Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Color depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

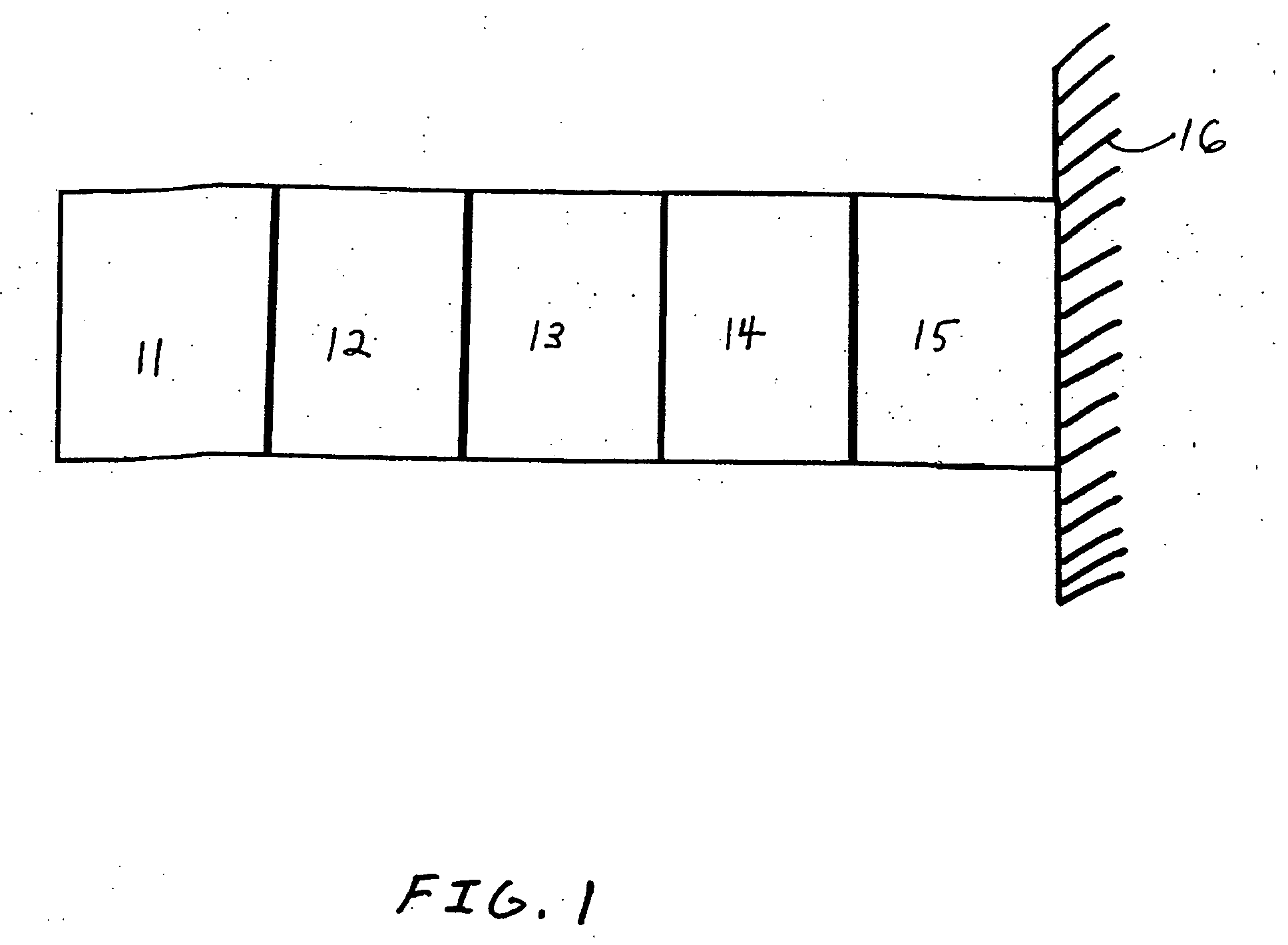

Smokable rod for a cigarette

InactiveUS20050066986A1Not easily dislodgedNot overly flakeyTobacco preparationCigar manufactureEngineeringTobacco smoke

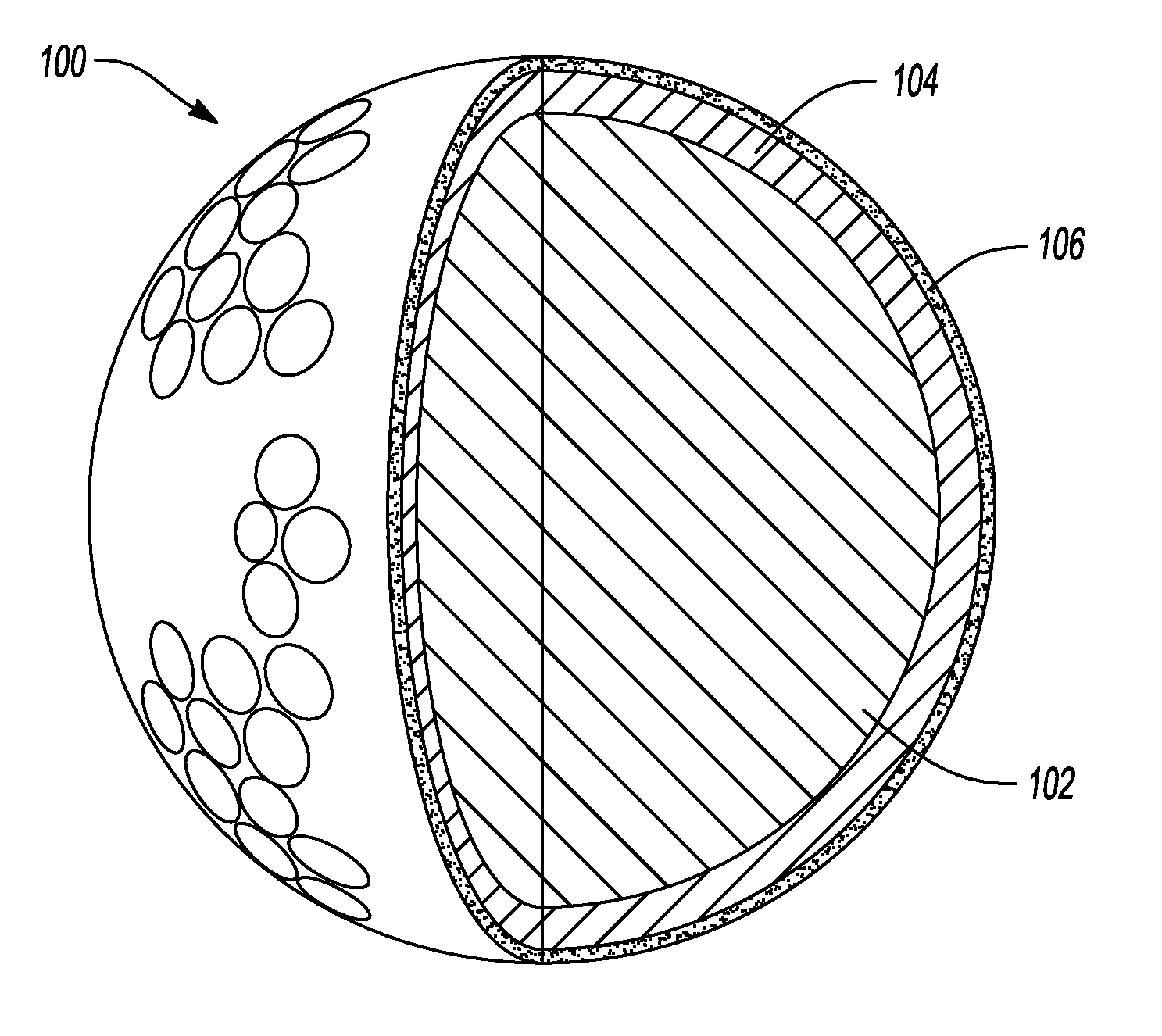

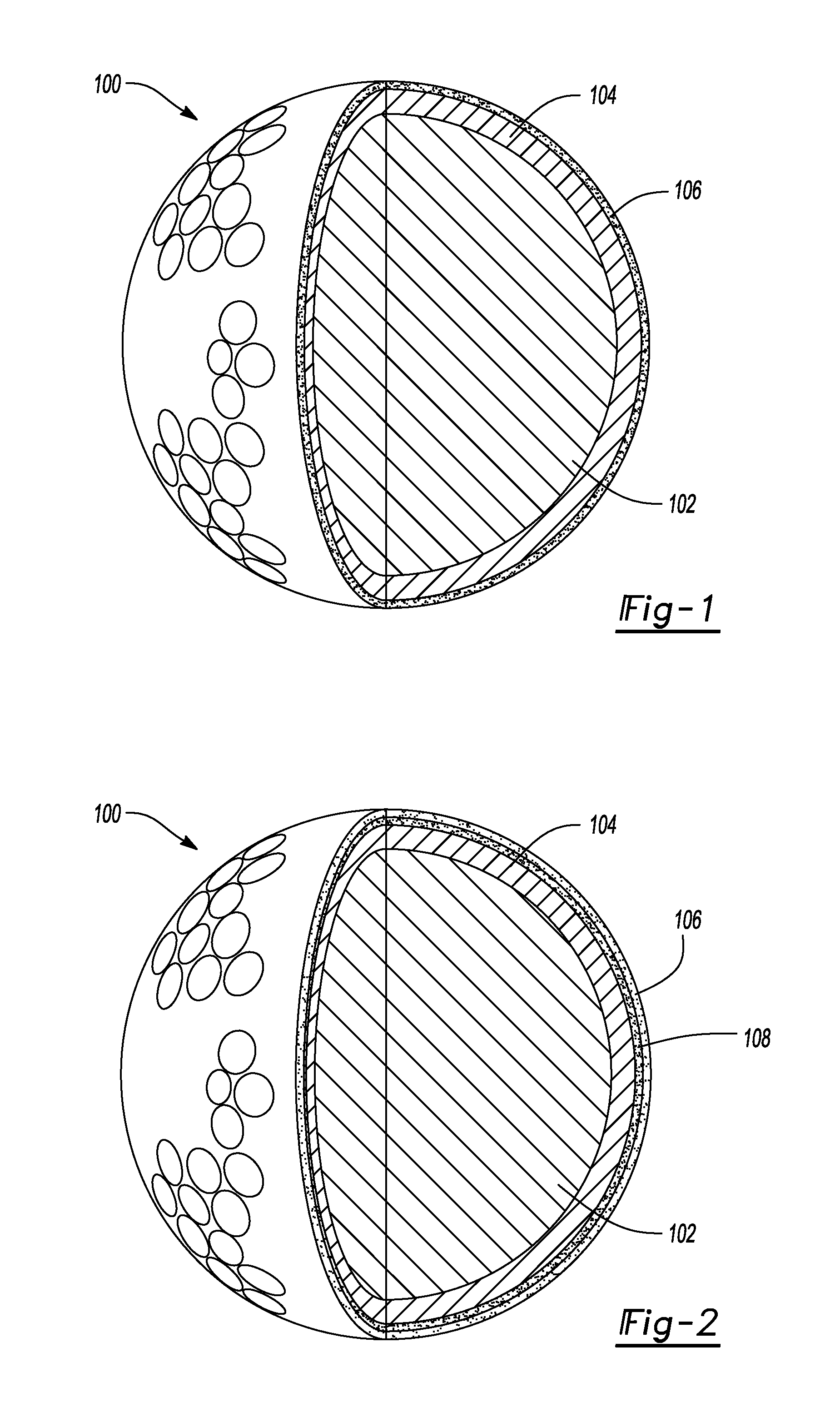

A smokable rod for a smoking article, such as a cigarette, possesses a co-axial or concentric construction. A longitudinally extending inner core of tobacco cut filler is positioned within a smokable rod. The outer material that circumscribes the inner core in an annular fashion is composed of a tobacco material treated with an optional burn suppressing agent, and the outer material acts as a substrate for an aerosol forming material. A preferred aerosol forming material is glycerin. An outer paper wrapper circumscribes the length of the smokable rod, and another paper wrapping material also can circumscribe the inner core material. In use, one end of the smokable rod is lit. When the opposite end of the smokable rod is drawn upon, an aerosol composed of tobacco smoke, thermal decomposition products of tobacco, and volatilized aerosol forming material, is provided. Alternatively, a smokable rod can be provided by positioning the tobacco cut filler in the outer annular region, and by constructing the inner core portion using the tobacco material treated with aerosol forming material and an optional burn suppressing agent. Alternatively, a smokable rod possesses a single blend of smokable materials; at least a portion the smokable material being a tobacco material carrying a relatively high amount of aerosol forming material; and optionally at least a portion of the smokable material being in intimate contact with a burn suppressing agent. A filtered cigarette can be produced by attaching a filter element to one end of any of those smokable rods.

