Diamond components for quantum imaging, sensing and information processing devices

a quantum imaging and sensing technology, applied in the direction of crystal growth process, polycrystalline material growth, chemically reactive gas, etc., can solve the problems of negate the requirement for expensive and bulky cryogenic cooling apparatus, defects exhibit a shorter spin coherence time, etc., to achieve low surface roughness, long spin coherence time, and low surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]As described in the summary of invention section, a method of fabricating a diamond component is provided for a quantum imaging, sensing, or information processing device, the method comprising:

[0043]growing a single crystal CVD diamond layer having an as-grown growth face, at least a portion of the as-grown growth face having a surface roughness Ra of no more than 100 nm;

[0044]implanting nitrogen into said as-grown growth face of the single crystal CVD diamond layer without any polishing or etching of the as-grown growth face; and

[0045]annealing the single crystal CVD diamond layer to cause migration of vacancy and / or nitrogen defects within the single crystal CVD diamond layer and formation of nitrogen-vacancy defects from the implanted nitrogen and the vacancy defects.

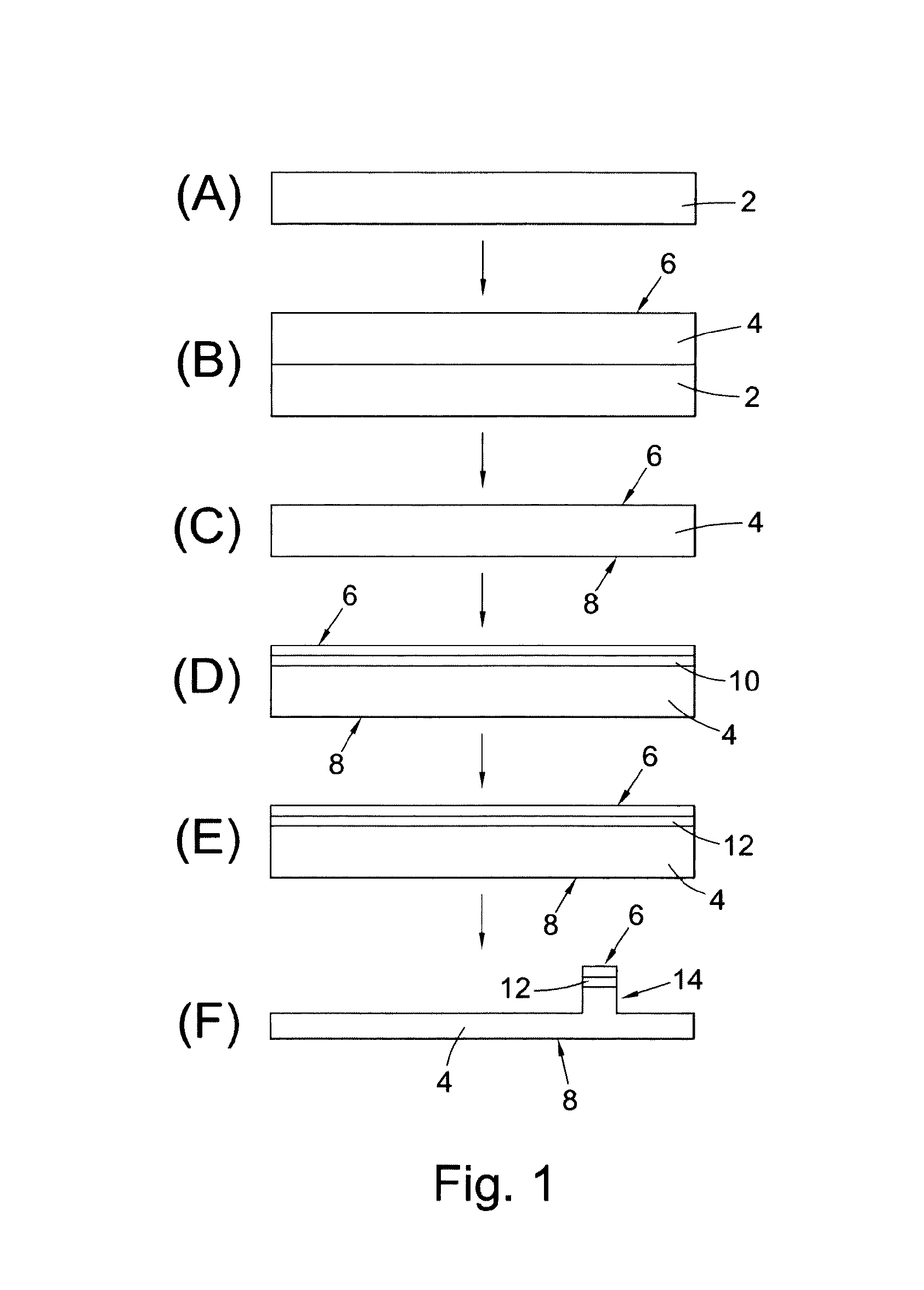

[0046]FIG. 1 illustrates the aforementioned method. The starting point (FIG. 1A) is a single crystal diamond substrate 2 which is suitably prepared for single crystal CVD diamond growth thereon.

[0047]Next (FIG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com