Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

194results about How to "Reduce light reflectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar Panel

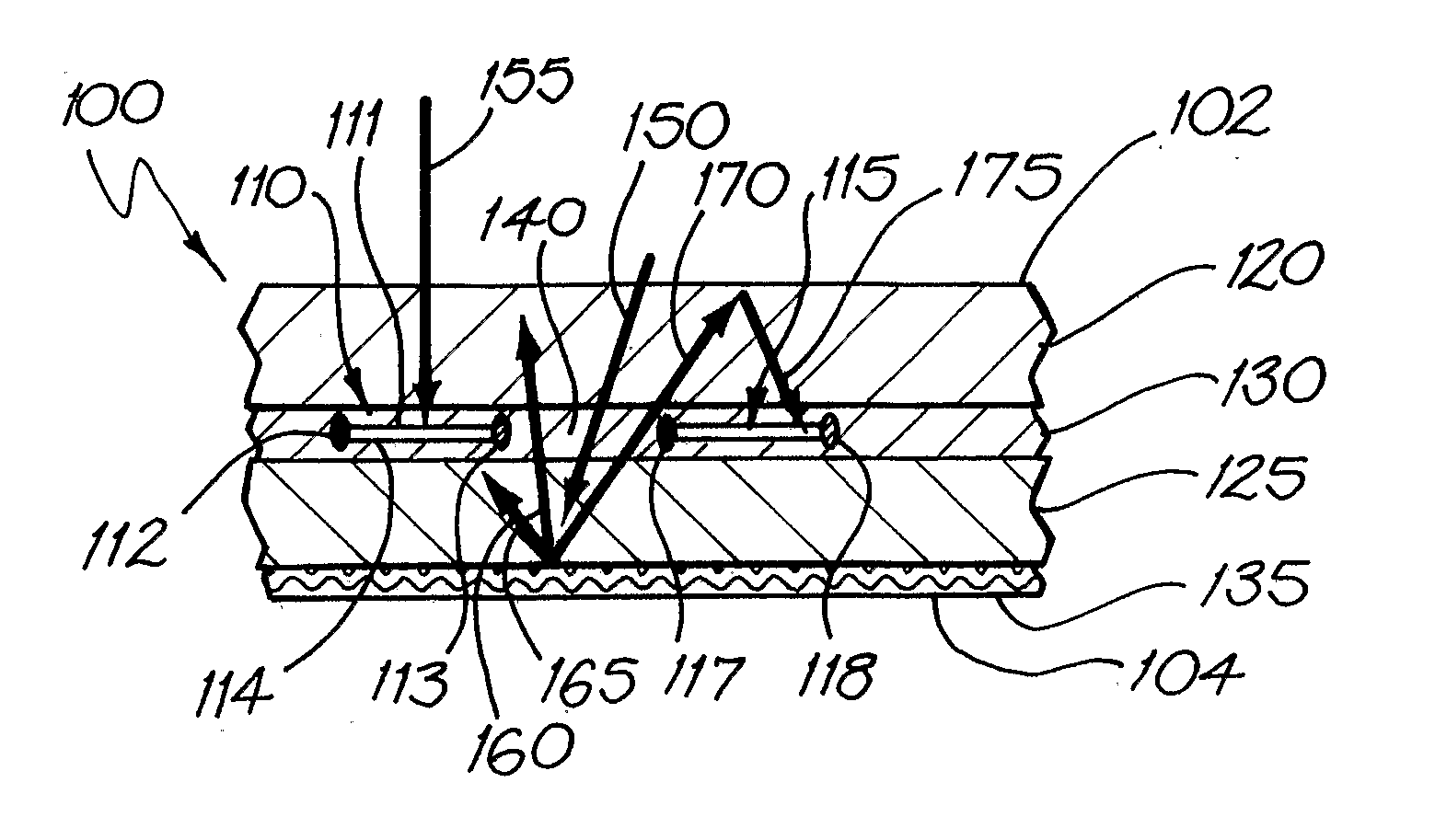

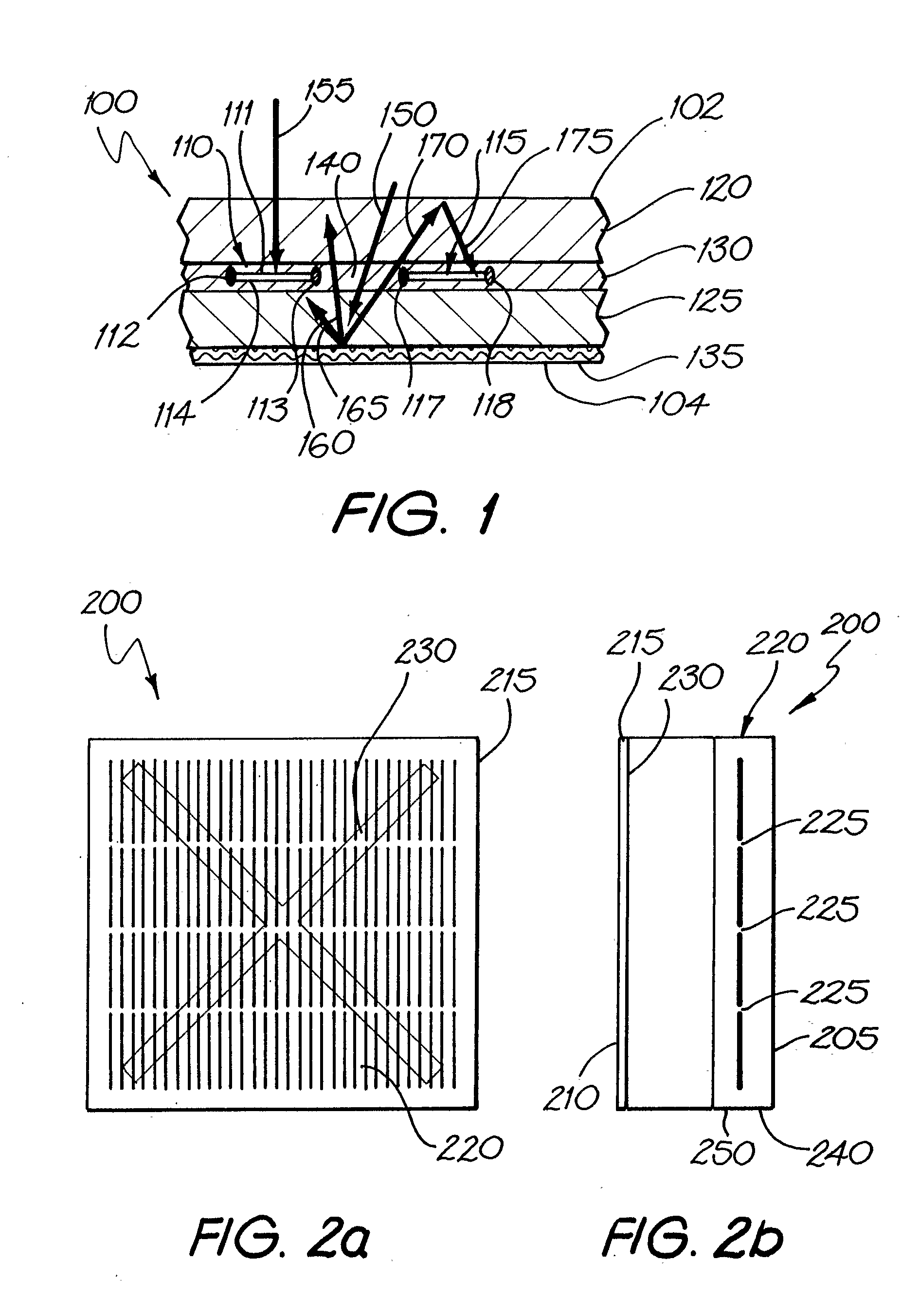

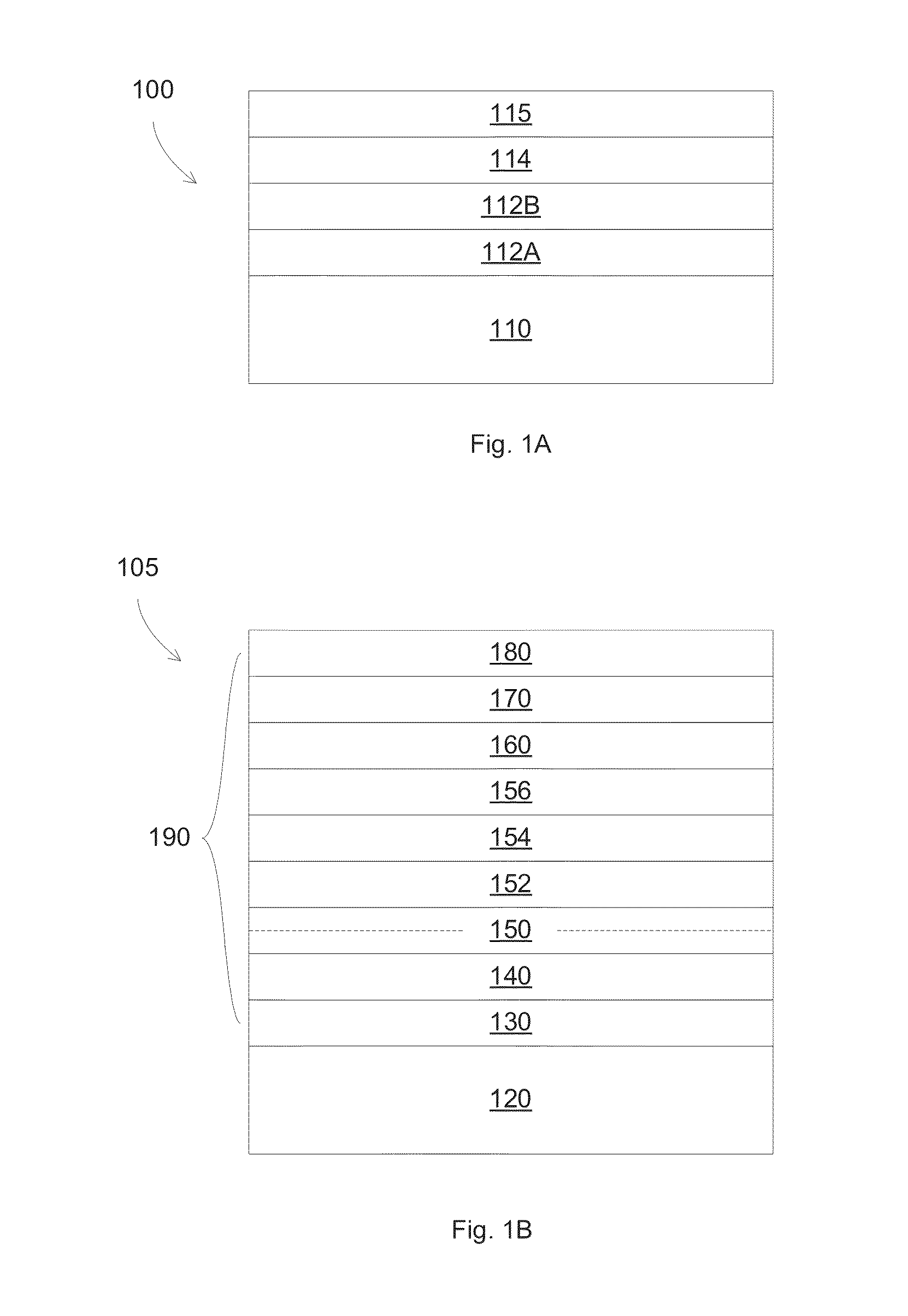

InactiveUS20070277810A1Reduce reflectivityReduce light reflectivitySolar heat devicesFinal product manufactureSolar lightEngineering

The invention provides a solar panel having a panel front and a panel back, comprising an array of solar cells and an element comprising a visually distinguishable feature. Each of the solar cells has a front and a back, wherein at least the front is capable of converting at least a portion of solar light incident thereon into electrical energy. There are spacings between at least some of the solar cells. The element comprising the visually distinguishable feature is located at at least one position selected from the group consisting of between the panel back and the panel front, on the panel front, on the panel back, at the panel front, and at the panel back, such that the visually distinguishable feature is at least partially distinguishable on viewing the panel front. The nature of the visually distinguishable feature and / or the location of the element relative to the solar cells does not completely prevent solar light incident on the panel front from being incident on at least a portion of the array.

Owner:TRANSFORM SOLAR

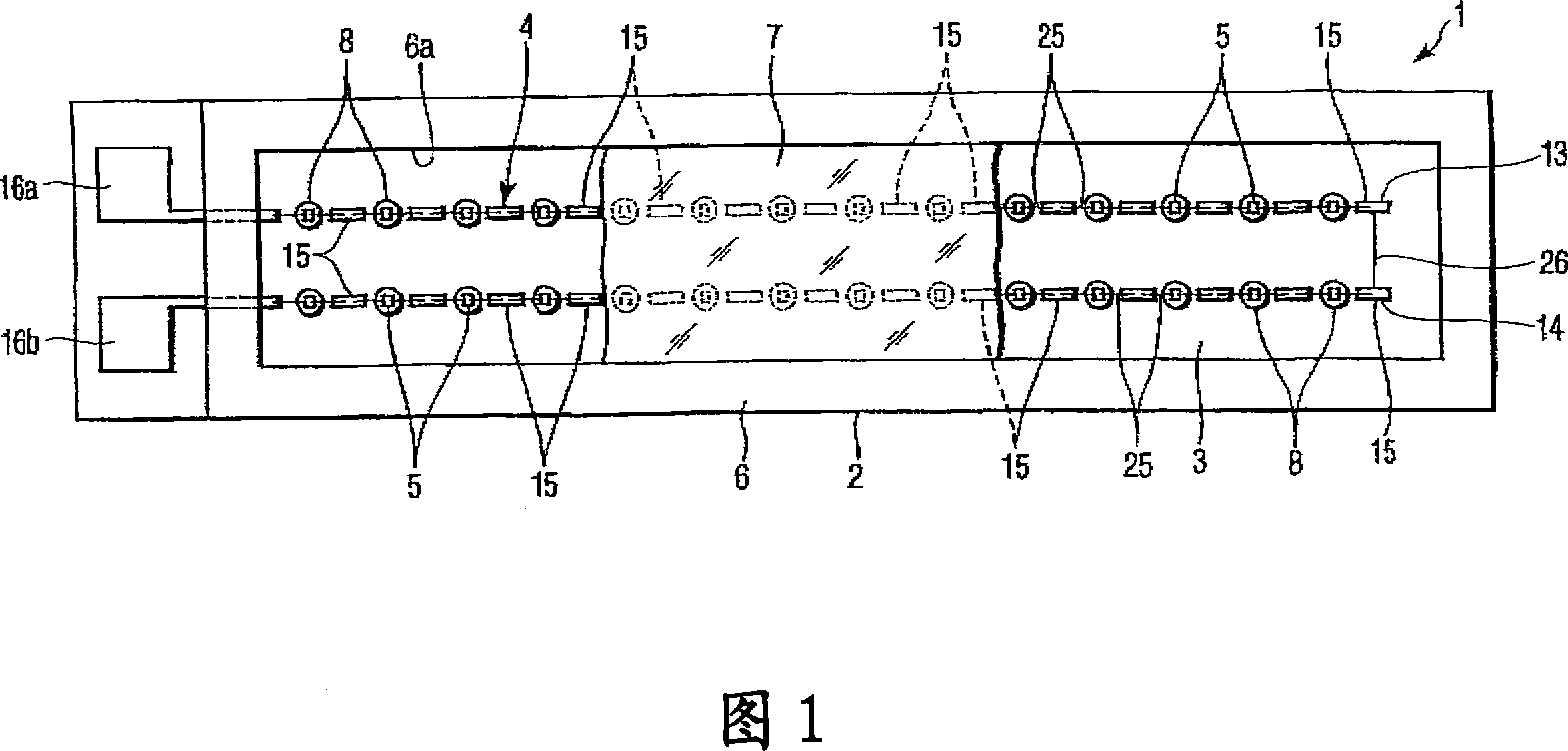

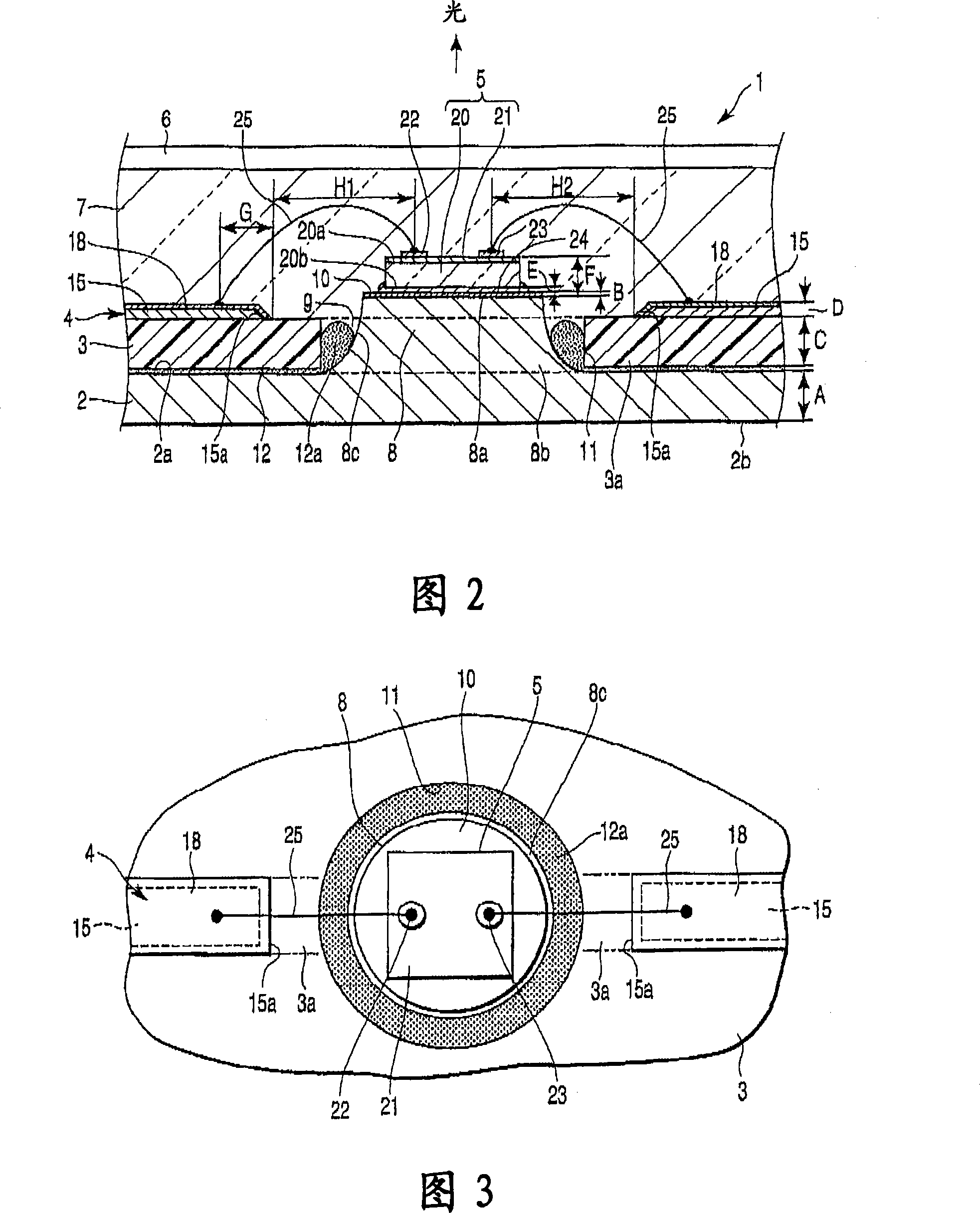

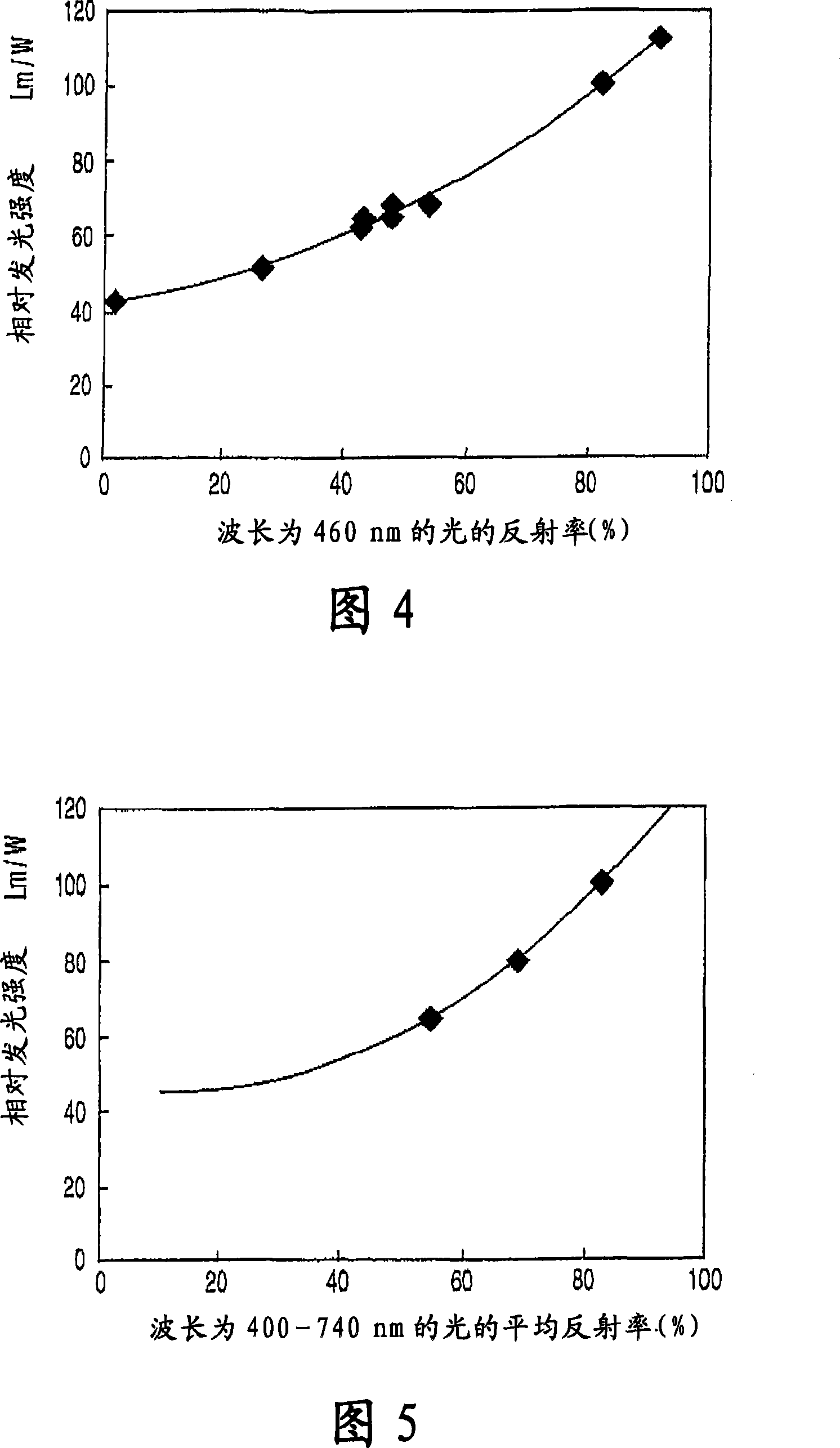

LED module, LED package, and wiring substrate and method of making same

InactiveUS20120002420A1Enhance light reflectionReduce manufacturing costLighting support devicesSolid-state devicesEngineeringLength wave

An LED module includes an electrical insulation material including a first surface having a total reflectivity of not less than 80% with respect to light with a wavelength of 450 nm, a via hole penetrating through the electrical insulation material, a wiring pattern on a second surface of the electrical insulation material, a metal filler formed in the via hole and electrically connected to the wiring pattern, and an LED chip bonded to a surface of the metal filler on the first surface of the electrical insulation material, and sealed with a resin.