Owner:R J REYNOLDS TOBACCO COMPANY

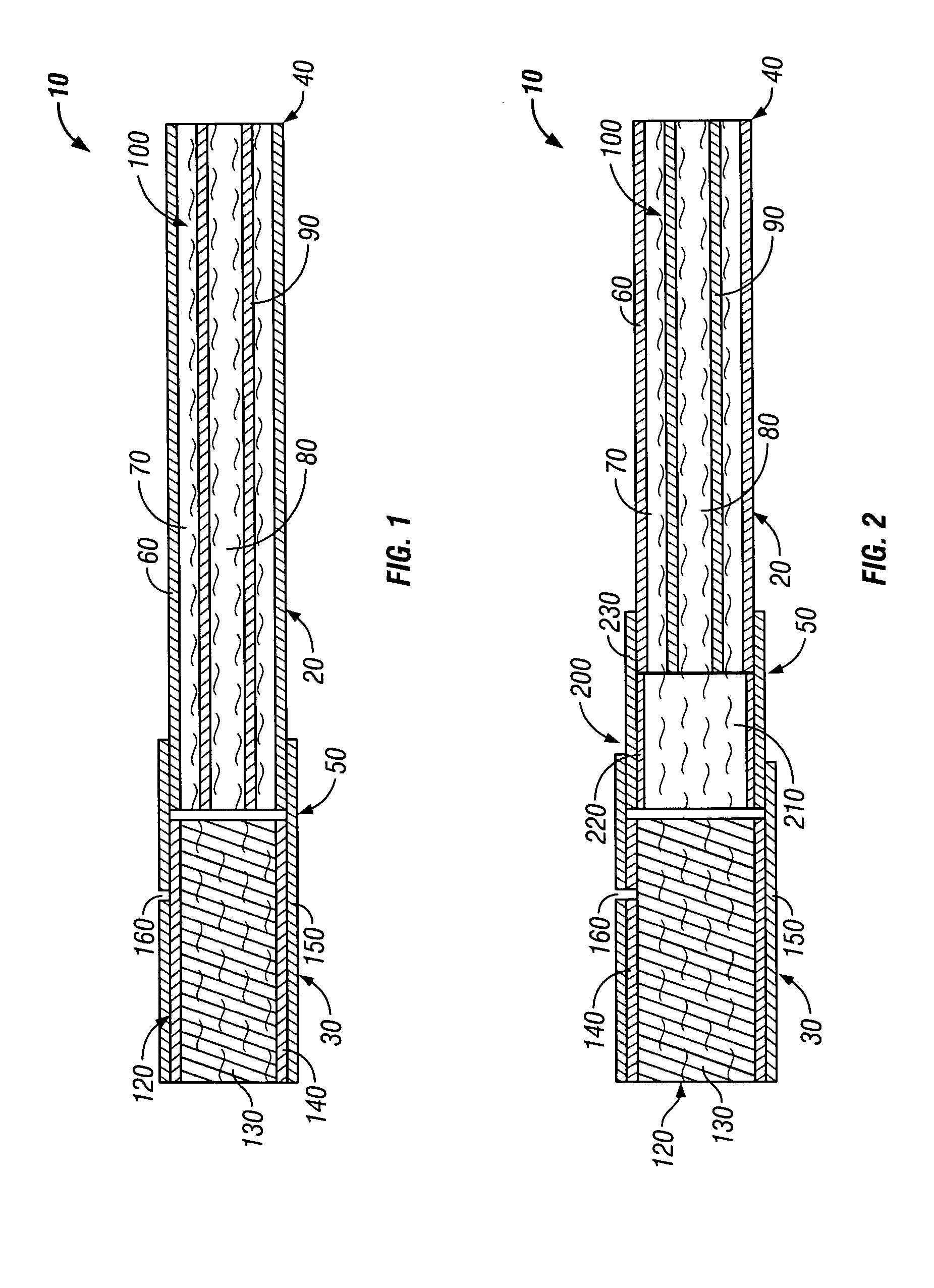

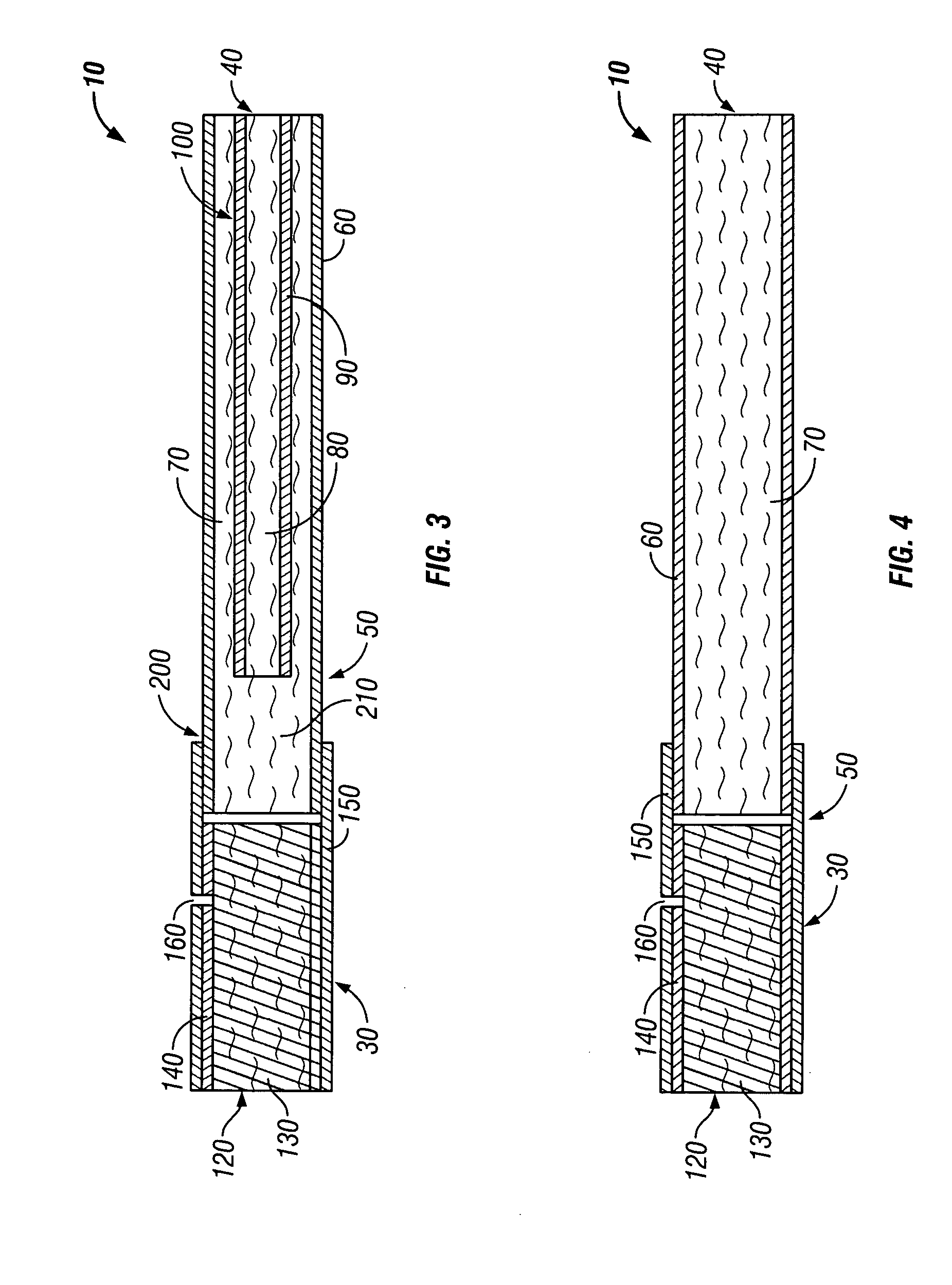

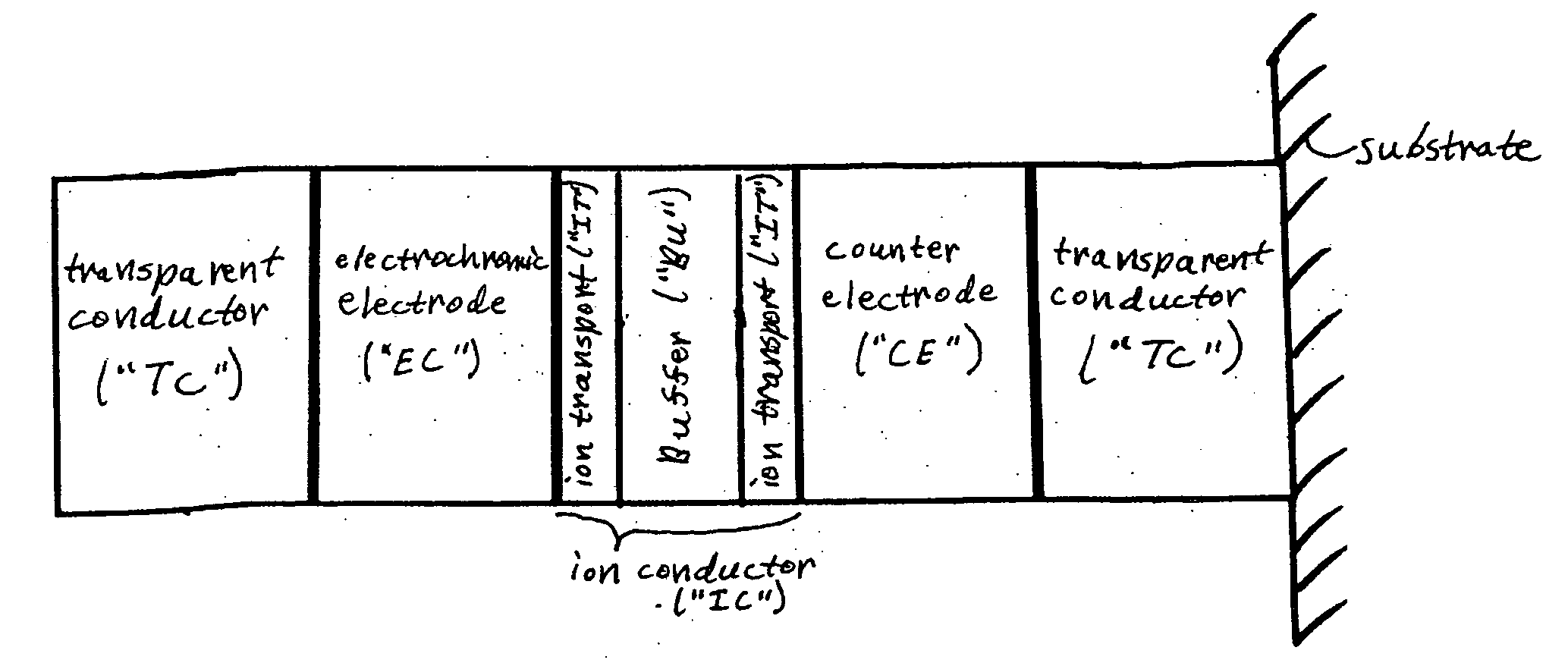

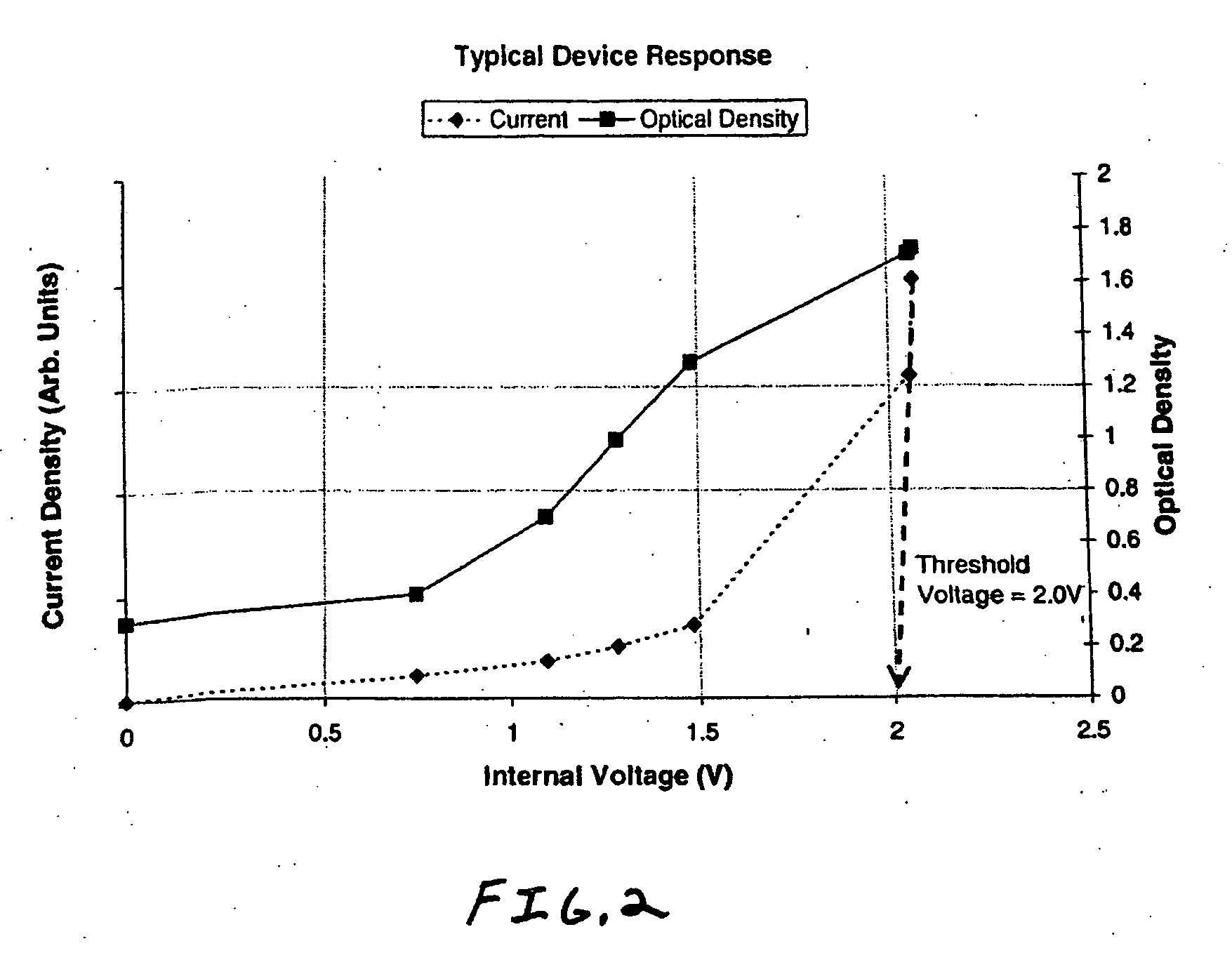

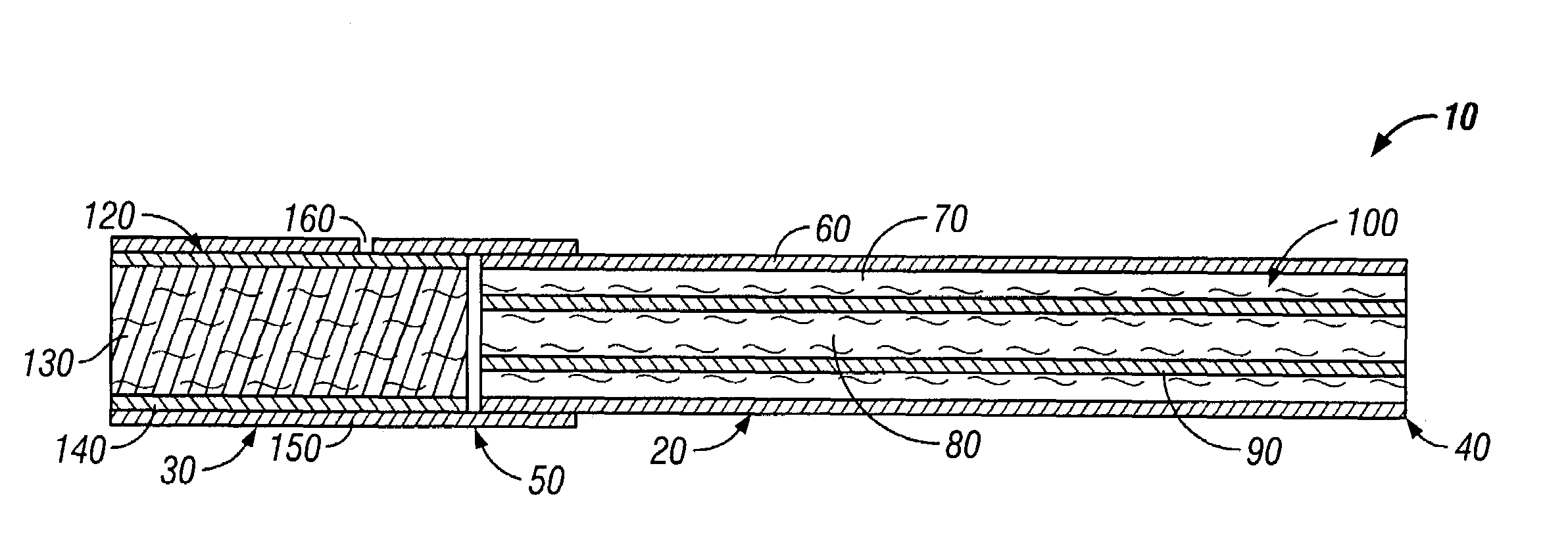

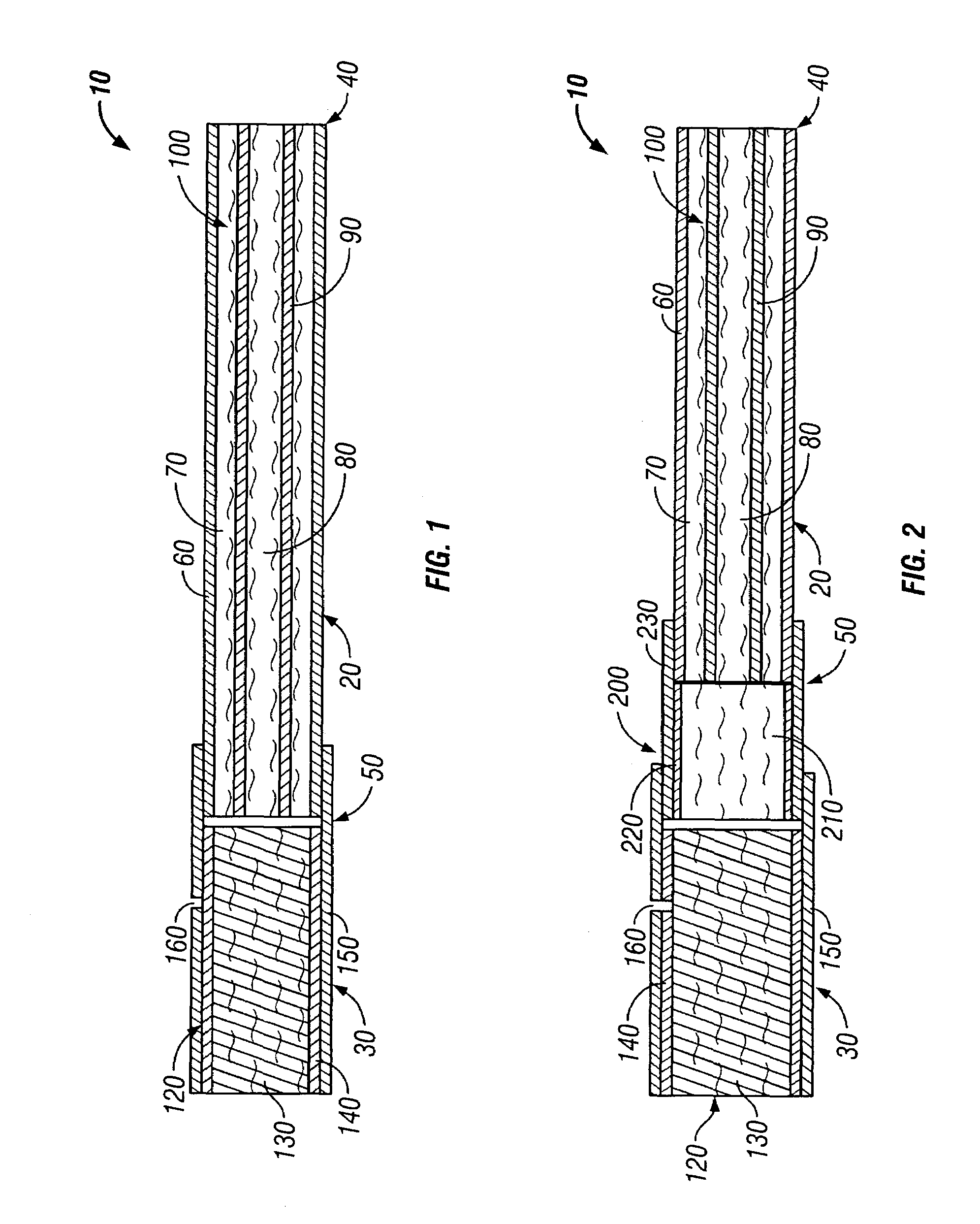

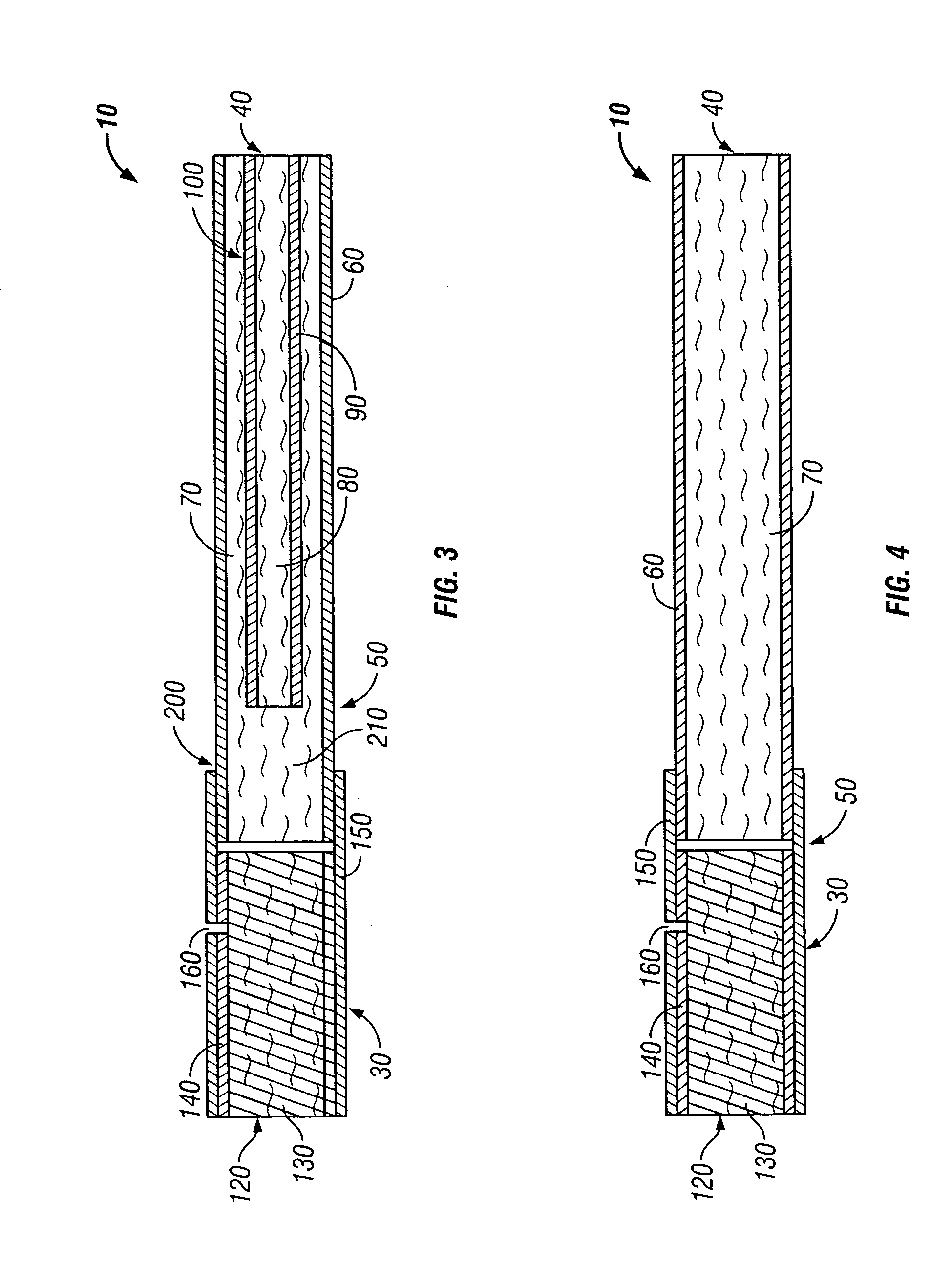

Electrochromic devices having improved ion conducting layers

InactiveUS20070097481A1Less susceptible to electronic leakageHigh voltageNon-linear opticsElectricityElectrical conductor

An improved ion conductor layer for use in electrochromic devices and other applications is disclosed. The improved ion-conductor layer is comprised of at least two ion transport layers and a buffer layer, wherein the at least two ion transport layers and the buffer layer alternate within the ion conductor layer such that the ion transport layers are in communication with a first and a second electrode. Electrochromic devices utilizing such an improved ion conductor layer color more deeply by virtue of the increased voltage developed across the ion conductor layer prior to electronic breakdown while reducing the amount of electronic leakage. Also disclosed are methods of making electrochromic devices incorporating the improved ion conductor layer disclosed herein and methods of making ion conductors for use in other applications.

Owner:SAGE ELECTROCHROMICS

Smokable rod for a cigarette

ActiveUS7503330B2Not easily dislodgedNot overly flakeyTobacco preparationNon-fibrous pulp additionEngineeringTobacco smoke

A smokable rod for a smoking article, such as a cigarette, possesses a co-axial or concentric construction. A longitudinally extending inner core of tobacco cut filler is positioned within a smokable rod. The outer material that circumscribes the inner core in an annular fashion is composed of a tobacco material treated with a burn suppressing agent, and the outer material acts as a substrate for an aerosol forming material. In use, one end of the smokable rod is lit, and the tobacco cut filler of the inner core burns to yield tobacco smoke. The outer material smolders, and hence thermal decomposition products of the outer tobacco material and volatilized aerosol forming material are produced. When the opposite end of the smokable rod is drawn upon, an aerosol composed of tobacco smoke, thermal decomposition products of tobacco, and volatilized aerosol forming material, is provided.

