Method for manufacturing double-layer film of crystalline silicon solar cell

The technology of a solar cell and its manufacturing method, which is applied in the field of solar cells, can solve the problems of reducing reflectivity and low reflectivity, and achieve the effects of improved photoelectric conversion efficiency, high power, and improved absorption

Inactive Publication Date: 2010-08-25

上海泰阳绿色能源有限公司

View PDF0 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the reflectivity of silicon solar cells with silicon nitride anti-reflection film is not very low, how to further reduce the reflectivity has become a big problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

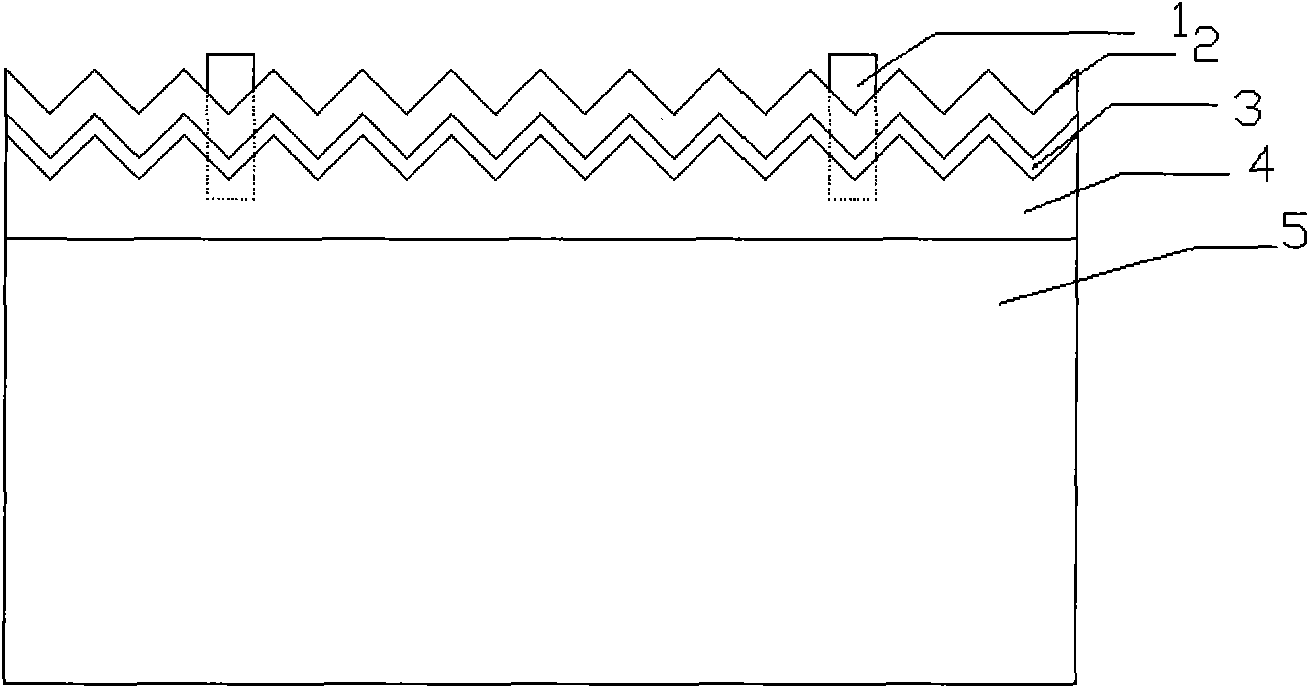

The invention relates to a method for manufacturing a double-layer film of a crystalline silicon solar cell. The method is characterized by comprising the following specific steps of: mixing tetraethyl orthosilicate and ethanol, stirring and heating, adding dilute solution of hydrochloric acid into the solution, cooling, adding an organic additive into the solution, stirring and dissolving, and closing and aging to obtain a sol; and preparing a substrate of the crystalline silicon solar cell by a routine method, forming a silicon nitride film by a plasma enhanced chemical vapor deposition method, spraying the prepared sol on the silicon nitride film to prepare a silicon dioxide film, performing heat treatment on the obtained silicon dioxide film at the temperature of between 200 and 600 DEG C, printing positive and negative electrodes and a back field, drying, and sintering. The method has the advantages that: the light reflectivity of the surface of the solar cell is lower; the power of a solar cell plate is higher; and the short-wave and long-wave absorption of the double-layer film cell is further improved.

Description

A kind of manufacturing method of bilayer film of crystalline silicon solar cell technical field The invention relates to a method for manufacturing a double-layer film of a crystalline silicon solar cell, belonging to the technical field of solar cells. Background technique Crystalline silicon solar cells are optoelectronic devices that convert light energy into electrical energy. Its photoelectric conversion efficiency is defined as the ratio of the total output power to the total power of sunlight incident on the surface of the solar cell. In order to improve the photoelectric conversion efficiency of crystalline silicon solar cells, the reflection loss of light on the surface of the cell should be reduced and the transmission of light should be increased. At present, two methods are mainly used: (1) corroding the surface of the battery into a suede surface to increase the number of incident light on the surface of the battery; (2) coating one or more layers of anti-re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01L31/18H01L31/042H01L31/0216

CPCY02E10/52Y02P70/50

Inventor 郭明星熊胜虎孔慧郭群超何涛郭爱娟

Owner 上海泰阳绿色能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com