Anti-reflection coating and super-hydrophobic self-cleaning anti-reflection coating and preparation method thereof

A kind of anti-reflection anti-reflection and self-cleaning technology, applied in the field of nanomaterial preparation, can solve the problems of limited applicable conditions, unsatisfactory durability, blocking orifices, etc., and achieve the effects of simple equipment, low cost, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

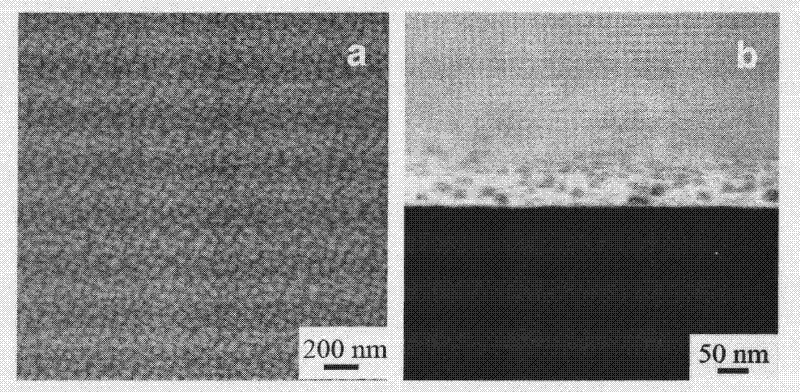

Embodiment 1

[0043] Anti-reflection coating: a layer of SiO with a particle size of 10-30nm 2 Nano particle composition, its preparation method comprises the following steps:

[0044] (1) Add 3-6mL of ammonia water and 50-150mL of absolute ethanol into the Erlenmeyer flask at room temperature and stir for 8-12 minutes, then stir for 1-3 minutes at 50-70 degrees Celsius, and add 2-4mL of ethyl orthosilicate dropwise under stirring Ester (TEOS), vigorously stirred at 50-70 degrees Celsius for 10-14 hours, a translucent suspension was obtained, which contained SiO with a diameter of 10-30nm 2 Spherical nanoparticle suspension, and diluting it into a suspension with a mass fraction of 0.1% to 1% for subsequent use;

[0045] (2) Immerse the common glass sheet into the newly prepared Pirhana solution (the H concentration is about 98%) 2 SO 4 with a mass concentration of about 30% H 2 o 2 7:3 mixed solution by volume) for 5 to 20 minutes, take it out, wash it with distilled water, and dry it...

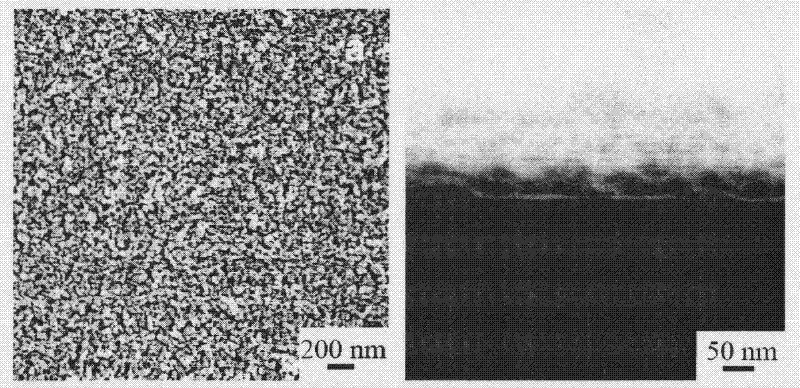

Embodiment 2

[0051] Anti-reflection coating: four layers of SiO with a particle size of 10-30nm 2 Nano particle composition, its preparation method comprises the following steps:

[0052] (1) Add 3-6mL of ammonia water and 50-150mL of absolute ethanol into the Erlenmeyer flask at room temperature and stir for 8-12 minutes, then stir for 1-3 minutes at 50-70 degrees Celsius, and add 2-4mL of ethyl orthosilicate dropwise under stirring Ester (TEOS), continue to stir at 50-70 degrees Celsius for 10-14 hours to obtain a translucent suspension containing SiO with a diameter of 10-30nm 2 Spherical nanoparticle suspension, and diluting it into a suspension with a mass fraction of 0.1% to 1% for subsequent use;

[0053] (2) Immerse the common glass sheet into the newly prepared Pirhana solution (the H concentration is about 98%) 2 SO 4 with a mass concentration of about 30% H 2 o 2 7:3 mixed solution by volume) for 5 to 20 minutes, take it out, wash it with distilled water, and dry it with ni...

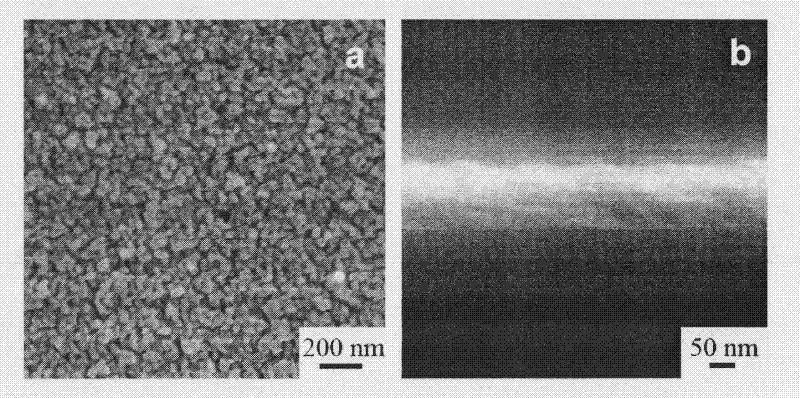

Embodiment 3

[0059] Anti-reflection coating: eight layers of SiO with a particle size of 10-30nm 2 Nano particle composition, its preparation method comprises the following steps:

[0060] (1) Add 3-6mL of ammonia water and 50-150mL of absolute ethanol into the Erlenmeyer flask at room temperature and stir for 8-12 minutes, then stir for 1-3 minutes at 50-70 degrees Celsius, and add 2-4mL of ethyl orthosilicate dropwise under stirring Ester (TEOS), continue to stir at 50-70 degrees Celsius for 10-14 hours to obtain a translucent suspension containing SiO with a diameter of 10-30nm 2 Spherical nanoparticle suspension, and diluting it into a suspension with a mass fraction of 0.1% to 1% for subsequent use;

[0061] (2) Immerse the common glass sheet into the newly prepared Pirhana solution (the H concentration is about 98%) 2 SO 4 with a mass concentration of about 30% H 2 o 2 7:3 mixed solution by volume) for 5 to 20 minutes, take it out, wash it with distilled water, and dry it with n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com