Owner:R J REYNOLDS TOBACCO COMPANY

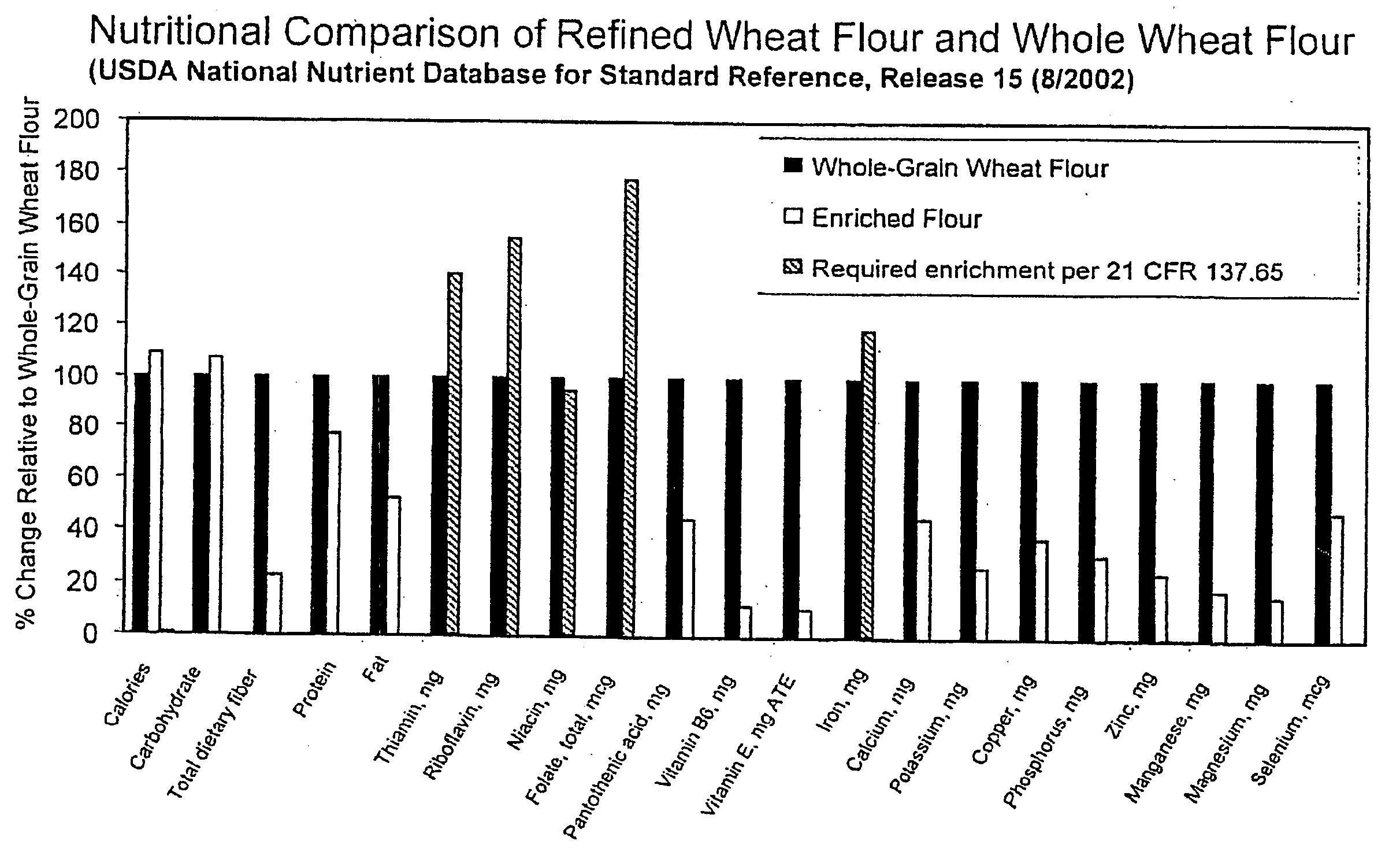

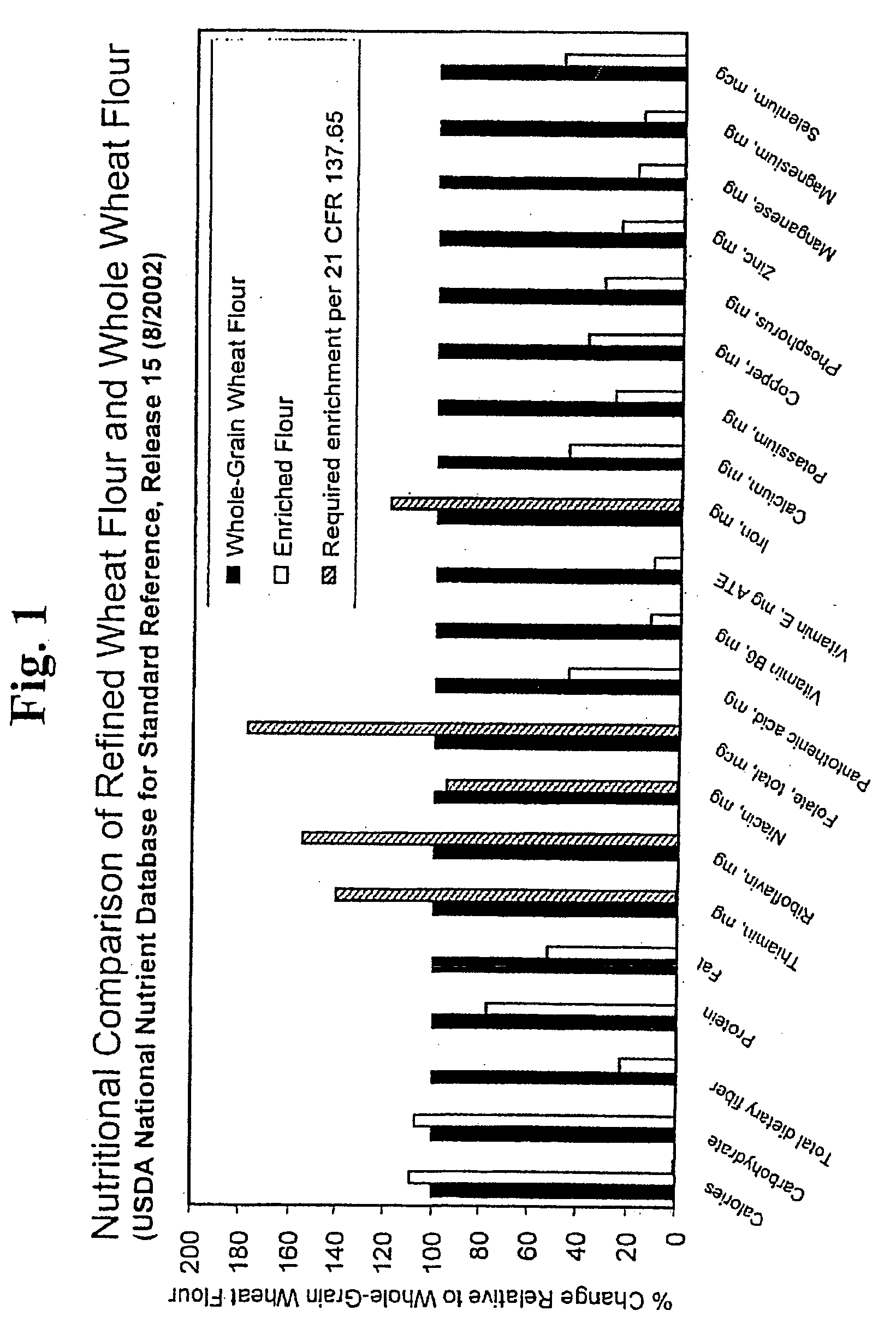

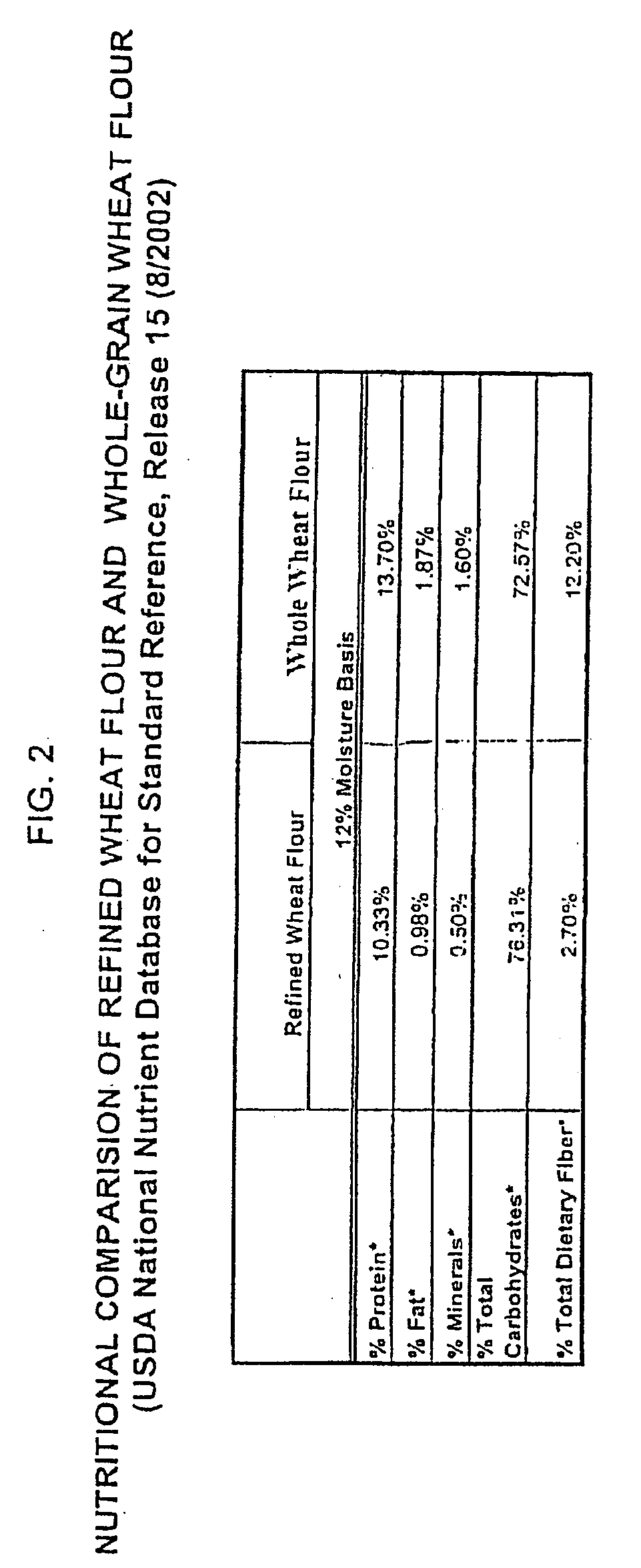

Process for producing an ultrafine-milled whole-grain wheat flour and products thereof

InactiveUS20060073258A1High nutritional valueHigh in fiberDough treatmentGrain treatmentsSnack foodUltra fine

A process for producing an ultrafine-milled whole-grain wheat flour which has the full nutritional value of wheat kernels, while retaining the texture of refined wheat flour and an appearance similar to refined wheat flour, and the products which can be made from the ultrafine-milled whole-grain wheat flour. The process can also be used for producing an ultrafine-milled coarse fraction, which can be used as a replacement and to fortify refined wheat flour. The ultrafine-milled coarse fraction can be used in bakery products, snack products and food products.

Owner:CONAGRA FOODS

Vehicle cabin cooling system for capturing and exhausting heated boundary layer air from inner surfaces of solar heated windows

InactiveUS6186886B1Uniform pressure dropColor depthAir-treating devicesRailway heating/coolingProximal pointSolar water heating

The cabin cooling system includes a cooling duct positioned proximate and above upper edges of one or more windows of a vehicle to exhaust hot air as the air is heated by inner surfaces of the windows and forms thin boundary layers of heated air adjacent the heated windows. The cabin cooling system includes at least one fan to draw the hot air into the cooling duct at a flow rate that captures the hot air in the boundary layer without capturing a significant portion of the cooler cabin interior air and to discharge the hot air at a point outside the vehicle cabin, such as the vehicle trunk. In a preferred embodiment, the cooling duct has a cross-sectional area that gradually increases from a distal point to a proximal point to the fan inlet to develop a substantially uniform pressure drop along the length of the cooling duct. Correspondingly, this cross-sectional configuration develops a uniform suction pressure and uniform flow rate at the upper edge of the window to capture the hot air in the boundary layer adjacent each window.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