Owner:SHINDO DENSHI KOGYO KK

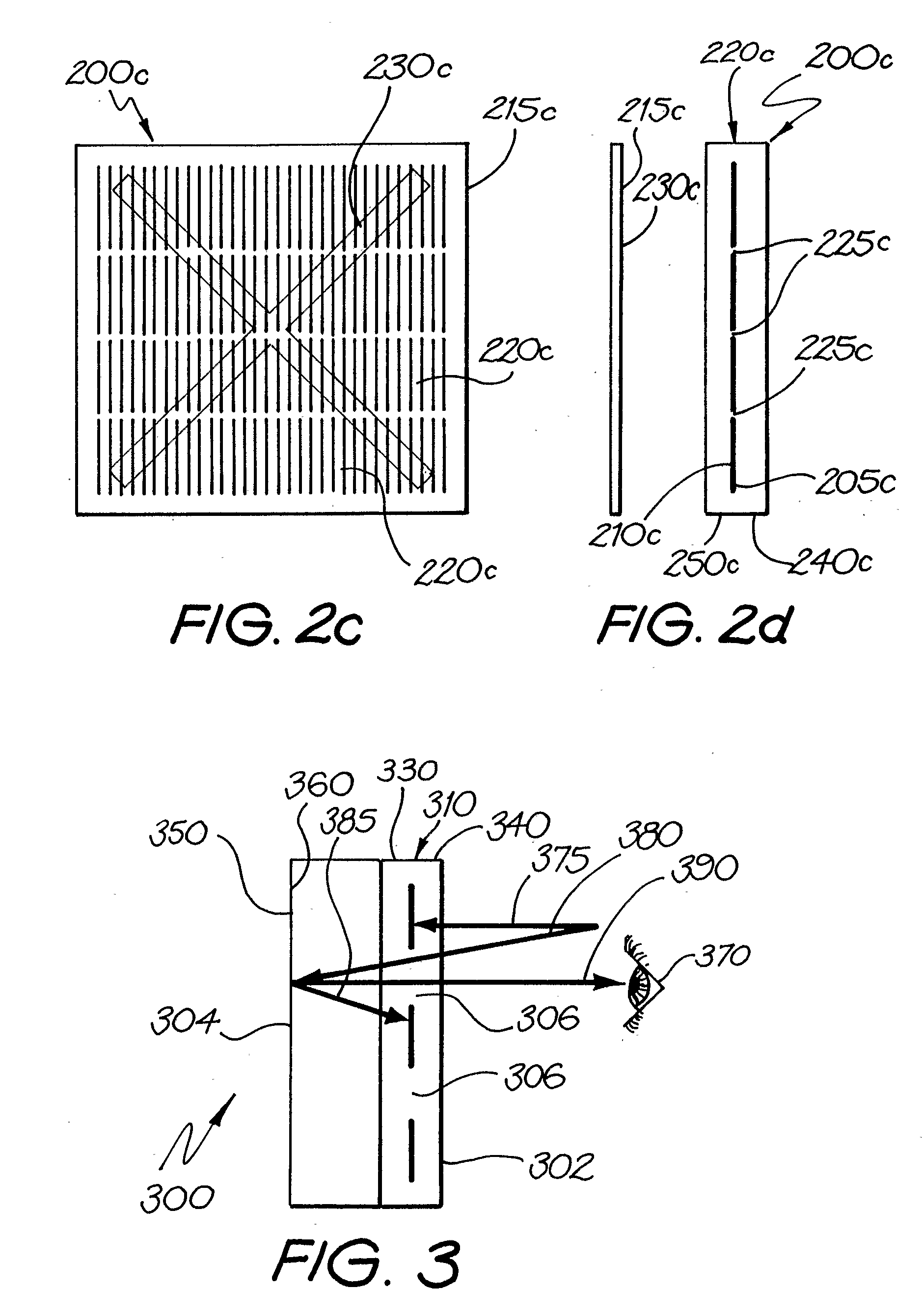

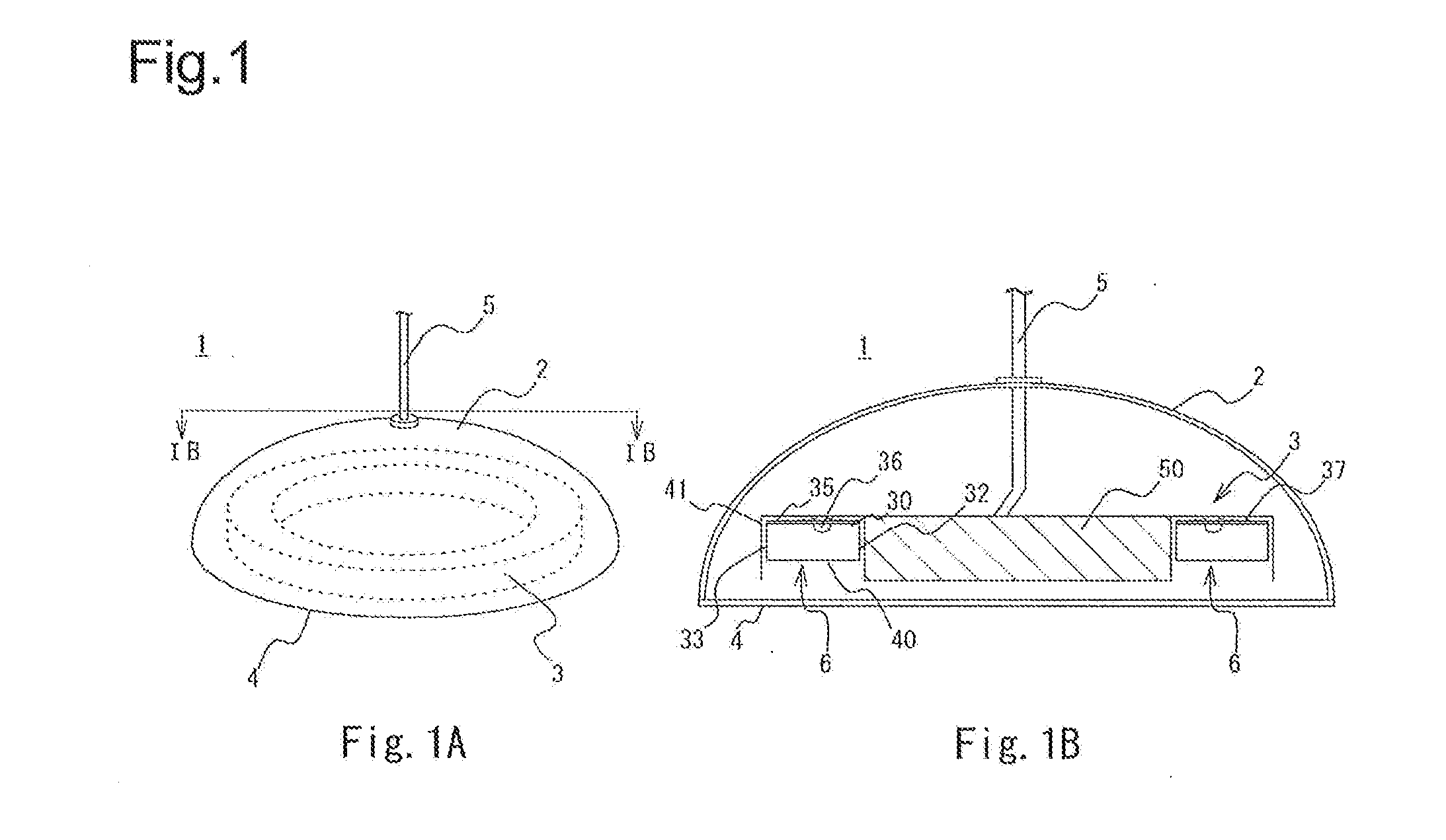

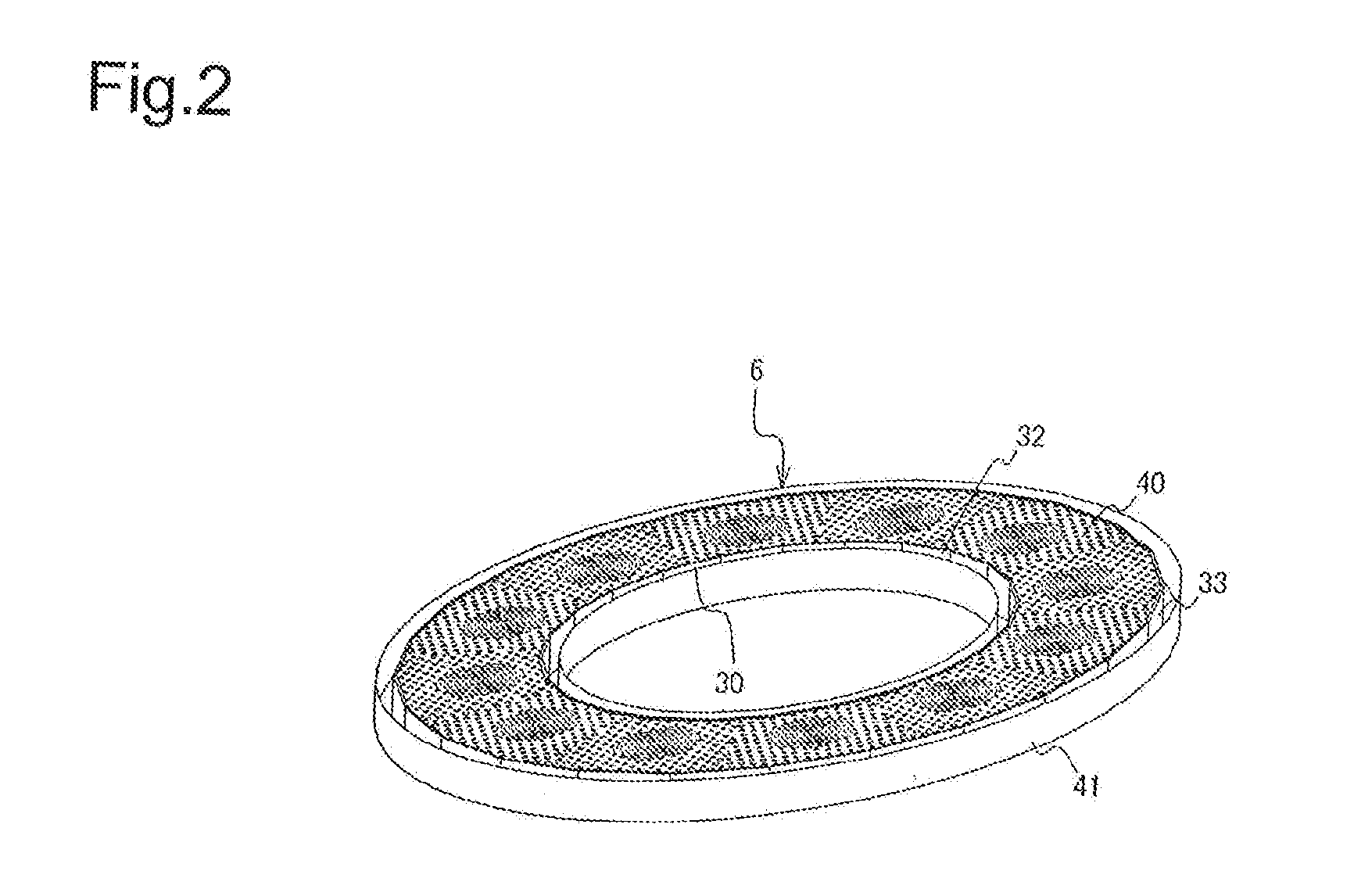

Surface illumination fixture and surface illumination device

InactiveUS20130044480A1Suppress generationLow light transmittanceNon-electric lightingPoint-like light sourcePoint lightLight guide

[Purpose] To provide a surface illumination fixture using a point light source having strong directivity.[Constitution] In the surface illumination fixture 3 including a surface illumination light-source device 6 converting light from a plurality of point light sources 36 having strong directivity into surface illumination and an illumination fixture main body 41, the surface illumination light-source device 6 includes a casing 30 having a flat plate part 35 being used to attach the surface illumination light-source device to the illumination fixture main body, lateral plate parts standing from the flat plate part, and an opening on a surface opposite to the flat plate part, and includes a light-guide reflection plate covering the opening. The flat plate part 35, the lateral plate parts 32 and 33, and the light-guide reflection plate 40 are formed by members having a high light reflectance and a low light transmittance. The light-guide reflection plate 40 is formed to have a lower light reflectance and a higher light transmittance as the distance from the corresponding point light source increases. The illumination fixture main body 41 having attaching means for attachment to a ceiling or a wall.

Owner:OPTO DESIGN INC

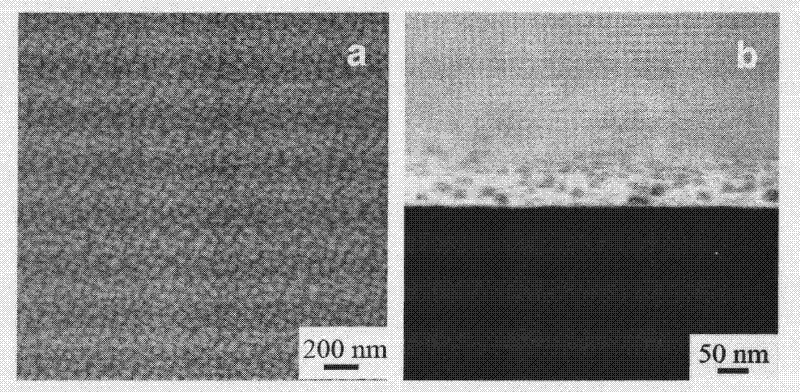

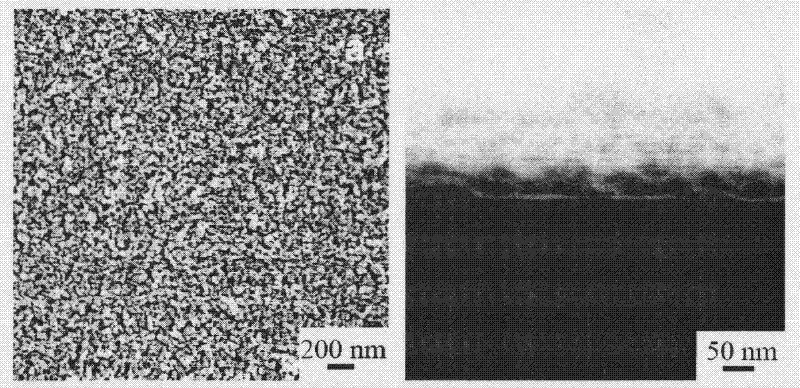

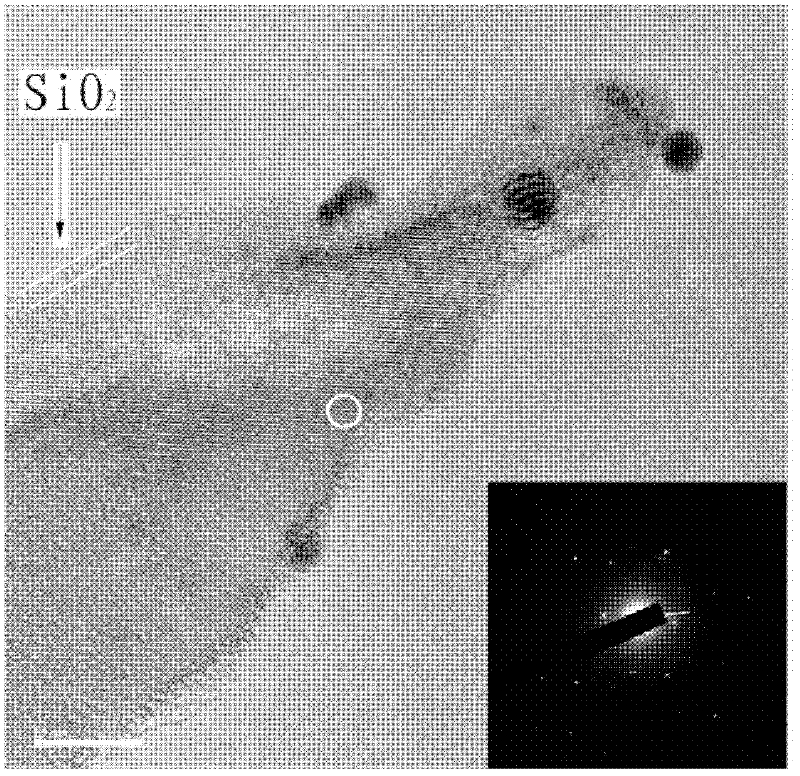

Anti-reflection coating and super-hydrophobic self-cleaning anti-reflection coating and preparation method thereof

The invention relates to an anti-reflection coating and a super-hydrophobic self-cleaning anti-reflection coating and a preparation method thereof. The anti-reflection coating is formed by a SiO2 ball-shaped nanoparticle layer with the particle size of 10-100 nm, and the surface of the coating has a rough structure. The super-hydrophobic self-cleaning anti-reflection coating is formed by providing a low surface energy substance on the surface of the anti-reflection coating, and the surface of the low surface energy substance has a rough structure. The coatings are obtained by using layer-by-layer electrostatic self-assembly technique. The light transmittance of the glass coated with the super-hydrophobic self-cleaning anti-reflection coating can increase to 99.1 from 91.3%, and the single-side reflectivity of the glass can reduce lowest to 0.3%. Compared with a solar cell coated with a common glass flake, a standard mono-silicon solar cell panel coated with a glass with the super-hydrophobic self-cleaning anti-reflection coating can utilize solar energy more effectively, and the efficiency can be improved to more than 6.6%.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

