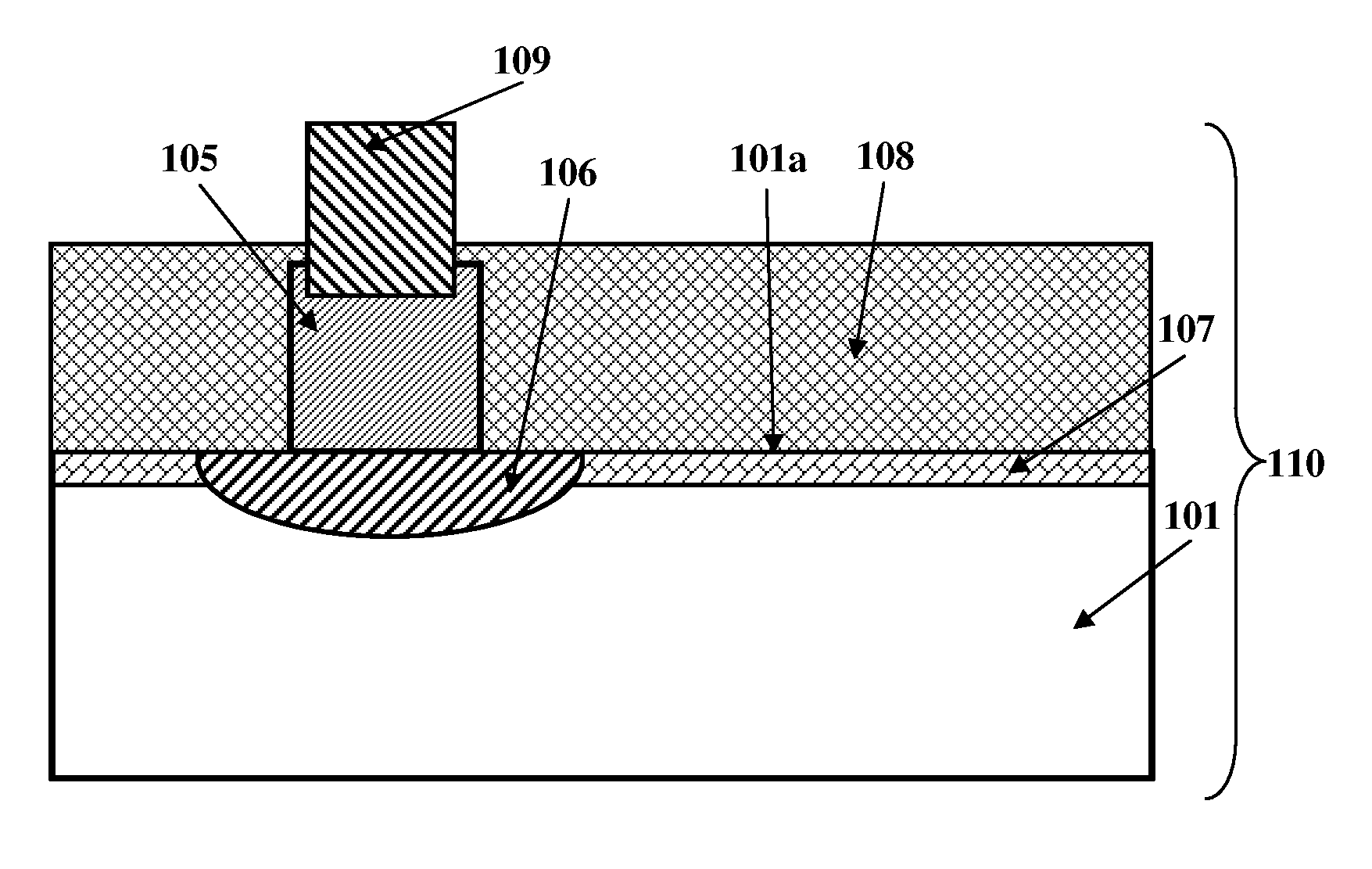

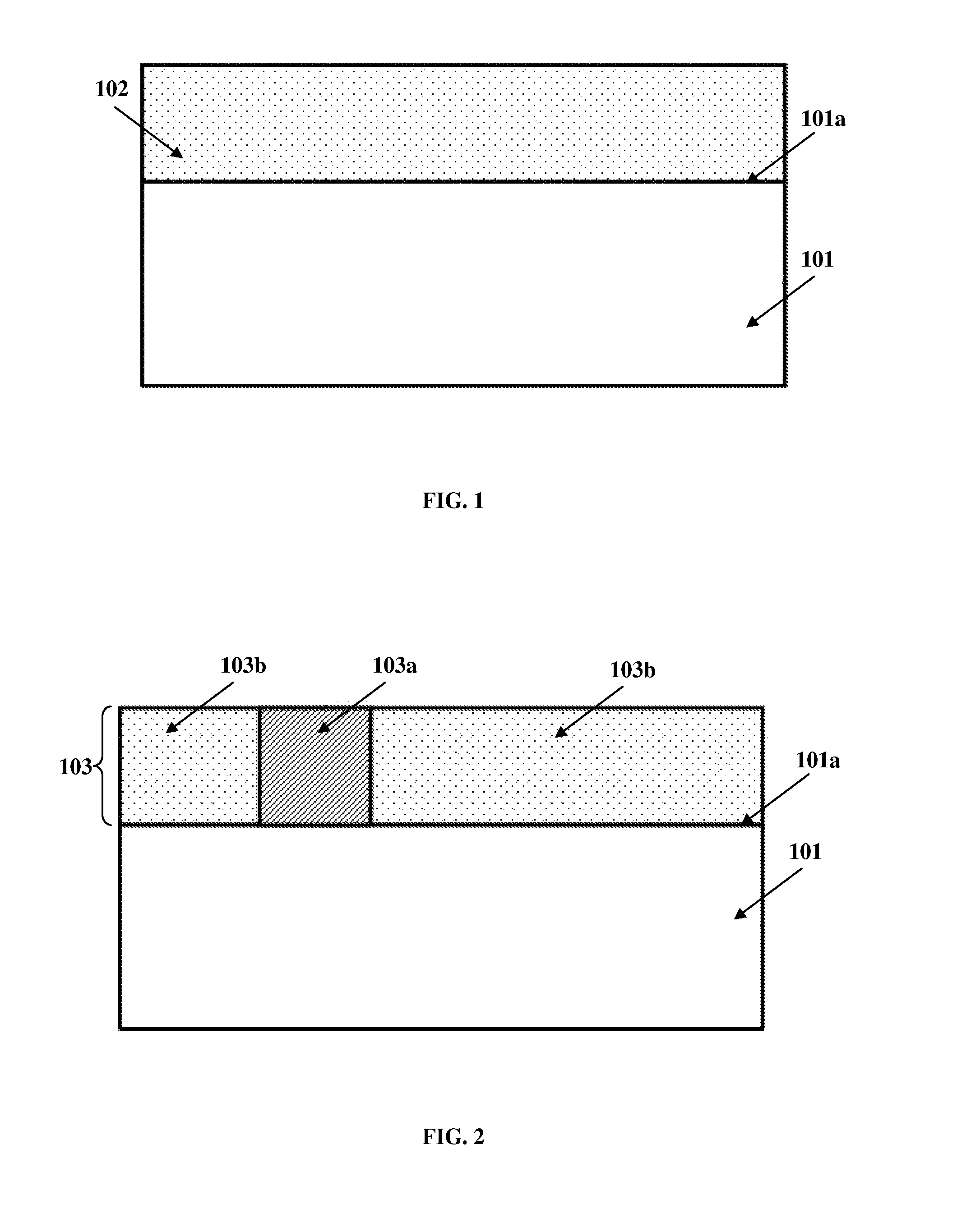

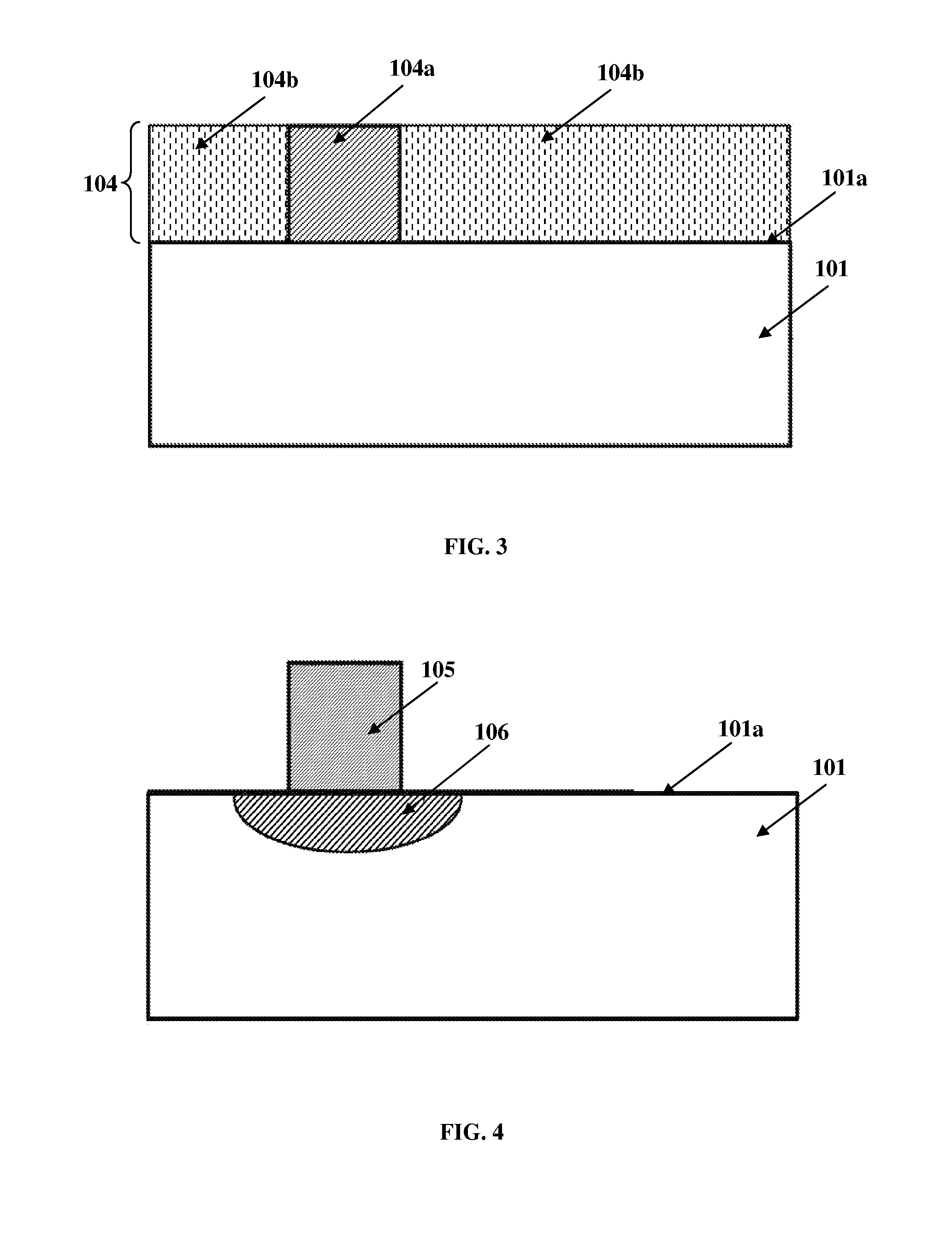

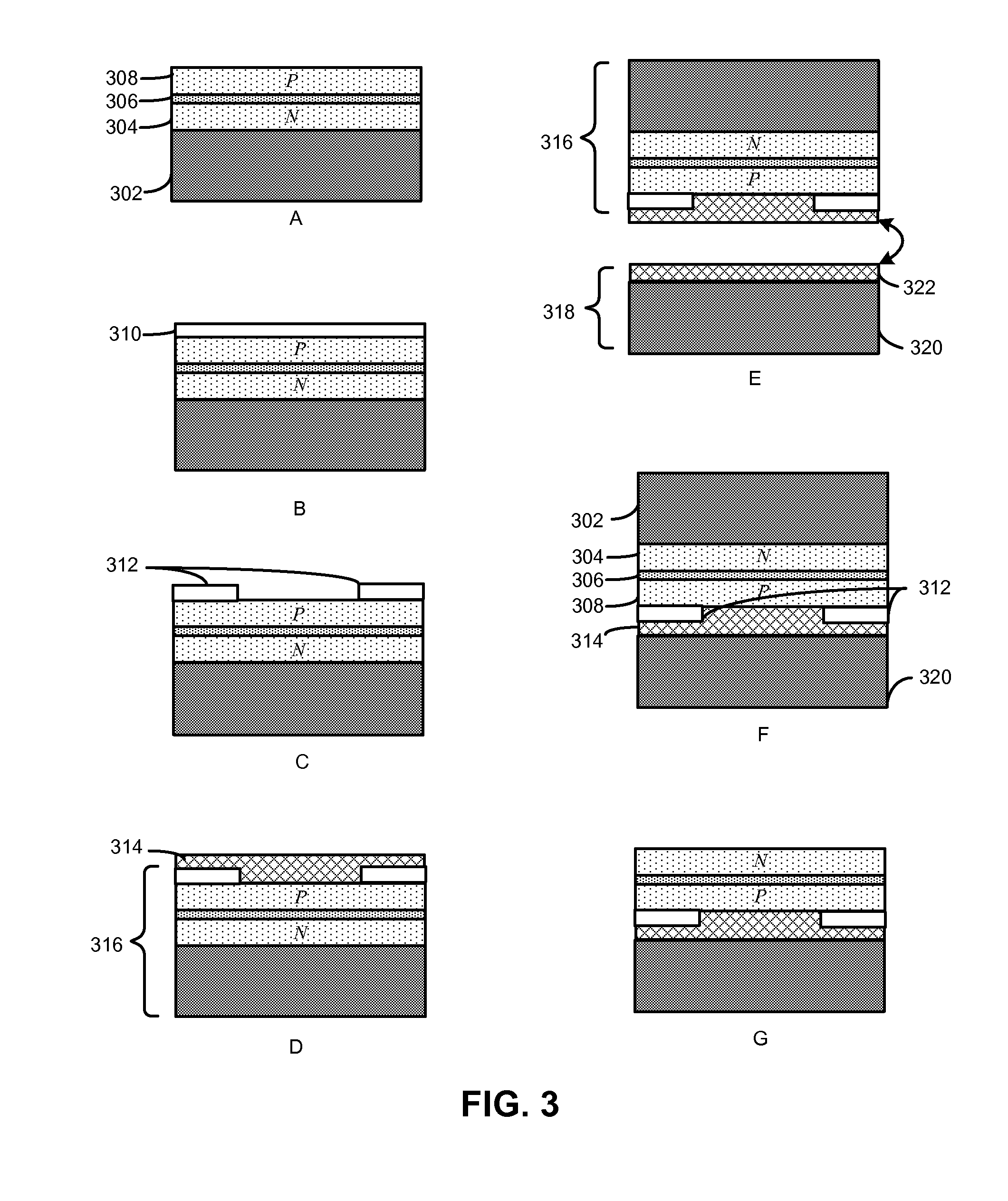

Back contact solar cell with various tunnel junction structures and preparation method thereof

PendingCN110838536AAccurateReduce optical lossFinal product manufacturePhotovoltaic energy generationChemical physicsBack surface field

The invention relates to a back contact solar cell with various tunnel junction structures and a preparation method thereof. The solar cell comprises an N-type crystalline silicon substrate; the frontsurface of the N-type crystalline silicon substrate comprises a lightly-doped n+ surface field and a passivation antireflection film, and the back surface of the N-type crystalline silicon substratecomprises a P-type emitter region, an N-type back surface field region and a groove structure; the P-type emitter region is located in the groove structure, and the N-type back surface field region islocated above the groove structure; the N-type back surface field region sequentially comprises a tunneling SiOX layer, an n+poly layer, an oxide layer, an n+poly layer, a tunneling SiOX layer and ap+poly layer from inside to outside; the SiOX layer and the n+poly layer form a c-Si / SiOX / n+poly tunnel junction; the oxide layer and the n+poly layer form an n+poly / Oxide / n+poly tunnel junction, andthe tunneling SiOX layer and the p+poly layer form an n+poly / SiOX / p+poly tunnel junction; the P-type emitter region sequentially comprises a tunneling SiOx layer and a p+poly layer from inside to outside, and the SiOx layer and the p+poly layer form a c-Si / SiOX / p+poly tunnel junction; the P-type emitter region is provided with a P-type metal electrode, and the N-type back surface field region is provided with an N-type metal electrode.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