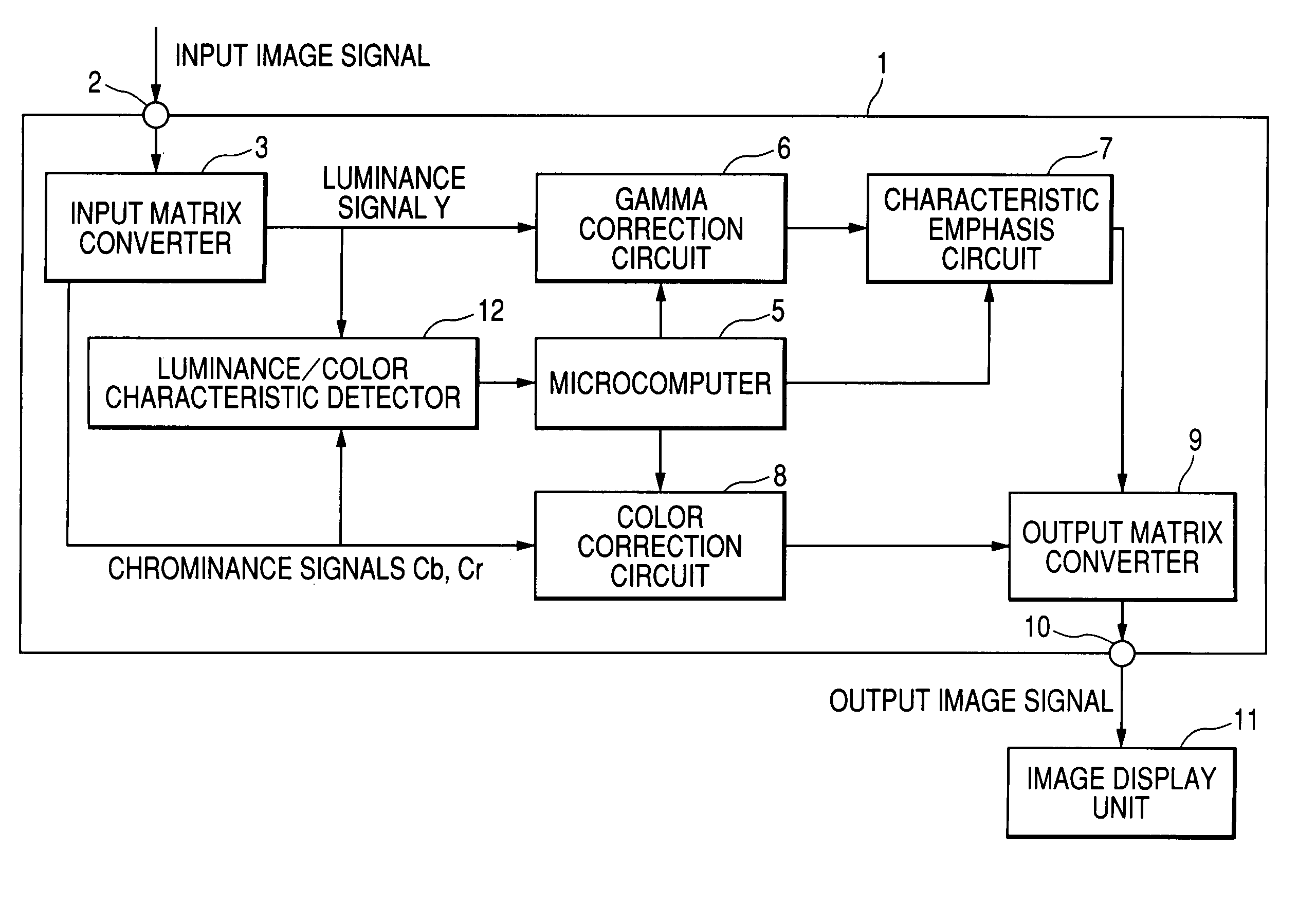

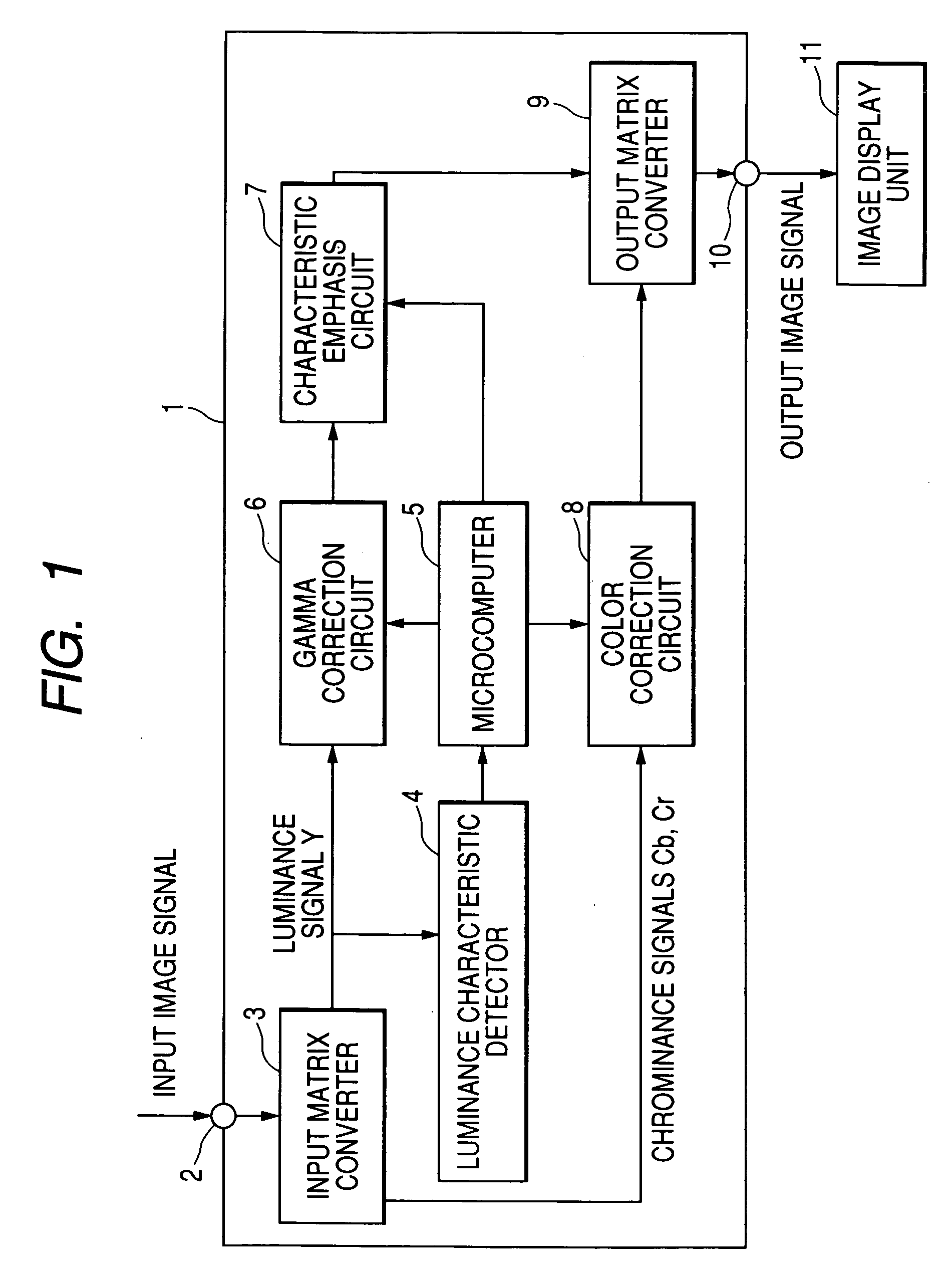

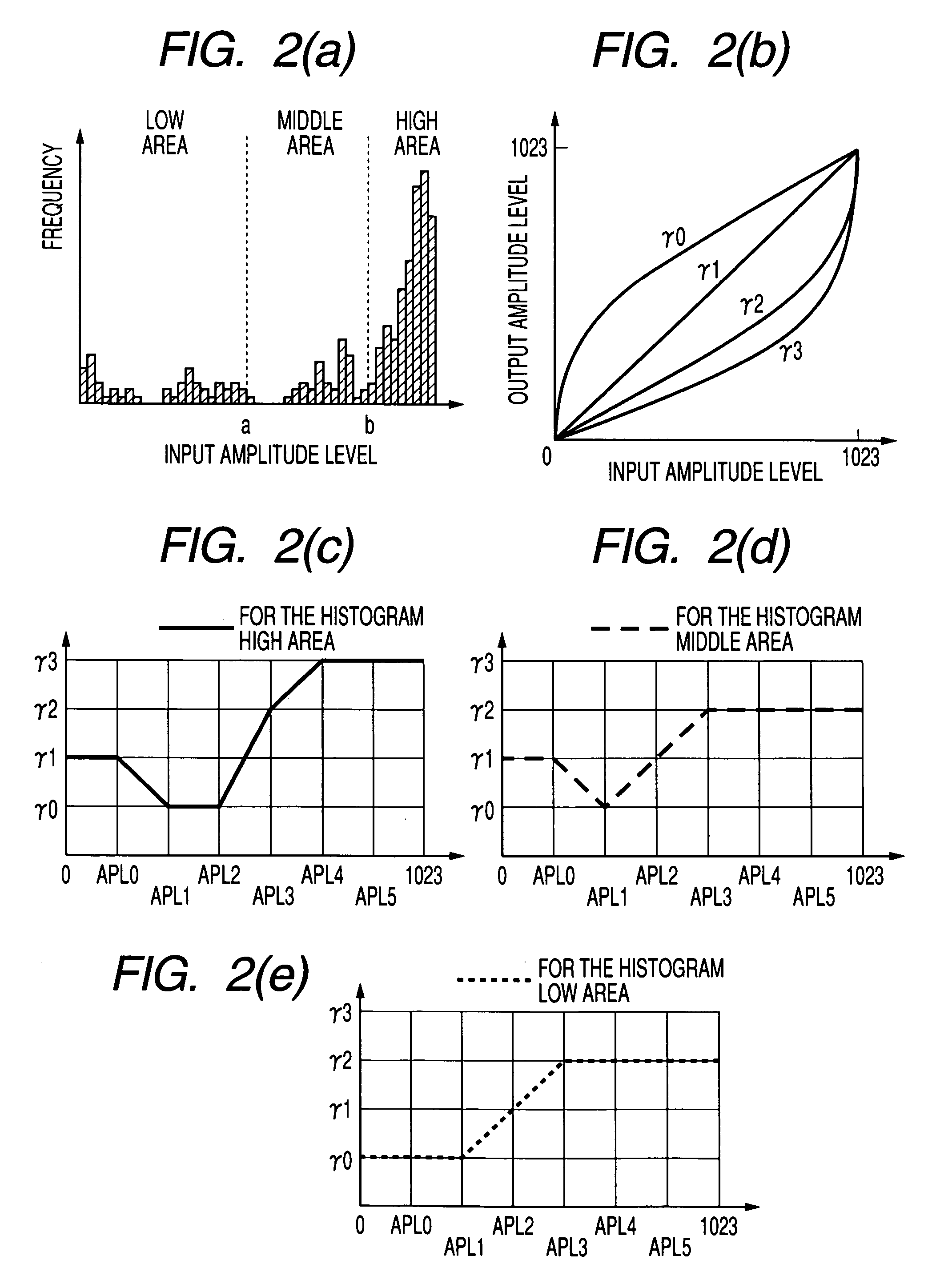

Image display apparatus

ActiveUS20060061842A1Prevent color collapse and likeColor depthTelevision system detailsColor signal processing circuitsMicrocomputerLuminosity

The present invention provides a technique for performing gamma correction processing when there are a plurality of characteristic areas, each of which is characterized by the high frequency in a luminance histogram to improve the impression of contrast. According to the present invention, a luminance characteristic detector (4) detects the luminance of an input image signal and a microcomputer (5) calculates an APL and a luminance histogram of an input image signal. A gamma correction circuit (6) performs the gamma correction processing in response to the luminosity of the input image signal by use of the result of the calculation carried out by the microcomputer (5). Then, if there are a plurality of characteristic areas, each of which is characterized by the high frequency in the luminance histogram, a characteristic emphasis circuit (7) performs grayscale extension processing for the plurality of characteristic areas. This makes it possible to perform the most suitable processing in response to the input image signal so that the impression of contrast is improved.

Owner:MAXELL HLDG LTD

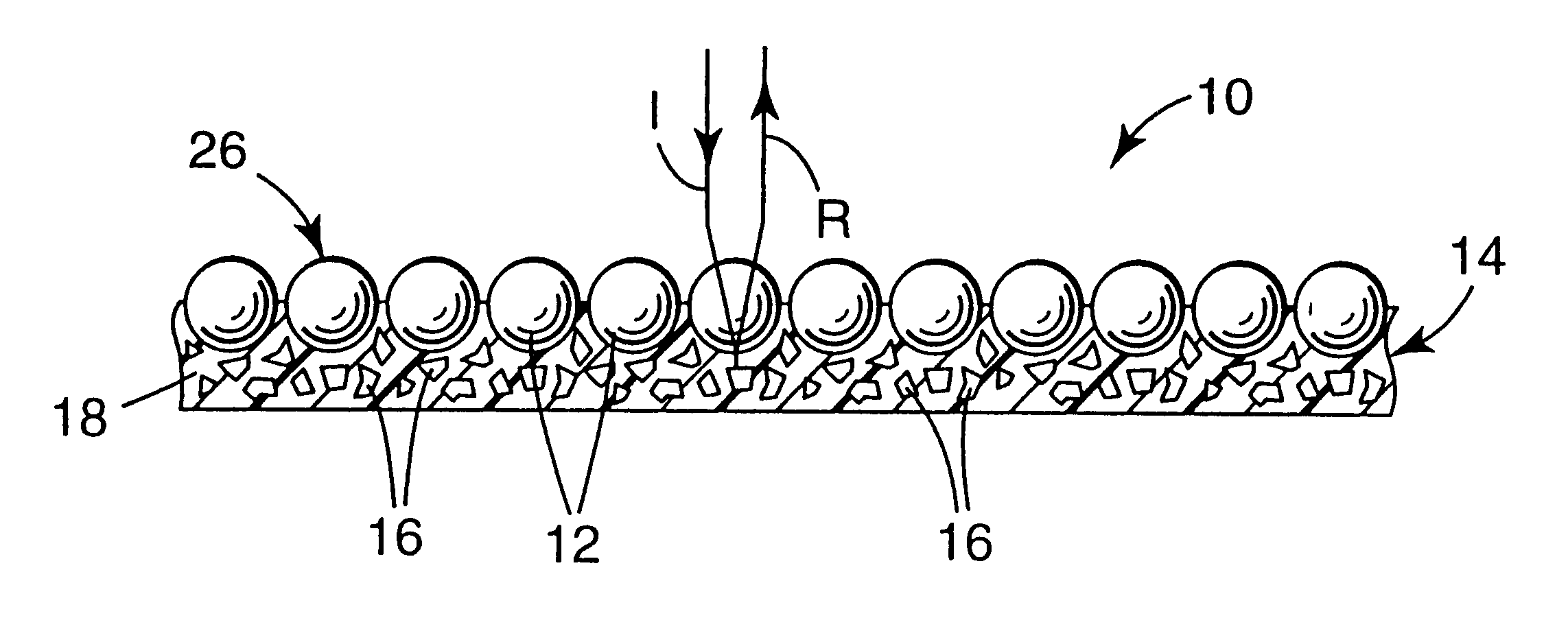

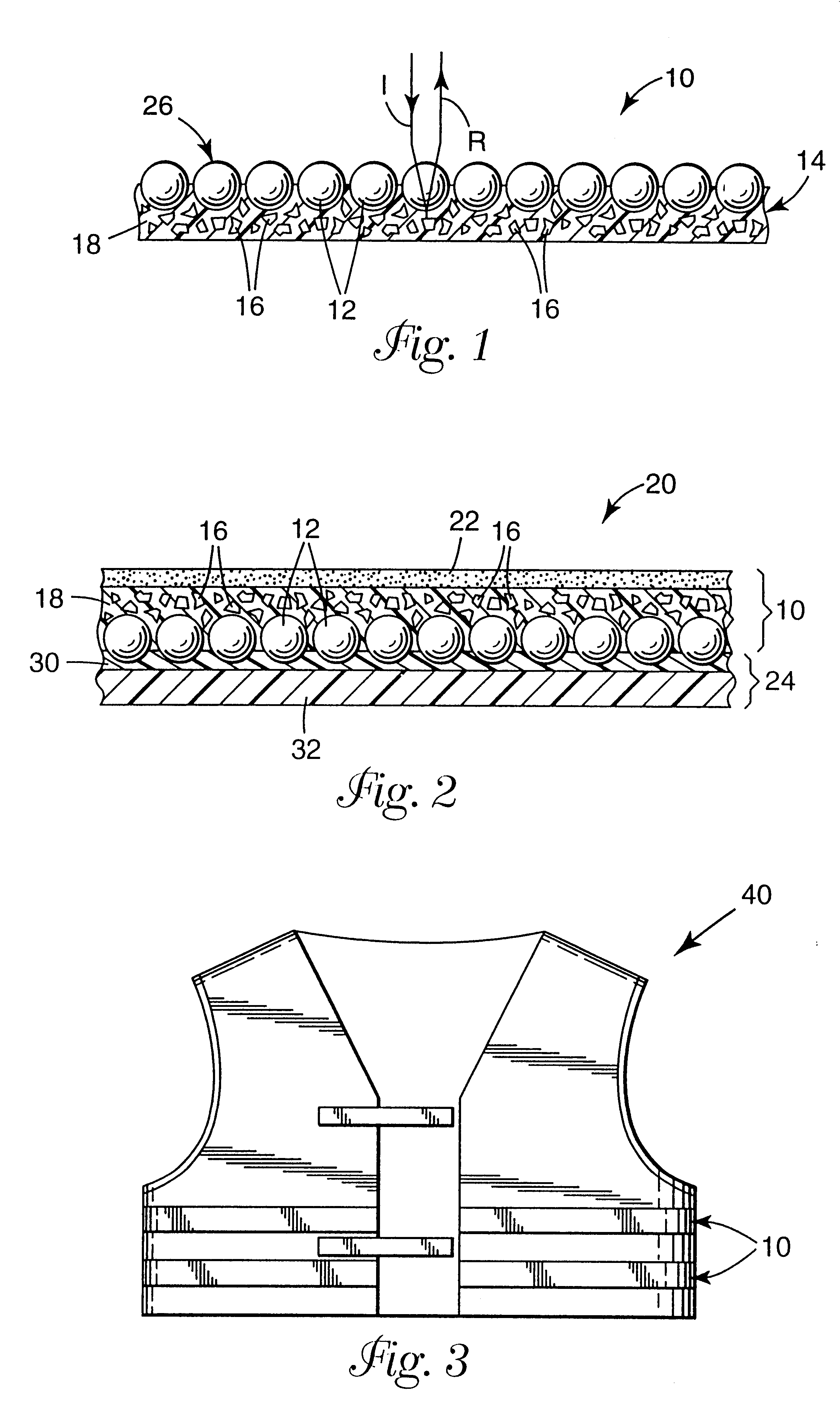

Retroflective article having a colored layer containing reflective flakes and a dye covalently bonded to a polymer

Exposed lens retroreflective article 10 that comprises a colored layer 14 and a layer of optical elements 12 that are partially embedded in the colored layer 14. The colored layer 14 comprises reflective flakes 16 and a dye that is covalently bonded to a polymer 18. The articles can retain their color after multiple industrial wash cycles. The use of a reactive dye, reflective flakes, and / or polymer precursor during the preparation of the colored layer enables a launderably-durable colored retroreflective article to be made without the use of a solvent and without the use of a temporary carrier.

Owner:3M INNOVATIVE PROPERTIES CO

Glass ceramic panel with a pleasing black decoration applied with a decorative paint

InactiveUS20080139375A1Smoother and less rough surfaceColor depthStoves/ranges topsHot plates heating arrangementsGlass-ceramicPigment

Decorative paints are typically burned in at relatively high temperatures, preferably in connection with the thermal ceramicizing process. In order to provide a glass ceramic panel having a cooking surface with a pleasing deep black, very smooth decoration by a burned-in decorative paint, the glass ceramic panel is formed from a melt that is black and the decorative paint on the black glass ceramic panel contains a colorless glass flux and from 0 to 10 percent by weight of at least one black pigment. The decorative paint can consist of the colorless melted-on glass flux. The glass flux preferably has a composition in percent by weight of Li2O, 0-5; Na2O, 0-5; K2O, <2; ΣLi2O+Na2O+K2O, 1-10; MgO, 0-3; CaO, 0-4; SrO, 0-4; BaO, 0-4; ZnO, 0-4; B2O3, 15-27; Al2O3, 10-20; SiO2, 43-58; TiO2, 0-3; ZrO2, Sb2O3, 0-2; F, 0-3.

