Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Improve machine quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

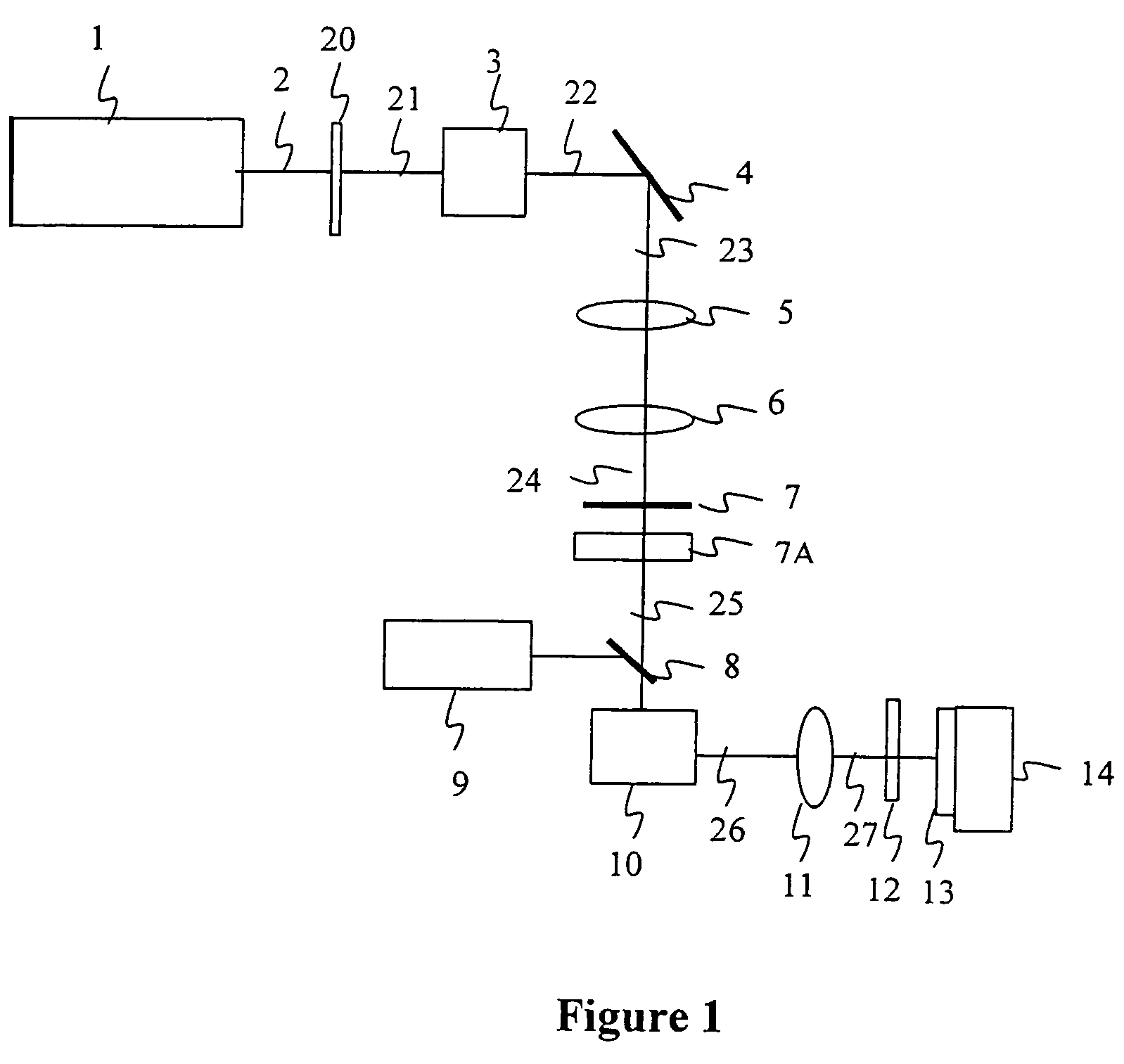

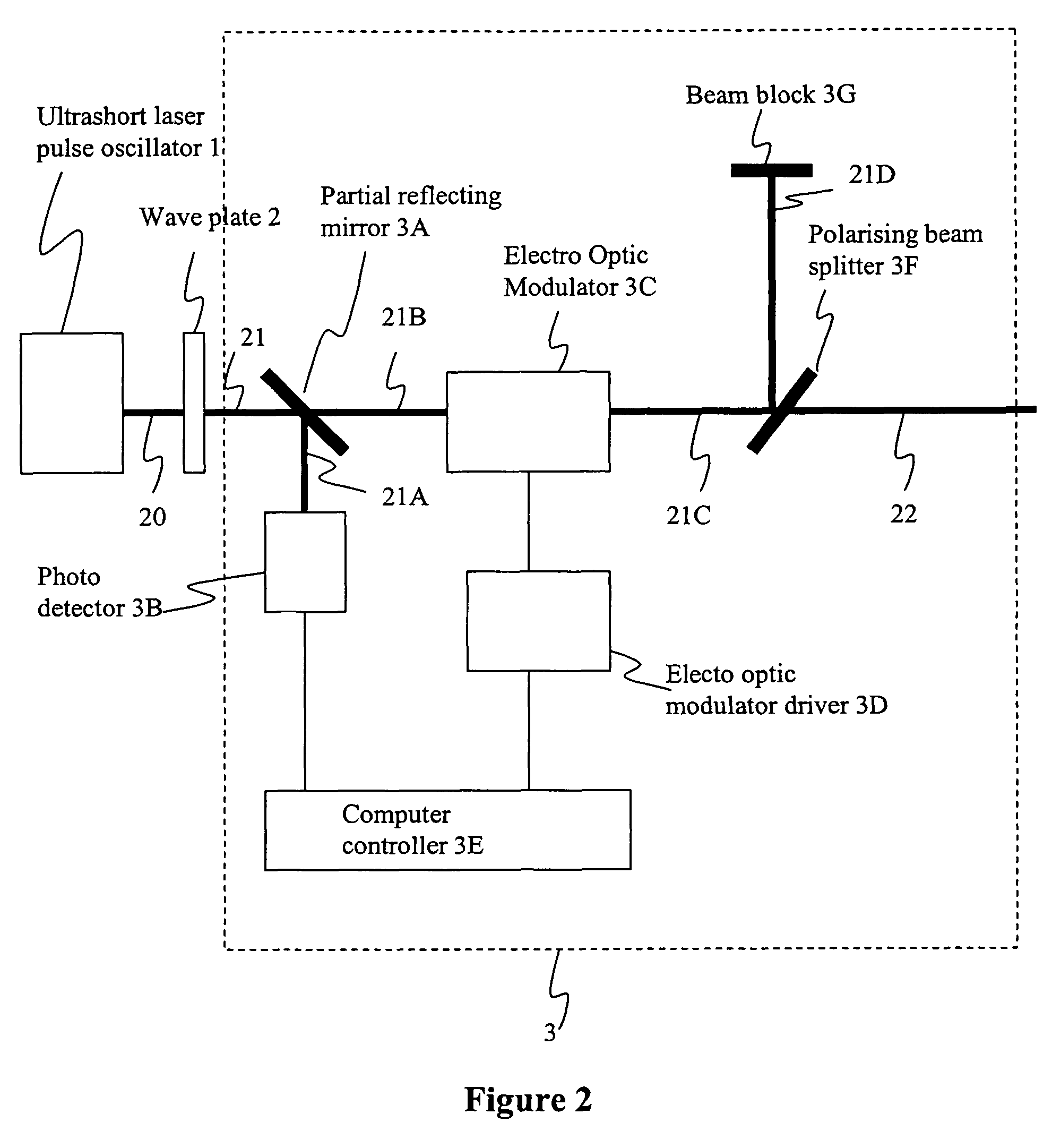

