Composition for producing golf balls and multi-piece golf balls

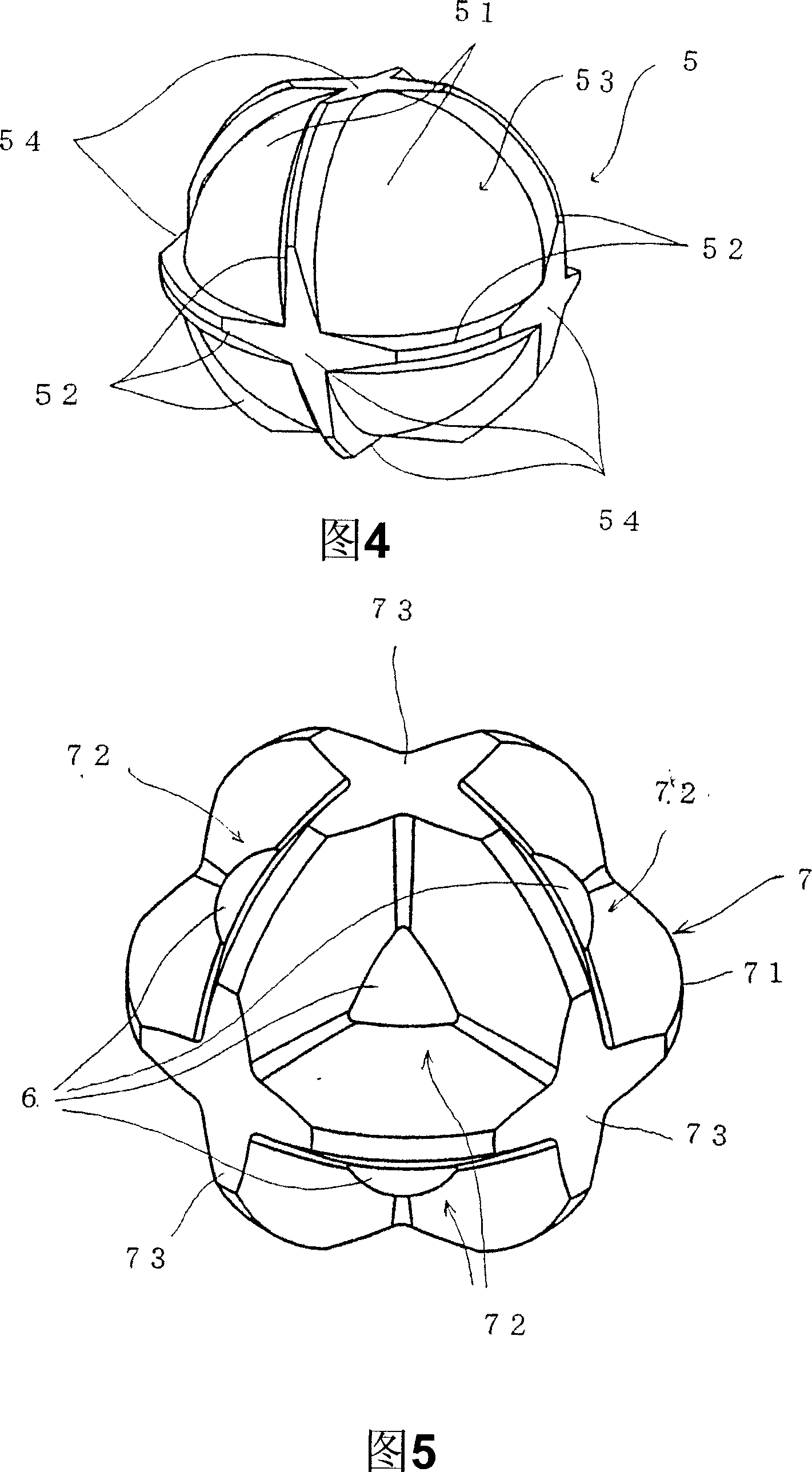

一种多层高尔夫球、高尔夫球的技术,应用在高尔夫球、高尔夫球、球类等方向,能够解决触感硬、不能延长飞行距离、高尔夫球很难实现等问题,达到反弹性优异、密合性提高、耐用性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0293] Hereinafter, the present invention will be specifically described by way of examples and test examples, but the present invention is not limited to the given examples.