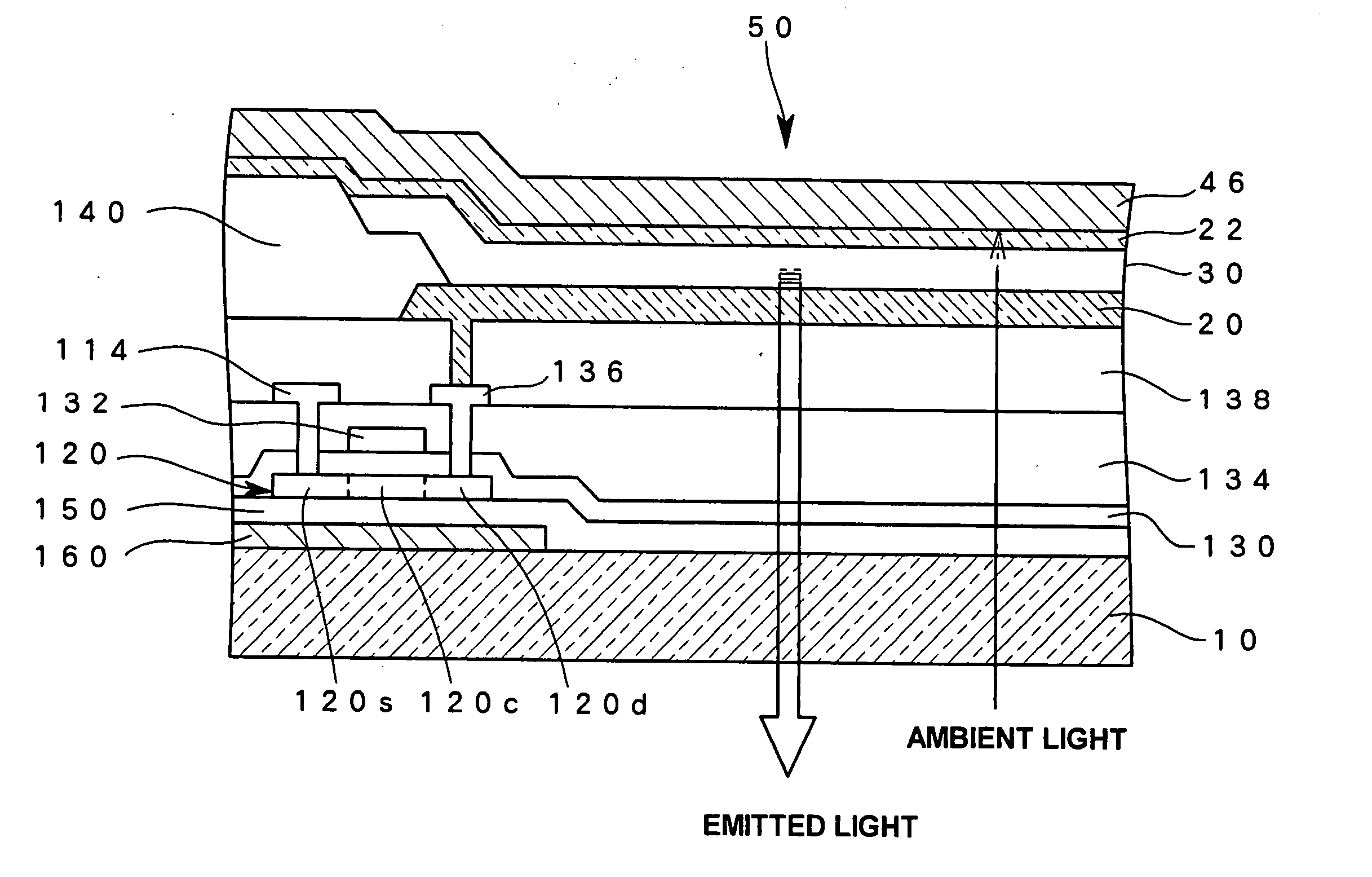

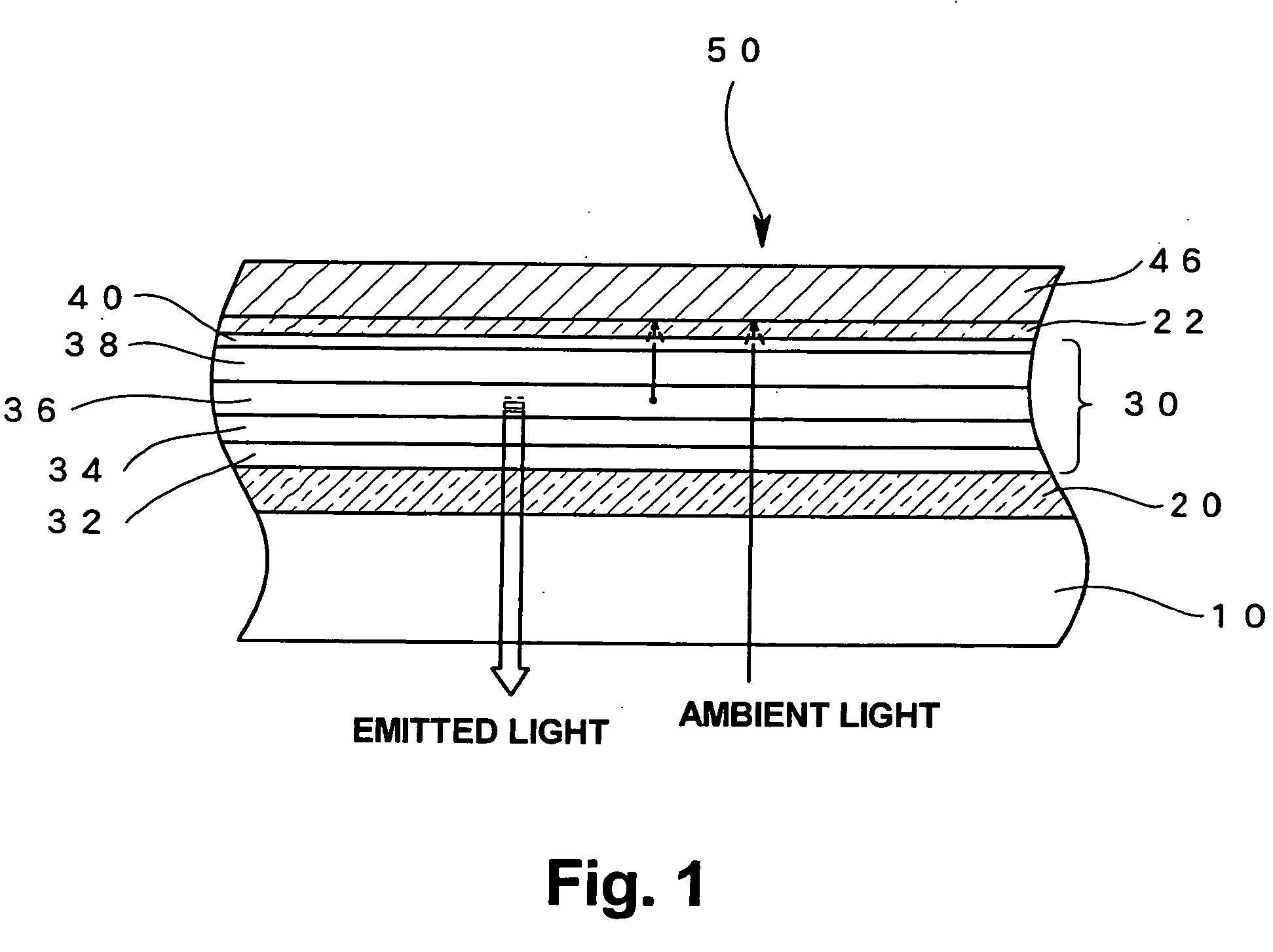

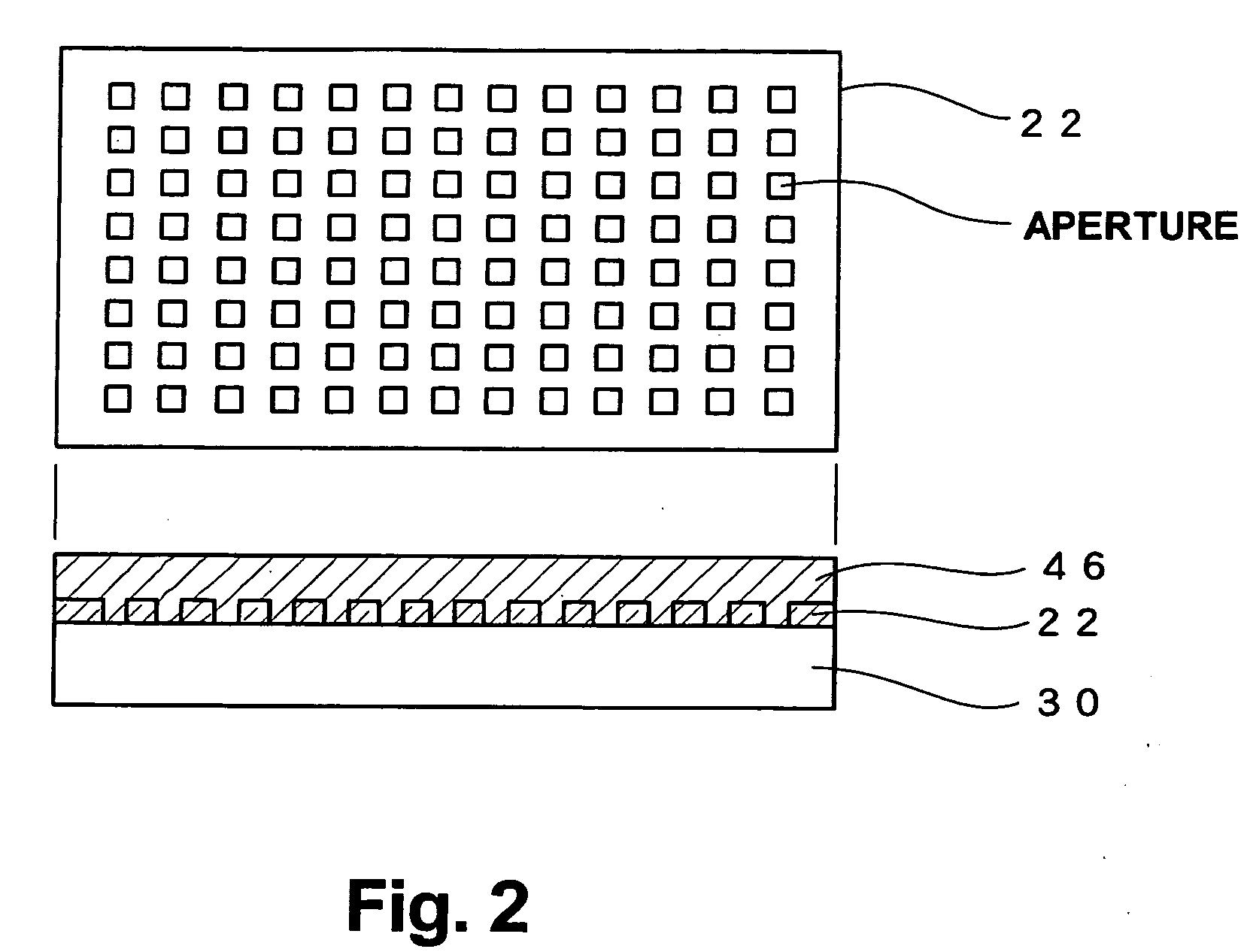

Light emitting element and light emitting display

InactiveUS20040206960A1Reduce contrastEasy to seeElectroluminescent light sourcesSolid-state devicesDisplay deviceMetallic materials

A light emitting element such as an organic EL element comprises a first electrode formed of a transparent electrode on a side from which light is emitted to outside, and a second electrode formed on a back side of the element so as to be opposed to the first electrode with a light emitting element layer interposed therebetween. The second electrode is designed to be a semitransparent electrode, and, on a further back side of the second electrode, an antireflective layer with a low optical reflectivity is formed. The semitransparent second electrode does not reflect but transmits light incident from outside of the element and transmitted through the transparent electrode, and then the antireflective layer absorbs the transmitted light, thereby making it possible to suppress reflection of ambient light on a surface of the back-side electrode and to achieve improvement in contrast. The second electrode may, for example, be made of a metal material formed as a thin film, or be provided with apertures to thereby exhibit semitransparency.

Owner:SANYO ELECTRIC CO LTD

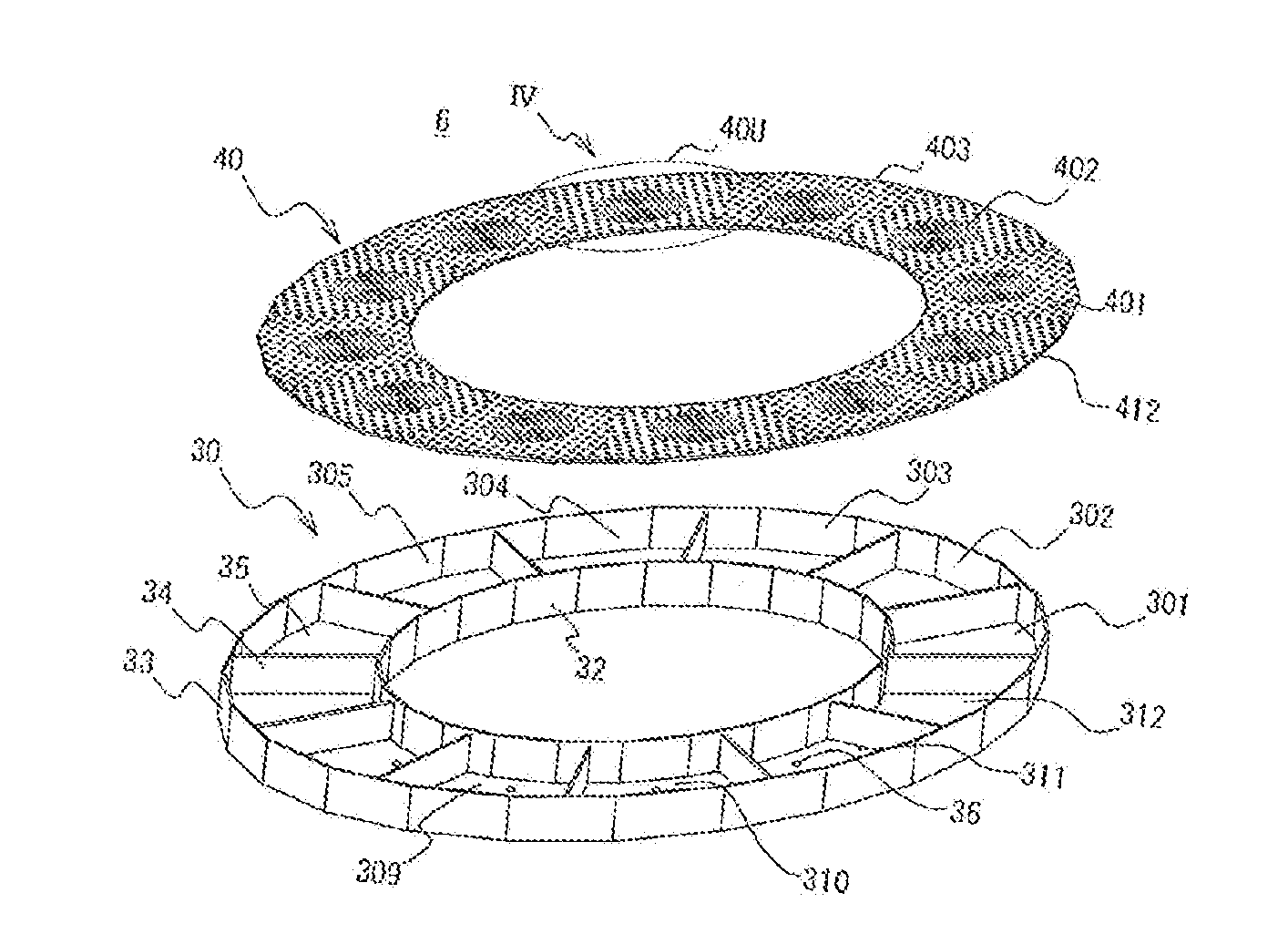

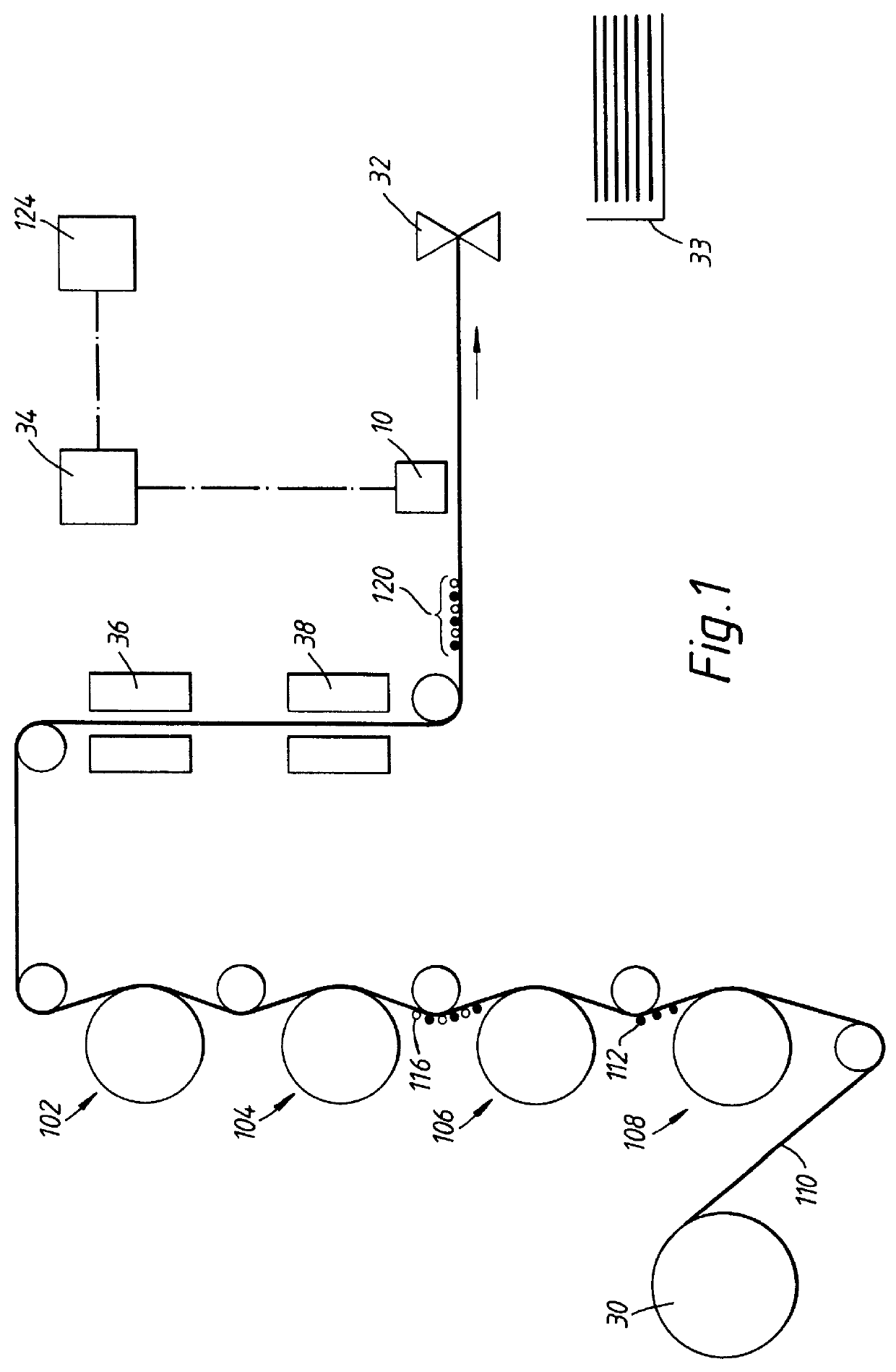

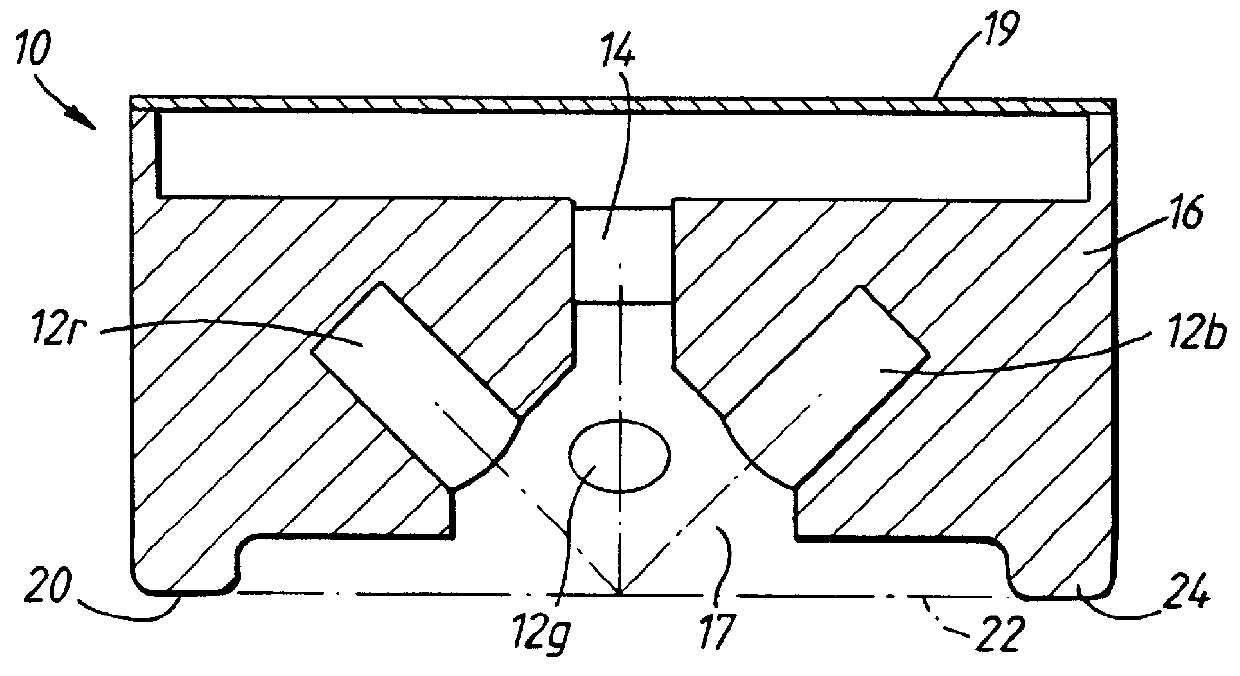

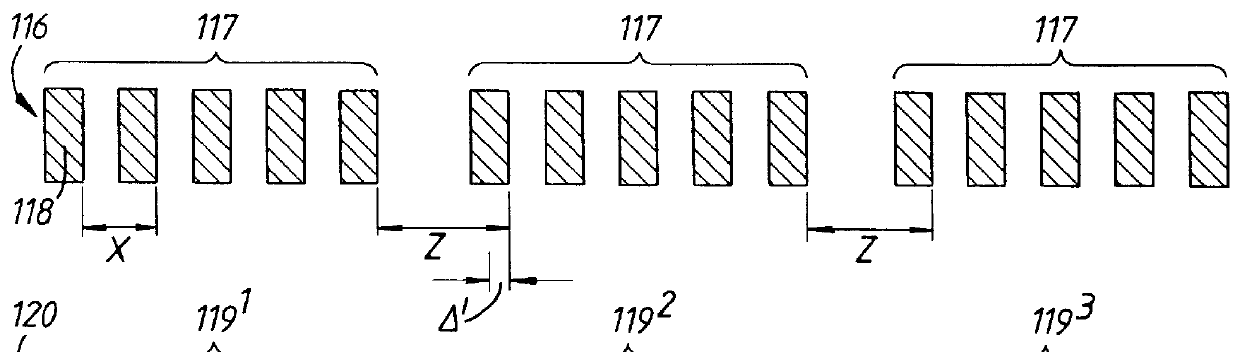

Method for monitoring registration of images printed by a printer

InactiveUS6065400AFacilitate web handlingPrecise positioningPlaten pressesOther printing apparatusComposite patternEngineering

The printer has at least two printing stations which cause images to be printed on a substrate. The printer is capable of registration adjustment. First and second patterns of spaced registration marks are printed onto the substrate by operation of the printing stations. The second pattern partially overlaps the first pattern to form a composite pattern of registration marks. The composite pattern is illuminated and the reflectivity thereof is examined at wavelengths complementary to the colors of the first and second patterns to obtain a reflectivity signature for the composite pattern. The reflectivity signature of the composite pattern (120) is compared with a predetermined signature to determine an adjustment factor for the printer.