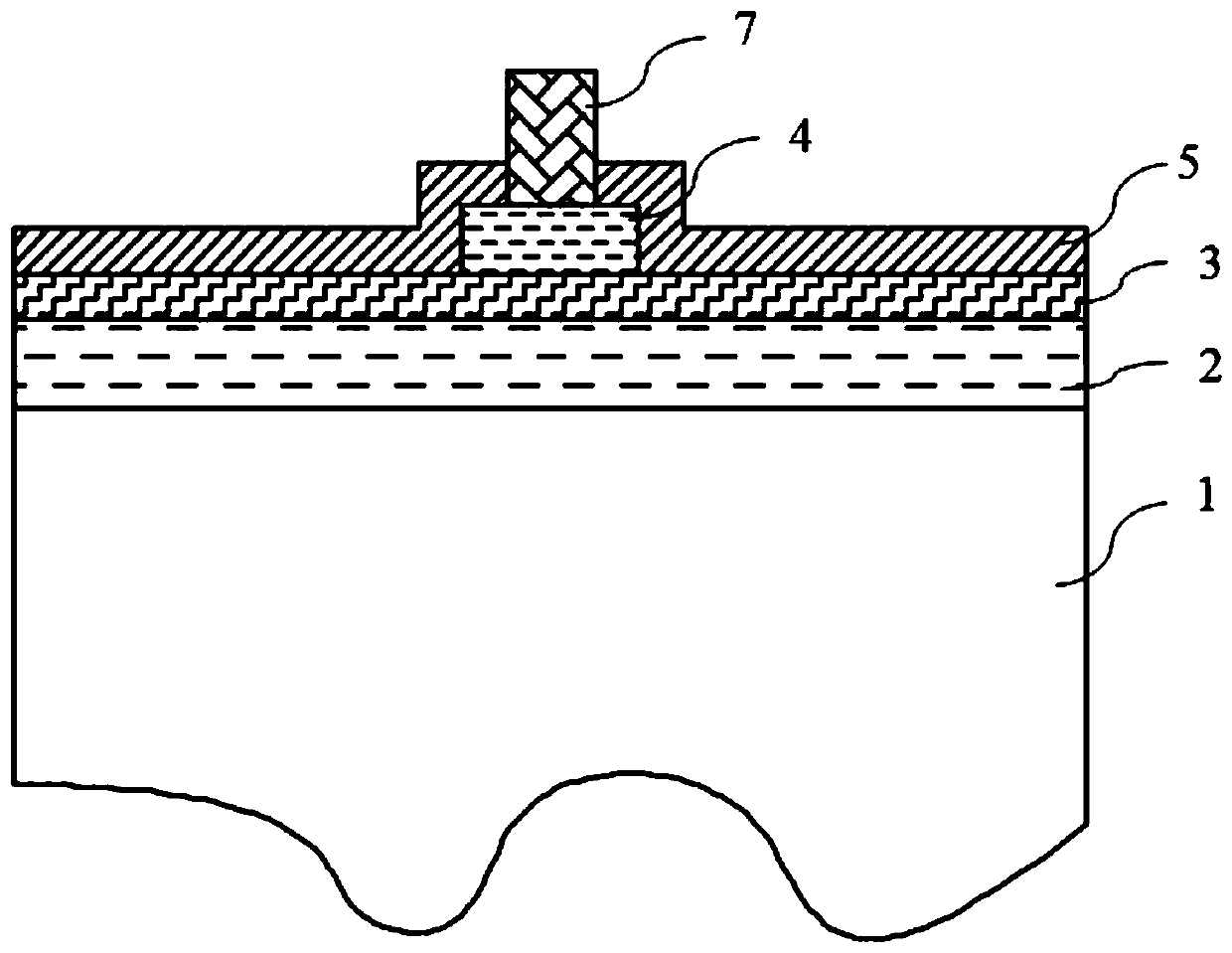

Method for preparing hidden-type emitter silicon solar cells

InactiveCN101752460ARealize full back contact interconnectionHigh densityFinal product manufacturePhotovoltaic energy generationScreen printingSilicon solar cell

The invention relates to a method for preparing hidden-type emitter silicon solar cells, which adopts a quadratic diffusion process. The method comprises the following steps: 1. laser boring; 2. cleaning, radiation damage removing and suede preparation; 3. diffusion; 4. hiding launching area; 5. emitter area corrosion and periphery joint removing; 6. hiding removing; 7. oxidizing and surface passivation; 8. screen printing electrode; and 9. sintering. The method can prepare the hidden-type emitter silicon solar cells.

Owner:YUNNAN NORMAL UNIV

Process for surface diffusion treatment of silicon chip of solar cell

InactiveCN101587920AReduce surface recombinationAchieve removalFinal product manufactureSemiconductor devicesProcess equipmentNormal diffusion

The invention relates to the technical field of solar cell manufacturing, in particular to a process for the surface diffusion treatment of a silicon chip of a solar cell. The process comprises the following steps: firstly, before diffusion source deposition, introducing gases containing chlorine and oxygen into a diffusion furnace to perform chlorine doped oxidization treatment on the silicon chip surface to form a layer of silicon dioxide layer containing chlorine on the surface of the silicon chip; and secondly, performing diffusion source deposition. The chlorine doped oxidization treatment performed before a normal diffusion process can effectively reduce the surface recombination of the silicon chip and realize an excellent surface state, so the performance of finished cells is improved. The novel process avoids increasing novel processing equipment and manpower, influence on productivity and environmental pollution, and is extremely suitable for the industrial application.

Owner:TRINA SOLAR CO LTD

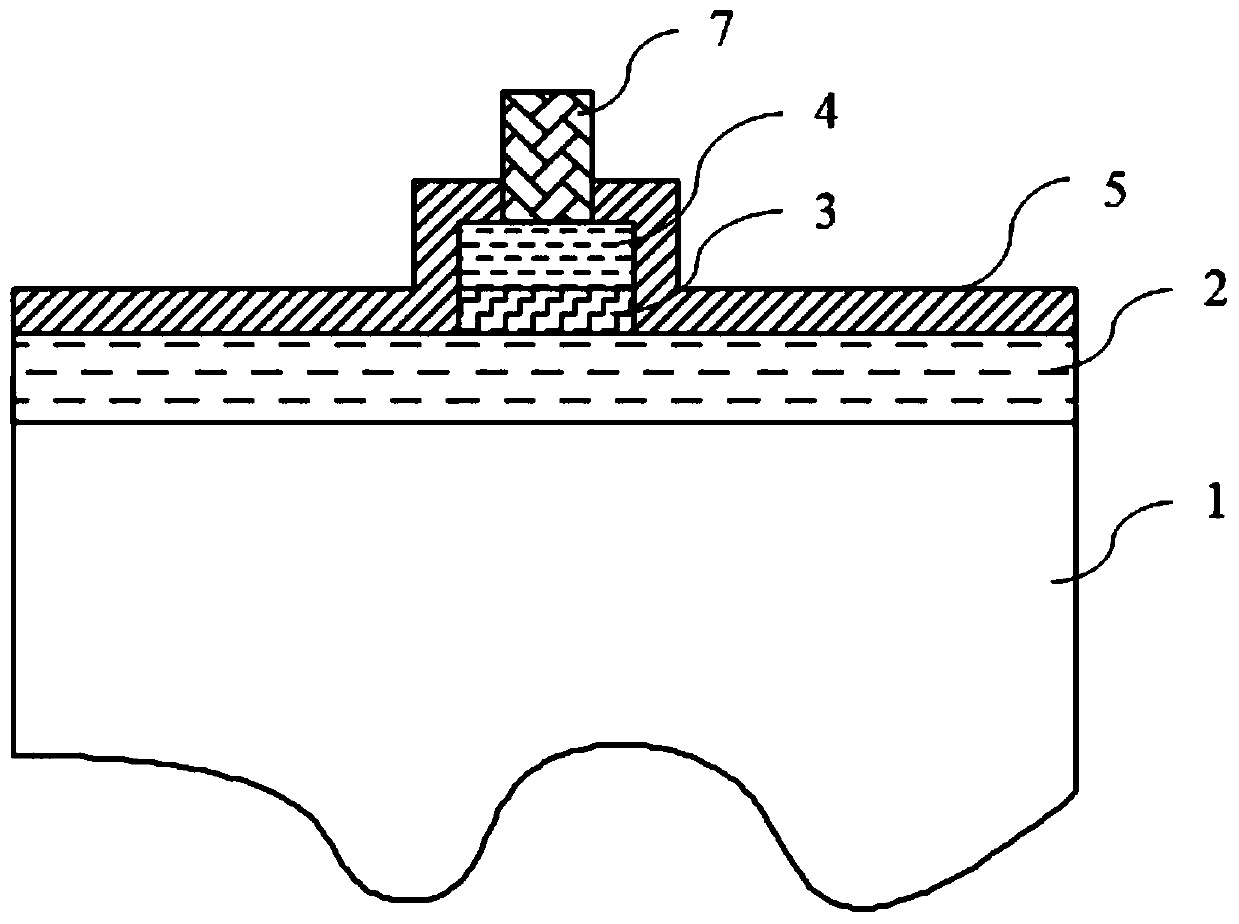

Passivation contact structure and solar cell

PendingCN109841693AShielding high recombinationGood surface passivationPhotovoltaic energy generationSemiconductor devicesSolar cellElectrode

The invention discloses a passivation contact structure and a solar cell. The passivation contact structure comprises a substrate, a first doping layer is arranged on a first surface area of the substrate, the first doping layer is provided with a passivation tunneling layer in at least part of the side far from the substrate, a doping film layer is arranged in part of the surface, far from the first doping layer, of the first doping layer, and a first dielectric film layer is arranged in an area formed by the surfaces of the first doping layer, the doping film layer and the passivation tunneling layer; and a first electrode penetrates the first dielectric film layer and makes contact with the doping film layer. The first doping layer is separated from the first electrode to effectively shielding a high combination effect of the first electrode effectively, surface recombination is reduced substantially, sound surface passivation is provided for the cell, and the conversion efficiencyof the solar cell is improved.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

N-type surface tunneling oxidation passivation contact manufacturing method for silicon-based solar cell

InactiveCN107464855AReduce interface state densityReduce surface recombinationFinal product manufacturePhotovoltaic energy generationSurface oxidationPhosphor

The invention relates to an N-type surface tunneling oxidation passivation contact manufacturing method for a silicon-based solar cell, and the method comprises the following steps: (1), washing the surface of a monocrystalline wafer through a solution after a former operation, and removing a surface oxidation layer; (2), carrying out the oxidation of the surface of the monocrystalline wafer, and forming a superthin tunneling oxidation layer; (3), depositing a silicon thin layer above the superthin tunneling oxidation layer through a chemical vapor deposition method, and completing the phosphor doping of the silicon thin layer; (4), carrying out the oxidizing annealing of the silicon wafer, and further improving the micro-structure and performance of the silicon layer; (5), employing a plasma enhanced chemical vapor deposition method to deposit a silicon nitride passivation antireflection layer above the phosphor-doped silicon thin layer; (6), printing a metal electrode on the surface of the silicon nitride passivation antireflection layer, and completing the manufacturing process. The method can greatly reduce the surface recombination of battery pieces, achieves the excellent passivation effect, and increases the open-circuit voltage. A product has good thermal stability, and there is no need to develop the dedicated low-temperature technology, thereby reducing the cost.