Owner:SCHOTT AG

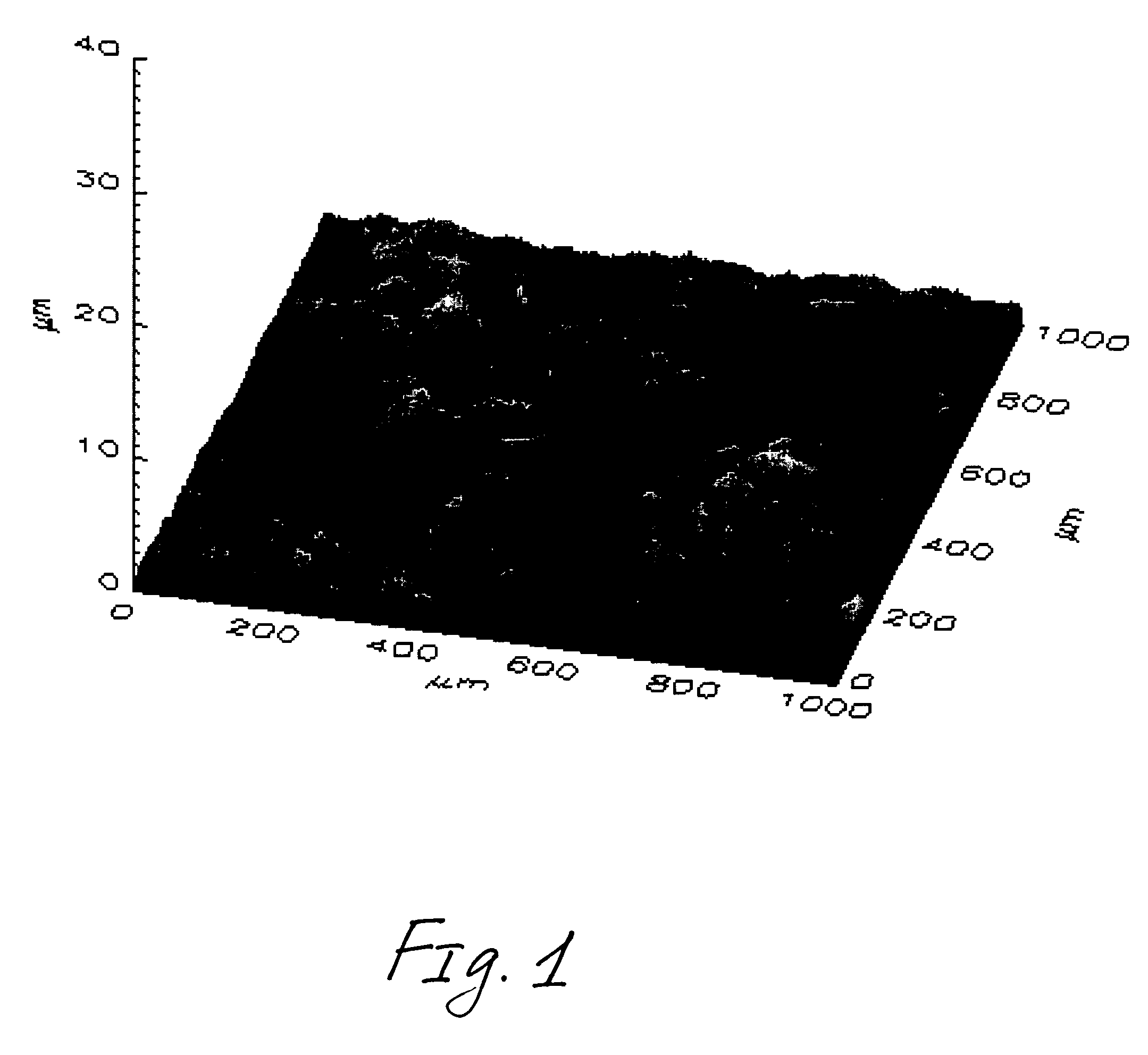

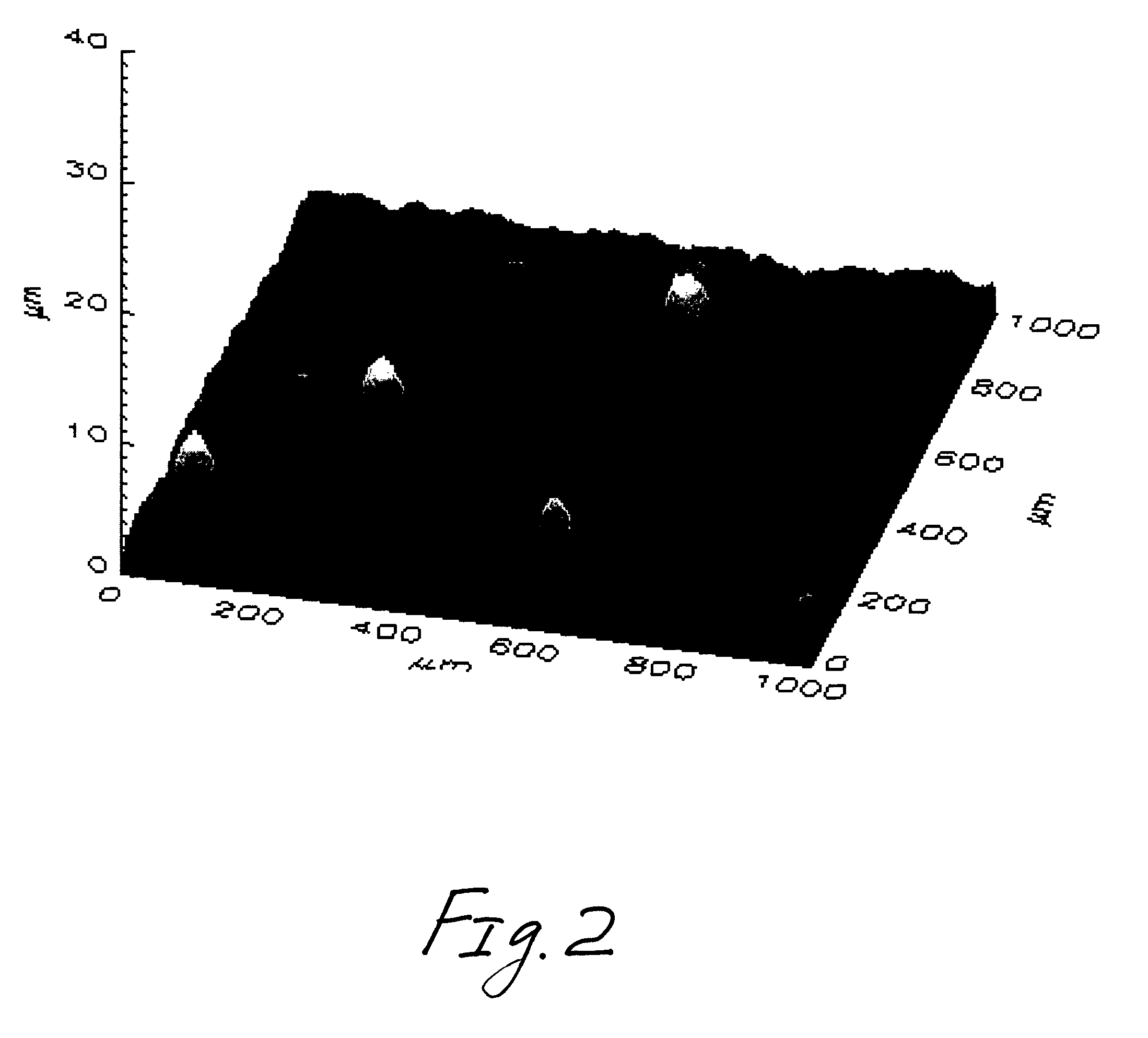

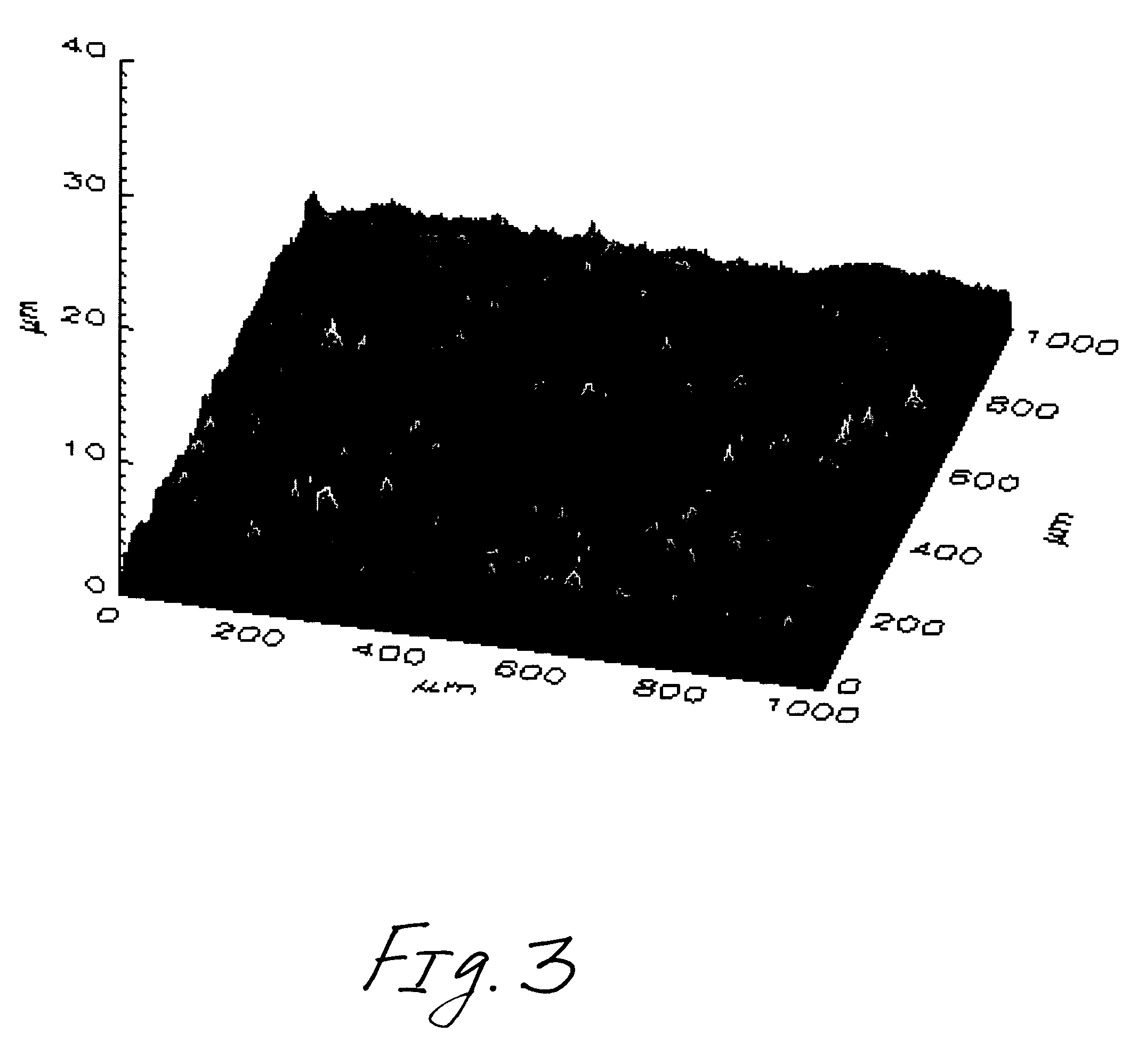

Copper foil having blackened surface or layer

ActiveUS7341796B2Improve featuresEffectively shielding electromagnetic wavesInsulating substrate metal adhesion improvementMagnetic/electric field screeningCopper foilFace sheet

A copper foil with a blackened surface or layer wherein one or both surfaces of a copper foil is subject to black treatment, and having a color difference ΔL*≦−70 and chroma C*≦15 of a black-treated surface when measured by a color difference meter represented by black; ΔL*=−100, white; ΔL*=0. The copper foil with a blackened surface or layer is especially useful for a plasma display panel (PDP) and has superior shielding characteristics of effectively shielding electromagnetic waves, near infrared rays, stray light, outside light and the like, has sufficient contrast, has a deep blackened color, is able to limit the reflected light of incoming light from the outside and reflected light of outgoing light from a plasma display panel, and has superior etching characteristics.

Owner:JX NIPPON MINING & METALS CORP

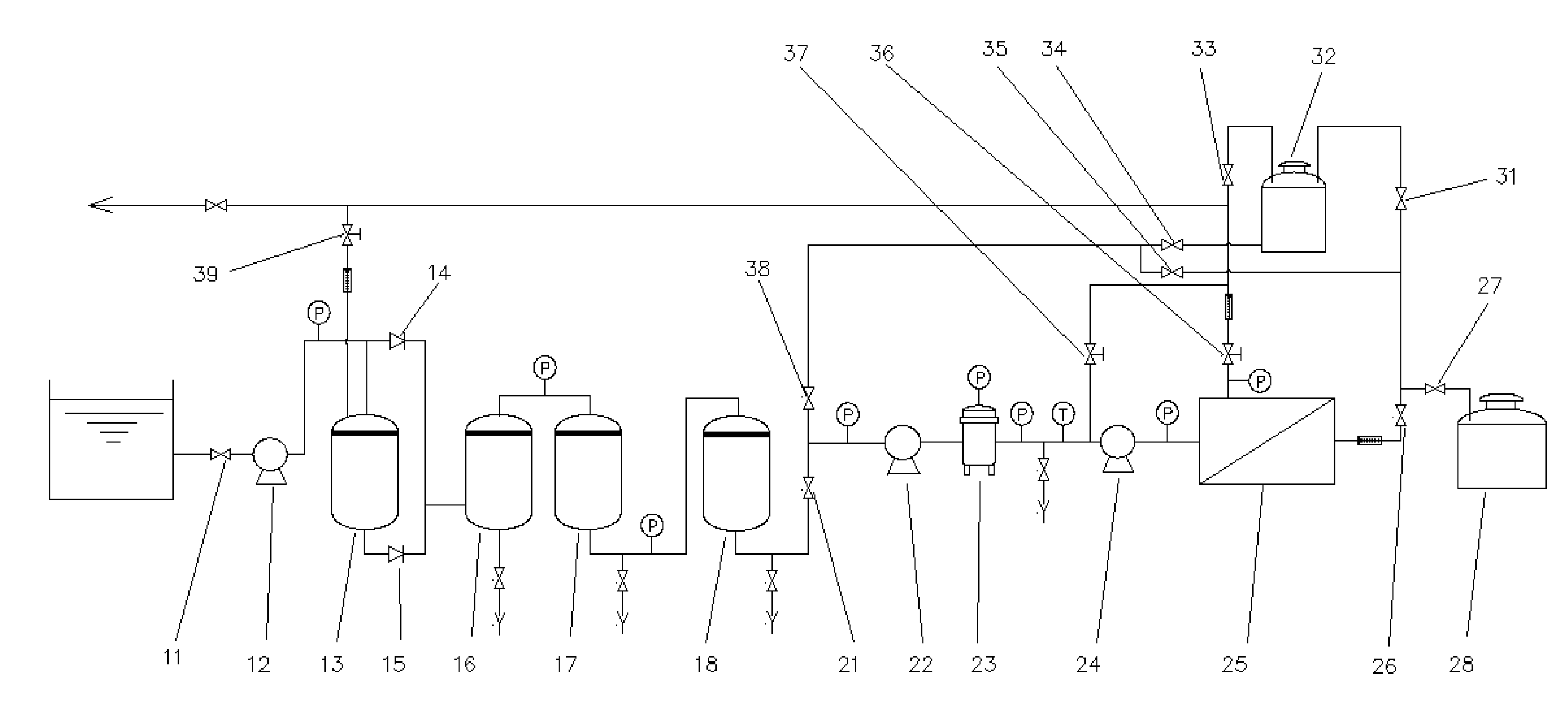

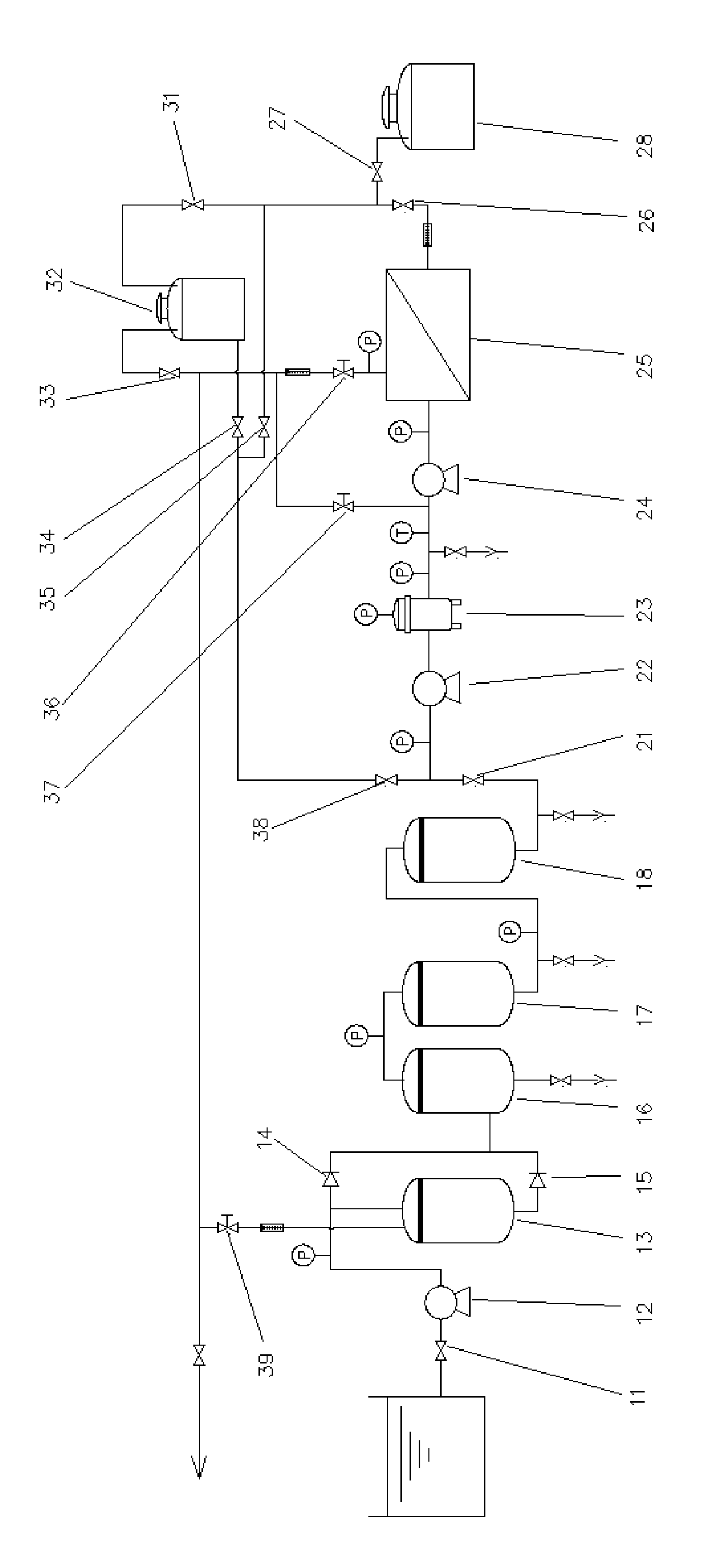

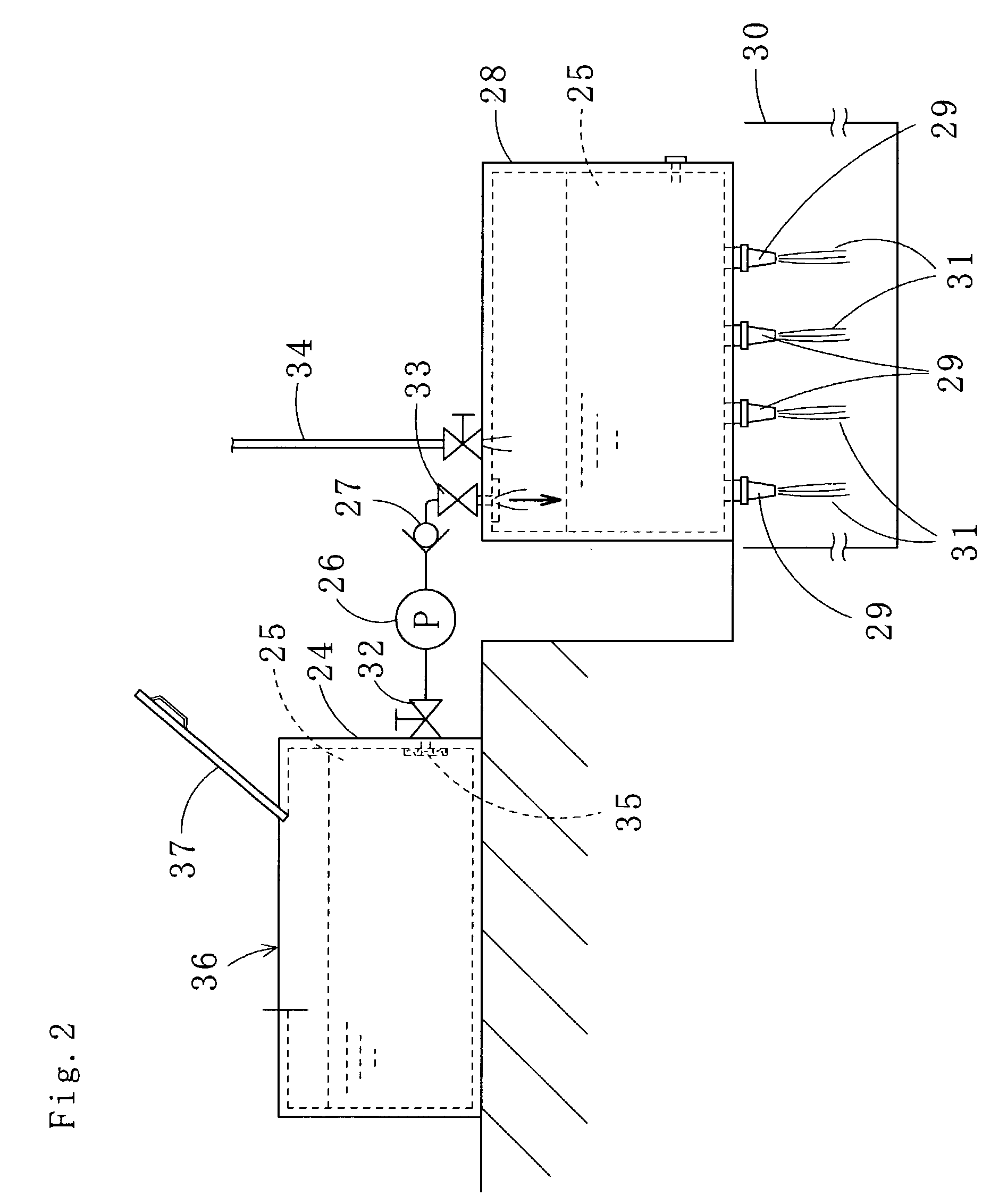

Purifying device for deeply treating printing and dyeing wastewater, and purifying process therefor

InactiveUS20120285887A1Easy dischargeLow costSemi-permeable membranesSpecific water treatment objectivesActivated carbonElectrolysis

A purifying device and a process for deeply treating printing and dyeing wastewater are provided. The device includes a nanometer catalytic microelectrolysis system, a membrane filtration and separation system and a a membrane washing regeneration system. The method includes the following steps of: drawing the printing and dyeing wastewater by a first water pump (12), pumping a first part of the wastewater into a nanometer catalytic microelectrolysis tank (13) to perform catalysis microelectrolysis, and a second part of the wastewater into a neutralization tank (16) to mix with the water from the nanometer catalytic microelectrolysis tank (13) to precipitate, filtering the wastewater by a sand filtration tank (17), and then pumping the wastewater into an adsorption and filteration device of granular active carbon (18) for adsorption and filtration. The process has lower cost and higher energy efficiency, and can realize recycled water to be reused.