Owner:PUNCH GRAPHIX INT

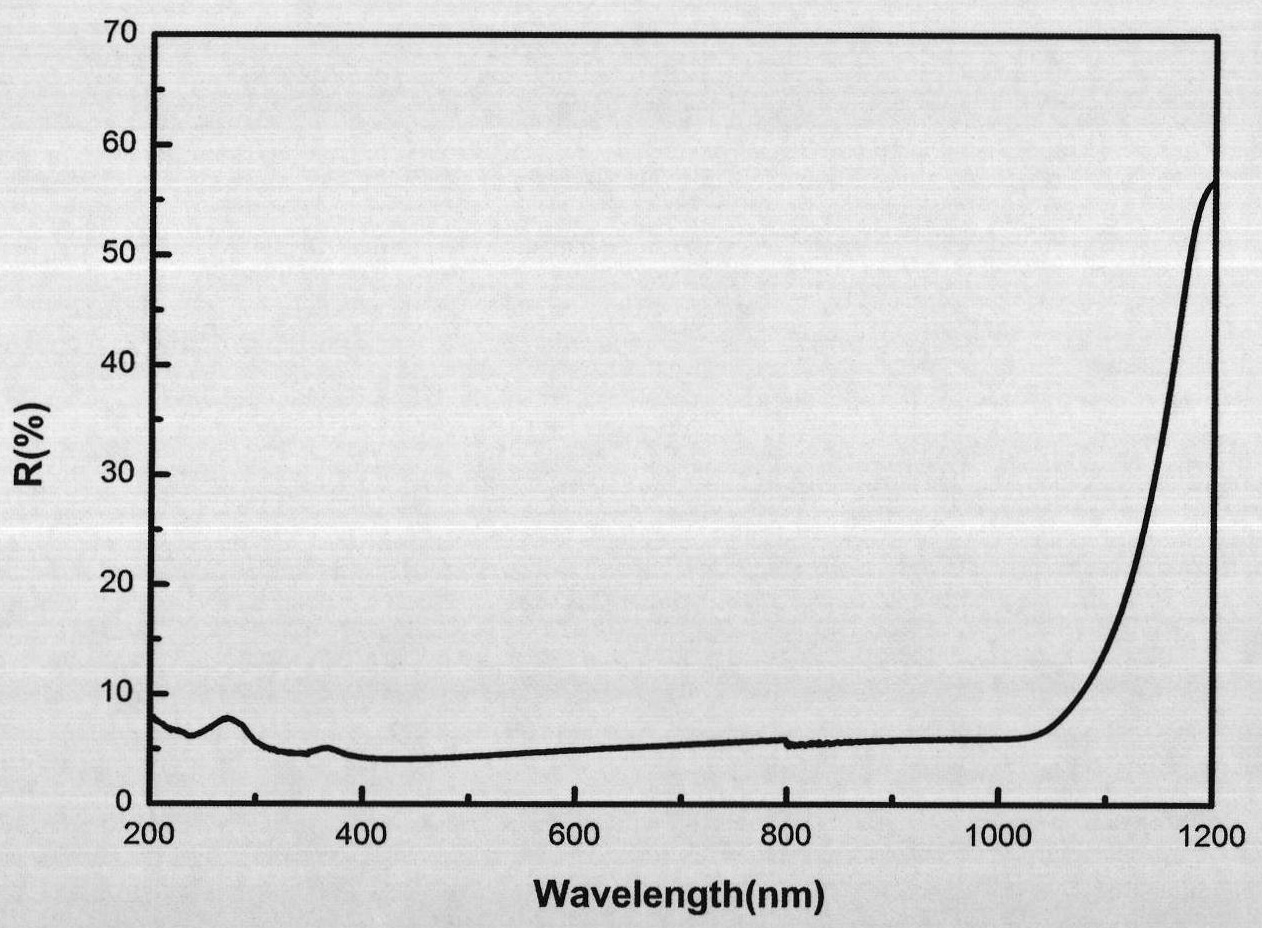

Method for reducing surface light reflectivity of silicon chip

InactiveCN102157608AReduce light reflectivityDoes not affect the preparation processFinal product manufactureSemiconductor devicesHydrofluoric acidSilicon chip

The invention discloses a method for reducing the surface light reflectivity of a silicon chip, and the method comprises the following steps: step 1): immerging the silicon chip into mixed solution of hydrofluoric acid and salts containing Ag ions, Cu ions, Ni ions or Mg ions for etching; and step 2): placing the silicon chip after etching into nitric acid or aqua regia for ultrasonic cleaning so as to remove a metal covering object on the surface. The method is simple in process, low in cost, convenient to operate and extensive in application conditions, the complex process is not required, the average light reflectivity of the silicon chip can be reduced to below 5% through only one step, and the method is suitable for large-scale industrial production.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

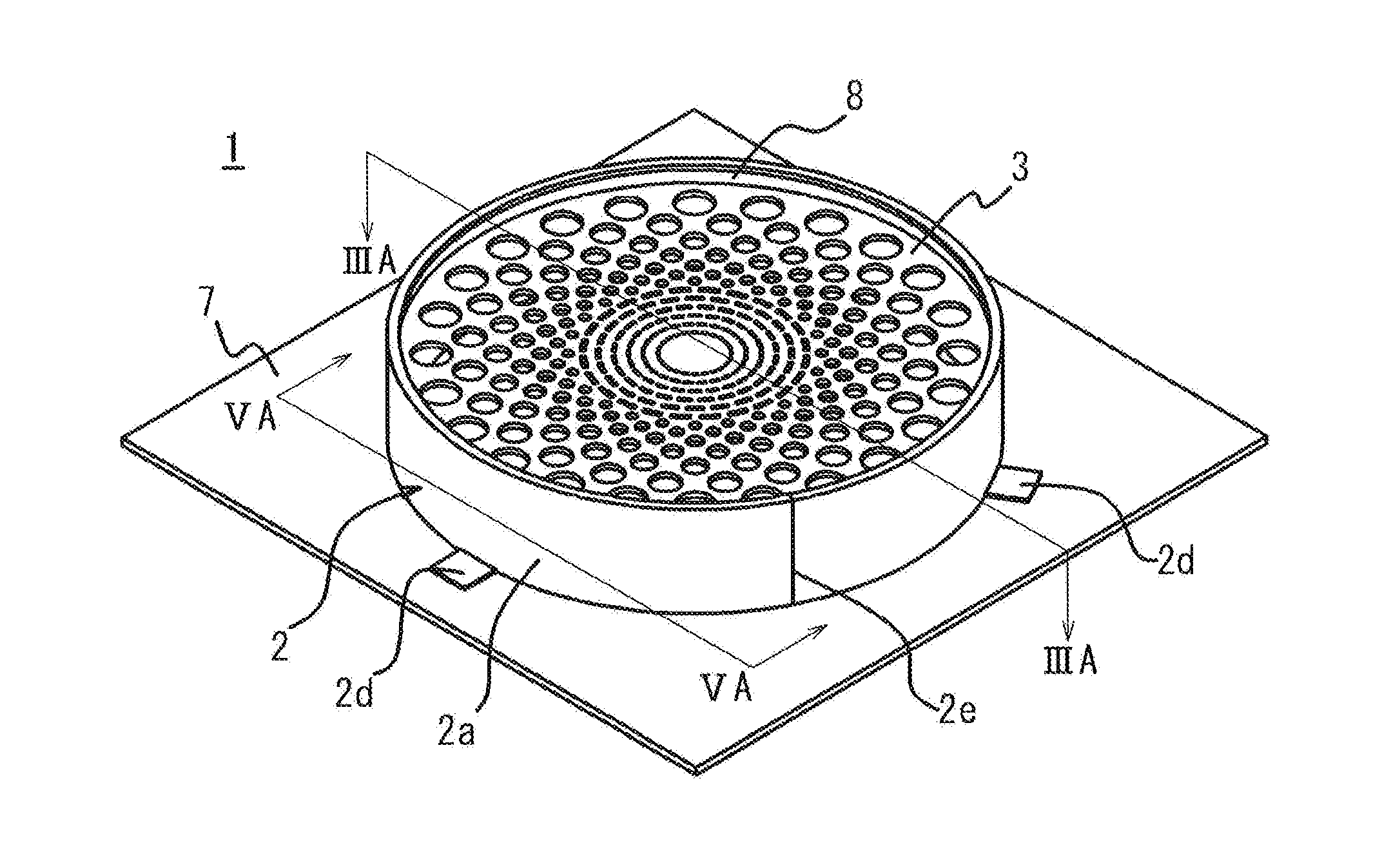

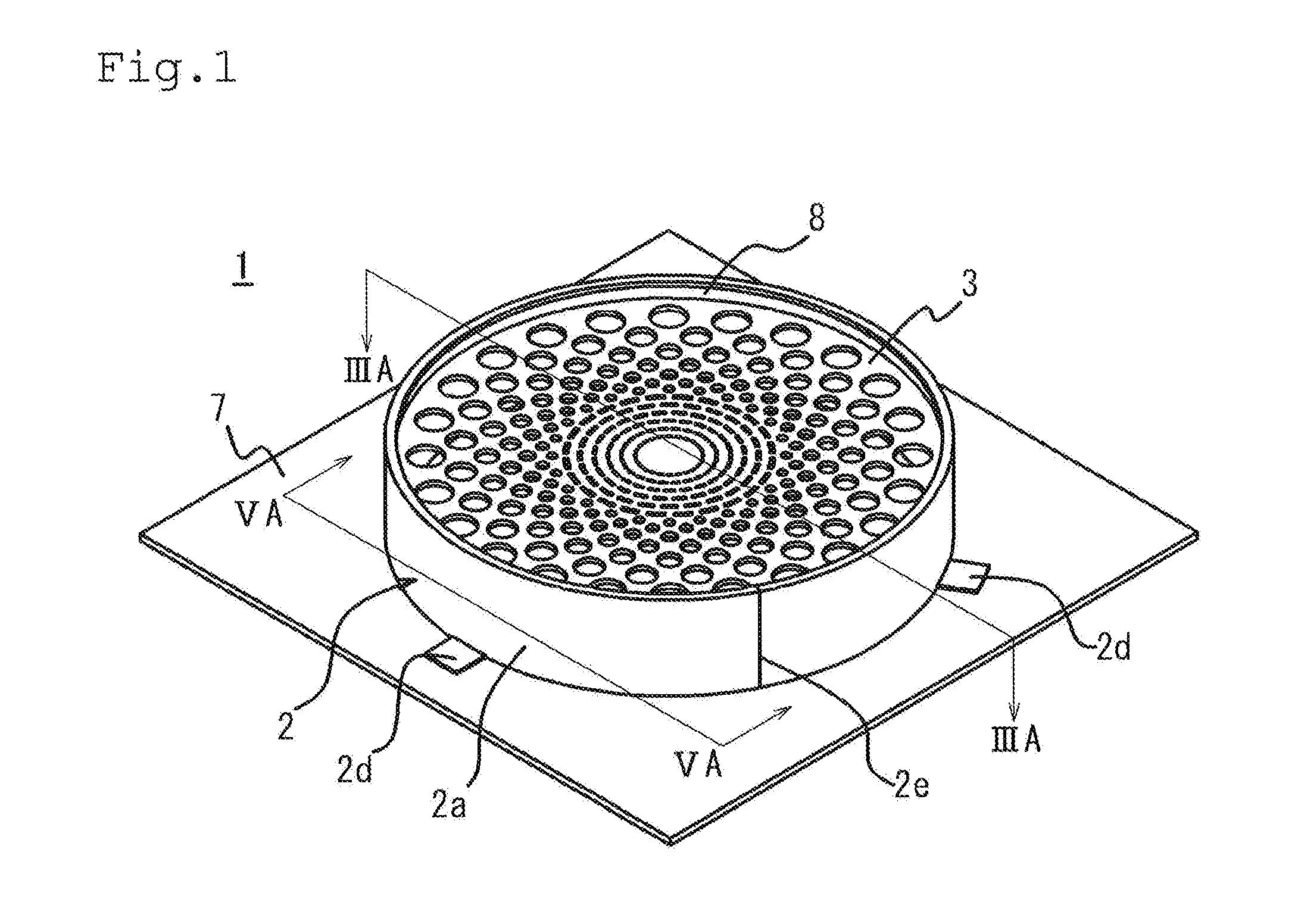

Illumination device with semiconductor light-emitting elements

InactiveCN101192601AIncrease temperatureEasy heat conductionSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor

An illumination device includes a base board, an insulator, a conductor, a plurality of semiconductor light-emitting elements and a light-transmissive sealing member. The base board includes a surface and projection portions. The projection portion is formed to become gradually thicker from its end toward the surface of the base board. The insulator is formed on the surface. The conductor is formed on the insulator. The semiconductor light-emitting elements are mounted on the projection portions. The semiconductor light-emitting elements are electrically connected to the conductor via connection members. The sealing member covers the insulator, the projection portions, the semiconductor light-emitting elements and the connection members.

Owner:TOSHIBA LIGHTING & TECH CORP

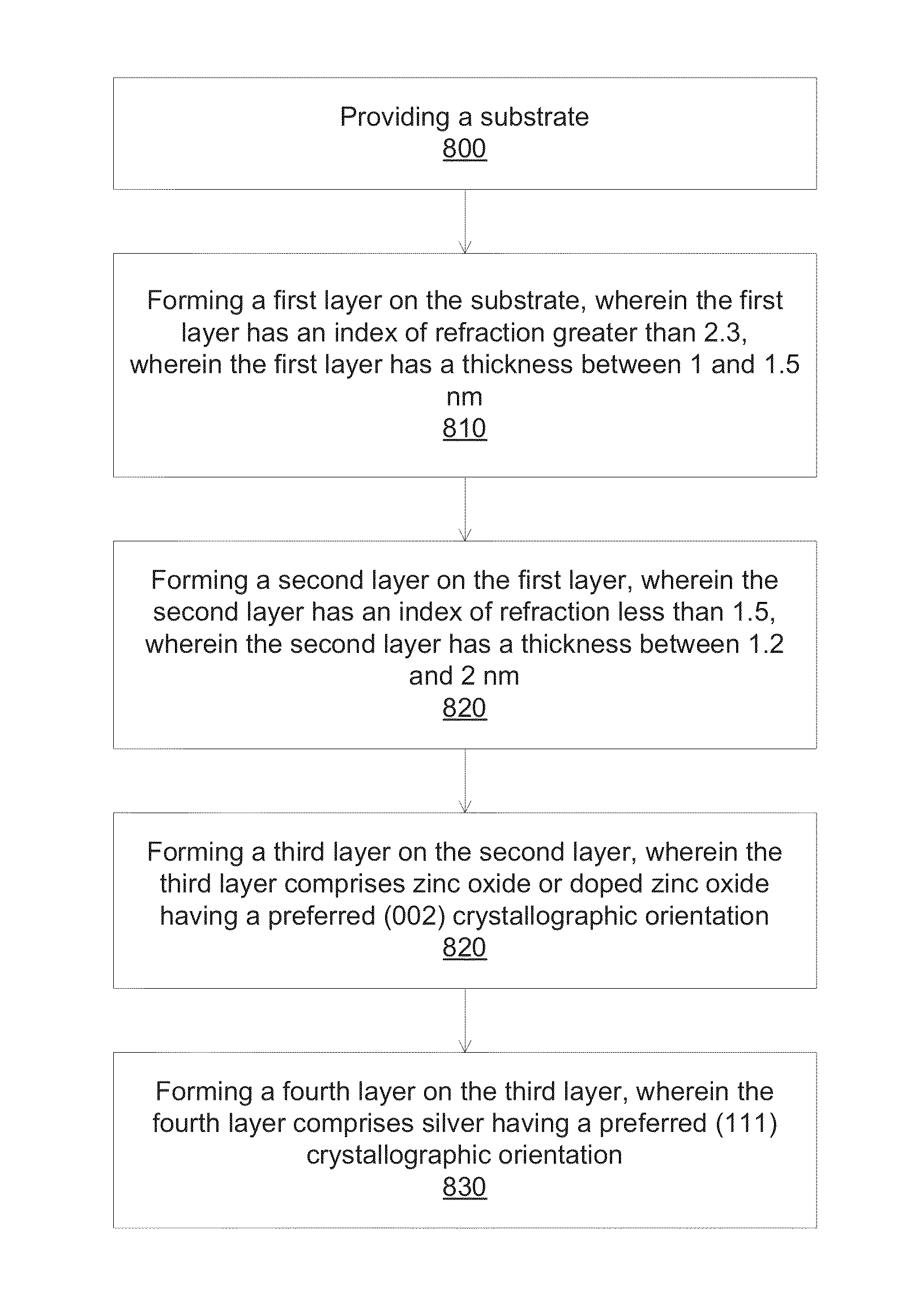

Base-layer consisting of two materials layer with extreme high/low index in low-e coating to improve the neutral color and transmittance performance

ActiveUS9365450B2Improve performanceLow emissivityCoatingsThin material handlingLow emissivityRefractive index

Low emissivity coated panels can be fabricated using a base layer having a low refractive index layer on a high refractive index layer. The low refractive index layer can have refractive index less than 1.5, and can include MgF2, CaF2, SiO2, or BO. The high refractive index layer can have refractive index greater than 2.3, and can include TiOx, NbOx, or BiOx. The multilayer base structure can allow color tuning with enhanced transmission, for example, as compared to similar structures having single layer base layer.