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV

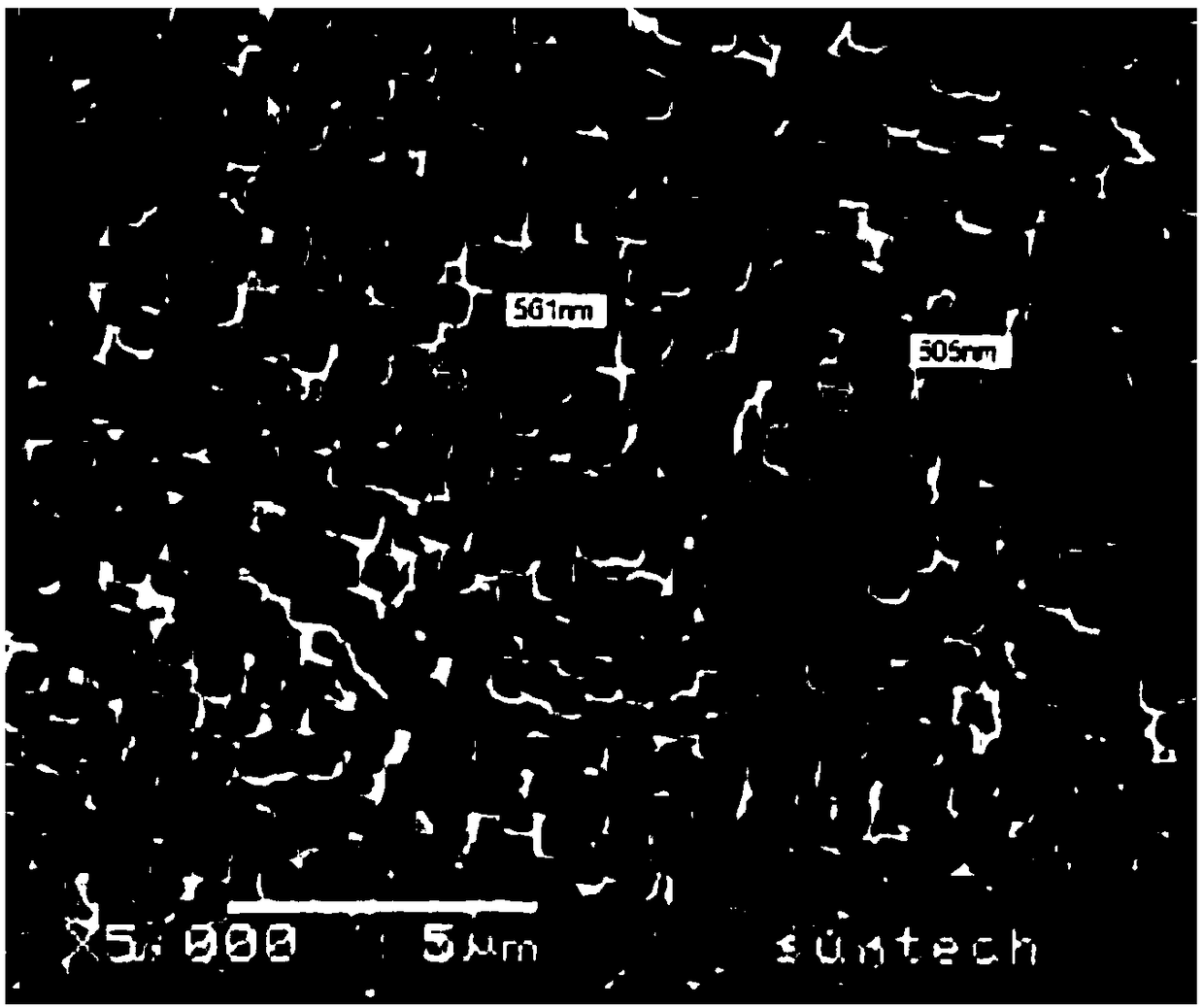

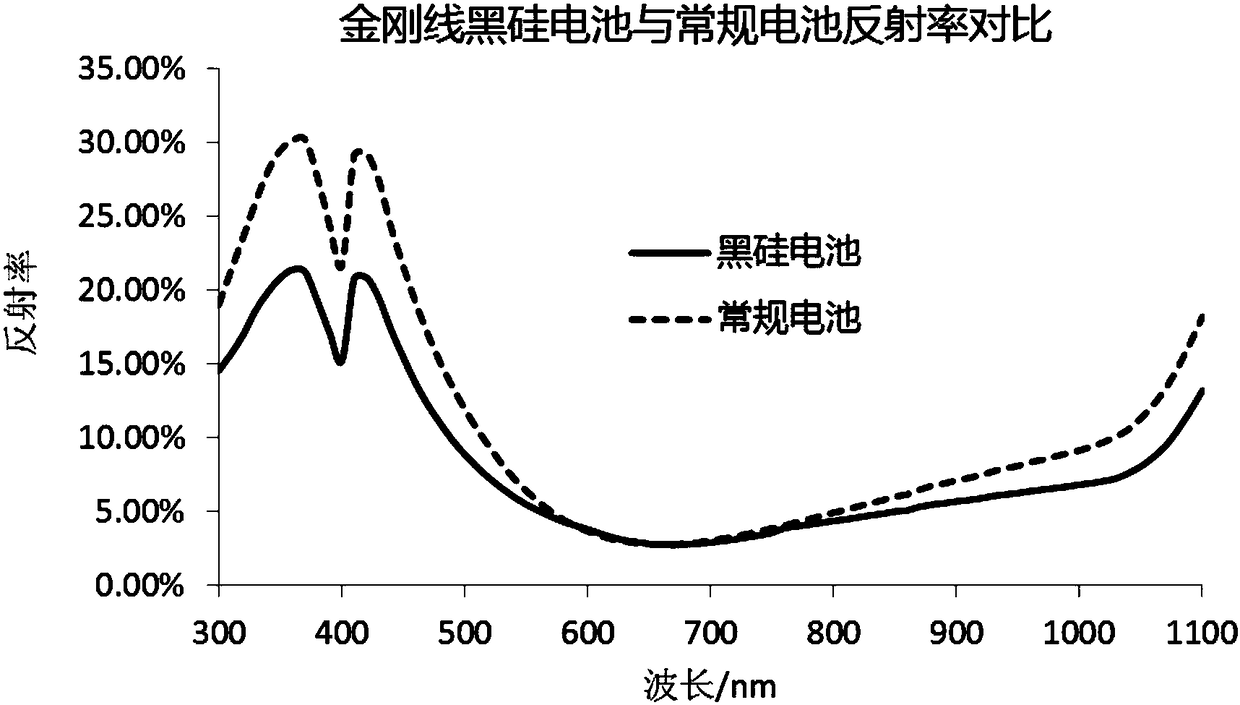

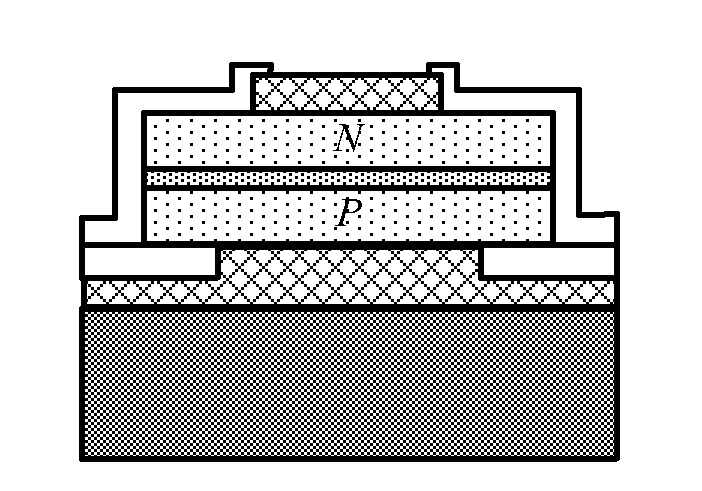

Preparation method for black-silicon poly-silicon PERC cell structure with selective emitter

