Method for preparing front electrodes of solar cells

A technology for solar cells and front electrodes, which is applied in the manufacture of circuits, electrical components, and final products. It can solve the problems of very high screen printing accuracy, no advantages, and reduced recombination, so as to avoid alignment problems and achieve good aspect ratios. , Reduce the effect of shading area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

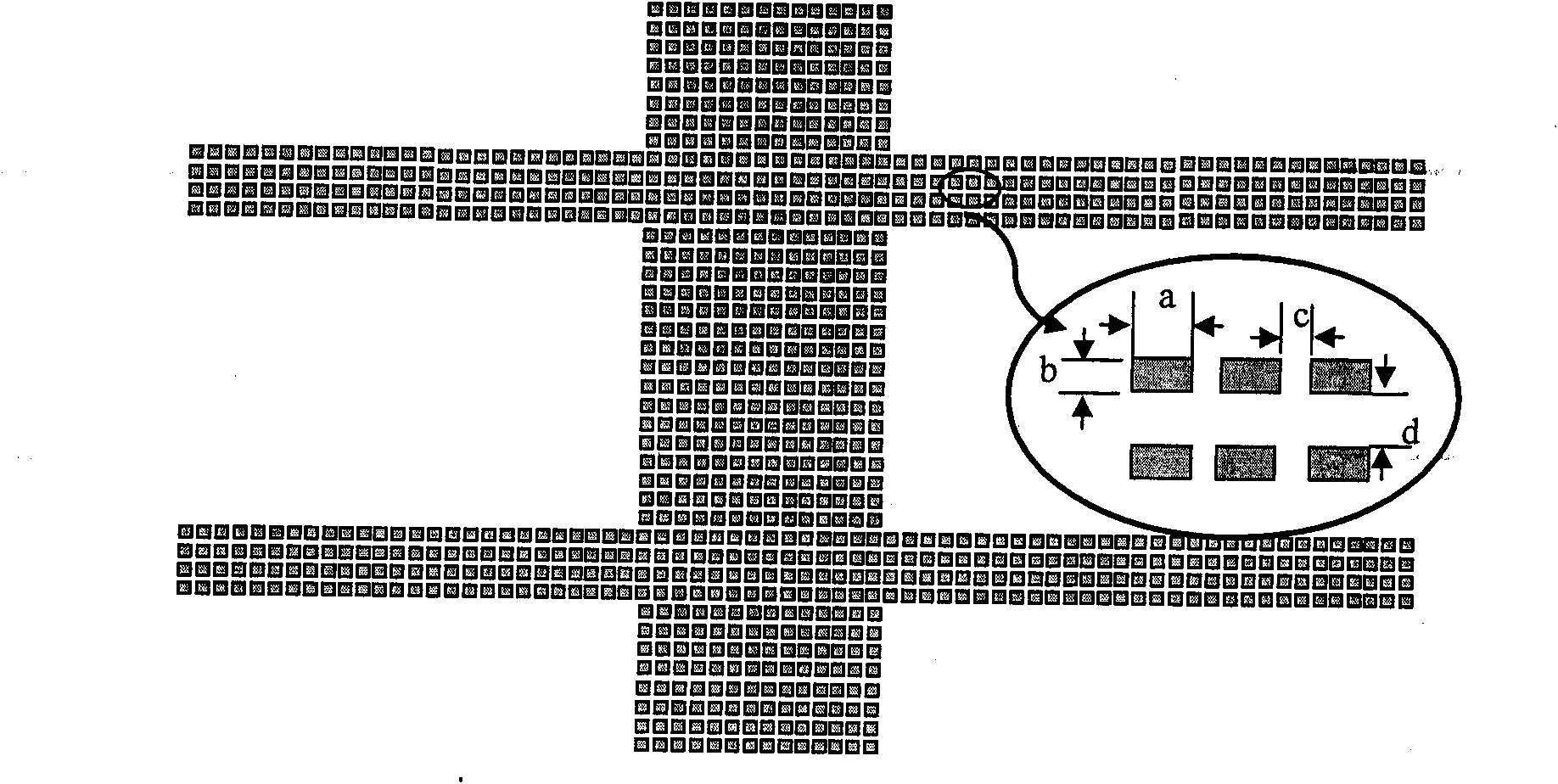

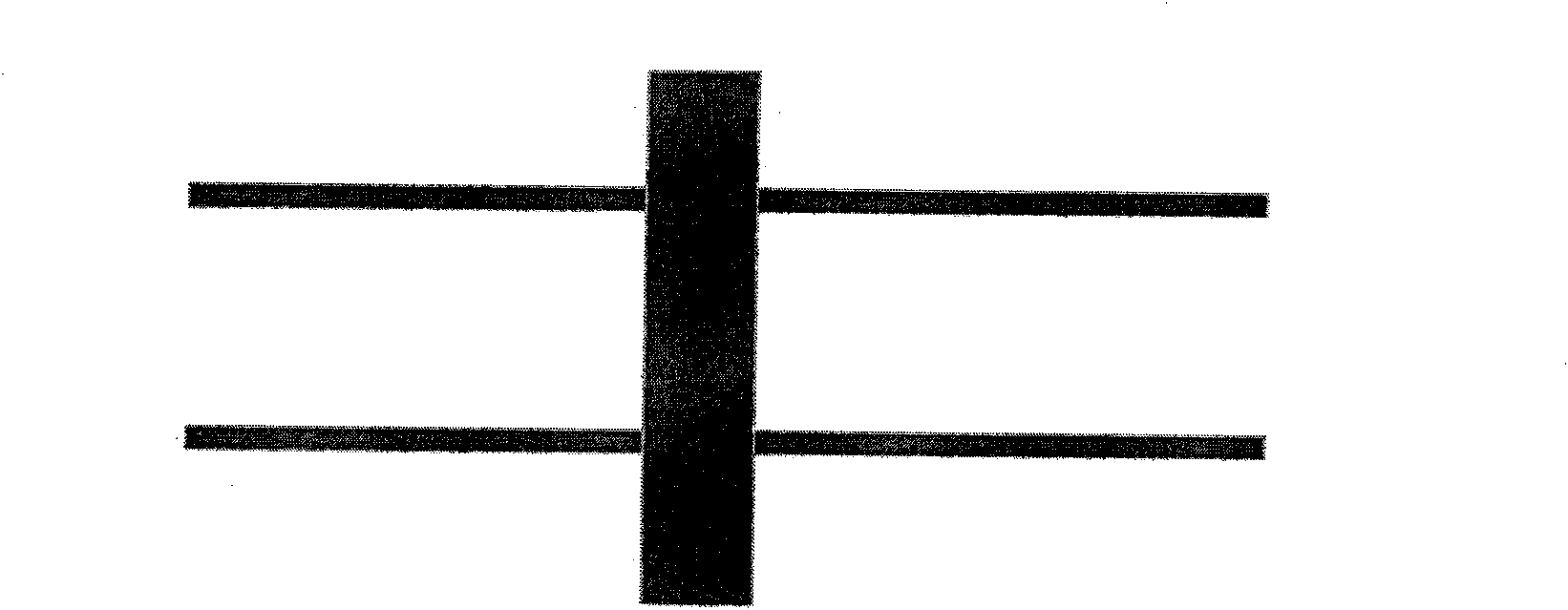

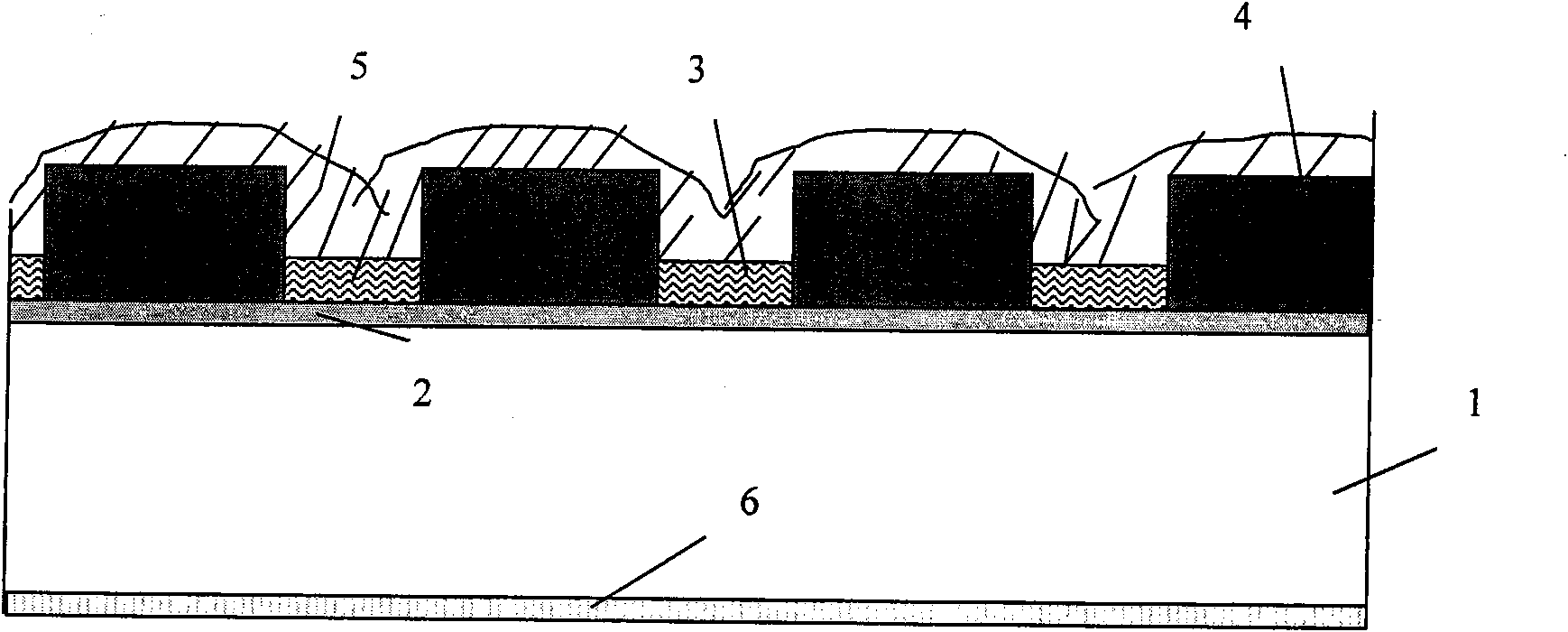

Embodiment 1

[0034] Example 1: After P-type silicon substrate (1) is cleaned and textured by conventional industrial cleaning methods, POCl is diffused at 850°C 3 The liquid source was used for 30 minutes to obtain an N-type emitter (2) of about 40Ω / □. Deposit a layer of SiN of about 90nm on the emitter with PECVD equipment x After the thin film is used as the dielectric film (3), screen-print aluminum paste on the side of the silicon substrate (1) without the dielectric film (3) as the back electrode (6), and then screen-print dot-shaped discontinuous Ag on the dielectric film by a screen printing machine. Metal paste (4), dot