Owner:GUARDIAN GLASS LLC

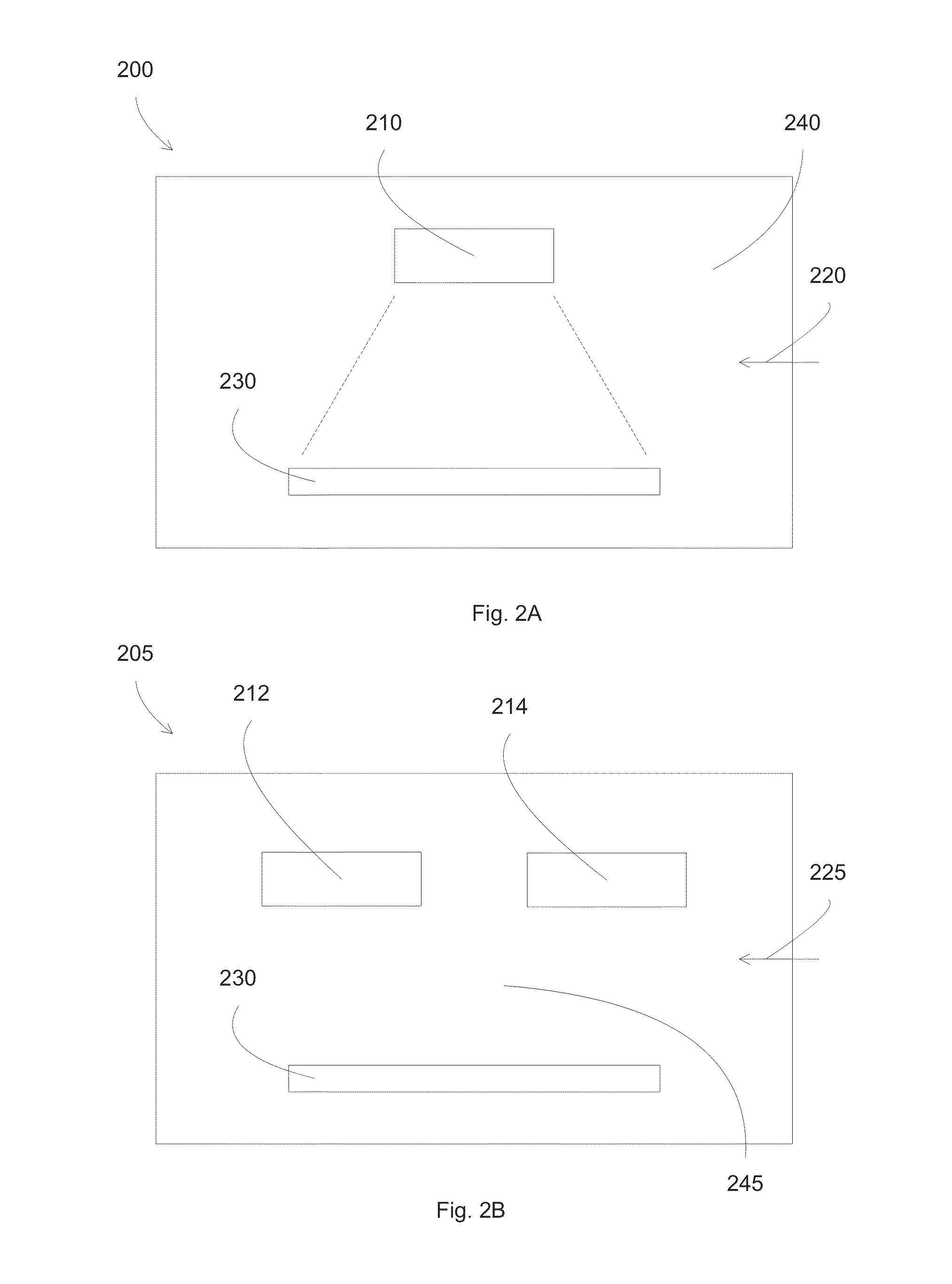

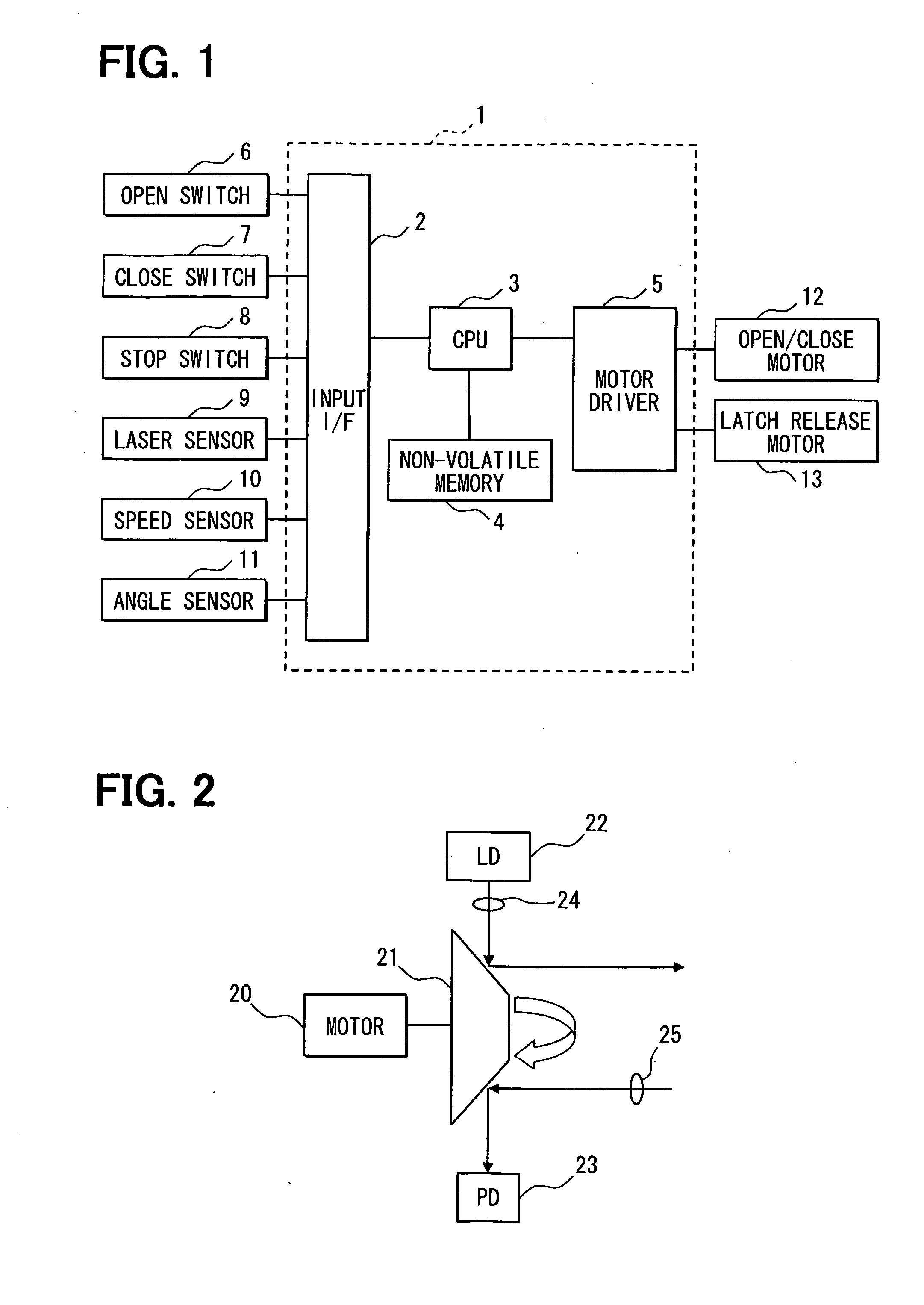

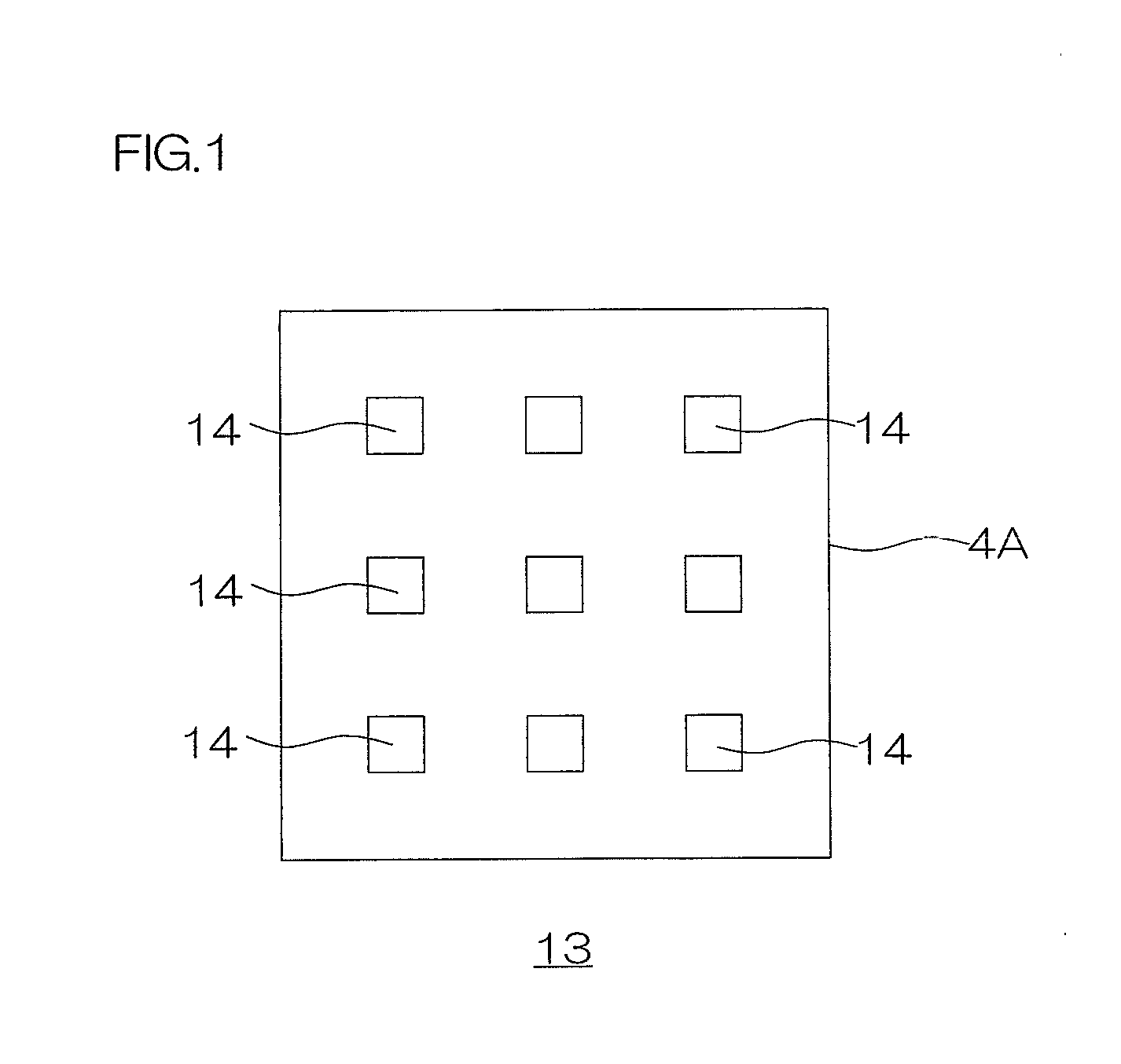

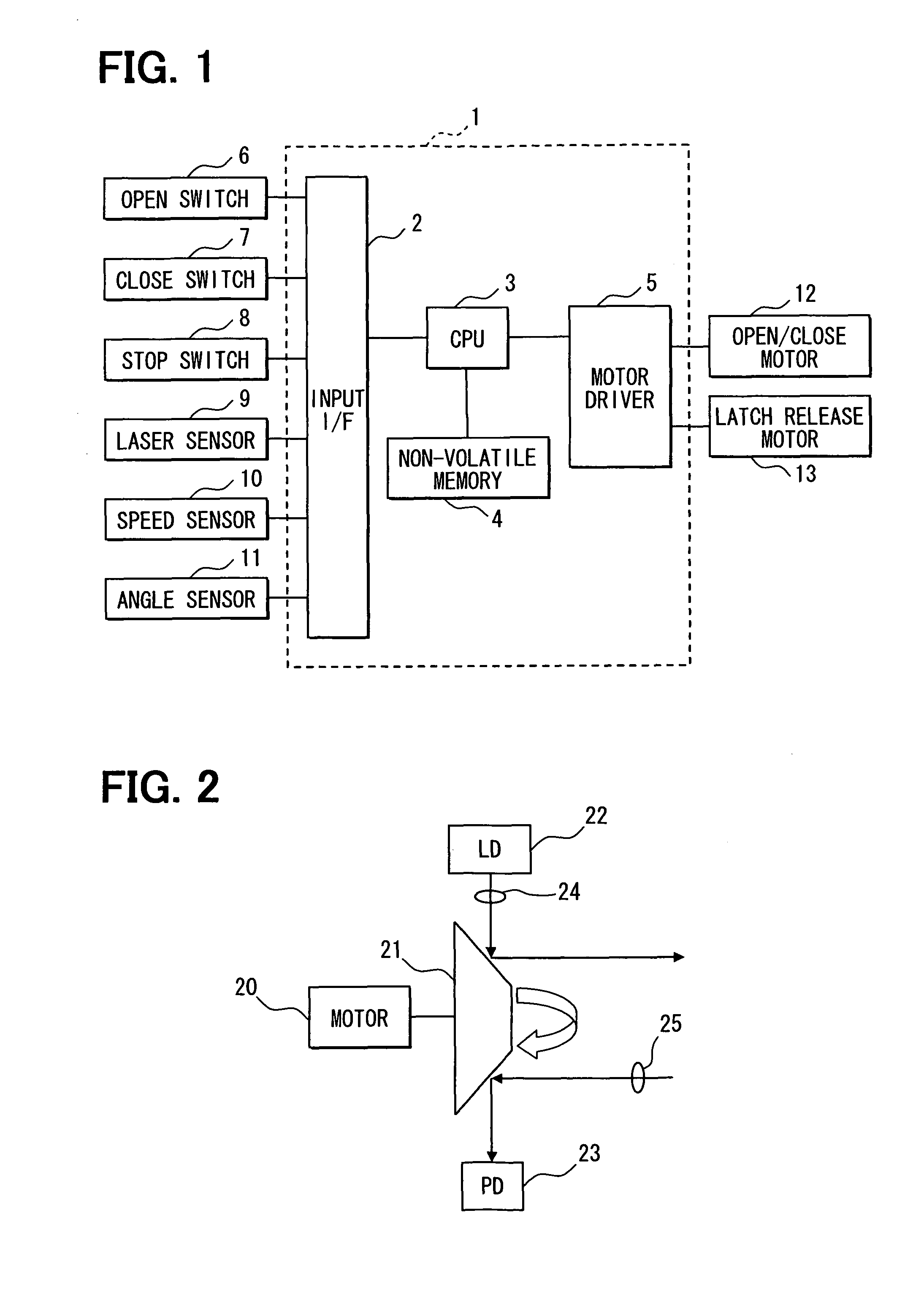

Vehicle door opening angle control system

ActiveUS20100228448A1Reduce light reflectivityDigital data processing detailsPower-operated mechanismControl systemLaser light

A laser sensor projects laser light in the downward direction. If the laser sensor does not receive any laser light reflected by an obstacle or the ground, it is determined that the obstacle is present in the direction of projection of the laser light. It is thus possible to detect the presence of the obstacle, which will at least affect the opening of the vehicle door.

Owner:DENSO CORP

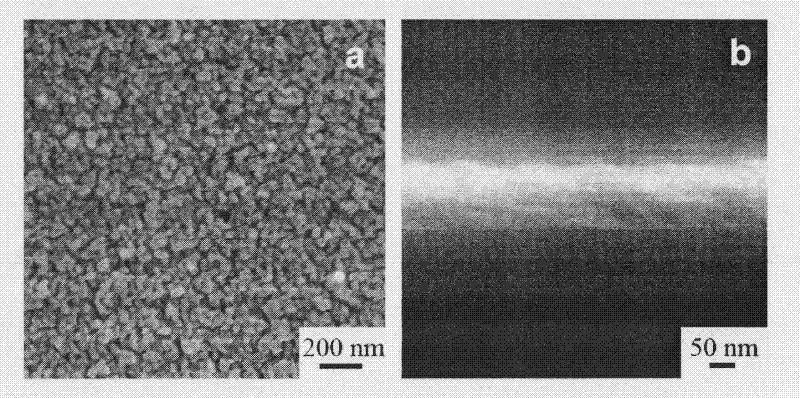

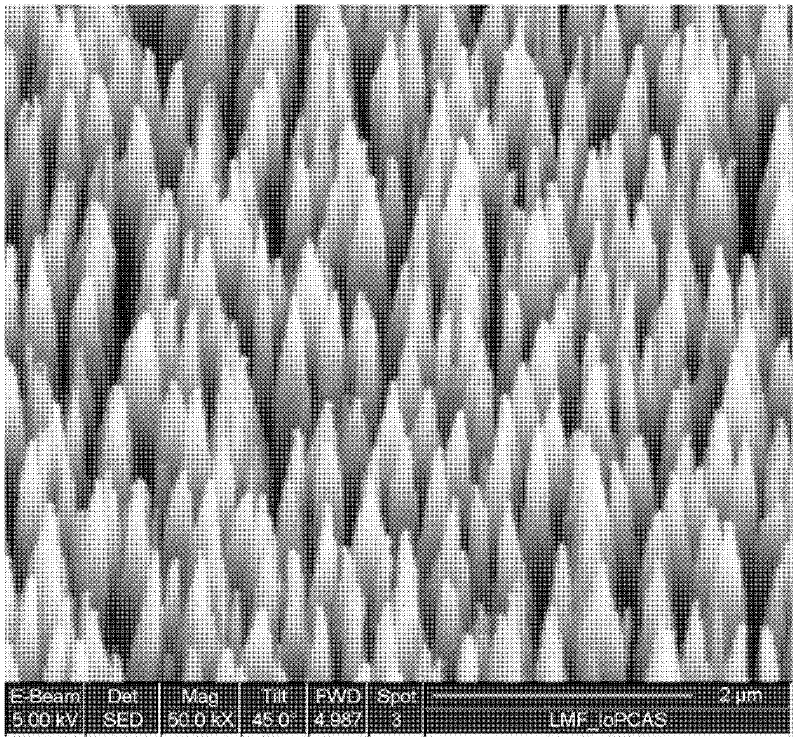

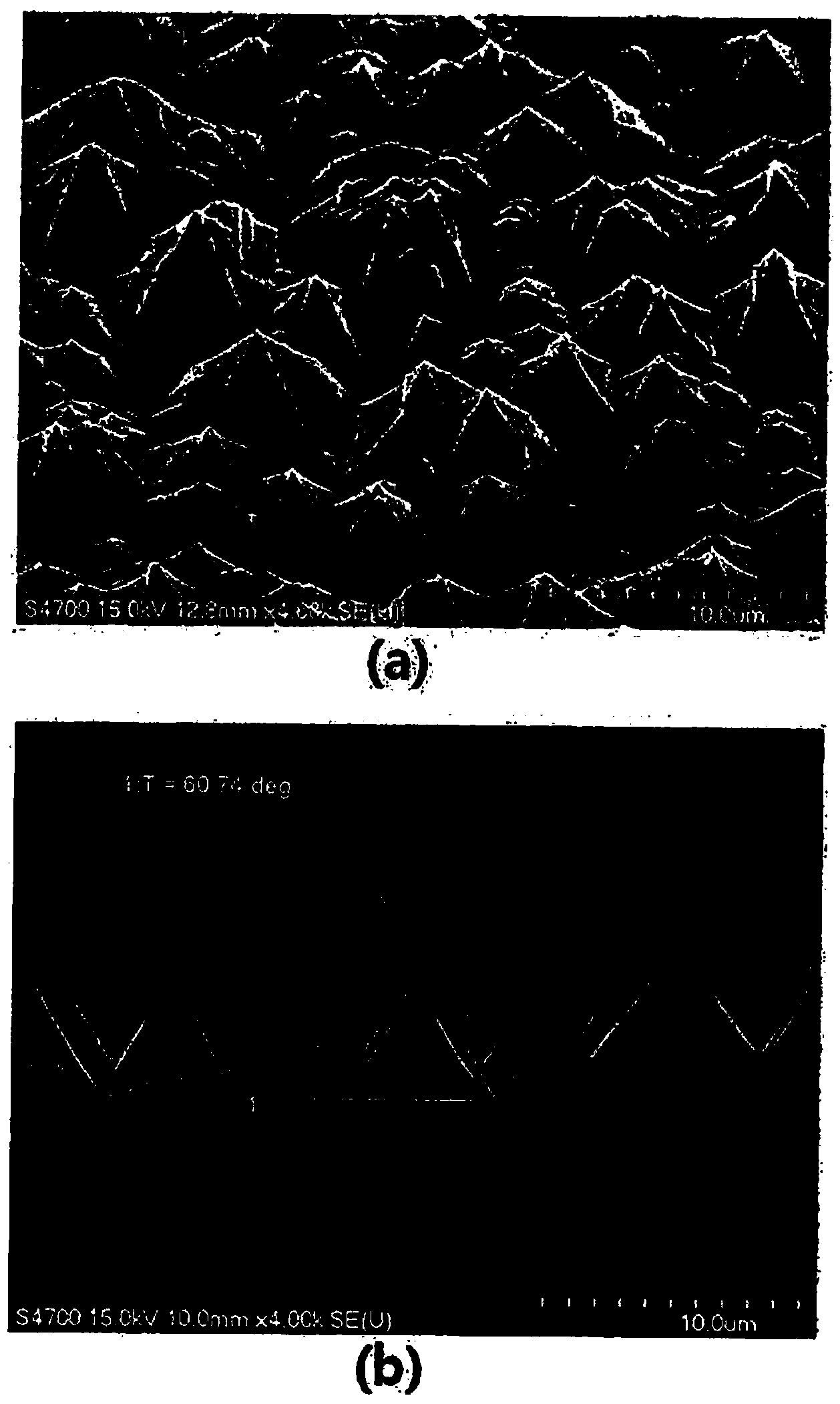

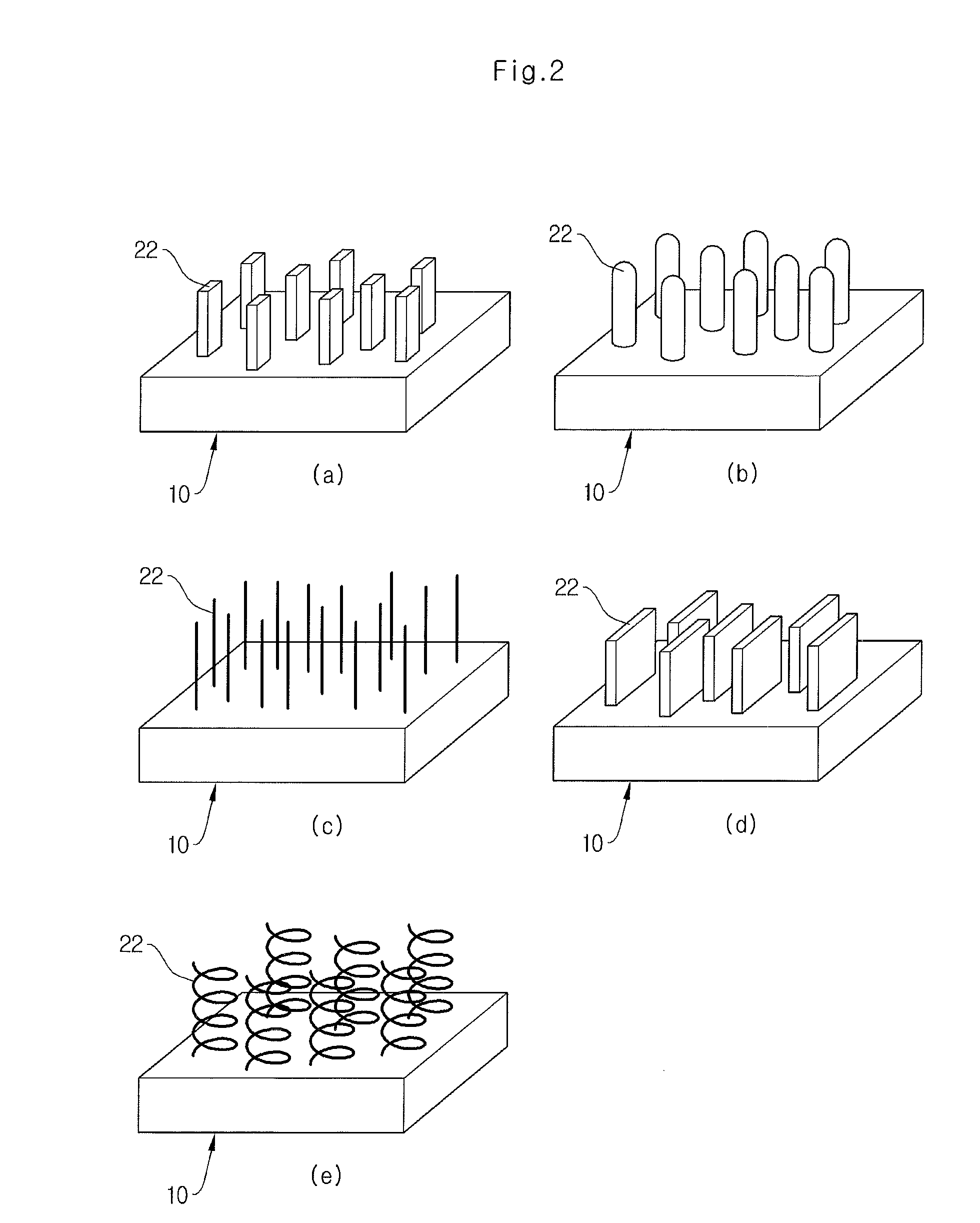

Preparation method for silicon surface anti-reflection nanometer array structure

ActiveCN102351569AOrientation to overcomeReduce light reflectivityInductively coupled plasmaReactive-ion etching

The invention relates to a preparation method for a silicon surface anti-reflection nanometer array structure, which comprises the following steps that: silicon chips are placed into an inductively coupled plasma (ICP) system, and nanometer conical array structures are obtained at the silicon surface under the conditions of the basic vacuum being 1.0*10<-6> Torr, the temperature being -100 DEG C to -140 DEG C, the gas flow rate ratio (SF6 / O2) being 36 / 22 to 44 / 14, the air pressure being 6 to 25mTorr, the reactive ion etching (RIE) power being 3 to 6W and the ICP power being 800 to 1000W. The method adopts a low-temperature etching technology, the masking process is not needed, the large-area silicon surface nanometer conical array structure with the super anti-reflection characteristic is directly prepared through etching, and in addition, the regulation and control on the nanometer conical structure feature is realized through regulating and controlling the corresponding parameters.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Optical tap module

In an optical tap module, a first lens, a focusing lens, and a photodiode are arranged such that a center axis of a cylindrical case housing the first lens, the focusing lens, and the photodiode is substantially located on the same line. When light propagates through a second optical fiber and is emitted from an end surface facing the first lens so as to be incident on an optical filter, and light transmitted the optical filter is converged by the focusing lens, the photodiode and a chip mounting support are arranged such that a focal point of light is located spatially distant from the surfaces of the photodiode and the chip mounting support.

Owner:GOFOTON HLDG

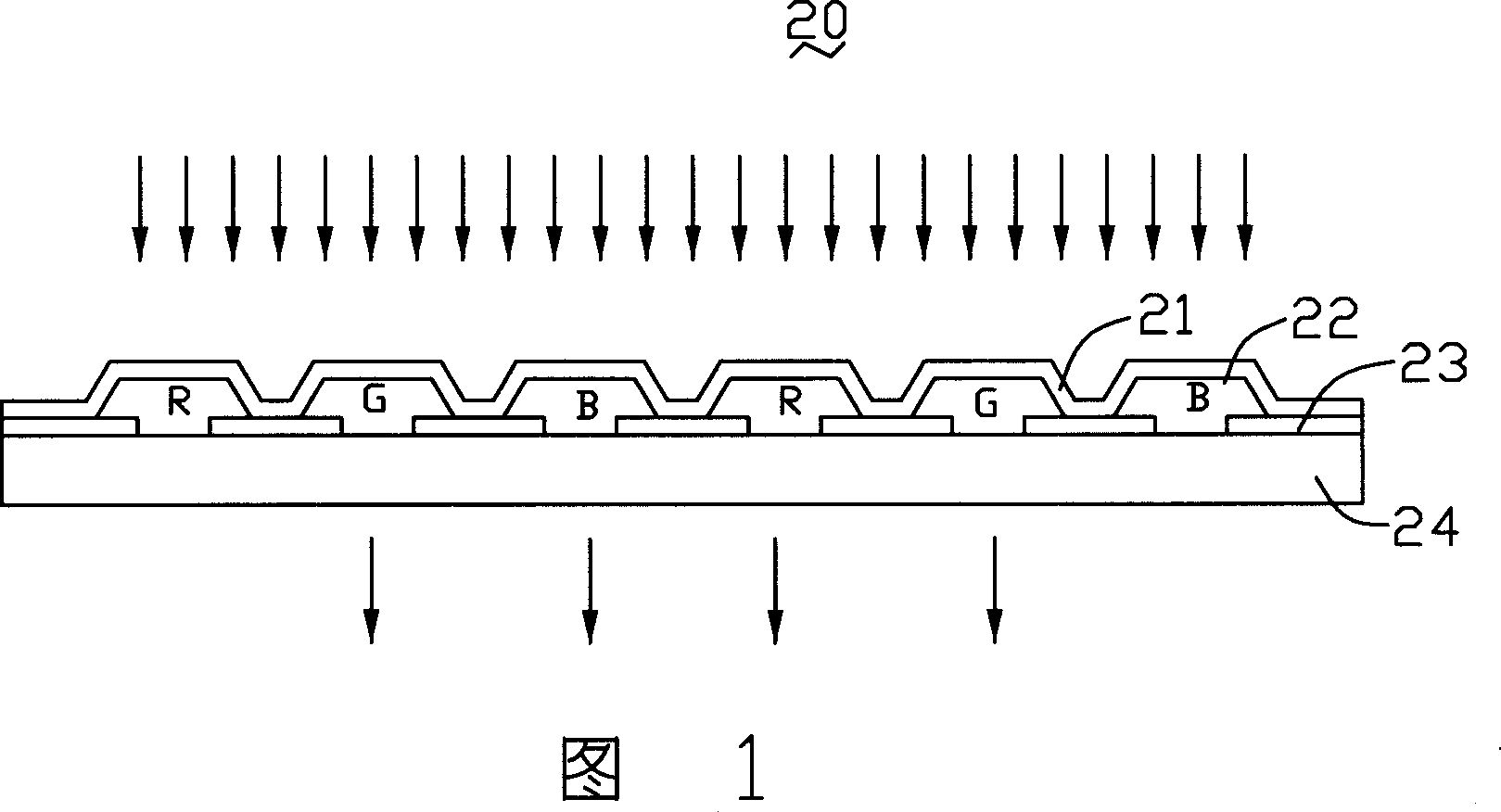

Organic light emitting diode display

InactiveUS20140284563A1Improve lighting efficiencyReduce light reflectivityElectroluminescent light sourcesSolid-state devicesDisplay deviceLight reflectance

An organic light emitting diode (OLED) display includes a substrate, a light path guide layer formed on the substrate and having an inclined side wall, an organic light emitting diode (OLED) formed on the substrate and the light path guide layer, and a phase transition layer formed on the OLED and formed so as to correspond to the inclined side wall. Therefore, in the OLED display, the phase transition layer is formed in the light path guide layer so that it is possible to minimize external light reflectance increased by the light path guide layer.