InactiveCN108365022ASolve the problem of high surface reflectivityImprove conversion efficiencyAfter-treatment detailsFinal product manufactureScreen printingSilver electrode

The invention relates to a preparation method for a black-silicon poly-silicon PERC cell structure with a selective emitter. The preparation method is characterized by comprising the following steps of (1) forming a nanometer texturing surface on a front surface of a silicon wafer, wherein a back surface is a polishing surface; (2) performing front-surface diffusion of the silicon wafer to form anN-type layer, and removing front-surface phosphorosilicate glass and a back-surface pn junction; (3) depositing a silicon nitride anti-reflection film layer on the front surface of the silicon wafer,and depositing a passivation dielectric layer on the back surface; (4) dotting or routing the back surface of the silicon wafer, and printing a silver electrode and aluminum paste; (5) performing low-temperature sintering to form a local aluminum back field; (6) spraying a mixed solution of phosphoric acid and alcohol on the front surface of the silicon wafer, and forming a main grid line regionand a secondary grid line region after heavy doping by laser; and (7) immersing the front surface of the silicon wafer in an electroplating solution, electroplating the front surface of the silicon wafer under an illumination condition, and annealing after electroplating. By the preparation method, the defects that a high-quality fine grid line is difficult to form by silk-screen printing and thegrid line and a selective emitter cannot be enabled to be accurately aligned are overcome, and shielding and leakage current caused by an electrode are minimum.

Owner:WUXI SUNTECH POWER CO LTD

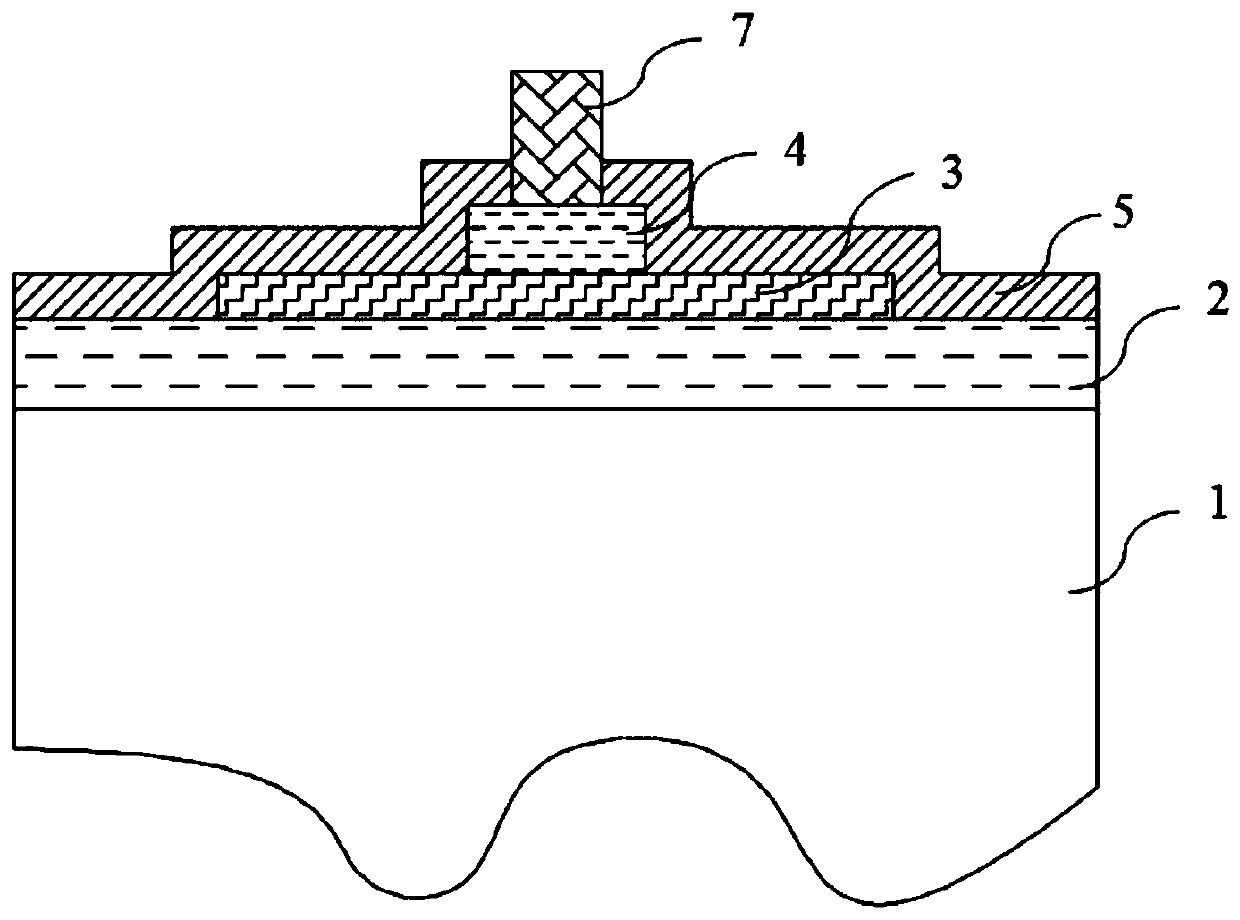

Semiconductor light-emitting device with double-sided passivation

ActiveUS20110001120A1Reduce surface recombinationSolid-state devicesSemiconductor/solid-state device manufacturingOhmic contactQuantum well

A light-emitting device includes a substrate, a first doped semiconductor layer situated above the substrate, a second doped semiconductor layer situated above the first doped layer, and a multi-quantum-well (MQW) active layer situated between the first and the second doped layers. The device also includes a first electrode coupled to the first doped layer and a first passivation layer situated between the first electrode and the first doped layer in areas other than an ohmic-contact area. The first passivation layer substantially insulates the first electrode from edges of the first doped layer, thereby reducing surface recombination. The device further includes a second electrode coupled to the second doped layer and a second passivation layer which substantially covers the sidewalls of the first and second doped layers, the MQW active layer, and the horizontal surface of the second doped layer.

