Plane grid rib for structure reinforcement, mould and manufacturing method of plane grid rib

A manufacturing method and technology of grid bars, which are applied to structural elements, bridge reinforcement, building components, etc., can solve the problems of gaps in the composite material layer, irregular interfaces, and irregular cross-sections, and achieve stable mechanical properties without difficulty. Cracked, uniform cross-section effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

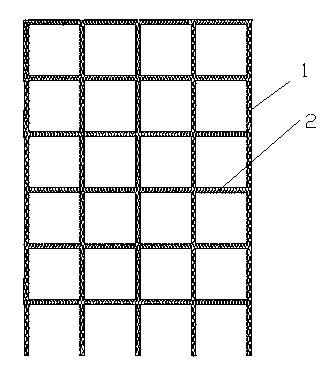

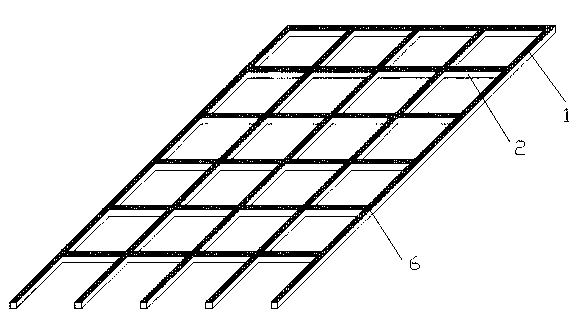

[0054] The preparation method of the present invention is characterized in that compression molding is adopted, and diamond-shaped fine grid patterns are engraved on the surfaces of the female mold 5 and the male mold 4, so that corresponding patterns are formed on the upper and lower surfaces of the plane grid ribs, and the plane surface can be enhanced during use. The combination of grid bars and concrete or other materials, and the process has high production efficiency, high and stable product quality, neat and beautiful appearance.

[0055] The planar grid reinforcement prepared by the invention has performance characteristics such as high fiber content, high tensile strength and high elastic modulus, and is suitable for strengthening bridges, tunnels, houses and other buildings.

Embodiment 1

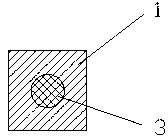

[0058] Using the manufacturing method of the present invention, the planar grid reinforcement is manufactured. The fiber selects high-performance glass fiber fiber, and the resin selects vinyl resin. The high-performance glass fiber is impregnated with thermosetting resin, arranged vertically and horizontally along the mold, molded and heated. In the first step, the mass content of fibers is 80% and the mass content of resin is 20%. In the second step, the distance between adjacent grooves 501 is 50 mm. In the third step, lay 800Tex resin-impregnated fibers in the groove 501 of the female mold, apply a pressure of 200Kg, heat and solidify, and finally make planar grid ribs with an interval of 50mm and a thickness of 1mm.

[0059] According to the different thickness requirements of the product design, different numbers of resin-impregnated fibers are arranged in the groove 501 of the female mold, and planar grid bars with different thicknesses can be prepared according to th...

Embodiment 2

[0061] Using the manufacturing method of the present invention, the planar grid reinforcement is manufactured. The fiber is selected from basalt fiber, and the resin is selected from epoxy resin. The basalt fiber is soaked in thermosetting resin, arranged vertically and horizontally along the female mold 5, molded and heated. In the first step, the mass content of fibers is 80% and the mass content of resin is 20%. In the second step, the distance between adjacent grooves 501 is 100 mm. In the third step, lay 4800Tex resin-impregnated fibers in the groove 501 of the female mold, apply a pressure of 1000Kg, heat and solidify, and finally make planar grid ribs with an interval of 100mm and a thickness of 10mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com