Owner:SAMSUNG DISPLAY CO LTD

Reflecting material and light emitting diode device

InactiveUS20120305969A1Improve heat resistanceHigh light reflectivityDiffusing elementsSolid-state devicesLight emitting deviceLight-emitting diode

A reflecting material contains a silicone resin composition prepared from a polysiloxane containing silanol groups at both ends, an ethylenic silicon compound, a silicon compound containing an epoxy group, an organohydrogenpolysiloxane, a condensation catalyst, and an addition catalyst; and a light reflecting component.

Owner:NITTO DENKO CORP

Vehicle door opening angle control system

ActiveUS8280593B2Reduce light reflectivityDigital data processing detailsPower-operated mechanismControl systemOptoelectronics

A laser sensor projects laser light in the downward direction. If the laser sensor does not receive any laser light reflected by an obstacle or the ground, it is determined that the obstacle is present in the direction of projection of the laser light. It is thus possible to detect the presence of the obstacle, which will at least affect the opening of the vehicle door.

Owner:DENSO CORP

Optical laminated film for liquid crystal display device

InactiveCN101128752AIncrease contrastReduce light reflectivityPolarising elementsCoatingsLiquid-crystal displayRefractive index

An optical laminated film for a liquid crystal display device is provided by successively laminating a hard coat layer and a low refraction index layer including an aerogel, on one surface of a base material film including a transparent resin, directly or through other layer. The optical laminated film satisfies the following inequalities [1-3], where nH is a refraction index of the hard coat layer, and nLis a refraction index of the low refraction index layer. [1] nL=1.37 [2] nH=1.53 [3] (nH)<1 / 2>-0.2+0.2.

Owner:MATSUSHITA ELECTRIC WORKS LTD +1

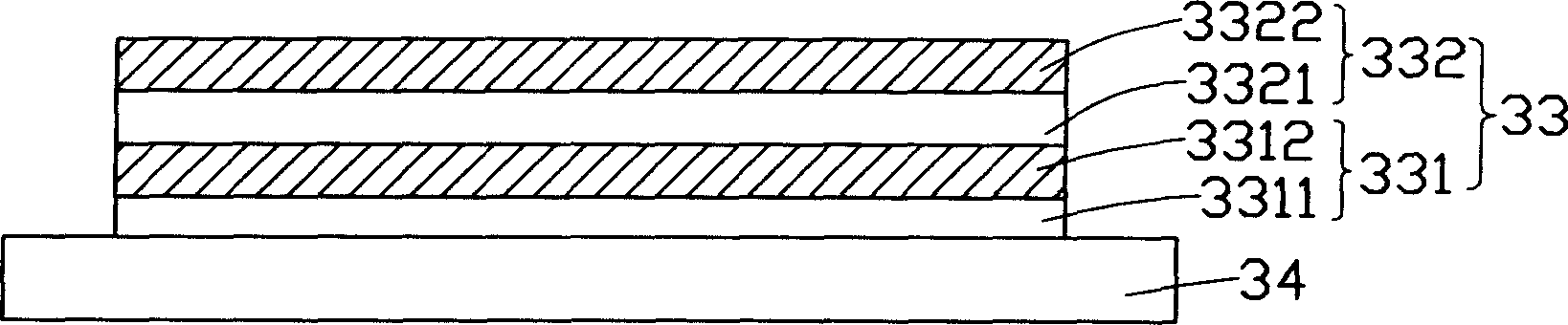

Display device

InactiveUS20100201929A1Reduce light reflectivityImprove barrier propertiesNon-linear opticsOptical elementsRefractive indexDisplay device

Provided is a display device, including: a barrier layer formed of a plurality of material layers being laminated; and a first material layer and a second material layer that sandwich the barrier layer, in which: the first material layer, the plurality of material layers forming the barrier layer, and the second material layer have light refractive indexes that are set so as to sequentially change from the first material layer to the second material layer in one of decreasing order and increasing order; and the plurality of material layers forming the barrier layer include a high stress film and a low stress film which are alternately laminated on each other. Therefore, the display device of the present invention can achieve crack prevention, enhancement in adhesion between the respective layers and enhancement in barrier property, together with reducing a light reflectance of the barrier layer.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

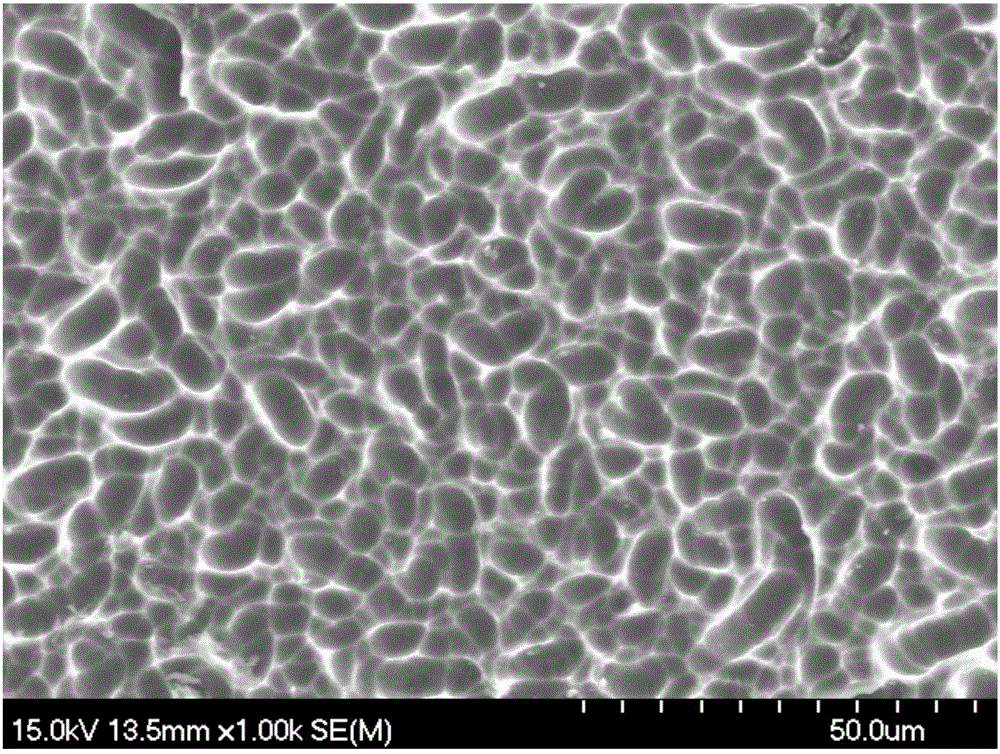

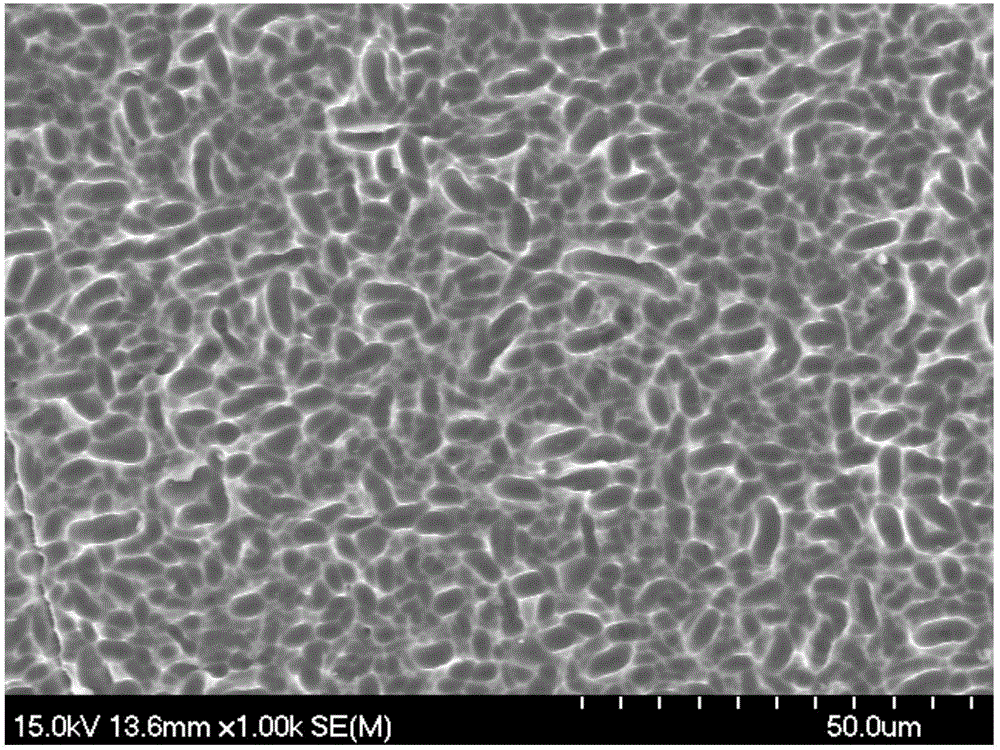

Additive for polycrystalline silicon wafer texturization and application method thereof

InactiveCN106222755AReduce reflectivitySteady increase in conversion efficiencyPolycrystalline material growthAfter-treatment detailsCarboxylic acidContamination

The invention provides an additive for polycrystalline silicon wafer texturization and a method of applying the additive to perform texturization. The additive is prepared from polymer carboxylic acid, micromolecular organic acid, non-ionic surfactant and water, wherein the weight ratio of the polymer carboxylic acid to the water is 0.5-5 to 100, the weight ratio of the micromolecular organic acid to the water ratio is 1-10 to 100, and the weight ratio of the non-ionic surfactant to the water is 0.01-1 to 100. The texturization is performed by using the additive, the uniformity of suede can be improved, further polycrystalline silicon wafer reflectivity is reduced, and the side effects such as silicon wafer surface contamination and suede inside porous silicon are not produced.

Owner:杭州飞鹿新能源科技有限公司

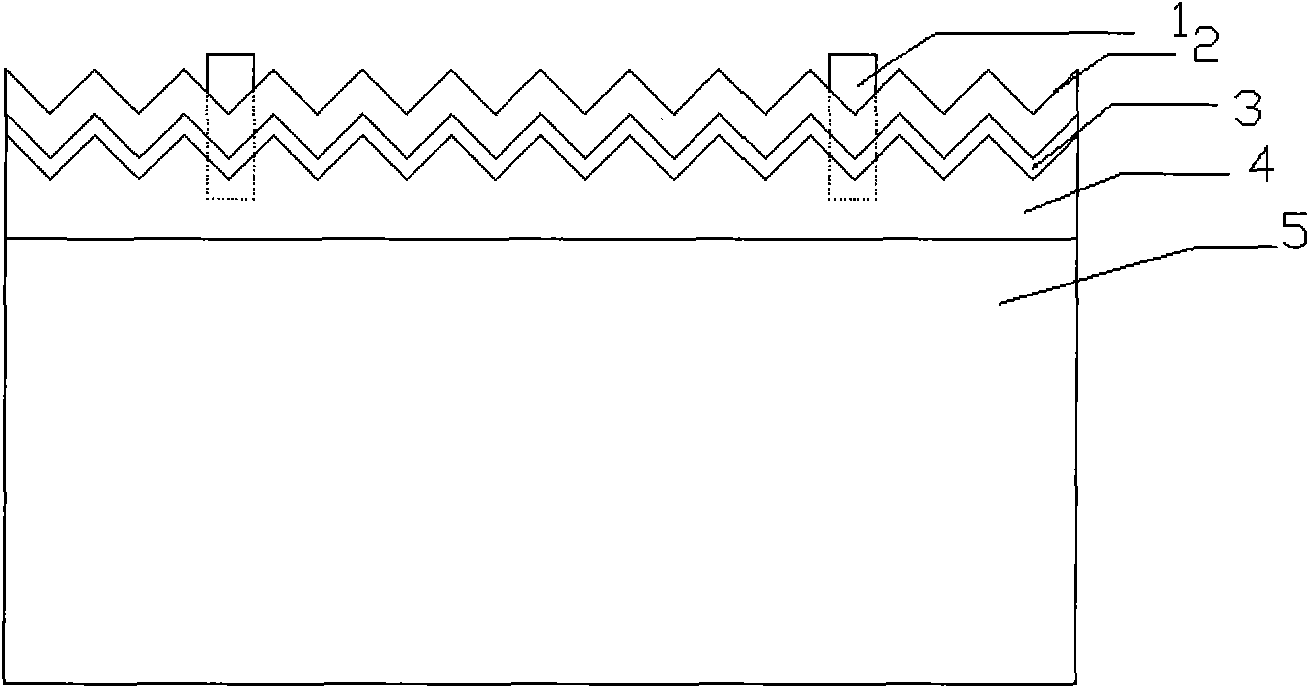

Method for manufacturing double-layer film of crystalline silicon solar cell

InactiveCN101814548AEasy to prepareLow costFinal product manufacturePhotovoltaic energy generationGas phaseOptoelectronics

The invention relates to a method for manufacturing a double-layer film of a crystalline silicon solar cell. The method is characterized by comprising the following specific steps of: mixing tetraethyl orthosilicate and ethanol, stirring and heating, adding dilute solution of hydrochloric acid into the solution, cooling, adding an organic additive into the solution, stirring and dissolving, and closing and aging to obtain a sol; and preparing a substrate of the crystalline silicon solar cell by a routine method, forming a silicon nitride film by a plasma enhanced chemical vapor deposition method, spraying the prepared sol on the silicon nitride film to prepare a silicon dioxide film, performing heat treatment on the obtained silicon dioxide film at the temperature of between 200 and 600 DEG C, printing positive and negative electrodes and a back field, drying, and sintering. The method has the advantages that: the light reflectivity of the surface of the solar cell is lower; the power of a solar cell plate is higher; and the short-wave and long-wave absorption of the double-layer film cell is further improved.

Owner:上海泰阳绿色能源有限公司

Illumination device

InactiveUS20130094216A1Easy to processDifficult to thermally weldPoint-like light sourceCoatingsOptical transmittanceOptoelectronics

An illumination device includes: a point light source; a substrate; a hollow frame having an engaging bent section at one of its edges; and a bottom surface reflection section, a side surface reflection section, and a light conducting reflection plate that are disposed inside the frame. The light conducting reflection plate is held between the bent section and the side surface reflection section that is held by the other edge of the frame and the bottom surface reflection section fixed to the substrate. The surface of the bottom surface reflection section facing the light conducting reflection plate, the inner surface of the side surface reflection section, and the surface of the light conducting reflection plate facing the bottom surface reflection section have high light reflectivity and low light transmissivity.

Owner:OPTO DESIGN INC

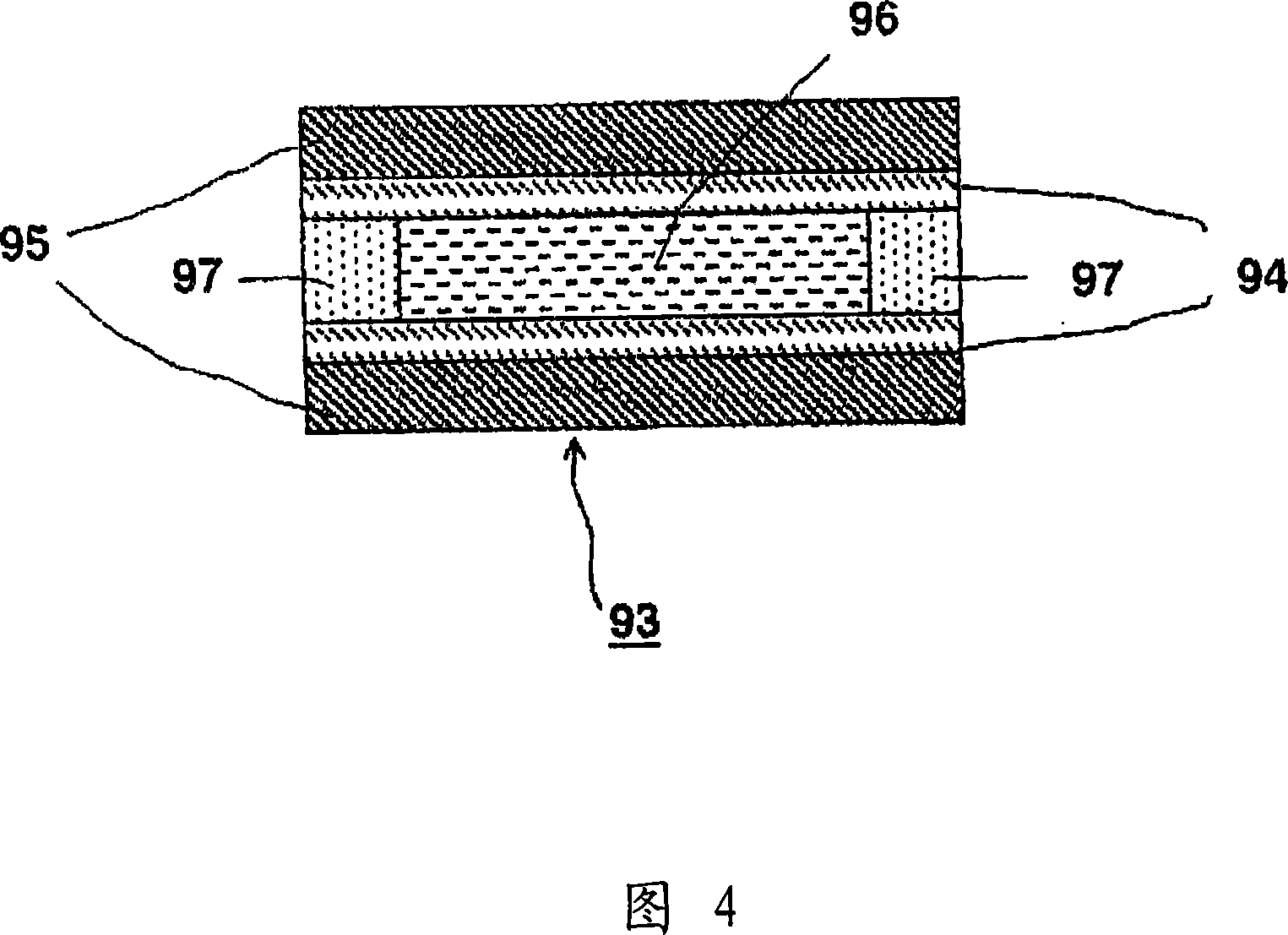

Resin composition, pre-preg, and metal foil clad laminate

InactiveCN103459493AHigh peel strengthSuppresses decrease in light reflectanceElectrical equipmentThin material handlingMetal foilUltraviolet lights

Provided are a resin composition, pre-preg therefor, and metal foil clad layer plate, that can be suitably used as a printed wiring board for LED packaging with high light reflectivity in the ultraviolet light region and the visible light region, that does not lose light reflectivity due to heating and light irradiation, and that also has excellent peel strength relative to a metal foil. This resin composition includes at least (A) an epoxy resin having a bisphenol A backbone, (B) an alicyclic epoxy resin, (C) an acid anhydride of a partially hydrogenated compound or a totally hydrogenated compound of an aromatic polycarboxylic acid, (D) titanium dioxide, and (E) a dispersing agent.

Owner:MITSUBISHI GAS CHEM CO INC

Base-layer consisting of two materials layer with extreme high/low index in low-e coating to improve the neutral color and transmittance performance

ActiveUS20140186598A1Improve performanceLow emissivityLayered productsSpecial surfacesLow emissivityTransmittance

Low emissivity coated panels can be fabricated using a base layer having a low refractive index layer on a high refractive index layer. The low refractive index layer can have refractive index less than 1.5, and can include Mg F2, CaF2, SiO2, or BO. The high refractive index layer can have refractive index greater than 2.3, and can include TiOx, NbOx, or BiOx. The multilayer base structure can allow color tuning with enhanced transmission, for example, as compared to similar structures having single layer base layer.