Owner:LATTICE POWER (JIANGXI) CORP

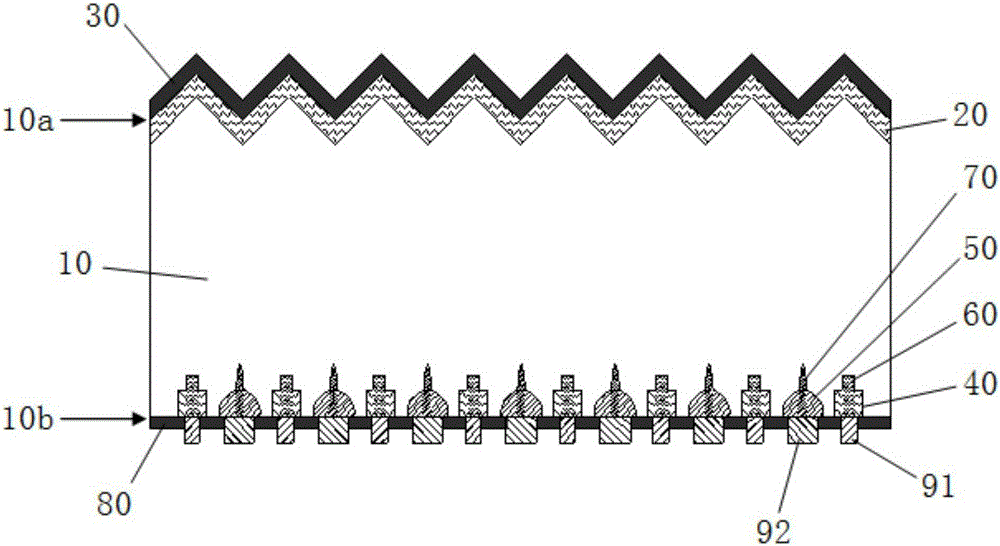

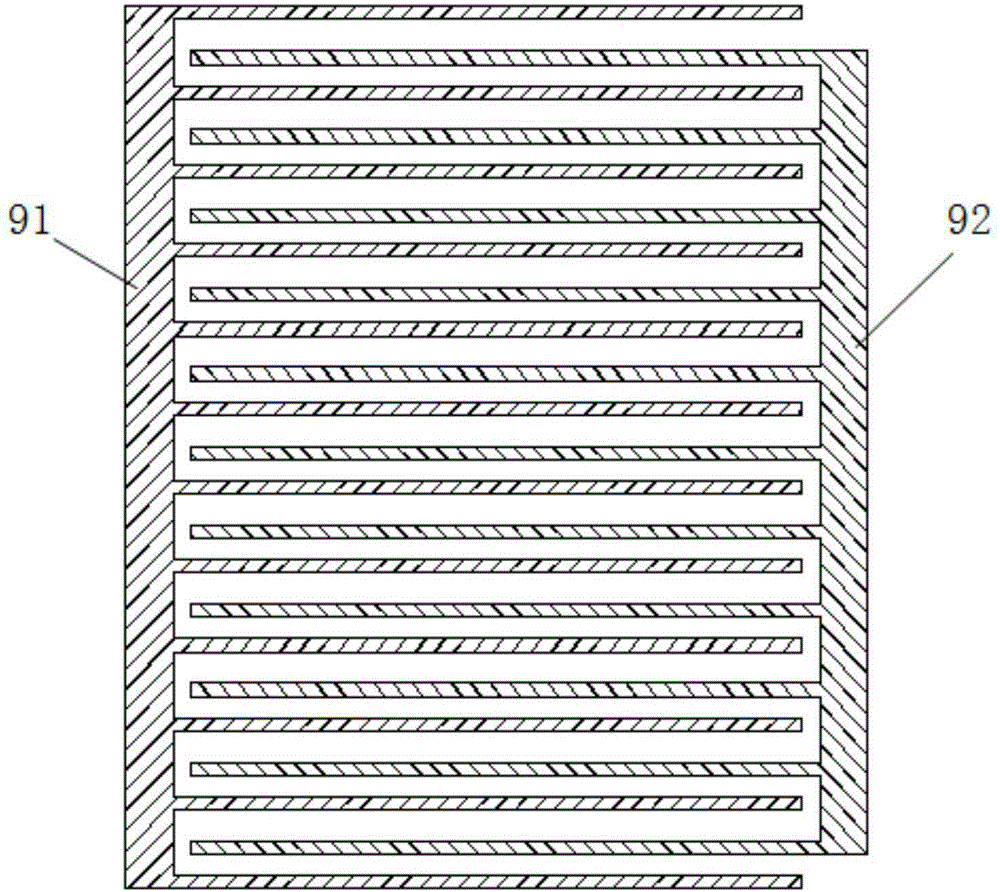

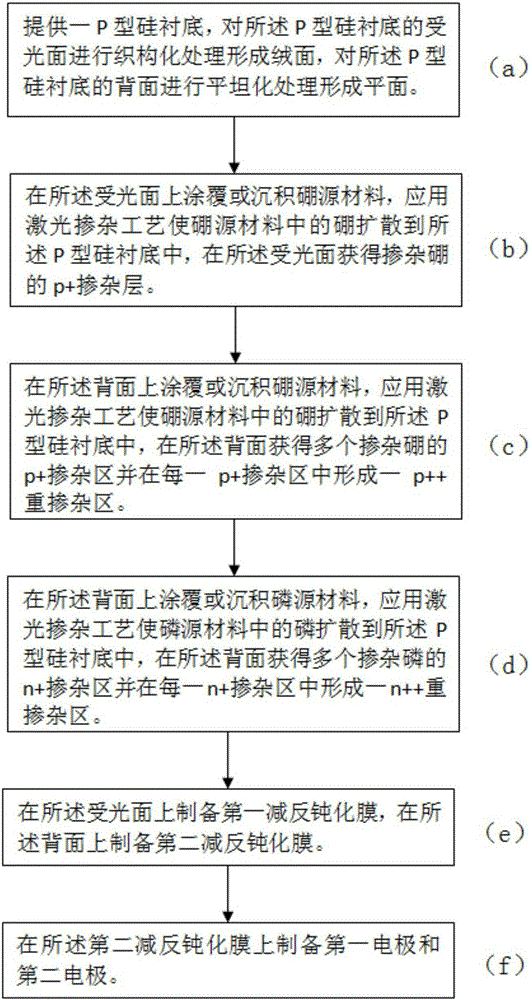

Back contact type solar cell based on P-type silicon substrate and manufacturing method thereof

ActiveCN105185858AHigh temperature action time is shortLow costFinal product manufacturePhotovoltaic energy generationContact typeSolar cell

The invention discloses a back contact type solar cell based on a P-type silicon substrate. One P-type silicon substrate is included. An illuminated surface of the P-type silicon substrate is provided with a p+ doping layer doped with boron. The illuminated surface is provided with a first anti-reflection passive film. A back side of the P-type silicon substrate is provided with a plurality of p+ doping regions doped with boron and a plurality of n+ doping regions doped with phosphori. Each p+ doping region is provided with one p++ heavily doped region. Each n+ doping region is provided with one n++ heavily doped region. A back side is provided with a second anti-reflection passive film. The second anti-reflection passive film is provided with a first electrode and a second electrode which are mutually insulated. The first electrode and the second electrode are electrically connected to the p++ heavily doped region and the n++ heavily doped region. The invention also discloses a manufacturing method of the solar cell. A P-type silicon wafer is used as a substrate material of the back contact type solar cell. A technology of the P-type silicon wafer is mature and an obvious cost advantage is possessed.