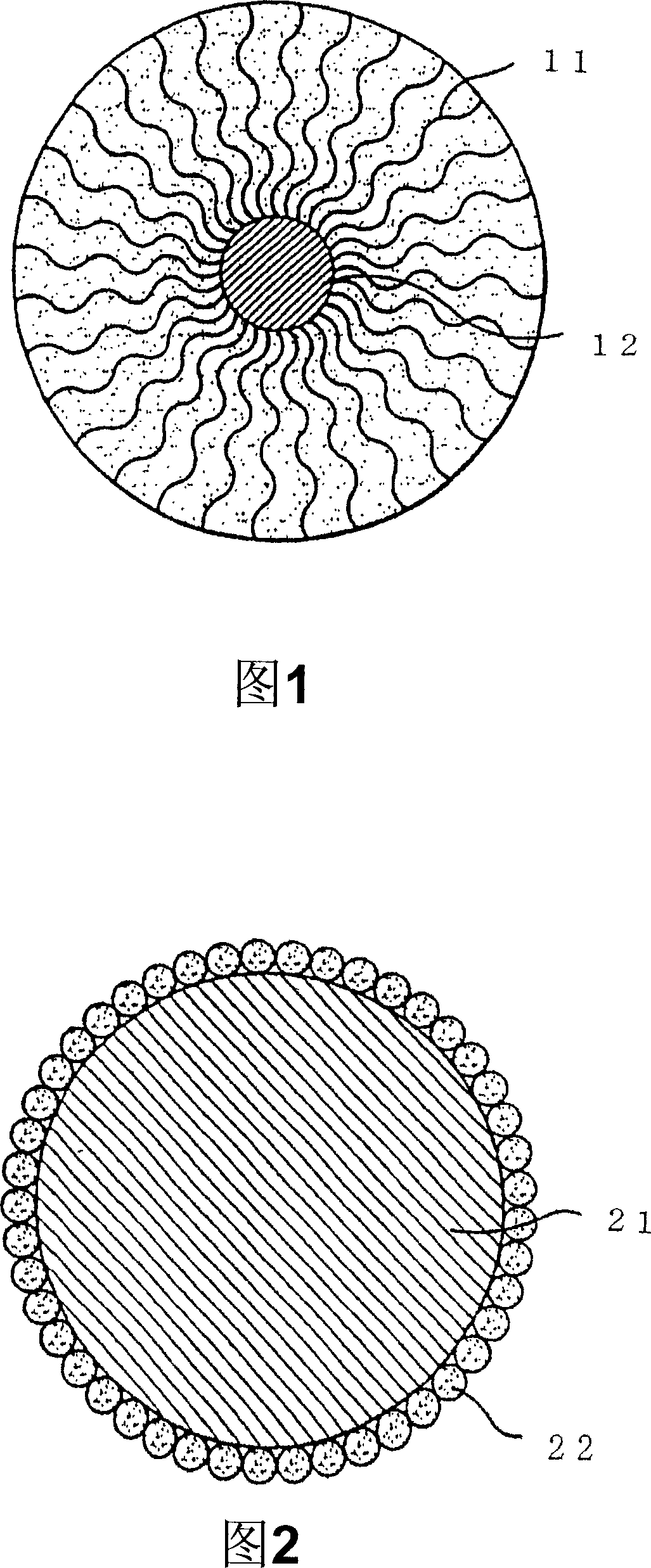

[0294] Polyurethane Gel Composite Particles

[0295] Polyurethane gel composite particles used in the following examples are DAIMIC BEAZ UCN-5070D series (average particle size: 7 μm) containing a thermosetting polyurethane resin manufactured by Dainichi Seika Kogyo Co., Ltd. The characteristics of the fine particles are shown in Table 1 below.

[0296] Table 1

[0297] UCN-5070D

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com