Owner:GUARDIAN GLASS LLC

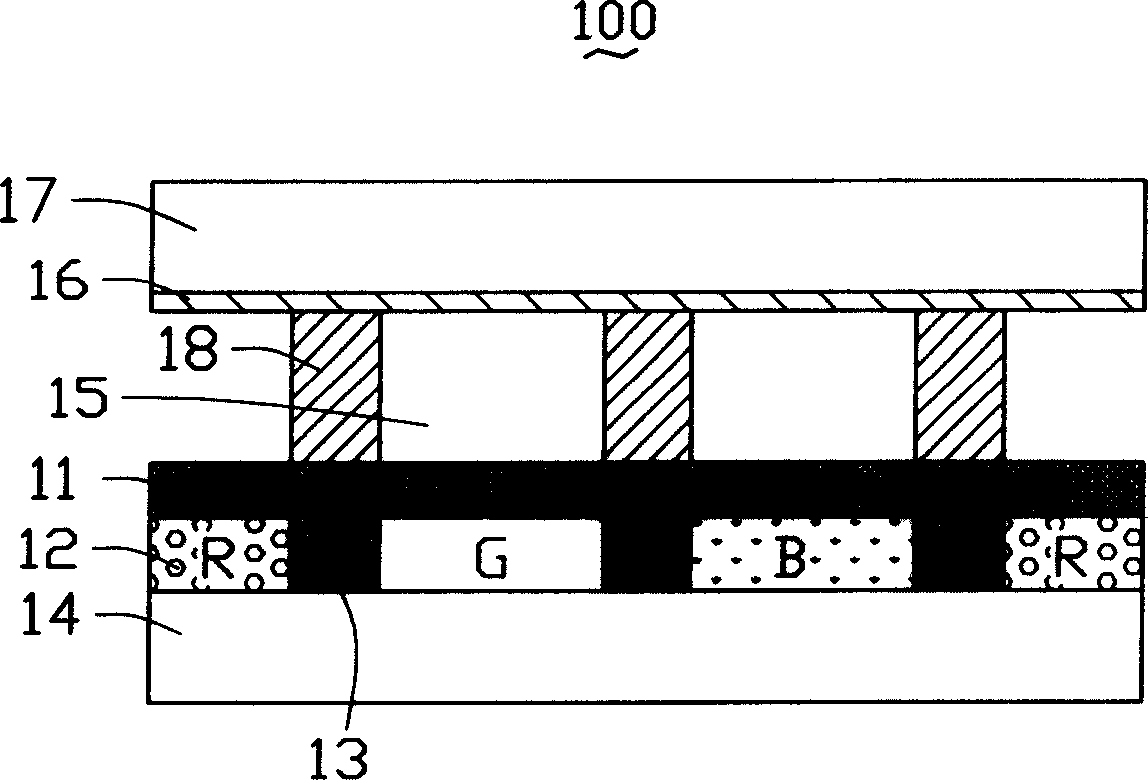

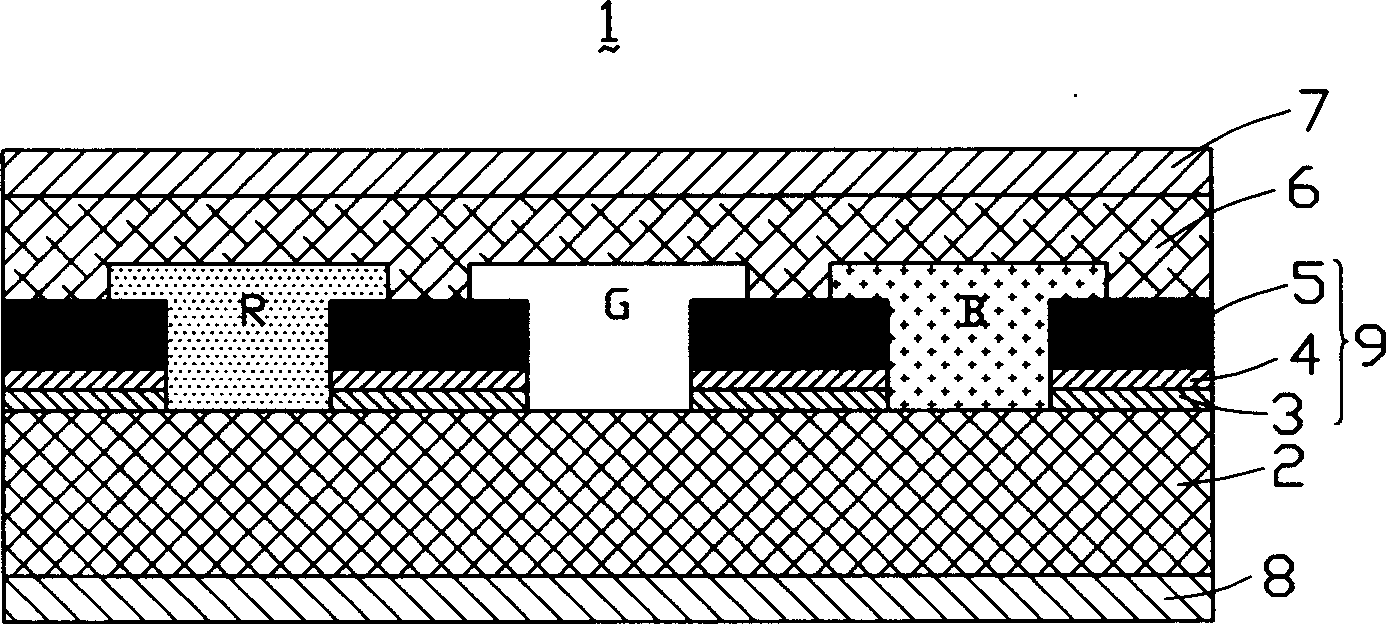

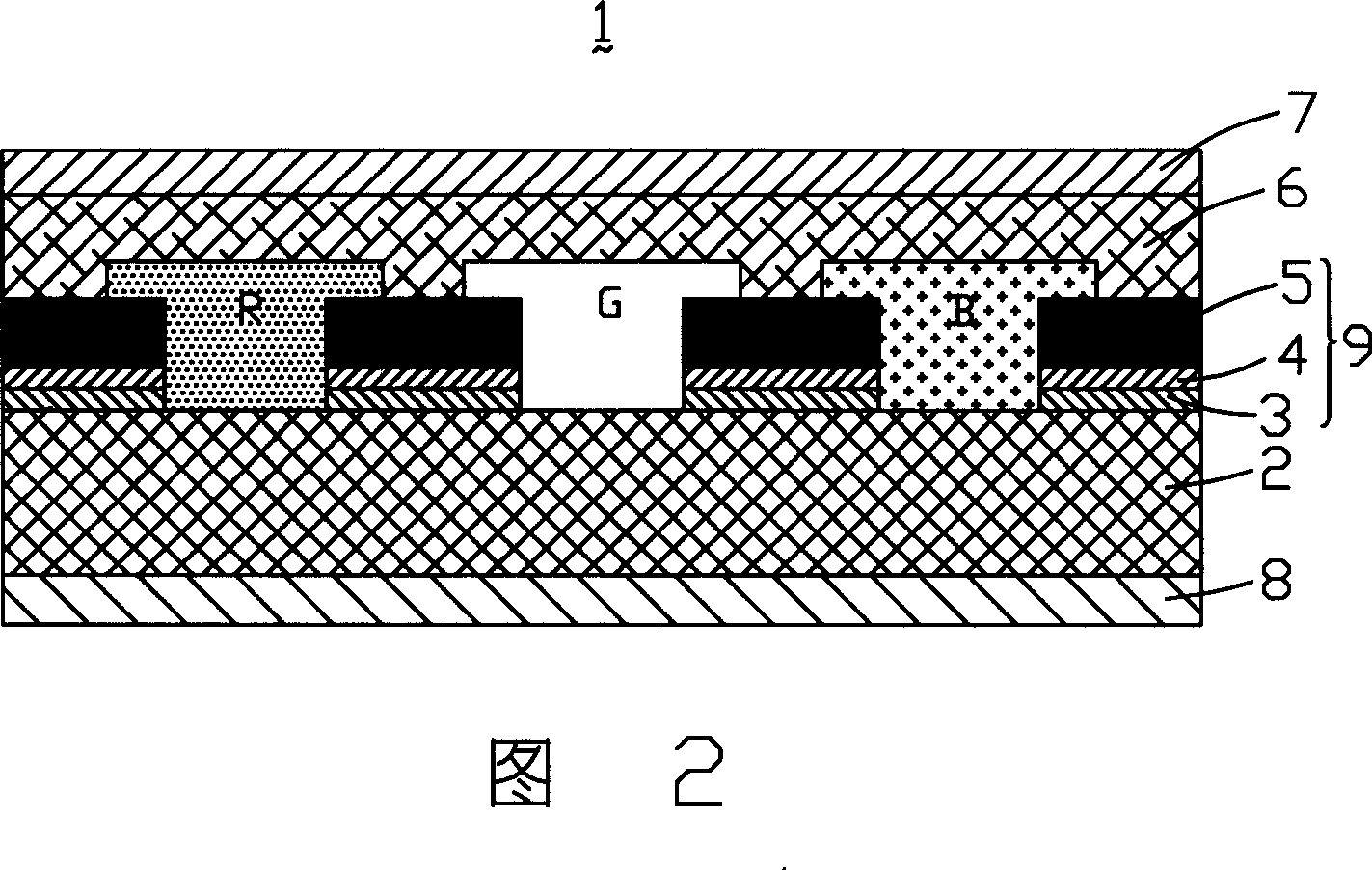

Black matrix, color filter and liquid crystal display device

InactiveCN1540366AEffective occlusionReduce reflectivityCoatingsNon-linear opticsRefractive indexEngineering

The black matrix includes at least two identical stacked anti reflection layers. Each anti-reflection layer includes first film and second film having different refractive indexes. The said first film and second film are stacked. The black matrix and color filter and liquid crystal display device utilizing the black matrix possess higher optical performances.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Texture etching solution composition and texture etching method of crystalline silicon wafers

InactiveCN103890139ASmall quality deviationImprove uniformityFinal product manufactureSurface treatment compositionsCrystallographyEtching

Disclosed are a texture etching solution composition for a crystalline silicon wafer, and a texture etching method using the same. The texture etching solution composition for a crystalline silicon wafer includes a polymer formed by polymerizing a monomer that is substituted with a cyclic compound having 4 to 10 carbon atoms as well as at least one nitrogen atom. The texture etching solution composition and the texture etching method are capable of forming pyramids with a specific structure which can minimize a quality deviation of a texture within a region in formation of a micro-pyramid structure on the surface of the crystalline silicon wafer to increase luminous efficiency while reducing a reflectivity.

Owner:DONGWOO FINE CHEM CO LTD

Lighting device, display device and television receiver

InactiveUS8297773B2Simple configurationReduce in quantityTelevision system detailsNon-electric lightingTelevision receiversDisplay device

The backlight device 12 of the present invention includes a plurality of tubular light sources 17 provided in a parallel arrangement and a light reflecting member 20 arranged on a opposite side from an illuminating side that is illuminated with light from the light sources 17. The arrangement of the tubular includes a narrow pitch area 17a in which an arrangement interval is relatively small and a wide pitch area 17b in which an arrangement interval is relatively large. A dot pattern including a plurality of dots 22 is formed on the light reflecting member 20. Light reflectivity of the dots 22 is different from that of the light reflecting member 20. Light reflectivity of a light reflecting surface including surfaces of the light reflecting member and the dot pattern is low in the narrow pitch area 17a than in the wide pitch area 17b.

Owner:SHARP KK

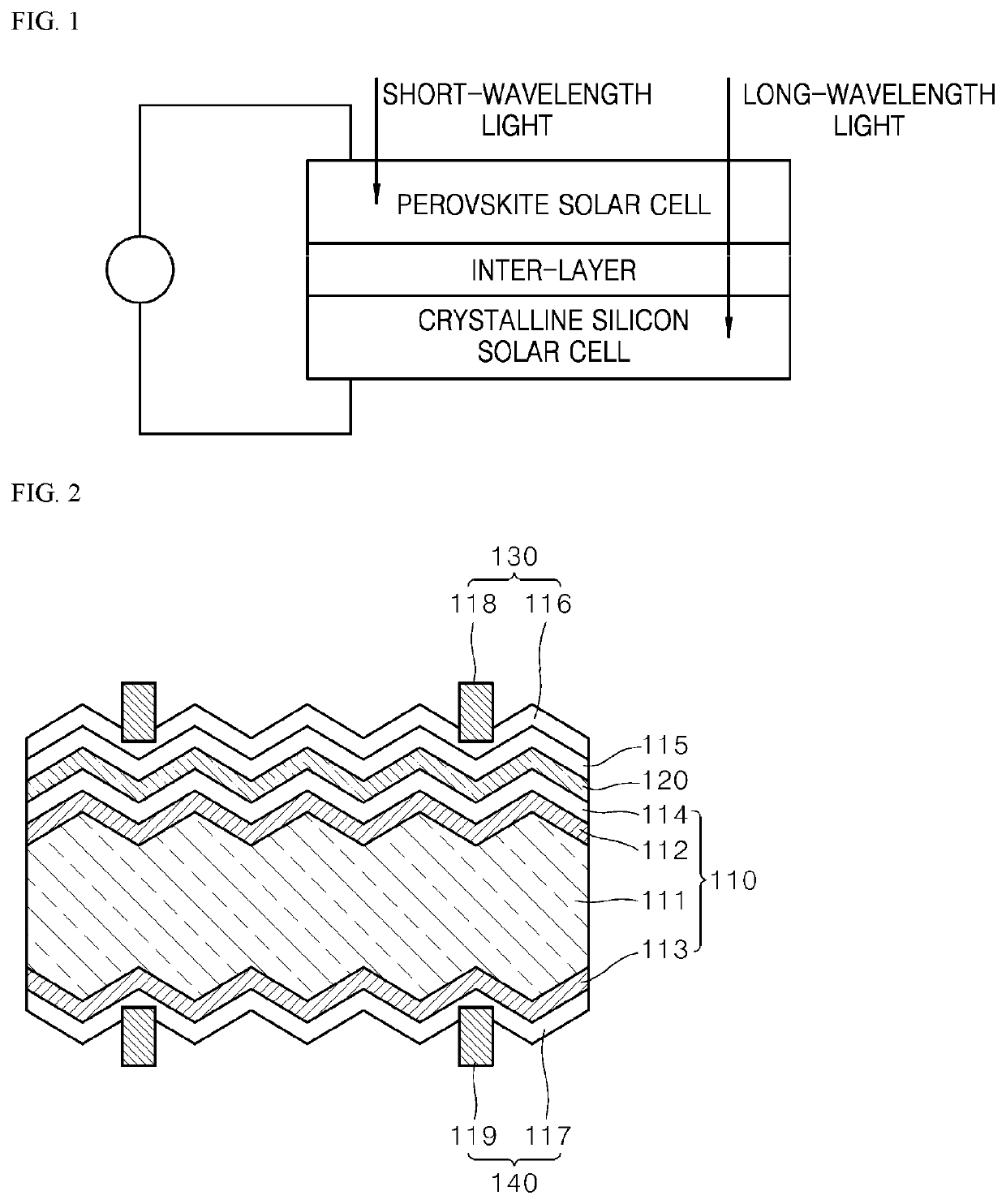

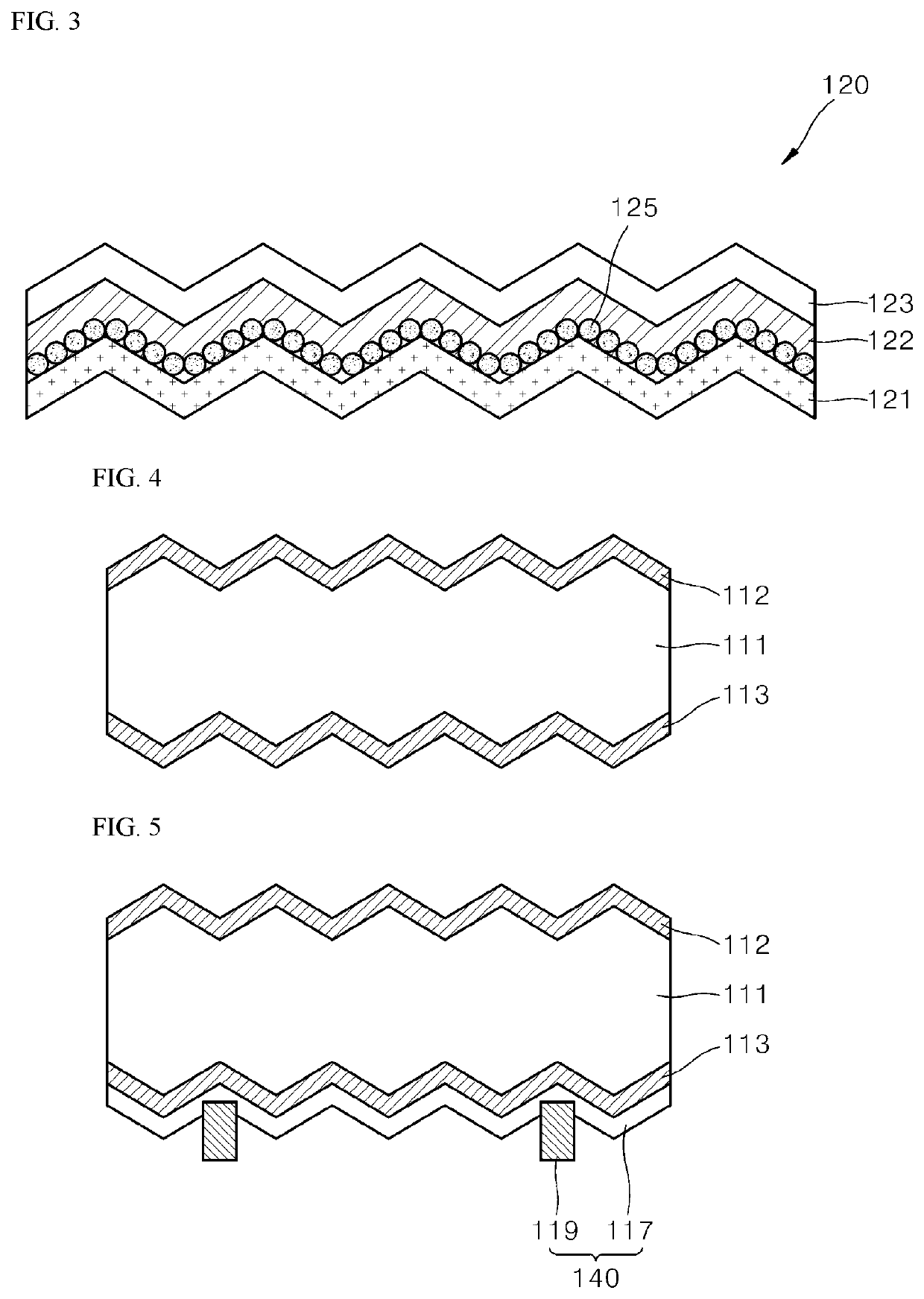

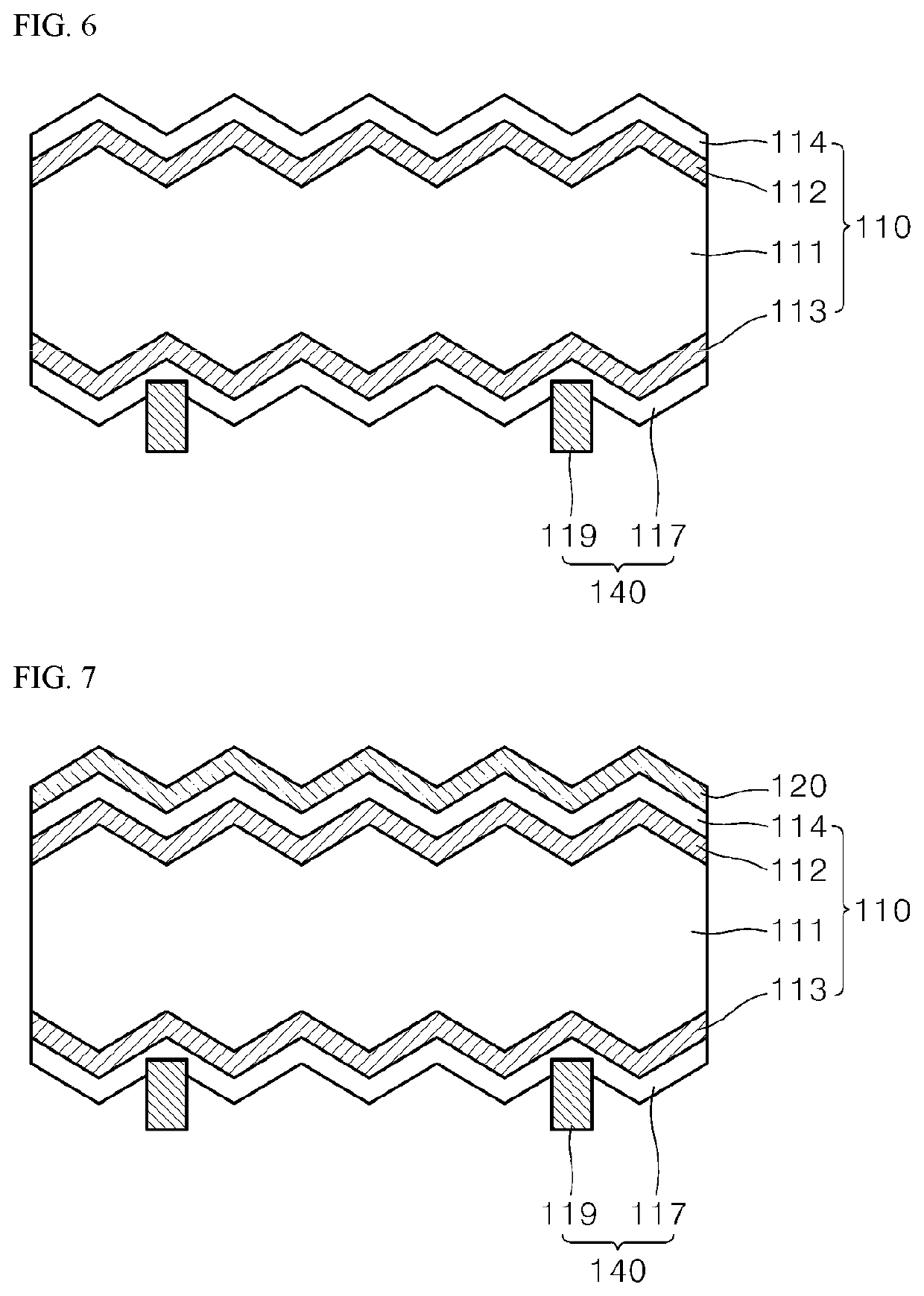

Method for manufacturing perovskite silicon tandem solar cell

ActiveUS20200212243A1Reduce reflectivityExtended pathFinal product manufacturePhotovoltaic energy generationPerovskite (structure)Engineering

The present disclosure relates to a method for manufacturing a monolithic tandem solar cell in which a perovskite solar cell is laminated and bonded on a silicon solar cell. According to the present disclosure, a first microporous precursor thin film is formed through a sputtering method on a substrate having an unevenly structured texture and then a halide thin film is formed on the first microporous precursor thin film to form a perovskite absorption layer, whereby light reflectance can be reduced and a path of light can be increased, and accordingly a light absorption rate can be increased.