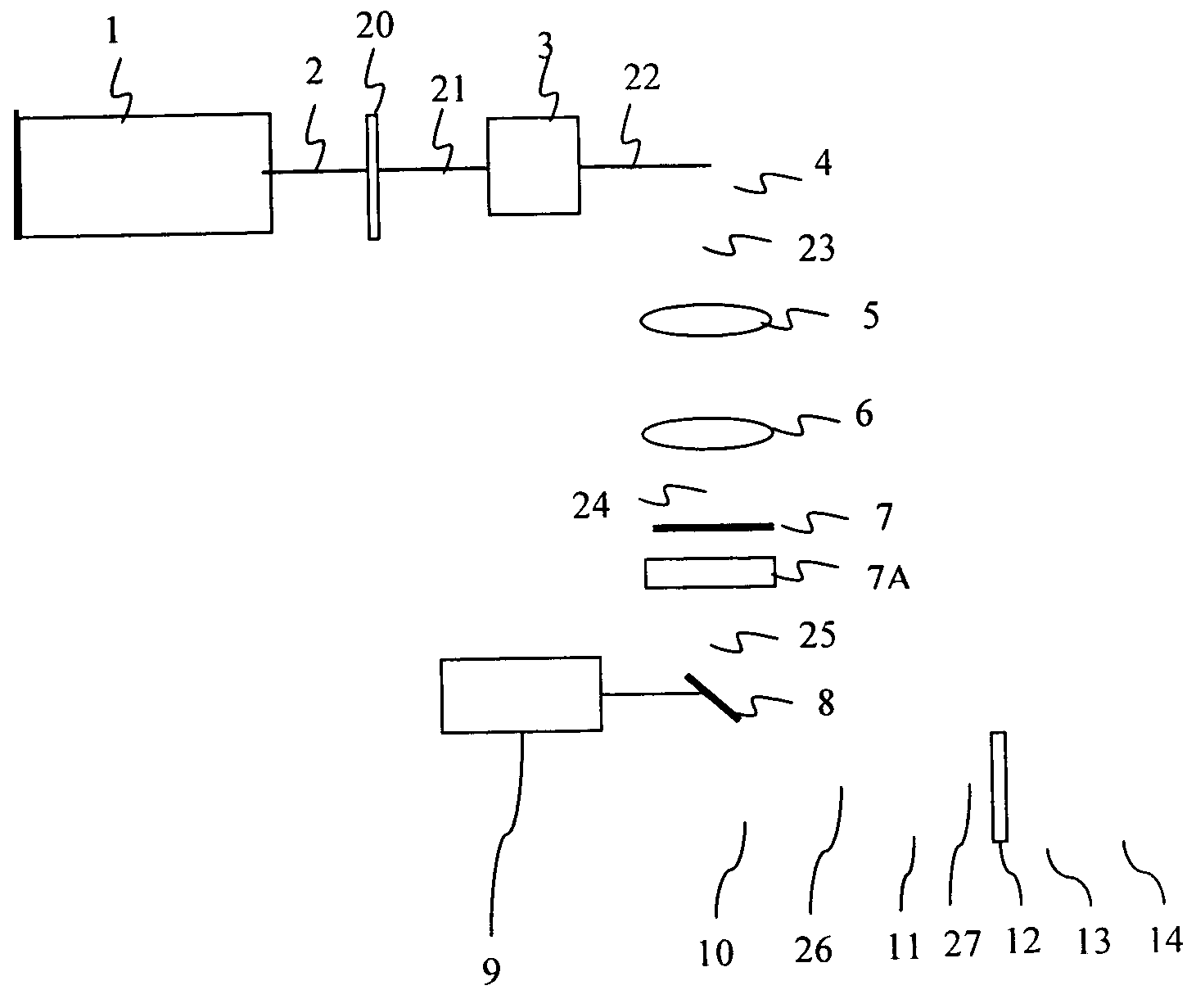

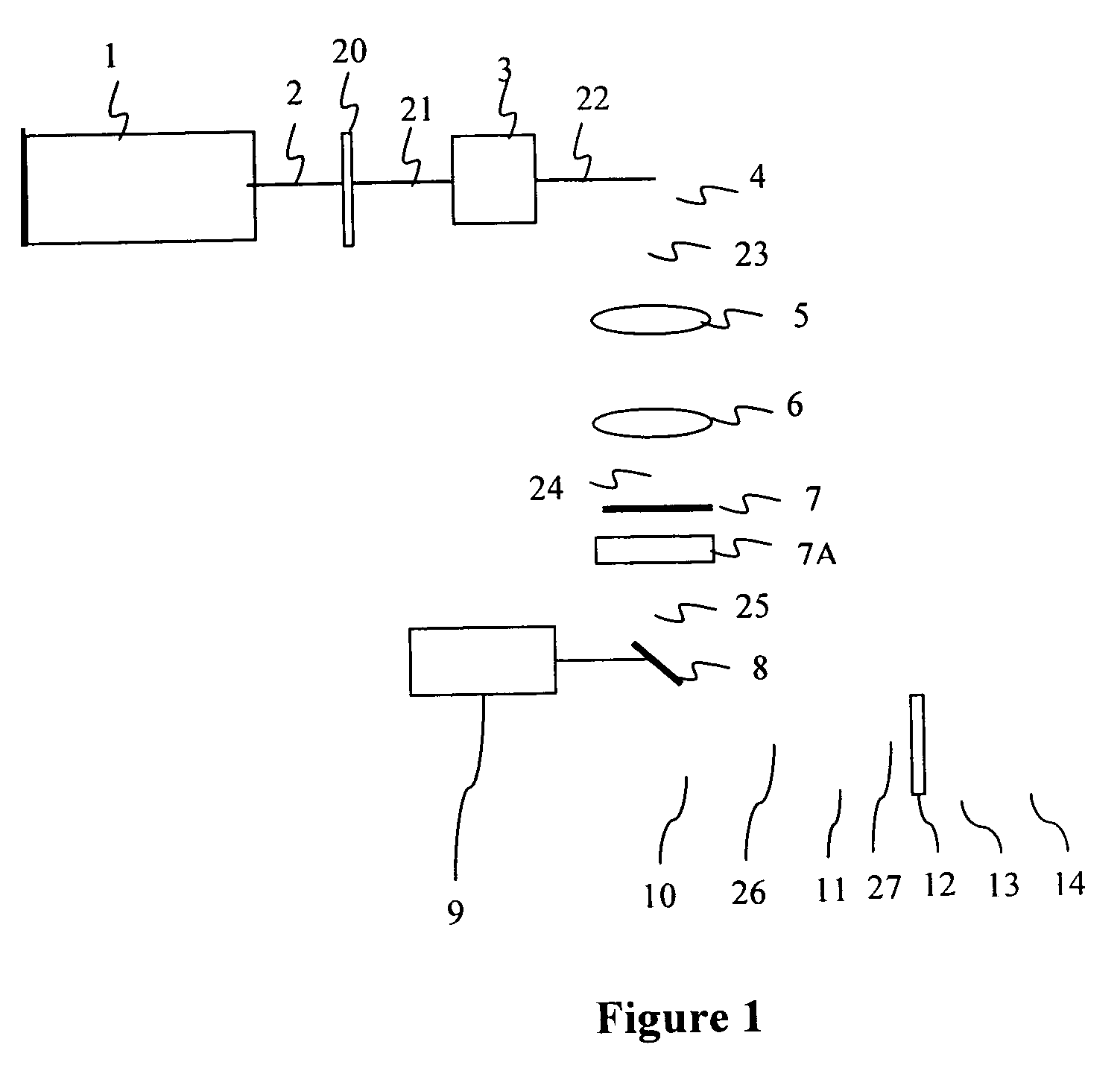

Method and apparatus for