Owner:YELLOW RIVER PHOTOVOLTAIC IND TECH CO LTD

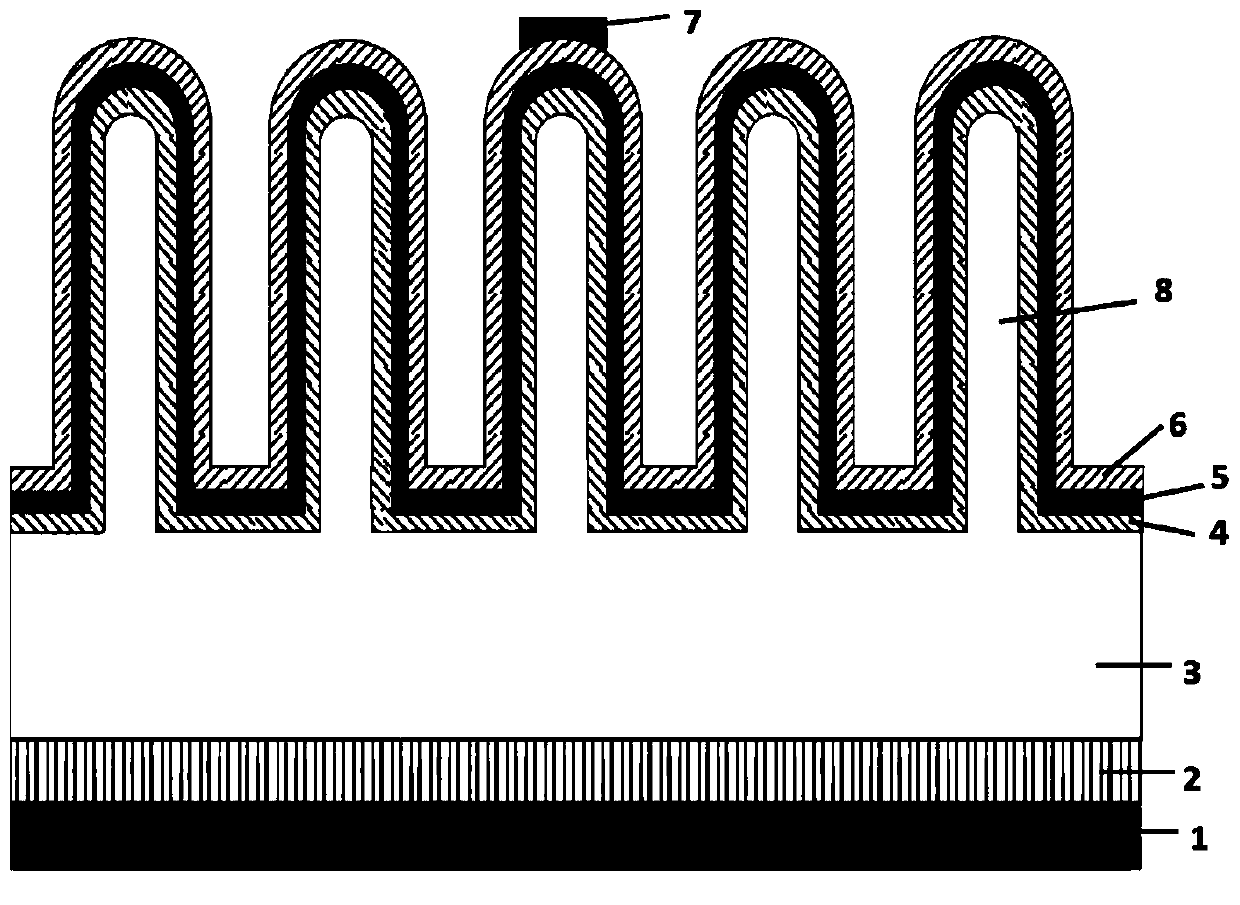

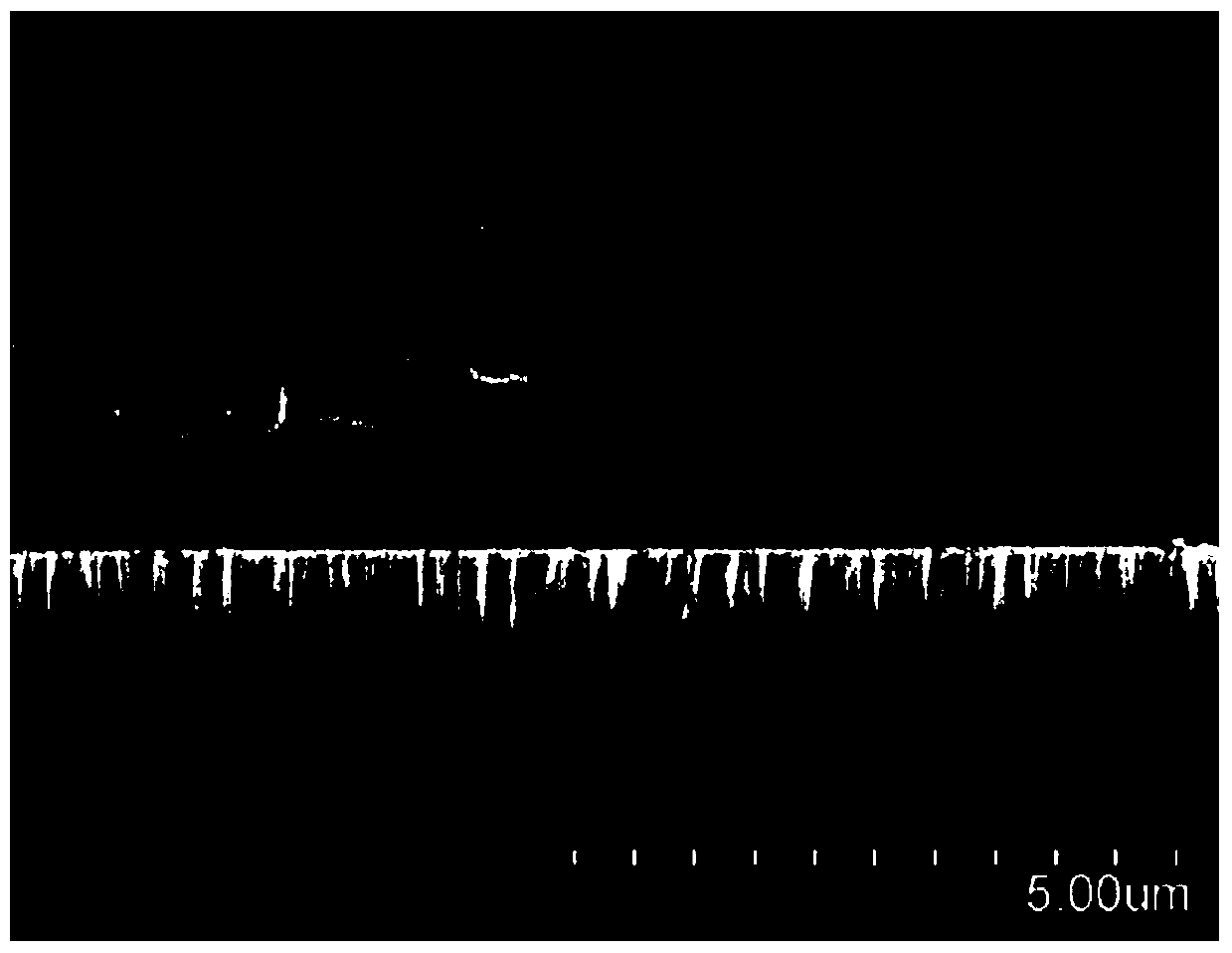

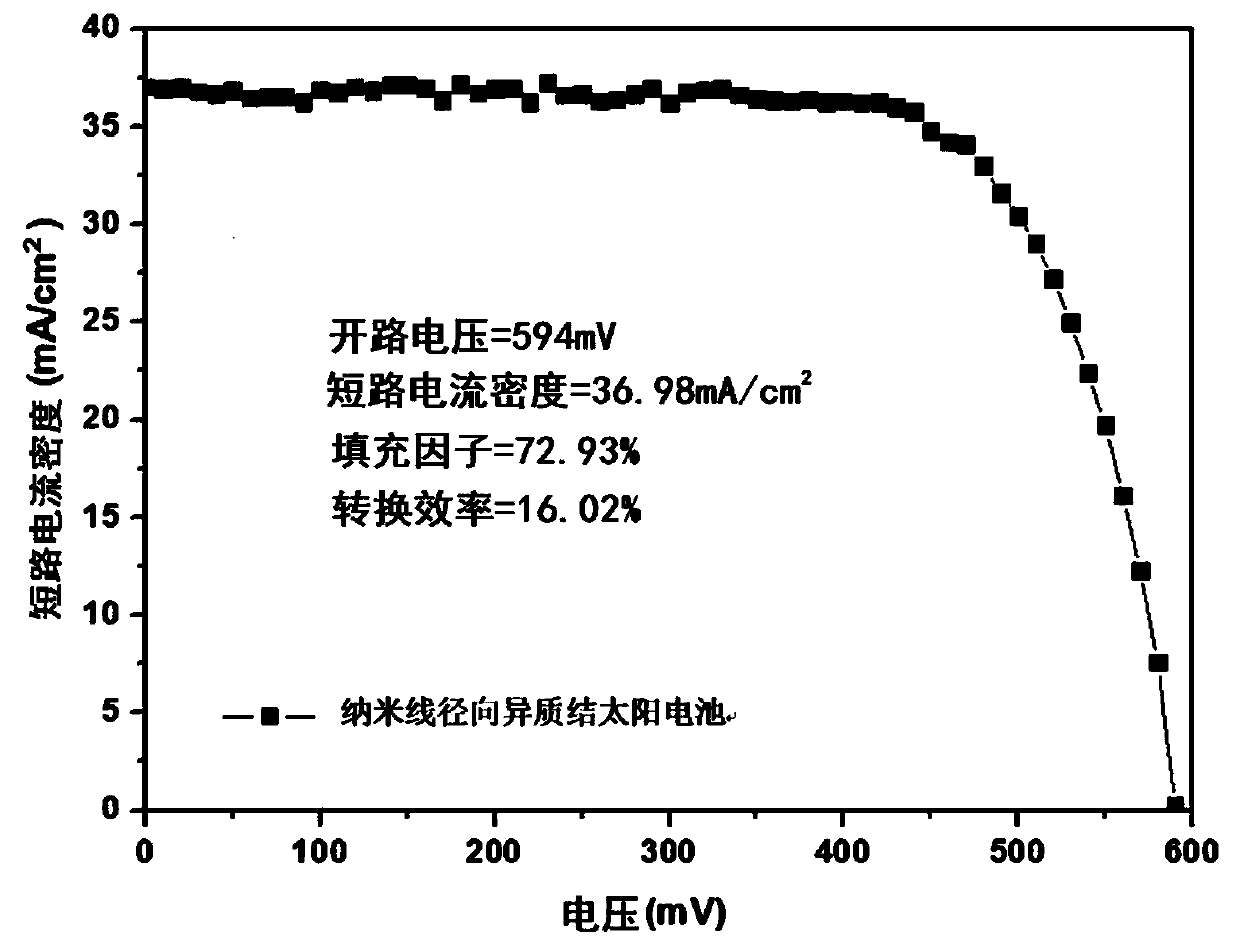

Silicon nanowire radial heterojunction solar battery manufacture method

InactiveCN103779448AReduce surface recombinationImprove interface passivation effectFinal product manufactureNanotechnologySilicon nanowiresSingle crystal silicon wafer

The invention relates to a silicon nanowire radial heterojunction solar battery manufacture method and belongs to the photovoltaic technical field. By means of a hot filament chemical vapor deposition technology, intrinsic and n-type amorphous silicon membranes are sequentially subjected to conformal deposition on a monocrystalline silicon piece with nanowires to manufacture a silicon nanowire radial heterojunction solar battery with the structure of n-a-Si: H / i-a-Si: H / p-c-SiNW. By the aid of good atom hydrogen treatment and intrinsic amorphous silicon passivation capacities of the hot filament chemical vapor deposition technology, properties of the manufactured nanowire radial heterojunction solar battery are substantially improved; the nanowire radial heterojunction solar battery has a novel structure, good properties and wide application values in the photovoltaic field.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