Owner:BOYING XIAMEN SCI & TECH

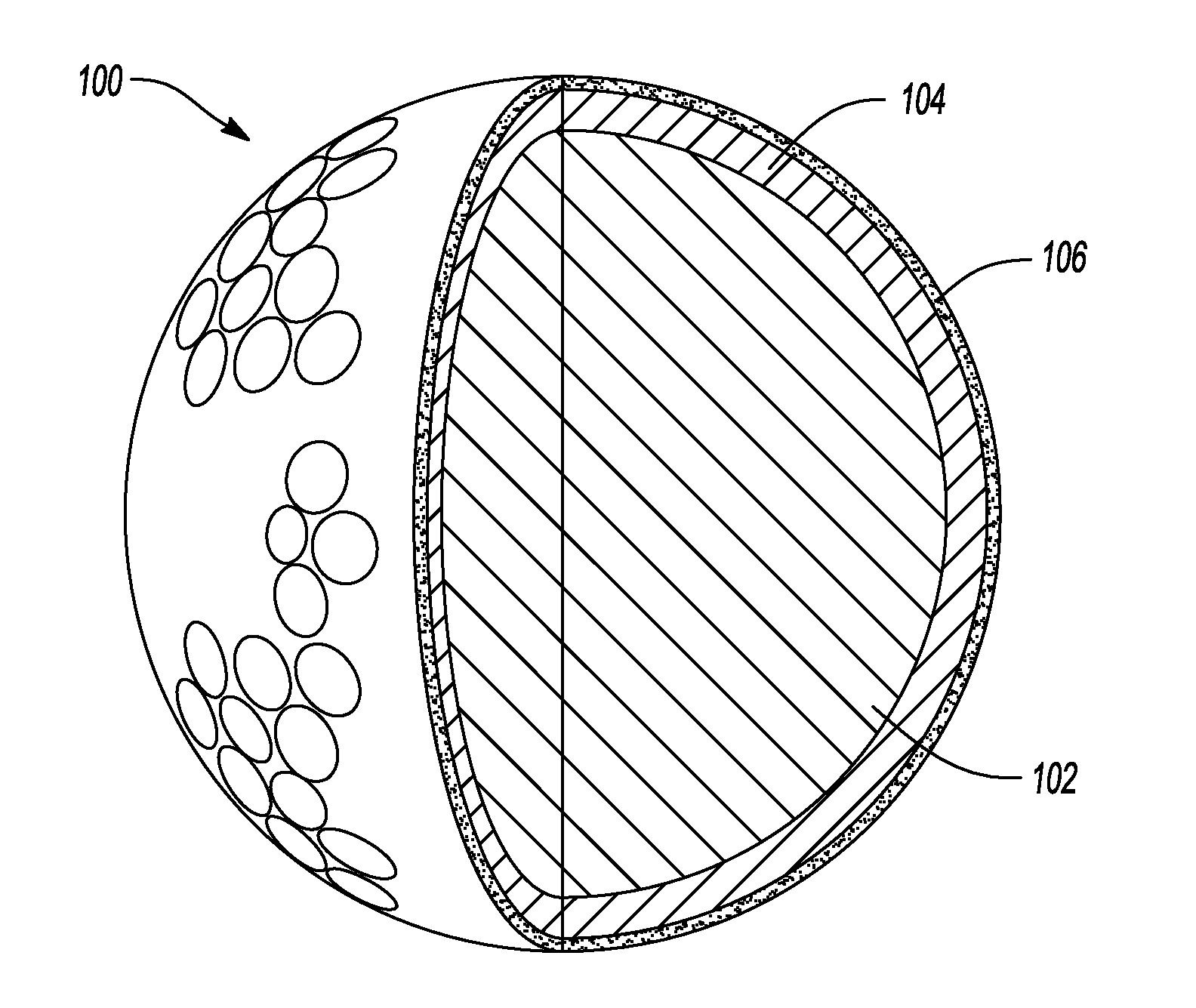

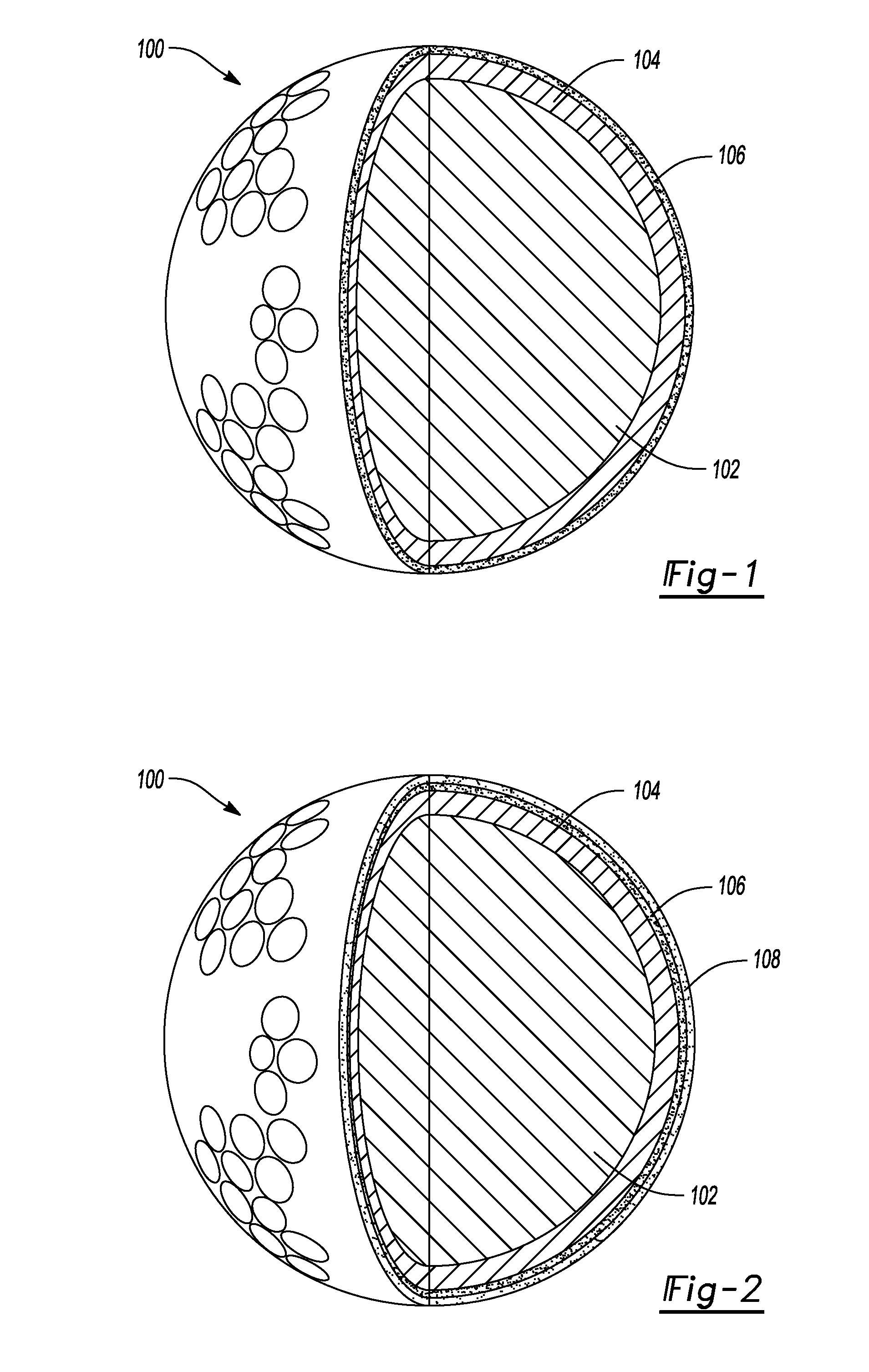

Method for dyeing golf balls and dyed golf balls

ActiveUS20140250609A1Significant expenseExpensive to produceDyeing processCoatingsDisperse dyePolyamide

A golf ball of a first color is dyed to a second color with an anionic or nonionic disperse dye. Either or both of a pigmented coating layer or an optional clear coating layer on the pigmented coating layer comprises a member selected from the group consisting of polyurethanes, polyureas, polyamides, and combinations thereof, which can be dyed by the anionic or nonionic disperse dye.

Owner:NIKE INTERNATIONAL LTD

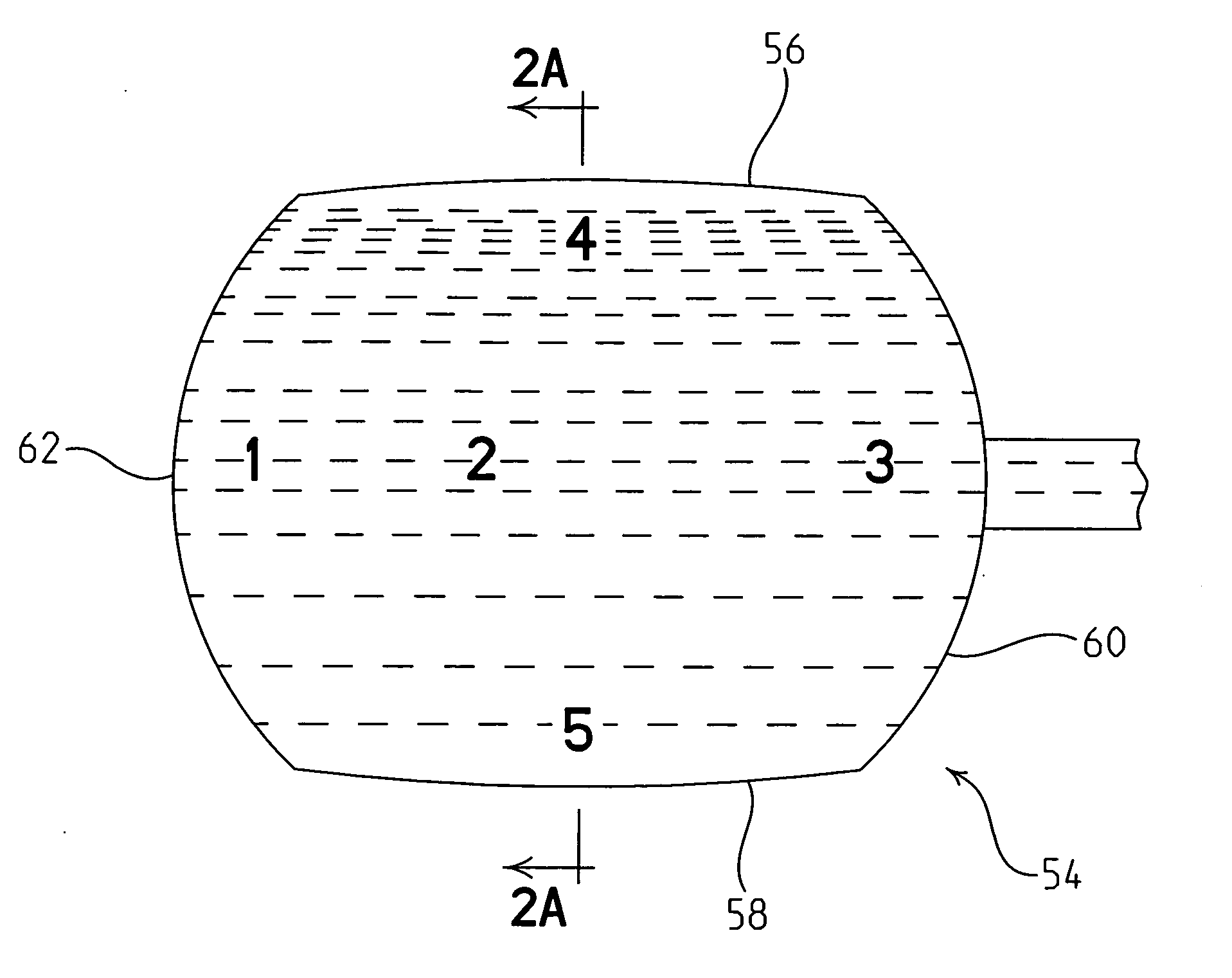

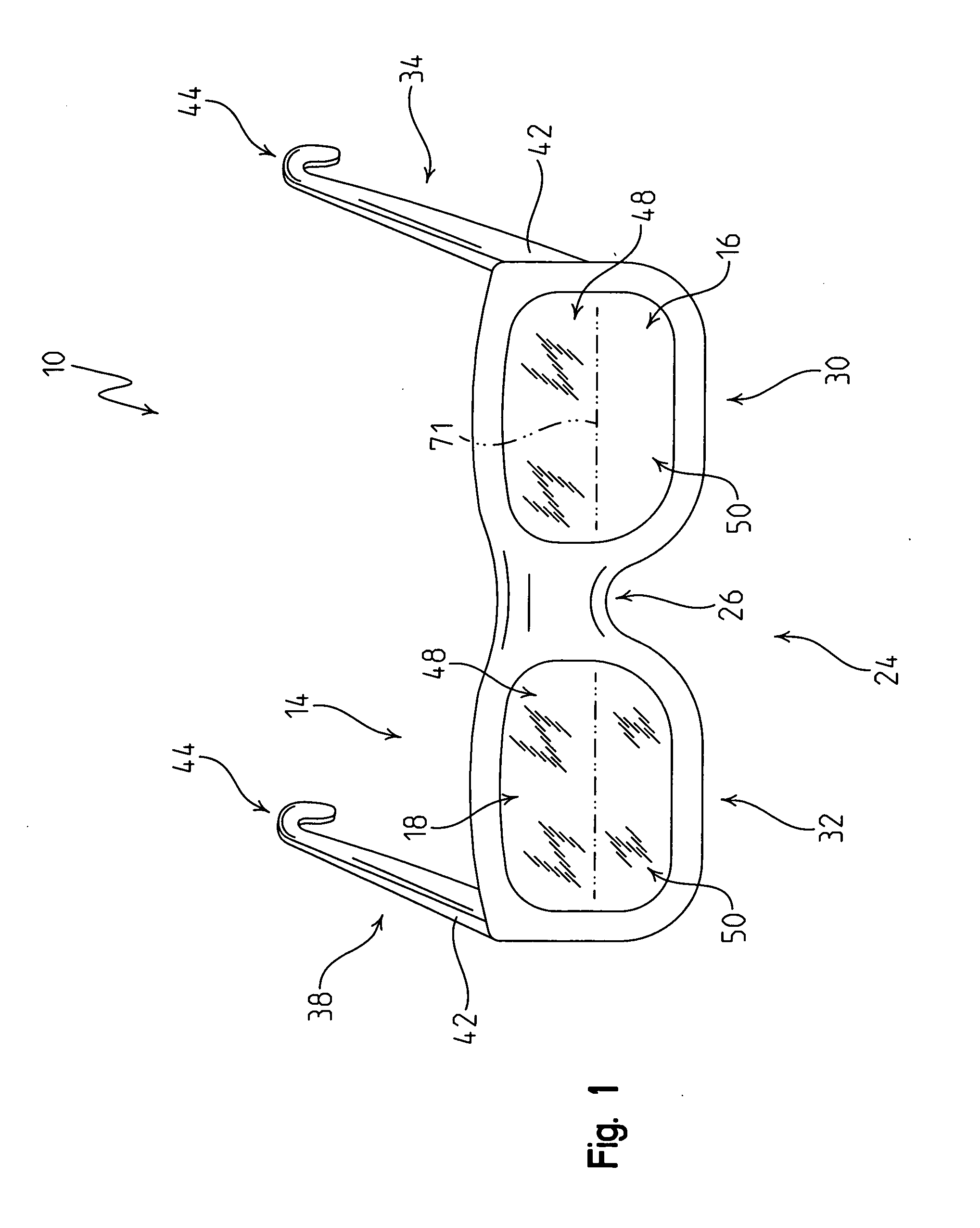

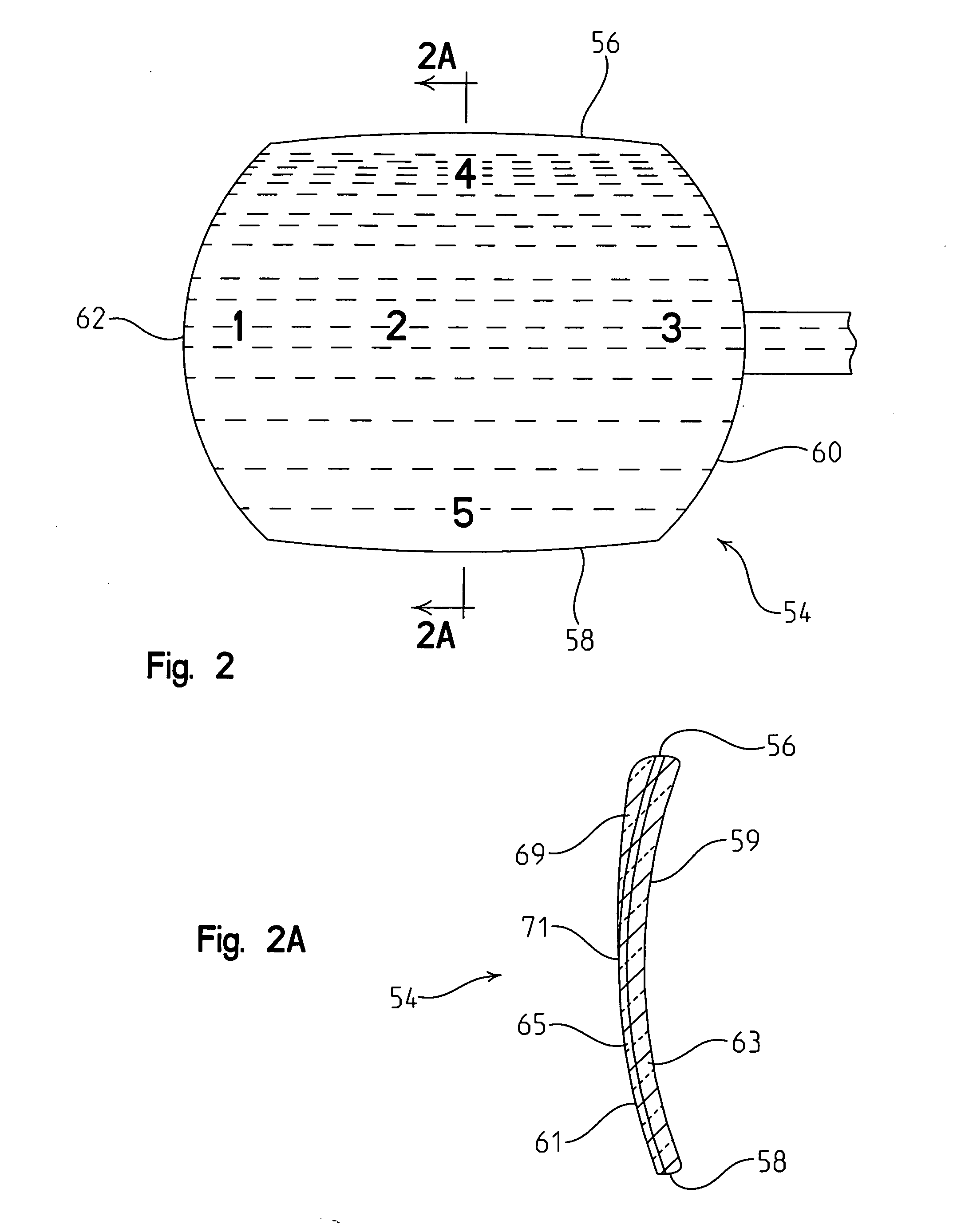

Sunglass lens

InactiveUS20110141432A1Reduce light transmittanceReduce eye fatigueSpectales/gogglesOptical partsCamera lensLens plate

A sunglass lens includes a lens body having a first and a second surface, a top edge, a bottom edge, a first side edge and a second side edge. The lens body also includes an upper portion disposed adjacent to the top side edge and a lower portion disposed adjacent to the bottom side edge. An aqua colored tint is applied to the lens body for highlighting an appearance of yellow colored objects to a user. A darkening tint is applied on the upper portion of the lens body for reducing the amount of light transmitted through the lens.

Owner:NESTY GARY W

Method for dyeing golf balls and dyed golf balls

InactiveUS20140256468A1Significant expenseExpensive to producePolyurea/polyurethane coatingsDyeing processDisperse dyePolyamide

A golf ball of a first color is dyed to a second color with an anionic or nonionic disperse dye. Either or both of the cover or an optional clear coating layer on the cover comprises a member selected from the group consisting of polyurethanes, polyureas, polyamides, and combinations thereof, which can be dyed by the anionic or nonionic disperse dye.

