Solar battery diffusion method

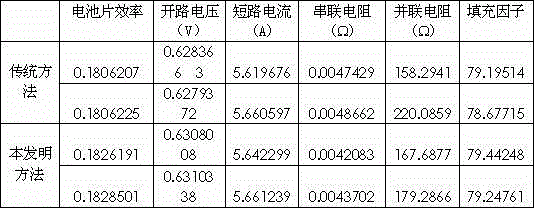

A solar cell and diffusion method technology, applied in the field of crystalline silicon solar cell manufacturing, can solve problems such as reduced filling, increased series resistance, and low-efficiency sheets in the production line, so as to reduce surface recombination and defect concentration, increase conversion efficiency, and improve The effect of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The raw material is P-type monocrystalline silicon wafer, the thickness is 200±20um, and the resistivity is 0.5-6W.cm. Place the slices in a diffusion furnace.

[0047] Step 1, the first oxidation

[0048] The temperature of the diffusion furnace is raised to 820°C, the flow rate of oxygen is 10slm, and the time of oxygen is 15min to form a 20nm oxide layer;

[0049] Step 2. Diffusion

[0050] 2.1, the first diffusion

[0051] The diffusion furnace is heated to 840°C, the flow rate of the small nitrogen is 1.2 slm, the flow rate of the large nitrogen is 9 slm, the flow rate of the oxygen is 1.3 slm, and the time for feeding the mixed gas is 6 minutes;

[0052] 2.2, the second diffusion

[0053] The diffusion furnace is heated to 850°C, the flow rate of the small nitrogen is 1.0 slm, the flow rate of the large nitrogen is 9 slm, the flow rate of the oxygen is 1.2 slm, and the time for feeding the mixed gas is 5 minutes;

[0054] 2.3. The third diffusion

[0055] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com