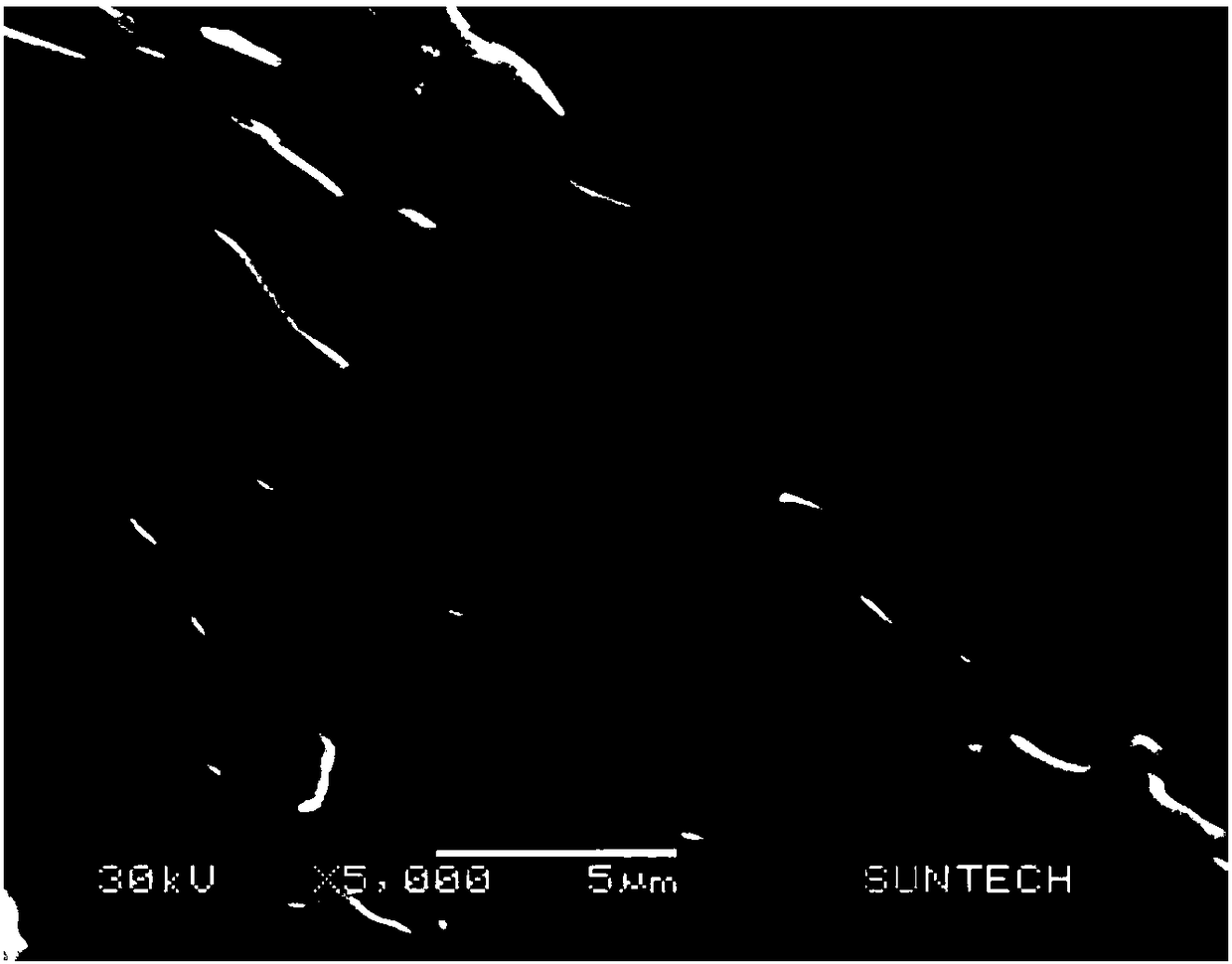

Polysilicon surface reverse pyramid structure and preparation method thereof

ActiveCN105428434AReduce reflectivityImprove trapping effectFinal product manufacturePhotovoltaic energy generationHigh surfaceSolar battery

The invention discloses a polysilicon surface reverse pyramid structure and a preparation method thereof. Back silicon is manufactured by use of different methods, then, a sample is placed in a mixed liquid of hydrogen peroxide and ethanolamine, then washed black silicon is placed in a mixed liquid of hydrogen peroxide, hydrofluoric acid, metaphosphoric acid and ammonium fluoride for reprocessing, and thus the polysilicon surface reverse pyramid structure is formed. According to the invention, by use of a wet chemical method different from soda acid corrosion, the method can reduce the influence of anisotropy to the maximum degree, and the back silicon with different nano structures is enabled to have a nanometer textured structure with a regular reverse pyramid structure through oxidation corrosion. Compared to a conventional polysilicon textured structure, the polysilicon reverse pyramid light tripping structure is higher in utilization rate of light and lower in reflectivity. Due to the feature of its reverse pyramid structure, compared to high surface recombination of the small yet dense structure of conventional black silicon, the surface recombination of the polysilicon surface reverse pyramid structure is obviously reduced, and the efficiency of a solar battery is higher.

Owner:江苏辉伦太阳能科技有限公司

Solar cell and front electrode thereof, and preparation methods and applications thereof

PendingCN112234109AImprove collection effectImprove conversion efficiencyFinal product manufactureOther printing apparatusSilver pasteSolar battery

The invention discloses a solar cell and a front electrode thereof, and preparation methods and applications thereof, and belongs to the technical field of solar cells. According to the front electrode of the solar cell, the number of welding spots on a single main grid is 15-70, the width of the single welding spot is 0.4-1.0 mm, and the length of the single welding spot is 0.1-0.6 mm. Accordingto the preparation method of the front electrode, a main grid and an auxiliary grid are printed step by step, specifically, by adopting front silver paste with the solid content of 80-95%, the tinningarea larger than 80% and the tension mean value larger than 1.0 N and not adopting burning through silicon nitride, synchronous printing is carried out on a main grid region, and synchronous printingis carried out on an auxiliary grid region by adopting positive silver paste which has a height-width ratio of 35% or above and can burn through silicon nitride. By adopting the technical scheme of the invention, the collection effect of the positive electrode on carriers can be effectively improved, so that the conversion efficiency of the solar cell can be improved.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

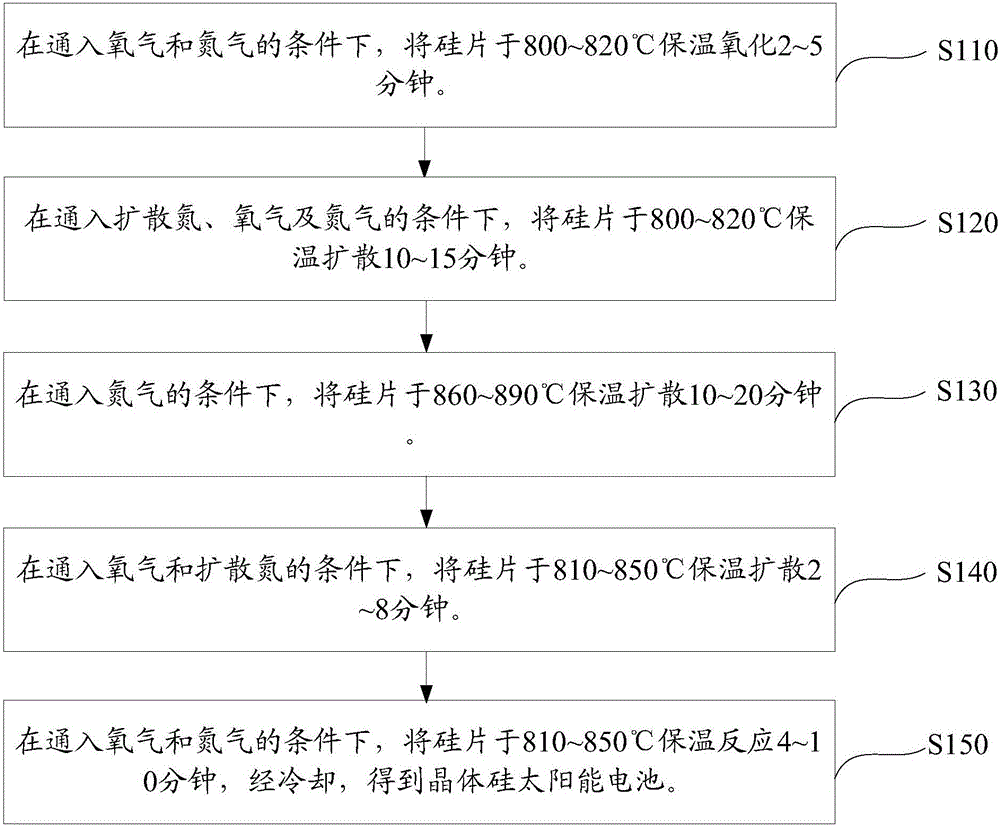

Crystalline silicon solar cell and diffusion method therefor

InactiveCN105070787AReduce surface recombinationReduce concentrationFinal product manufactureSemiconductor/solid-state device manufacturingDiffusion methodsPower flow

The invention relates to a crystalline silicon solar cell and a diffusion method therefor. The method comprises the following steps: 1, carrying out the heat preservation and oxidation of a silicon chip under the temperature from 800 DEG C to 820 DEG C under the condition of oxygen gas and nitrogen gas; 2, carrying out the heat preservation diffusion of the silicon chip under the temperature from 800 DEG C to 820 DEG C under the condition of diffused nitrogen, oxygen gas and nitrogen gas; 3, carrying out the heat preservation diffusion of the silicon chip under the temperature from 860 DEG C to 890 DEG C under the condition of nitrogen gas; 4, carrying out the heat preservation diffusion of the silicon chip under the temperature from 810 DEG C to 850 DEG C under the condition of oxygen gas and diffused nitrogen; 5, carrying out the heat preservation reaction of the silicon chip under the temperature from 810 DEG C to 850 DEG C under the condition of oxygen gas and nitrogen gas, wherein the diffused nitrogen is nitrogen containing phosphorus oxychloride. Moreover, the flow of the diffused nitrogen at step 4 is smaller than the flow of the diffused nitrogen at step 2. The method can increase the short-circuit current of the crystalline silicon solar cell.

Owner:CSG PVTECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com