Owner:NIKE INTERNATIONAL LTD

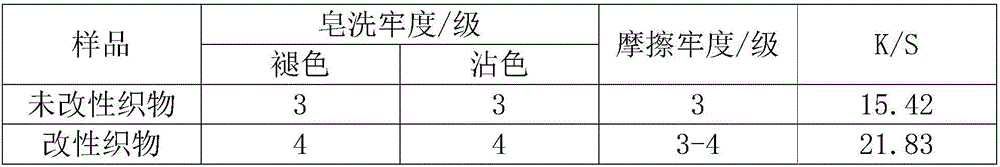

Modified cotton fiber as well as denim-effect fabric and preparation method thereof

The invention discloses modified cotton fiber as well as denim-effect fabric and a preparation method thereof. The preparation method of the denim-effect fabric comprises the following steps: mixing the modified cotton fiber and other fibers in a mass ratio of (1-99): (99-1), spinning into yarns, weaving to cloth, and finally dyeing and finishing to obtain the denim-effect fabric, wherein salt is not added in the dyeing and finishing process. A treatment of the modified cotton fiber comprises the following steps: blending the cotton fiber with a cationic modifier solution, heating up to 20-80 DEG C, and dipping for 1-30 minutes, wherein the cationic modifier solution to the cotton fiber is (0.01-0.1):1. By the preparation method, the mixed-color pattered denim-effect fabric can be dyed out at a time, the delivery deadline of the denim-effect fabric is shortened, the use of dye and auxiliary agents is reduced, the water washing and soaping frequency is reduced, and energy is saved and emission is reduced; an environment-friendly and functional fiber blended product also has the advantages of fashion, science and technology and high added product value.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

Photosensitive optically variable ink compositions useful for ink jet printing

InactiveUS20050279249A1Red fluorescenceSatisfactory solubility in waterMeasurement apparatus componentsLuminescent paintsWater solubleSurface tension

New photosensitive optically variable inks are capable of printing images having improved resistance to water. The inks produce images which can be viewed with both visible and ultraviolet light to have physically coincident positive and negative images. They contain at least two types of colorants and other suitable ingredients to enable preparation for printing. The first colorant comprises a fluorescent dye emitting light within a characteristic emission band when excited by fluorescent-exciting radiation. The second colorant, which comprises a colloidal pigment alone or with a dye, has a light absorption band at longer wavelengths than the characteristic emission band of the first colorant or overlapping the emission wavelength of the first colorant, effectively to result in a dark color. The composition also contains an aqueous liquid vehicle comprising water and a water-soluble vehicle in sufficient amounts to achieve an ink viscosity and surface tension effective for application of the ink to a substrate in a predetermined pattern by ink jet printing.

Owner:PITNEY BOWES INC

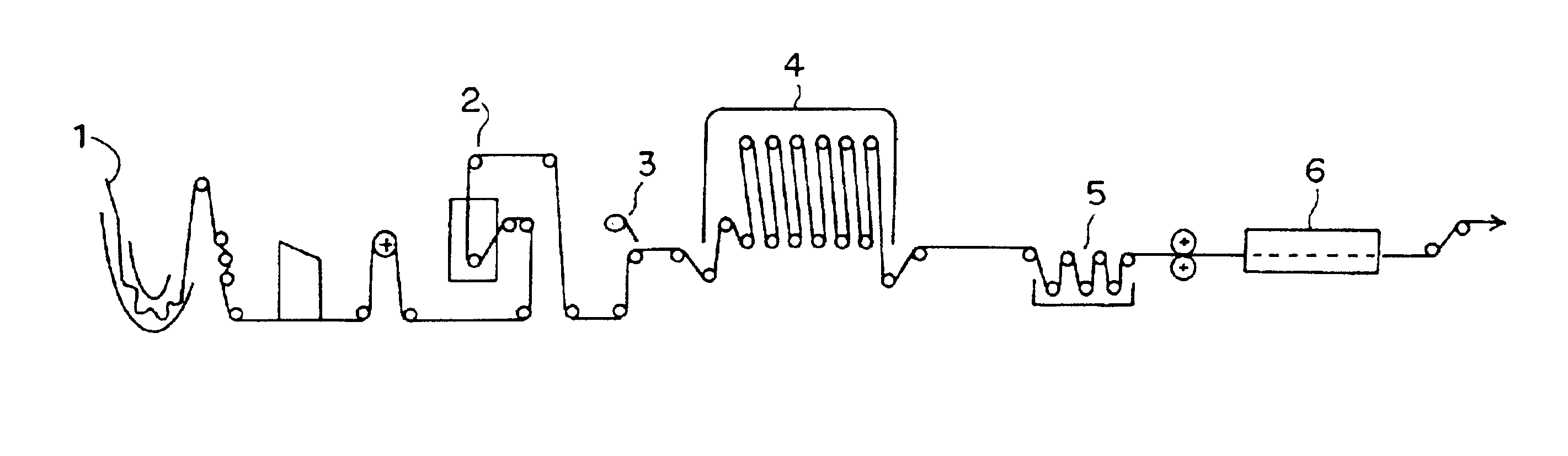

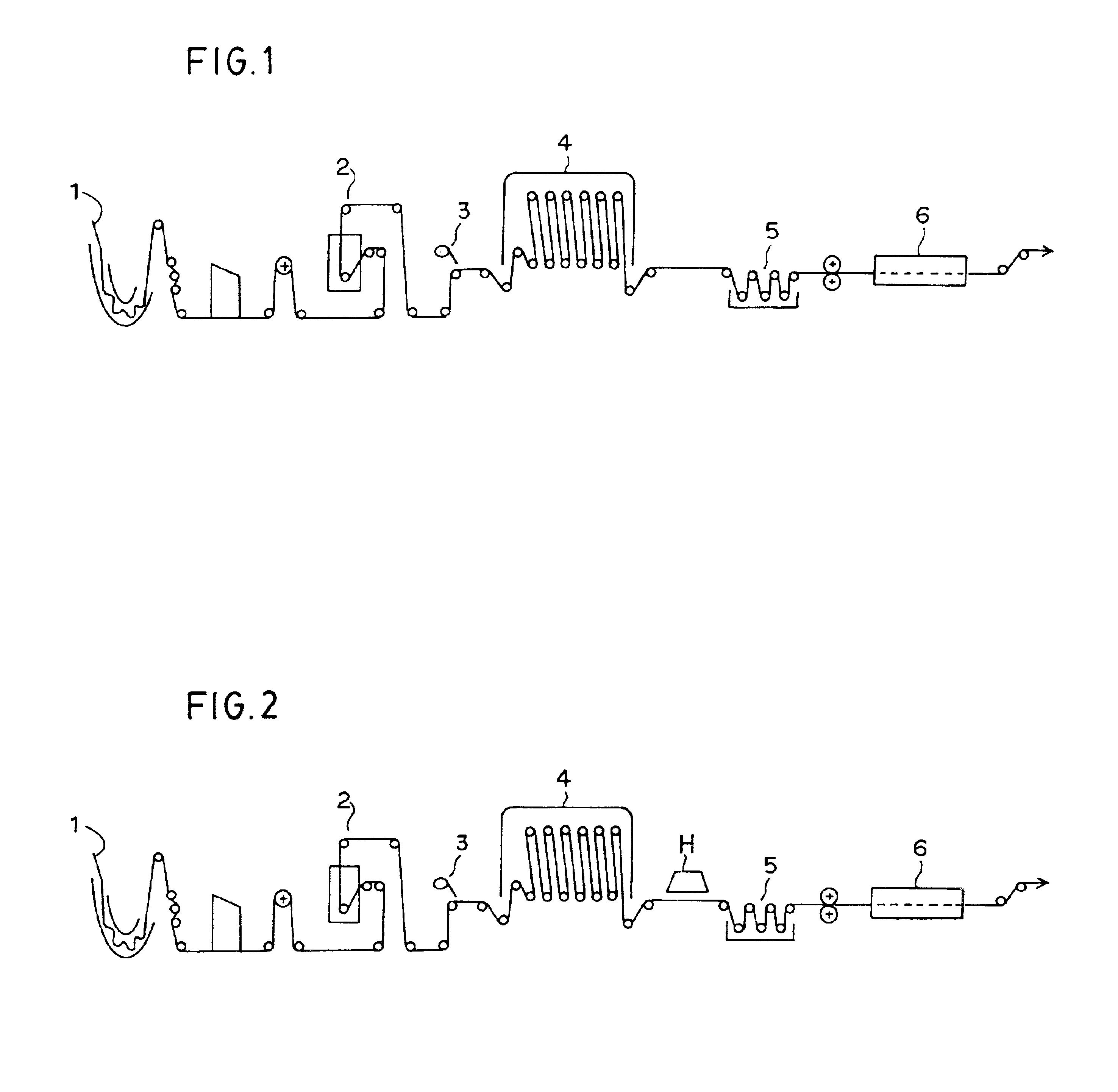

Process for dyeing poly (trimethylene terephthalate) carpet continuously

InactiveUS6836915B2Minimize the differenceAvoid frostFibre treatmentOrganic dyesPolyethylene terephthalateDry heat

In the process for continuously dyeing a poly(trimethylene terephthalate) bulked continuous filament yarn carpet an aqueous dyeing solution is applied to a continuously moving poly(trlmethylene terephthalate) bulked continuous filament yarn carpet at a temperature of 45° C. to 100° C., and then the poly(trimethylene terephthalate) bulked continuous filament yam carpet is steamed, rinsed and dried. Before applying the aqueous dyeing solution the carpet is heat-set at 120 to 150° C. The carpet is steamed with saturated steam at 102 to 150° C. for 5 to 10 mm. The aqueous dyeing solution does not include an anti-frosting agent. The process also advantageously includes heating the carpet with a dry heat of 140 to 300° C. for 30 to 60 sec after steaming the carpet and before rinsing it.

Owner:HYOSUNG CORP

Disperse dye capsule/active dye polyester-cotton fabric one-bath process dyeing technology

The invention relates to a disperse dye capsule / active dye polyester-cotton fabric one-bath process dyeing technology. Research on the disperse dye capsule / active dye polyester-cotton fabric one-bath process dyeing technology is performed from the points of selection of an active dye influencing the dyeing effect of the polyester-cotton fabric one-bath process, the bath ratio, the heating speed, the warm-keeping time and other factors, and an optimum dyeing technology is obtained. Compared with a routine one-bath method, under the premise of avoiding a reducing cleaning process, the obtained color is deeper than that of dyed fabric by using a routine method employing the reducing cleaning process, and the disclosed technology has the biggest advantage of preventing reducing cleaning from destroying the active dye; and the dry / wet friction fastness, and the staining fastness and the discoloring and fading grade at 60 DEG C of the dyed fabric are relatively high, and the grades are all 4 grade or more. The absorbance of a dyeing raffinate from which the microcapsule is filtered off is about half of the absorbance of a routine one-bath method, and the chroma of the raffinate is obviously reduced. The technology is simple, relatively short in time, relatively small in chroma of dyeing wastewater and relatively small in water consumption.

Owner:WUXI XINGLIN DYEING ENVIRONMENTAL PROTECTION EQUIP

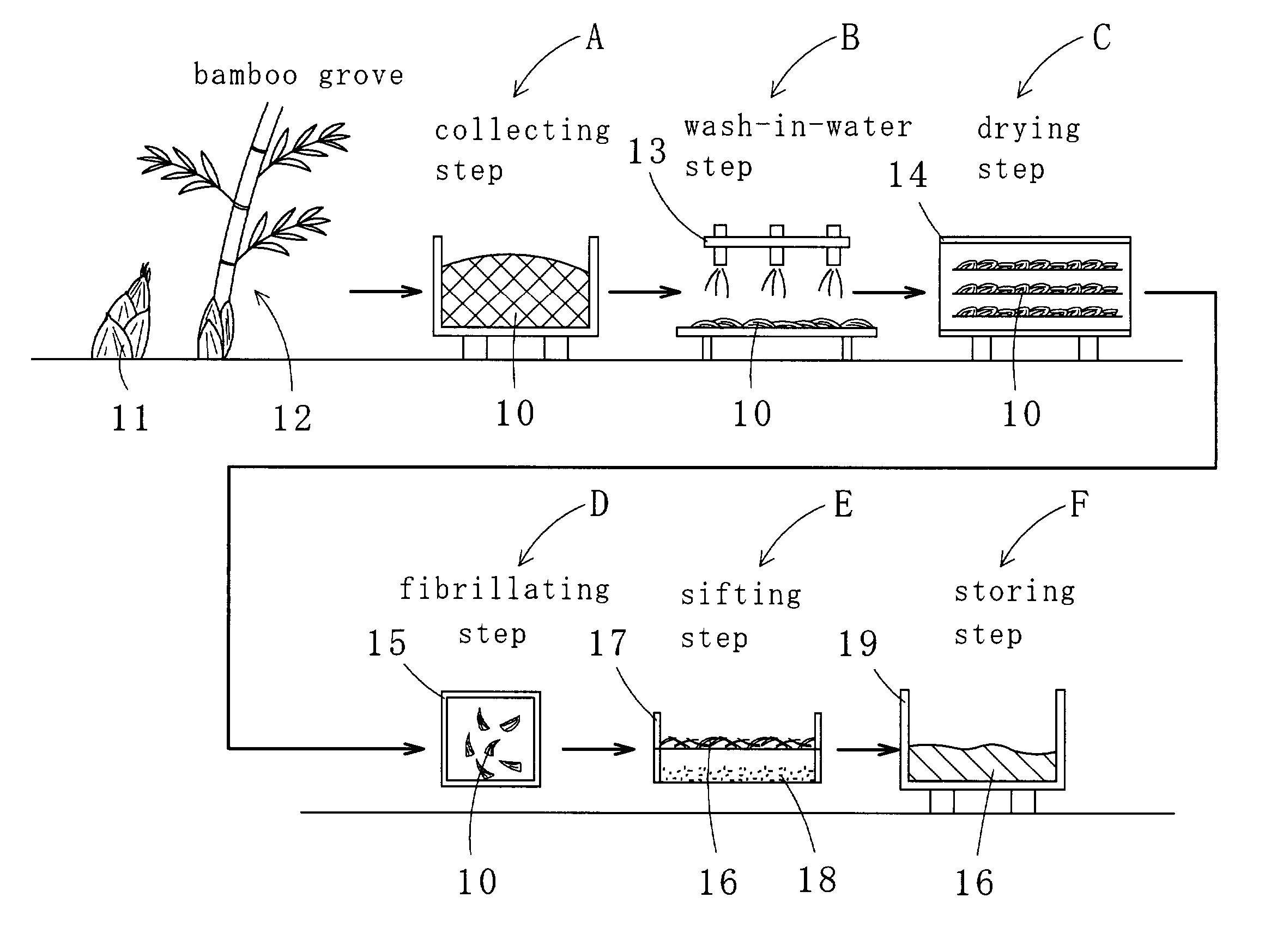

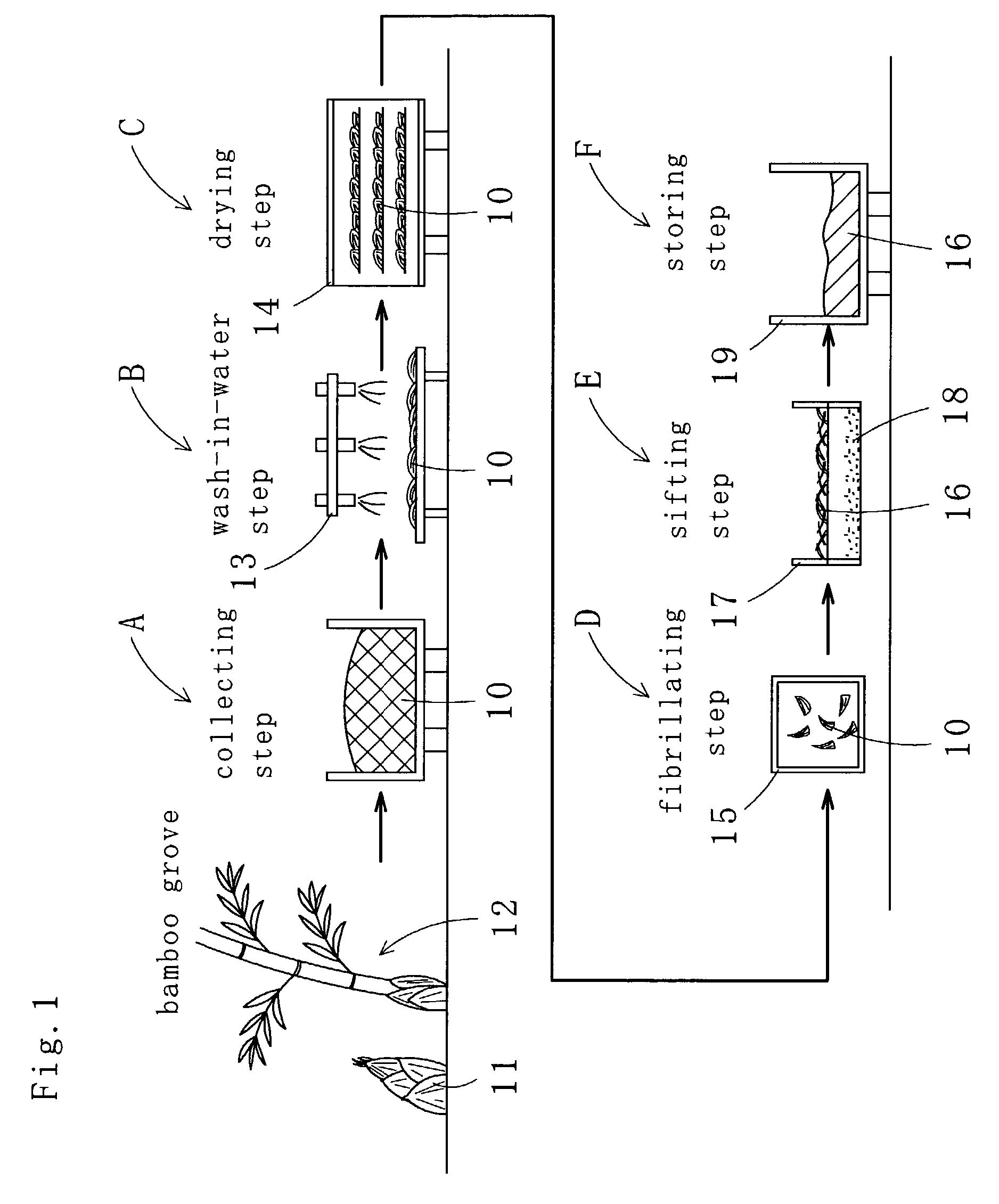

Yam and cloths made mainly from bamboo sheaths and methods for manufacturing the same

InactiveUS7060211B2Reduce the degree of polymerizationEasy to usePillowsArtificial filaments from cellulose solutionsFiberChemical treatment

The present invention provides yarn and cloths made by utilizing bamboo fiber and methods for manufacturing these yarn and cloths, thereby the bamboo fiber can be utilized by being extracted from sheaths of bamboo shoots or bamboo sheaths that generate at the root of bamboo abundantly, which have been left as they are or mostly disposed of as wastes. By fibrillating or chemically treating bamboo sheaths 10 which is a main raw material, bamboo fiber 16 mainly comprising cellulose is obtained, and then it is formed into yarn by spinning. A cloth is produced as woven or knitted fabric using the yarn.

Owner:KATSUYAMA TECHNOS

Dyeing method for modified polyimide fabrics

ActiveCN105951435AIncrease color depthHigh color fastnessFibre treatmentDyeing processFiberGraft reaction

The invention relates to the field of fabric dyeing, in particular to a dyeing method for modified polyimide fabrics. The method comprises the following steps that polyimide fabrics are cleaned and dried; low-temperature plasma is adopted for pretreatment; the polyimide fabrics are quickly put in an acrylic acid solution for a grafting reaction, and the modified polyimide fabrics are obtained after washing and drying; dispersed cationic dye is used for dyeing, washing is conducted after dyeing, and then drying is conducted. According to the method, cleaning is conducted firstly to wash away impurities, oil and the like on the surfaces of fibers, the low-temperature plasma is used for roughening the surfaces of the polyimide fibers, total reflection of light is weakened, and diffuse reflection of light is enhanced; besides, a polar group is introduced by initiating the grafting reaction of acrylic acid, cations on dye molecules can be in ionic bond combination with carboxyl, and therefore the problem that the polyimide fibers are hard to dye can be effectively solved. By the adoption of the dyeing method for the modified polyimide fabrics, the process is simple, and the fabrics obtained after dyeing are high in color depth and good in color fastness.