Owner:SHANGRAO JINKO SOLAR TECH DEV CO LTD

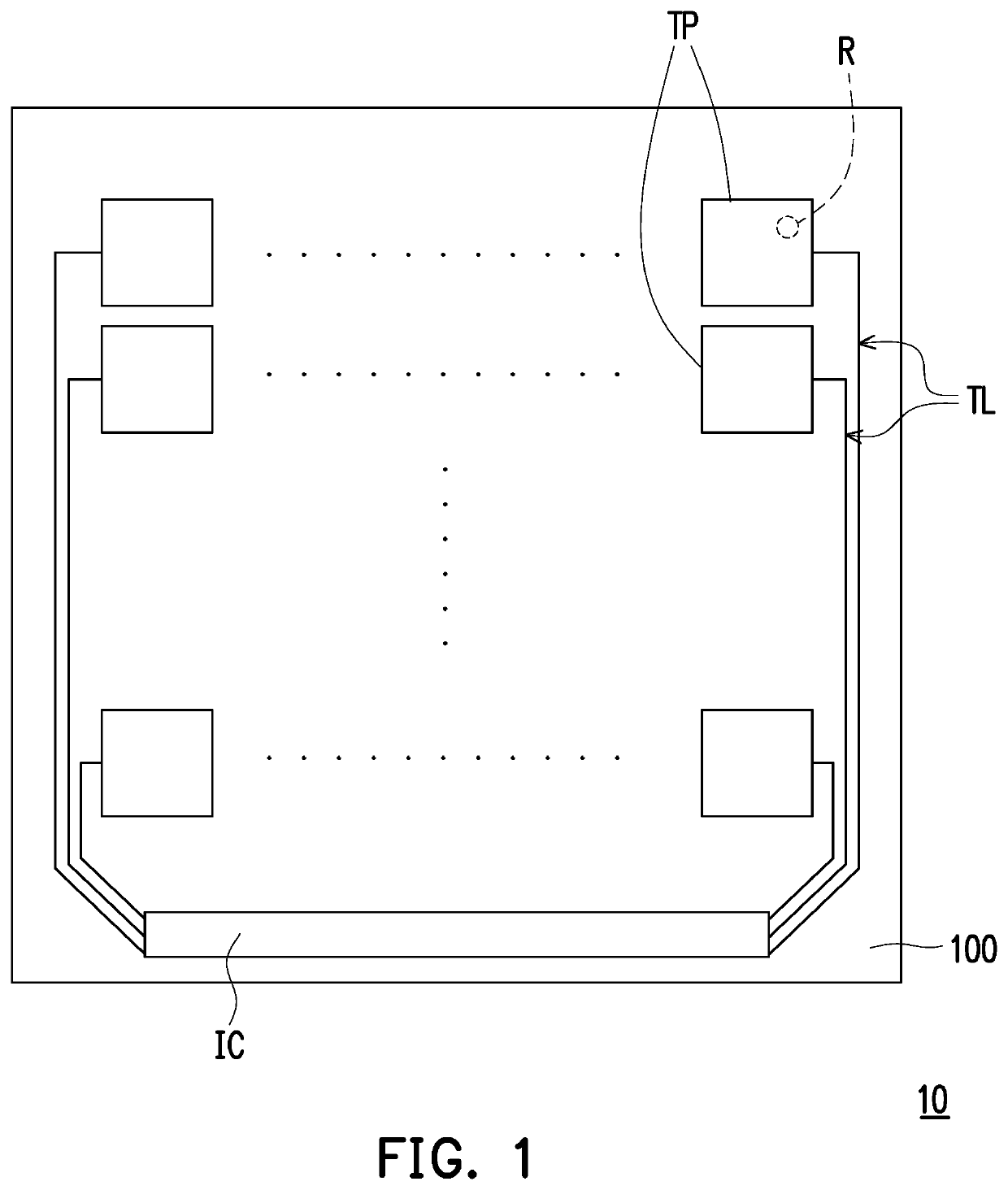

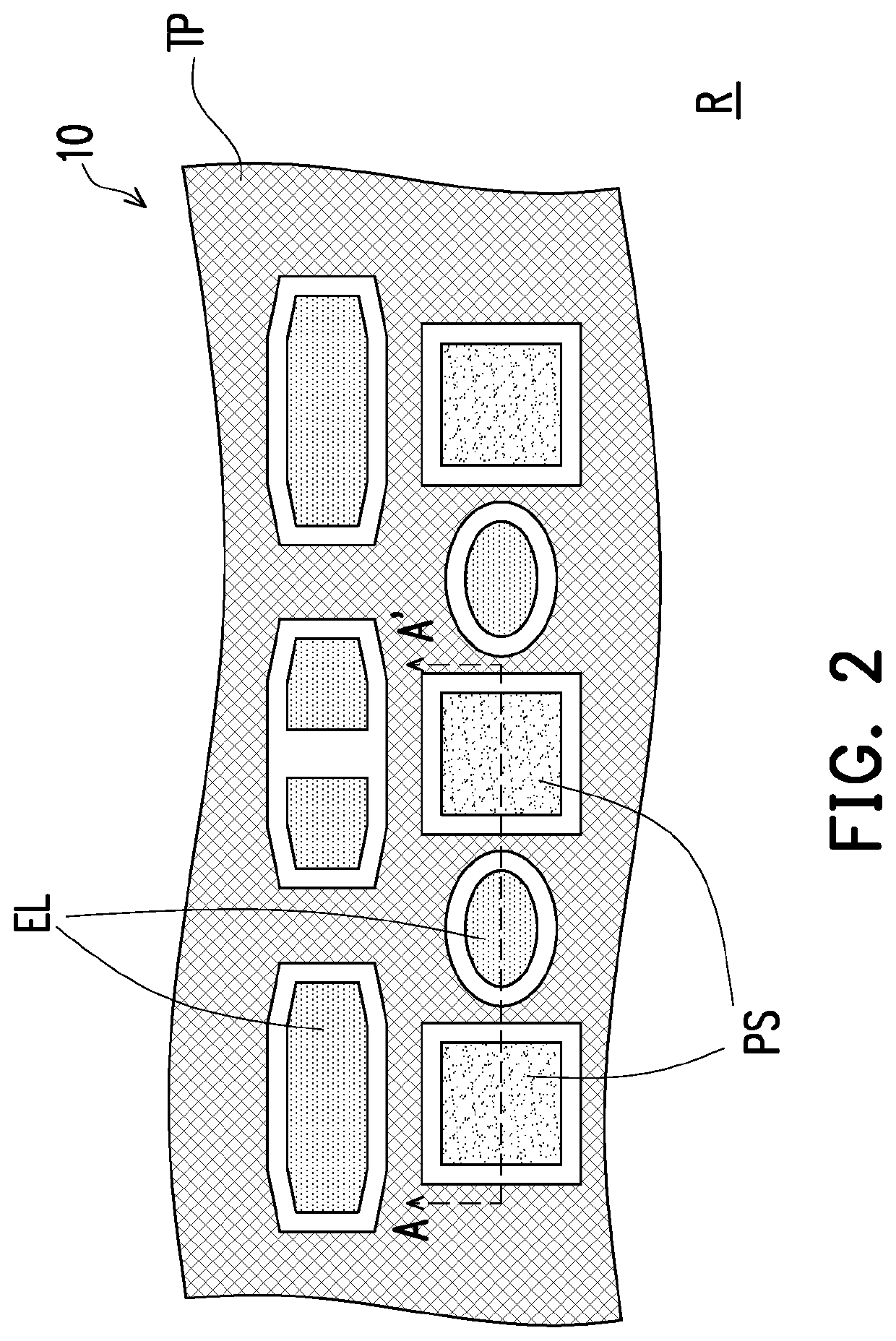

Anti-reflective integrated touch display panel

ActiveUS20200057520A1Increase flexibilityReduce disturbing noiseSolid-state devicesSemiconductor/solid-state device manufacturingSilicon oxideStrontium oxide

An anti-reflective integrated touch display panel includes an anti-reflective structure and touch electrodes. The anti-reflective structure includes a first insulating layer, a second insulating layer disposed on the first insulating layer, a conducting layer disposed on the second insulating layer, a third insulating layer disposed on the second insulating layer, and a fourth insulating layer disposed on the third insulating layer. The first insulating layer includes silicon oxide or silicon nitride, and has a thickness of 0.1 to 2 micrometers. The second insulating layer includes silicon oxide or strontium oxide, and has a thickness of 0.001 to 0.1 micrometer. The conducting layer includes molybdenum, and has a thickness of 0.01 to 0.05 micrometer. The fourth insulating layer includes silicon nitride, and has a thickness of 0.001 to 0.3 micrometer. The touch electrodes are disposed between the third insulating layer and the fourth insulating layer.

Owner:AU OPTRONICS CORP

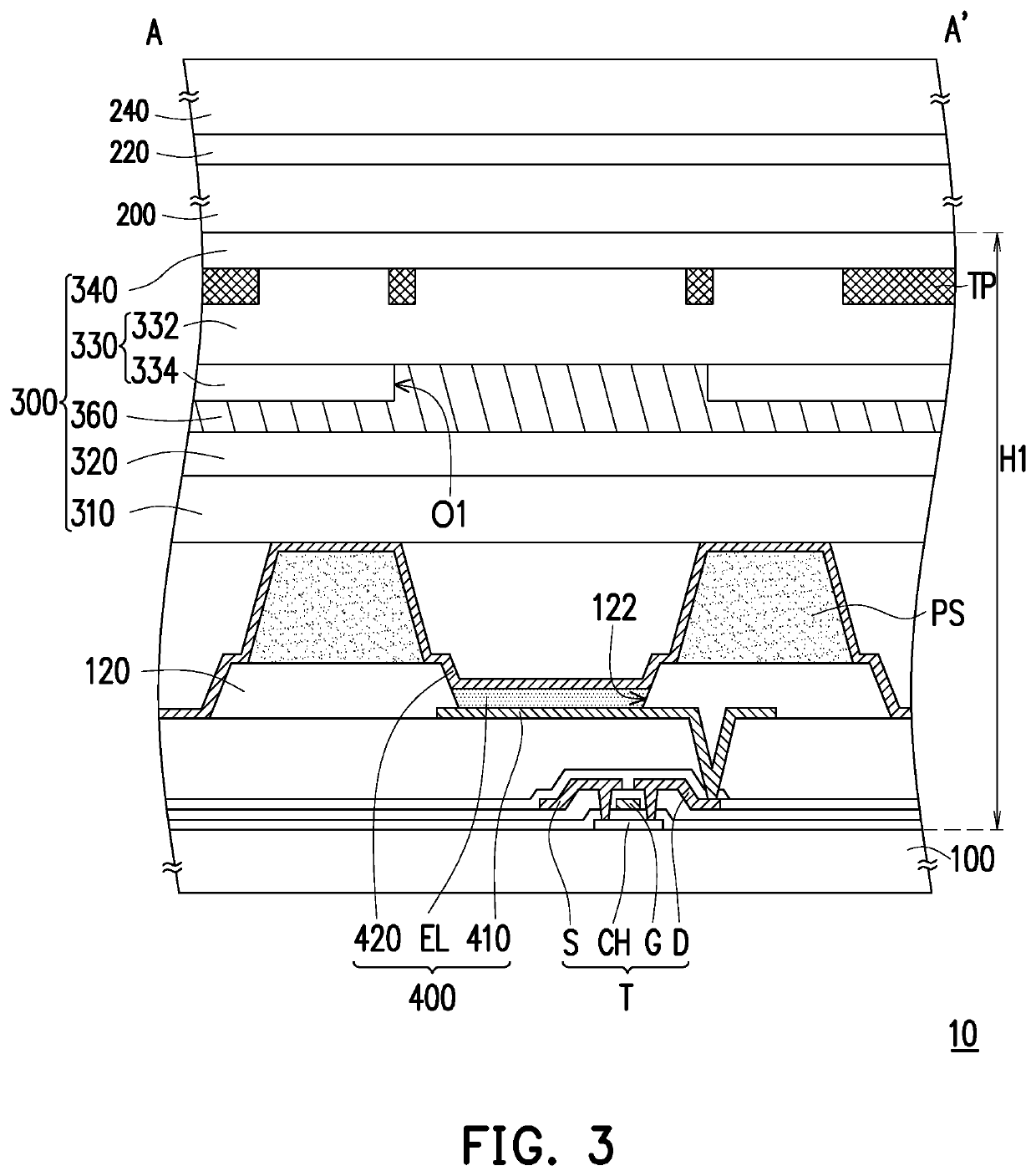

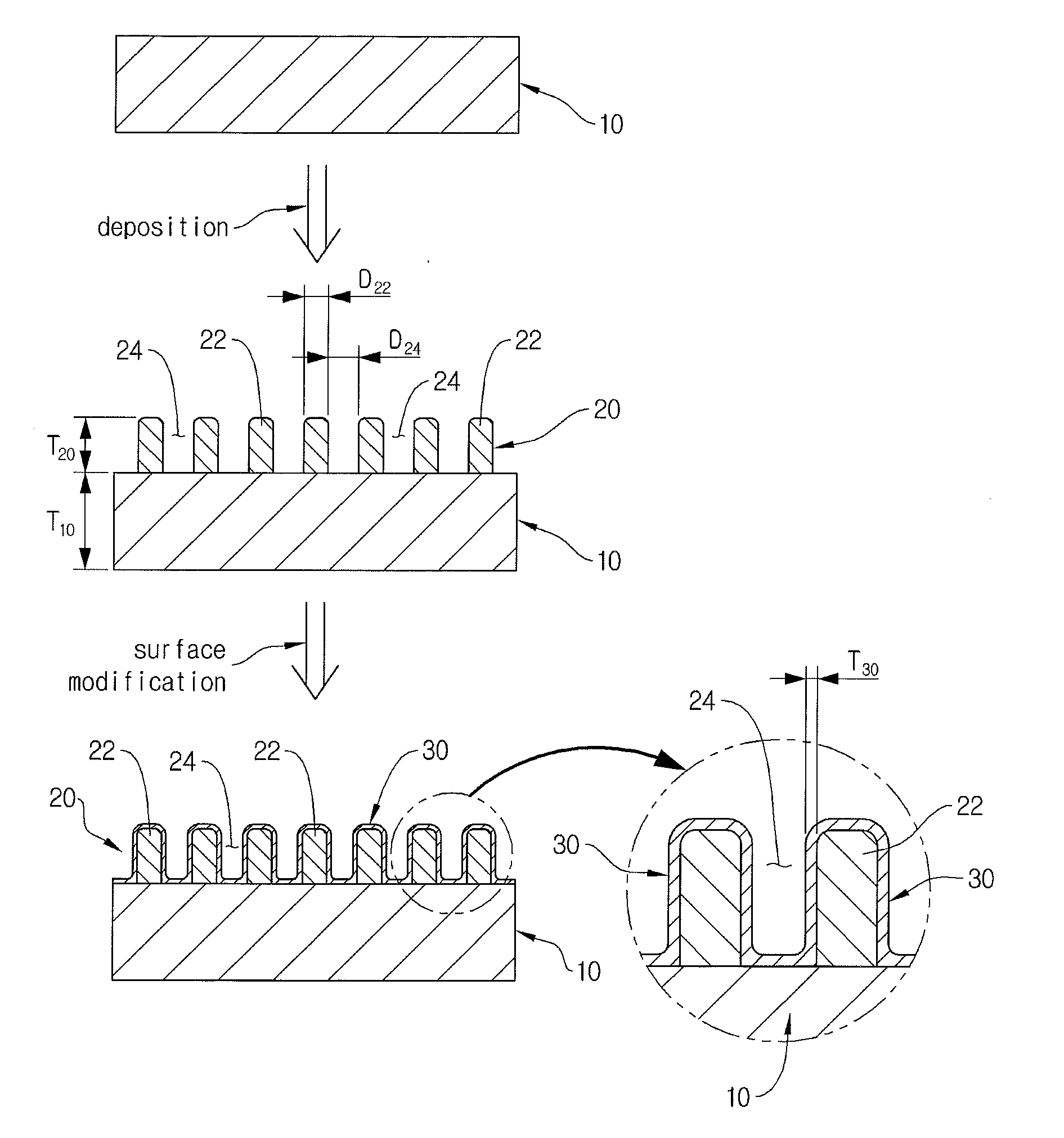

Hydrophobic substrate with Anti-reflective property method for manufacturing the same, and solar cell module including the same

InactiveUS20130199612A1Small light refractive indexReduce reflectivityMaterial nanotechnologyIndividual molecule manipulationSolar cellNanostructure

Provided are a hydrophobic antireflective substrate, a method for manufacturing the same, and a solar cell module including the same. The hydrophobic antireflective substrate includes: a substrate; a nanostructured layer having nanostructured portions formed on the substrate and nanoporous portions formed between the nanostructured portions; and a hydrophobic coating film formed on the nanostructured portions. The method for manufacturing a hydrophobic antireflective substrate includes: forming a nanostructured layer having nanostructured portions and nanoporous portions formed between the nanostructured portions on a substrate; and forming a hydrophobic coating film on the nanostructured portions. In the hydrophobic antireflective substrate disclosed herein, a porous nanostructured layer is formed on the substrate and a hydrophobic coating film is formed on the nanostructured layer, so that the hydrophobic antireflective substrate has ultra-hydrophobic property corresponding to a large water droplet contact angle.

Owner:KOREA INST OF SCI & TECH

Color optical filter and liquid crystal display device

InactiveCN1532567AGood optical performanceReduce reflectionNon-linear opticsOptical elementsLight filterComputer science

The present invention relates to color optical filter and LCD device therewith. The color optical filter includes one first substrate, and one black matrix and coloring layer. The black matrix layer includes one anti-reflecting layer and one mask layer set on the first substrate layer successively; the coloring layer and the black matrix layer are set on the first substrate alternately; and the coloring layer covers the surface of the mask layer.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

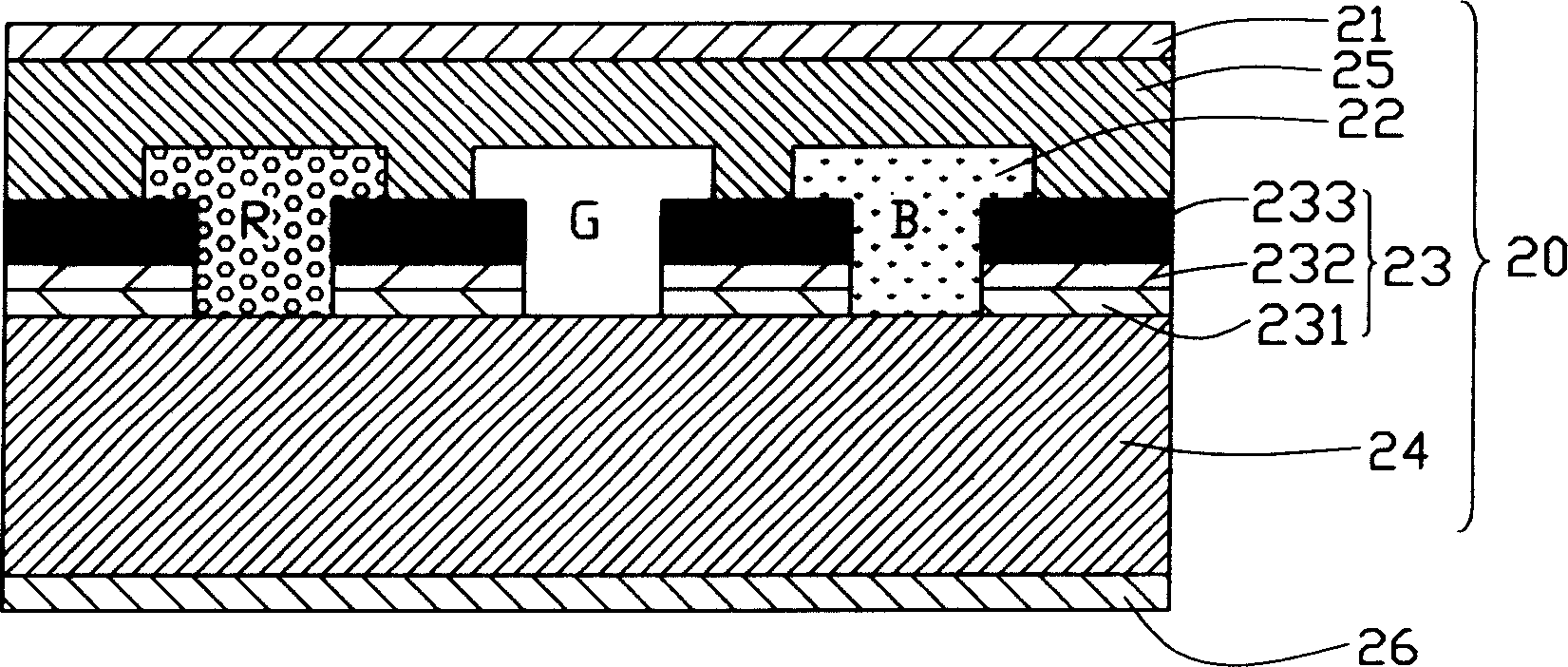

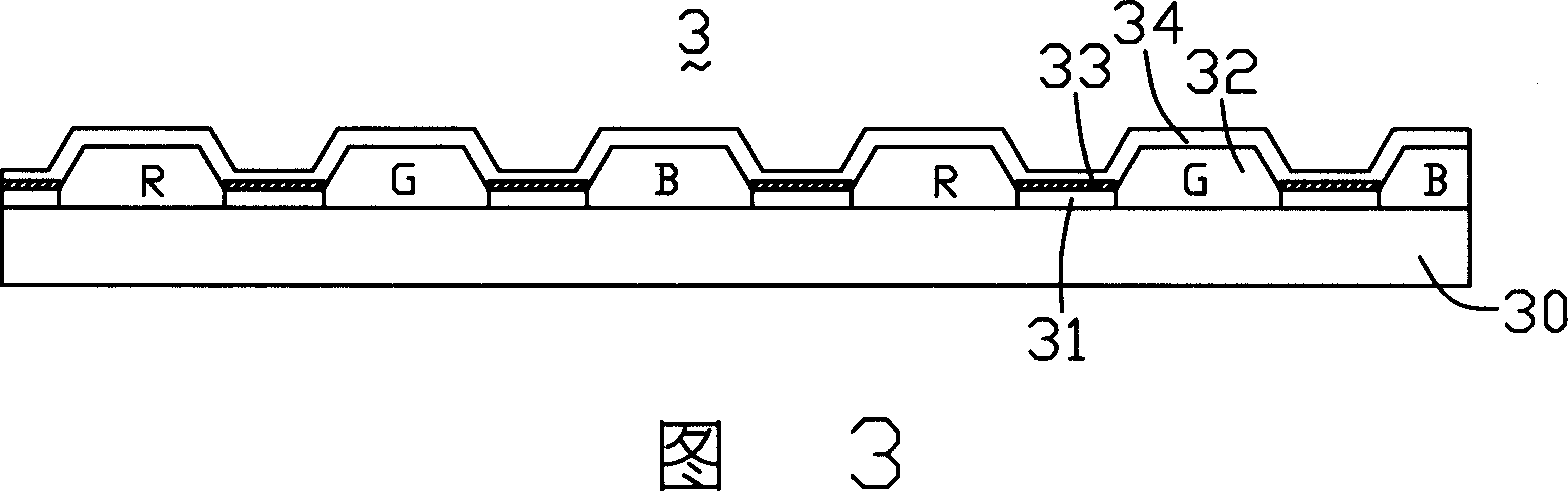

Colorful filter and its production method, liquid crystal display and its production method

InactiveCN101059575AGood optical performanceReduce light reflectivitySolid-state devicesNon-linear opticsTransparent conducting filmLight filter

The invention relates to a colorful filter and a relative production, also relates to a liquid crystal display device and a relative production. The production of the colorful filter comprises that preparing a substrate, preparing a black matrix on the surface of the substrate, forming a dyed layer on the surface of the substrate alternatively distributed with the black matrix on the surface of the substrate, forming an extinction layer on the surface of the black matrix, and forming a transparent conductive film on the extinction layer and the dyed layer. The invention also provides a liquid crystal display device which uses the colorful filter and a relative production. The inventive colorful filter has low light index of reflection, to improve the display quality of the liquid crystal display device which utilizes the colorful filter.

Owner:INNOCOM TECH SHENZHEN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com