electrode patterns are determined by the screen used. The length a of the point electrodes is 10 μm, the width b is 60 μm, the length of the horizontal spacing c of the point electrodes is 10 μm, and the length of the vertical spacing d is 0 μm. Putting the silicon substrate (1) which has completed the silk screen printing process into a sintering furnace for sint...

Embodiment 2

[0035] Example 2: After P-type silicon substrate (1) is cleaned and textured by conventional industrial cleaning methods, POCl is diffused at 850°C 3 The liquid source is used for 30 minutes to obtain an N-type emitter (2) of about 40Ω / □. Then prepare the dielectric film (3), the steps are as follows: oxidize at 860°C for 10 minutes to obtain a layer of SiO with a thickness of about 10nm 2 thin film, followed by APCVD on SiO 2 Deposit a layer of 80nm TiO on the film 2 Thin film, complete the preparation of the dielectric film (3). On the side of the P-type silicon substrate (1) without the dielectric film (3), the aluminum paste is screen-printed to form the back electrode (6) and then the dot-shaped discontinuous Ag metal paste is screen-printed on the dielectric film (3) through a screen printing machine ( 4), the dot electrode pattern is determined by the screen. Wherein the length a of the dot electrodes is 10 μm, the width b is 10 μm, the horizontal spacing length c o...

Embodiment 3

[0036] Example 3, P-type silicon substrate (1) was cleaned and textured by conventional industrial cleaning methods, and POCl was diffused at 850°C 3 The liquid source is used for 30 minutes to obtain an N-type emitter (2) of about 40Ω / □. Then deposit a layer of SiN of about 90nm on the emitter (2) by PECVD x After the thin film is used as the dielectric film (3), screen-print aluminum paste on the side of the silicon substrate (1) without the dielectric film (3) to form the back electrode (6), and screen-print dots on the dielectric film (3) by a screen printing machine. Discontinuous Ag electrode paste (4), dot electrode pattern is determined by the screen used. The length a of the point electrodes is 100 μm, the width b is 20 μm, the length of the horizontal interval c of the point electrodes is 100 μm, and the length of the vertical interval d is 0 μm. The silicon substrate (1) which has completed the silk screen printing process is put into a sintering furnace for sinte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com