Owner:DONGGUAN SENLIN TEXTILE LTD

Method of obtaining hemp plant juice and use of same for the production of beverages

The present invention relates to a method for producing beverages on the basis of juice from the hemp plant. The invention relates to a method for obtaining juice suitable for human consumption from the hemp plant, wherein the complete hemp stem is pressed after harvest without prior drying or retting. The invention further provides a method for obtaining juice from the hemp plant, wherein the upper leafy part of the hemp plant is cut, the leaves are stripped of the remaining stem, fibers and shives being separated from each other at the stem, the leafy part of the stem, the fibers and the shives being pressed individually under pressure and the so obtained pressed juices are being mixed in a controlled manner. In a yet further aspect, the invention relates to a method for the manufacturing of beverages on the basis of juice from the hemp plant, wherein the hemp juice is mixed with yeast and than fermented.

Owner:CLAREMONT COLLECTION HANDELSGMBH +1

Environmental protection lining tenel cloth production process

InactiveCN101182664AGood drapabilityColor depthTextile treatment machine partsFibre cleaning/openingYarnCarding

The invention discloses a production method of the environment-protecting fabric tencel cloth. The tencel cloth is made in the way that the tencel fiber is spun to get the yarns and the yarns are then woven to produce the tencel cloth. The production method comprises the working procedures of the raw material damping in a grading chamber, cotching, carding, drawing, roving, spinning, winding, scudding, sizing, reeding, weaving, perching, packing, warehousing, and so on. The environment-protecting fabric tencel cloth produced with the invention is provided with the top-grade quality, the soft and smooth texture, the distinctive cloth surface lines, and the wool-imitating feeling, and is completely suitable for the subsequent processing of top-grade products.

Owner:丁宏利

Method of Obtaining Hemp Plant Juice and Use of Same for the Production of Beverages

The present invention relates to a method for producing beverages on the basis of juice from the hemp plant. The invention relates to a method for obtaining juice suitable for human consumption from the hemp plant, wherein the complete hemp stem is pressed after harvest without prior drying or retting. The invention further provides a method for obtaining juice from the hemp plant, wherein the upper leafy part of the hemp plant is cut, the leaves are stripped of the remaining stem, fibres and shives being separated from each other at the stem, the leafy part of the stem, the fibres and the shives being pressed individually under pressure and the so obtained pressed juices are being mixed in a controlled manner. In a yet further aspect, the invention relates to a method for the manufacturing of beverages on the basis of juice from the hemp plant, wherein the hemp juice is mixed with yeast and than fermented.

Owner:CLAREMONT COLLECTION HANDELSGMBH +1

Photosensitive optically variable ink compositions useful for ink jet printing

InactiveUS7141103B2Low viscosityExcellent water fastnessLuminescent paintsInksUltraviolet lightsPhotopigment

New photosensitive optically variable inks are capable of printing images having improved resistance to water. The inks produce images which can be viewed with both visible and ultraviolet light to have physically coincident positive and negative images. They contain at least two types of colorants and other suitable ingredients to enable preparation for printing. The first colorant comprises a fluorescent dye emitting light within a characteristic emission band when excited by fluorescent-exciting radiation. The second colorant, which comprises a colloidal pigment alone or with a dye, has a light absorption band at longer wavelengths than the characteristic emission band of the first colorant or overlapping the emission wavelength of the first colorant, effectively to result in a dark color. The composition also contains an aqueous liquid vehicle comprising water and a water-soluble vehicle in sufficient amounts to achieve an ink viscosity and surface tension effective for application of the ink to a substrate in a predetermined pattern by ink jet printing.

Owner:PITNEY BOWES INC

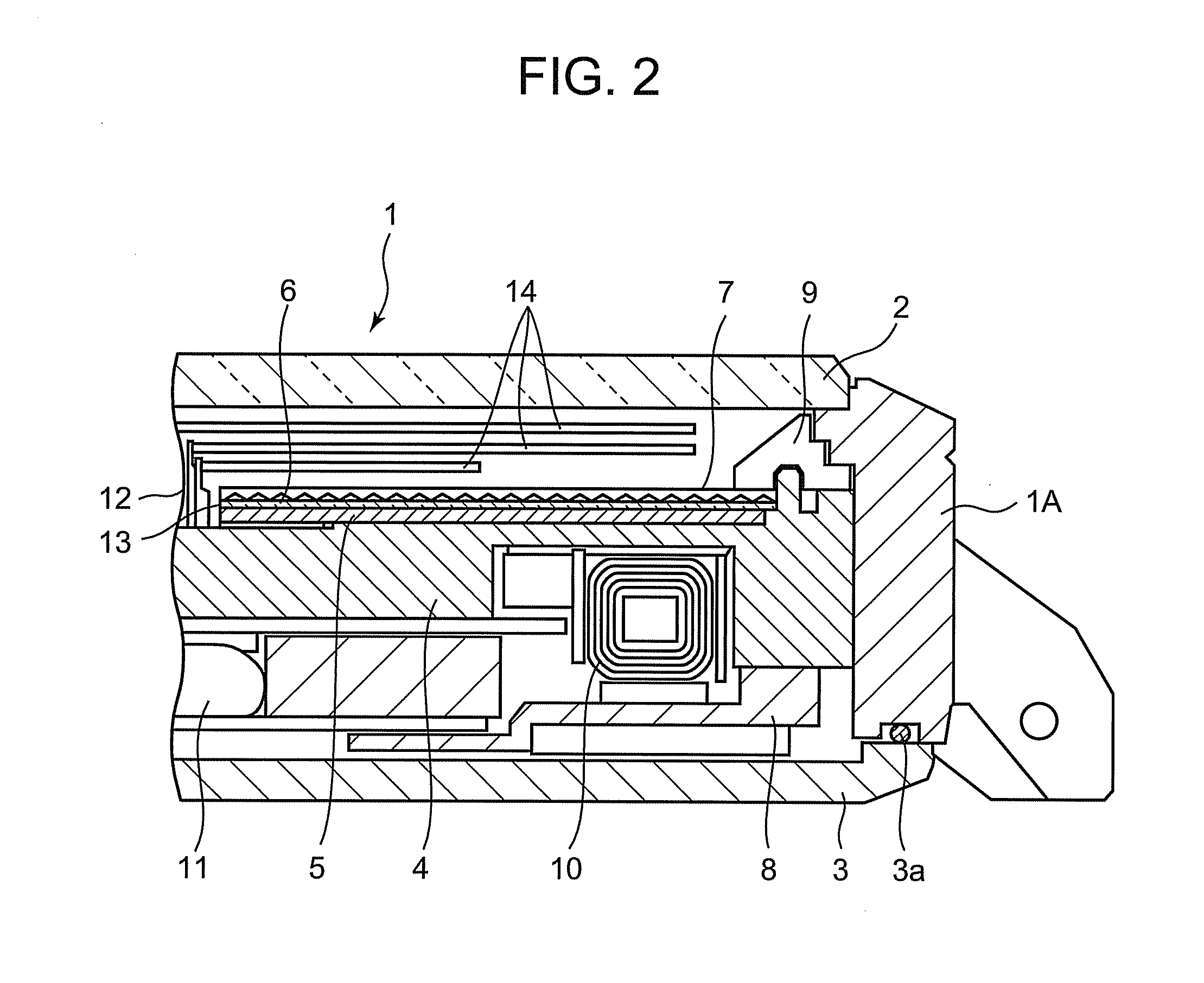

Electronic device and watch

InactiveUS20120134243A1Good sensitivity of antennaColor depthElectric windingClock driving mechanismsLight reflectionSolar cell

Disclosed is an electronic device in which a transparent member, a decorative plate, and a solar panel are arranged in this order in a metallic device case from an end side of an opening of the device case, wherein the decorative plate has light permeability and has a light refractive part made of a concavo-convex portion on a surface of the decorative plate on the side of the solar panel, and a semi-transmissive reflective plate having both light permeability and light reflectivity is provided between the decorative plate and the solar panel, and the semi-transmissive reflective plate has metal-free vapor deposited film.

Owner:CASIO COMPUTER CO LTD

Tea beverage and method for producing the same

ActiveUS20140127373A1Reduction in loss of fragranceMinimize in colorTea extractionFatty substance preservation using additivesAntioxidantReverse osmosis

Disclosed is a tea beverage and production method therefor. The tea beverage comprises tea, reverse-osmosis water which is deoxidized and deionized, and a food antioxidant, and the oxygen content in the freshly packaged tea beverage is ≦1 mg / L.

Owner:NONGFU SPRING CO LTD

Digital printing transfer process

PendingCN110230226AColor depthBrightly coloredTransfer printing processDyeing processColour fastnessEngineering

The invention discloses a digital printing transfer process. The digital printing transfer process comprises the following steps: preparing a digital printing paste; preparing active digital gravure ink; sizing: pretreating fabric by the paste prepared in S1; printing: directly spraying the ink prepared in S2 onto a film to form a pattern; transferring: transferring the film in S3 to the fabric sized in S2; steaming: steaming the fabric in S4 by a steam box for fixing and developing the color; washing: washing the fabric in S5 by a washing machine; shaping and performing weft finishing on thefabric washed in S6. The prepared printing paste enables the fabric after digital printing to have darker and brighter color, a clearer pattern and no stain bleeding phenomenon; the prepared active digital gravure ink has an environmentally-friendly effect and improves the color fastness; through direct transfer of a PET film pattern, the operation is simple, a printing effect is good, and the pattern effect is exquisite and beautiful.

Owner:苏州市彩旺纺织整理有限公司

Ink composition, inkjet recording method and colored body

ActiveUS20130257974A1Satisfactory storage stabilityHigh print densityOther printing matterInksColor saturationImage density

An aqueous black ink composition that produces a black recorded image that is stable even when stored for a long time period, exhibits a neutral black to gray color with low color saturation and no tinge, has a high printed image density and exhibits excellent fastness properties of the recorded image, particularly ozone-gas resistance. The ink composition contain at least one kind of coloring matter (I), which a coloring matter represented by formula (1) below, a tautomer thereof, or a salt of the coloring matter or the tautomer; at least one kind of coloring matter (II), which is a coloring matter represented by formula (2) below or a salt thereof; and coloring matter (III), which is a coloring matter having an azo group other than coloring matters (I) and (II), or a salt thereof.

Owner:NIPPON KAYAKU CO LTD

Glass ceramic panel with a pleasing black decoration applied with a decorative paint

InactiveUS7795163B2Smoother and less rough surfaceColor depthStoves/ranges topsHot plates heating arrangementsSilicate glassZinc

The black-colored glass ceramic panel has a cooking surface provided with a smooth black decoration by burning in a decorative paint, which contains a colorless zinc-containing glass flux and up to 10 wt. % of a partially coated pigment. The partially coated pigment consists of 20 to 40 wt. % of a black pigment with a grain size of at most 5μ and a grain size distribution characterized by a D50<2μ and 60 to 80% by weight of a zinc-free boro-alumino-silicate glass coating the black pigment. The glass flux consists, in wt. %, of Li2O, 0-5; Na2O, 0-5; K2O, <2; &Sgr;Li2O+Na2O+K2O, 1-10; MgO, 0-3; CaO, 0-4; SrO, 0-4; BaO, 0-4; ZnO, >0-4; B2O3, 15-27; Al2O3, 10-20; SiO2, 43-58; TiO2, 0-3; ZrO2, Sb2O3, 0-2; F, 0-3.

Owner:SCHOTT AG

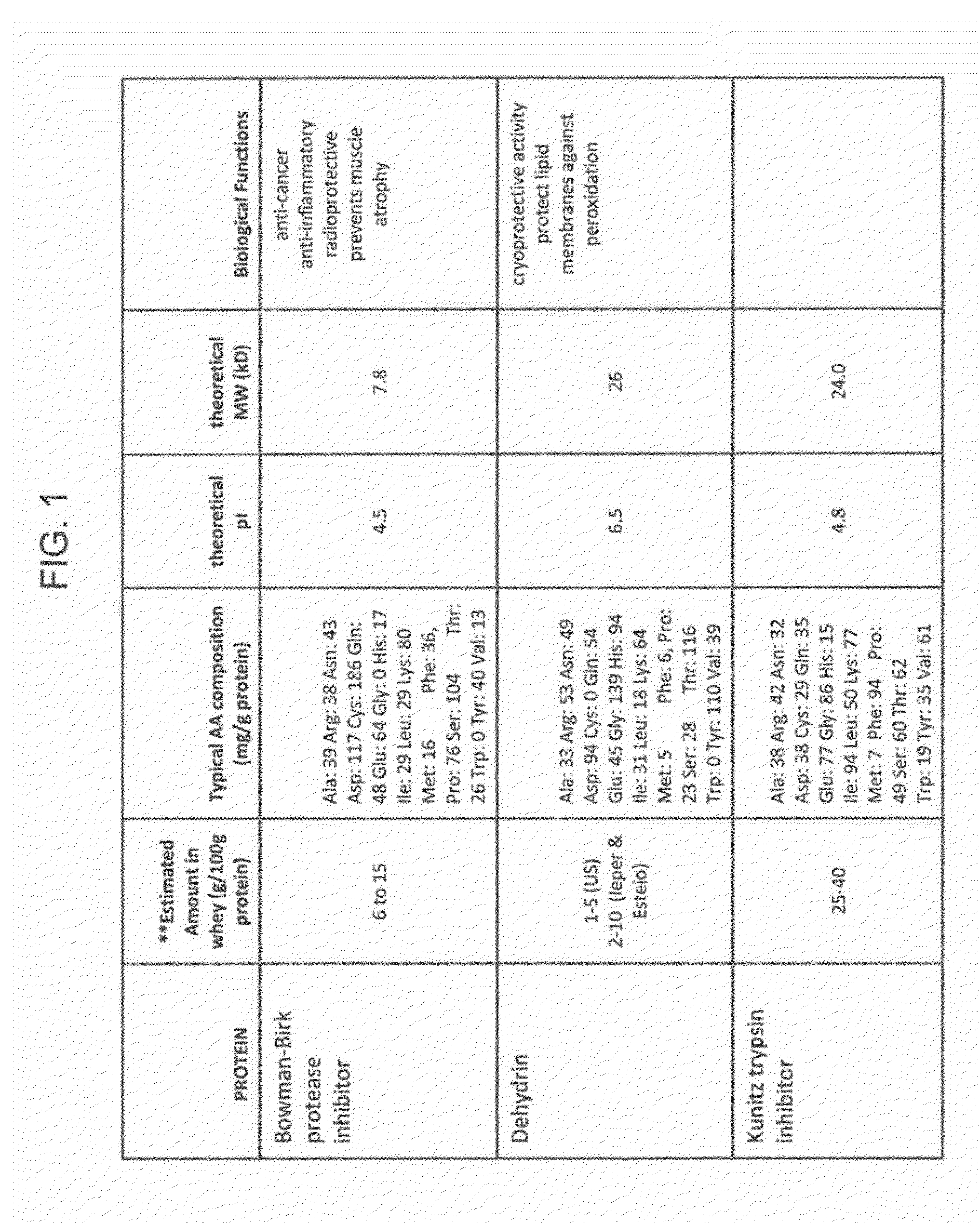

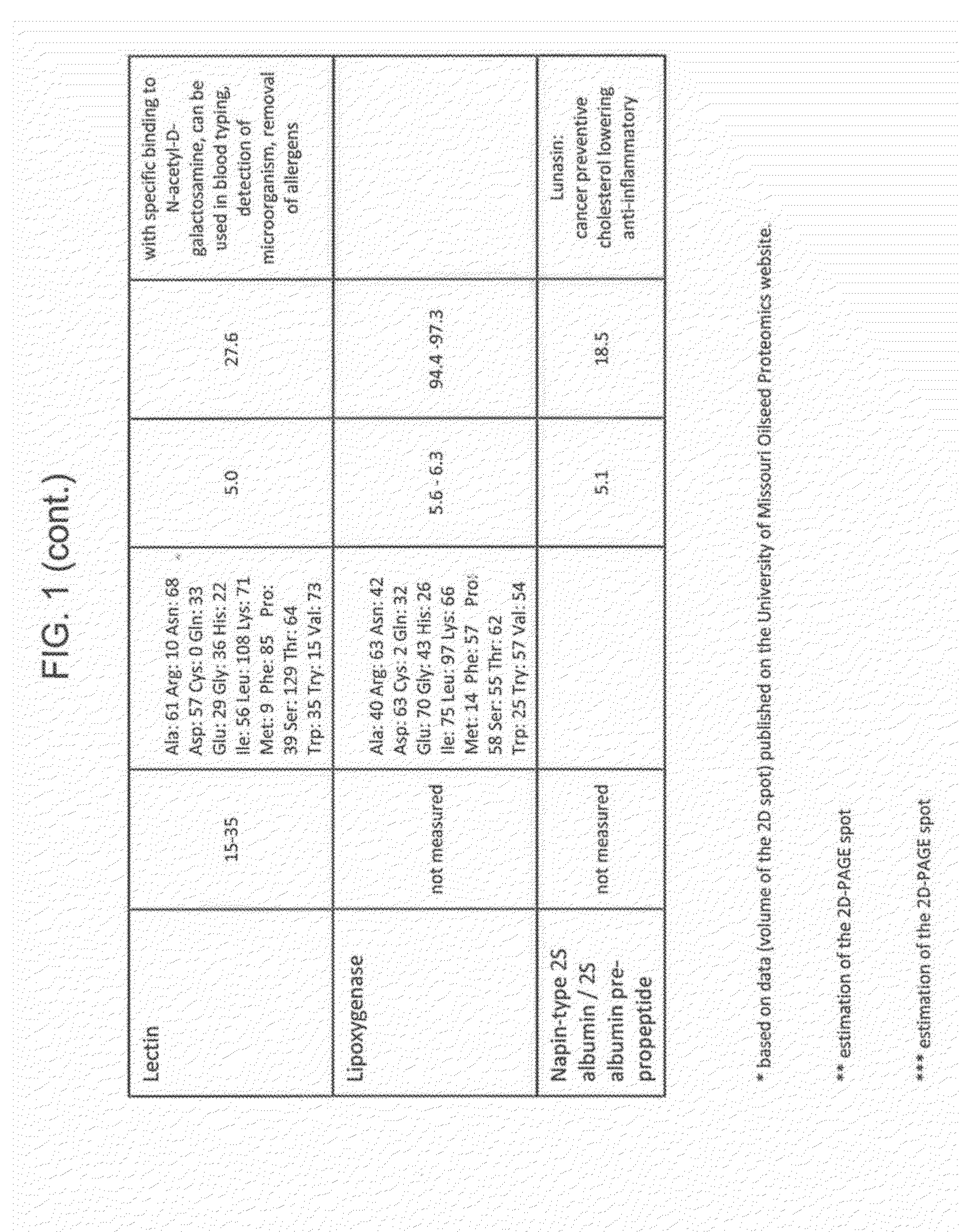

Dessert compositions comprising soy whey proteins that have been isolated from processing streams

InactiveUS20140134316A1Color depthReduce the amount of solutionProtein composition from vegetable seedsFrozen sweetsBiotechnologyWhey protein

A dessert composition comprising soy whey proteins that have been isolated from processing streams, wherein the dessert composition is used to form a dessert food product. A process for recovering and isolating soy whey proteins and other components from soy processing streams is also disclosed.

Owner:SOLAE LLC

Alkaline pad dyeing method for nylon 56 and cellulose fiber blended fabric

The invention provides an alkaline pad dyeing method for blended fabric of nylon 56 and cellulose fibers. According to the method, a vat dye, a reactive dye, a direct dye and a sulfur dye are adoptedto carry out one-bath pad dyeing on the blended fabric of the nylon 56 fibers and the cellulose fibers, the pad dyeing of the blended fabric can be completed by adopting a set of dyes, after dyeing, the fabric is bright in color and dark in color, the friction resistance and the water resistance can reach more than grade 3-4, the color fastness to sunlight can reach more than grade 5, the processis simple, and energy conservation and emission reduction are achieved.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com