dicing of thin and ultra thin semiconductor wafer using ultrafast pulse laser

InactiveUS20050274702A1Improve inner wall qualityImprove surface qualityWelding/soldering/cutting articlesMetal working apparatusPicosecond laserFacula

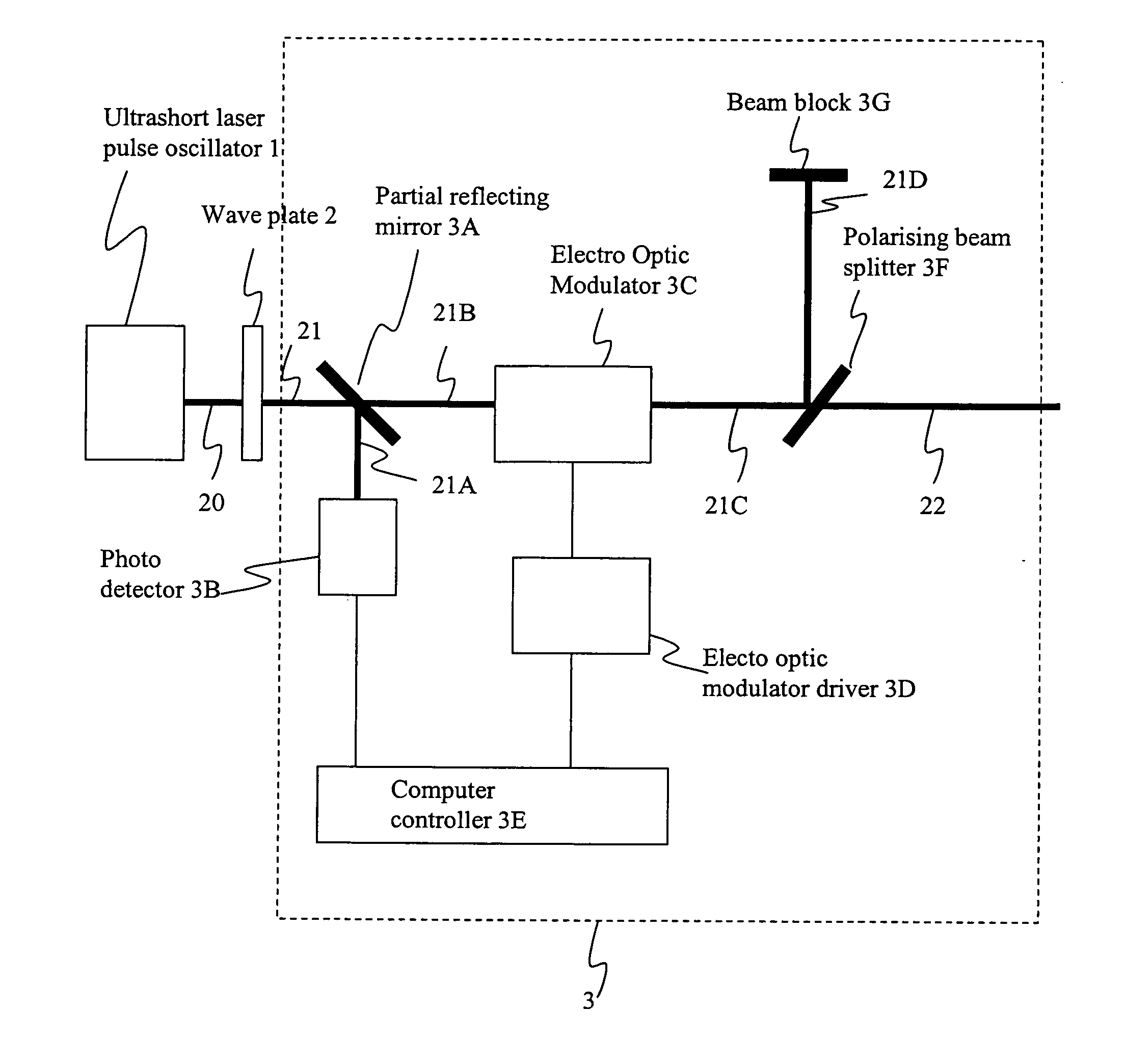

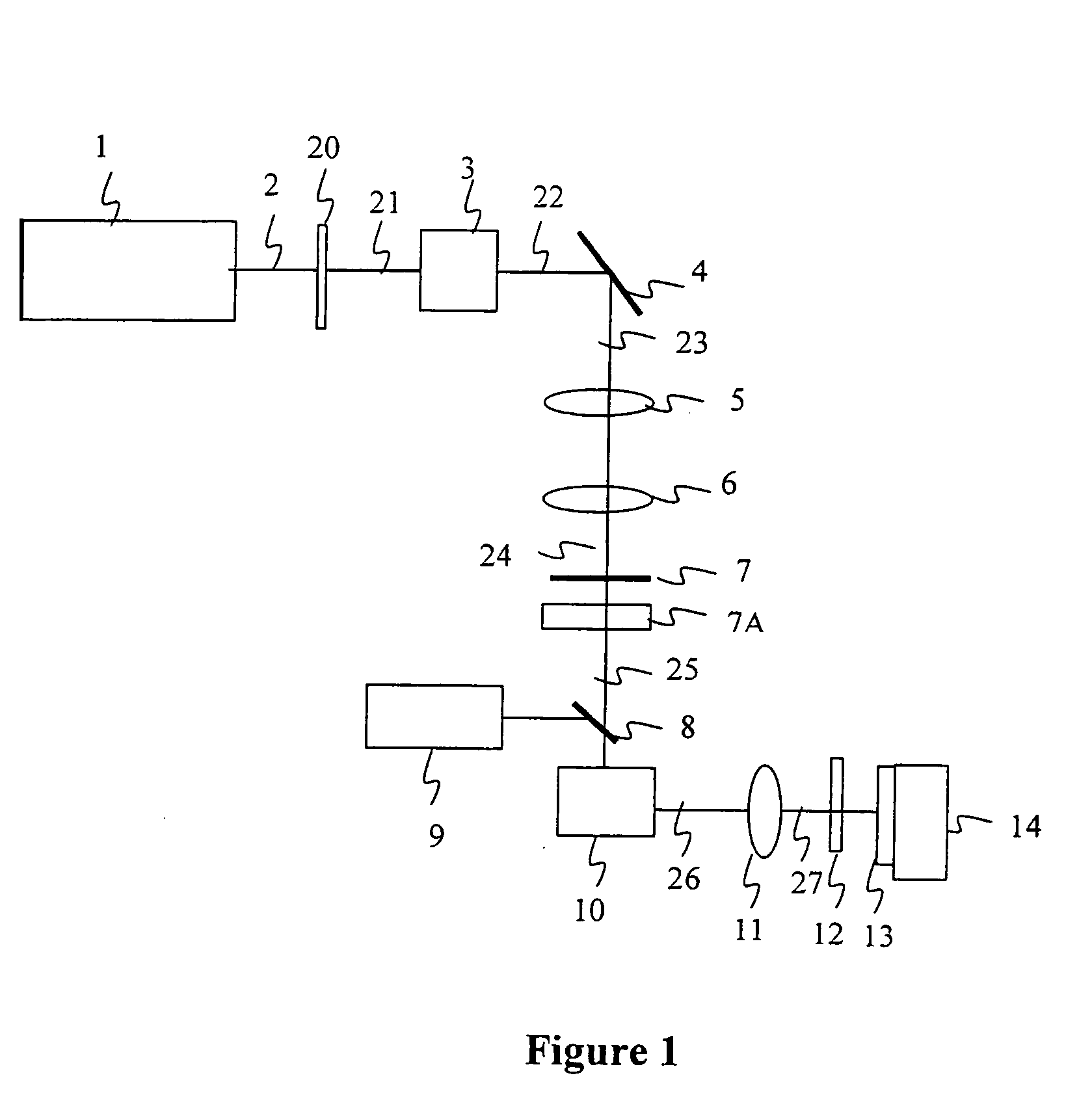

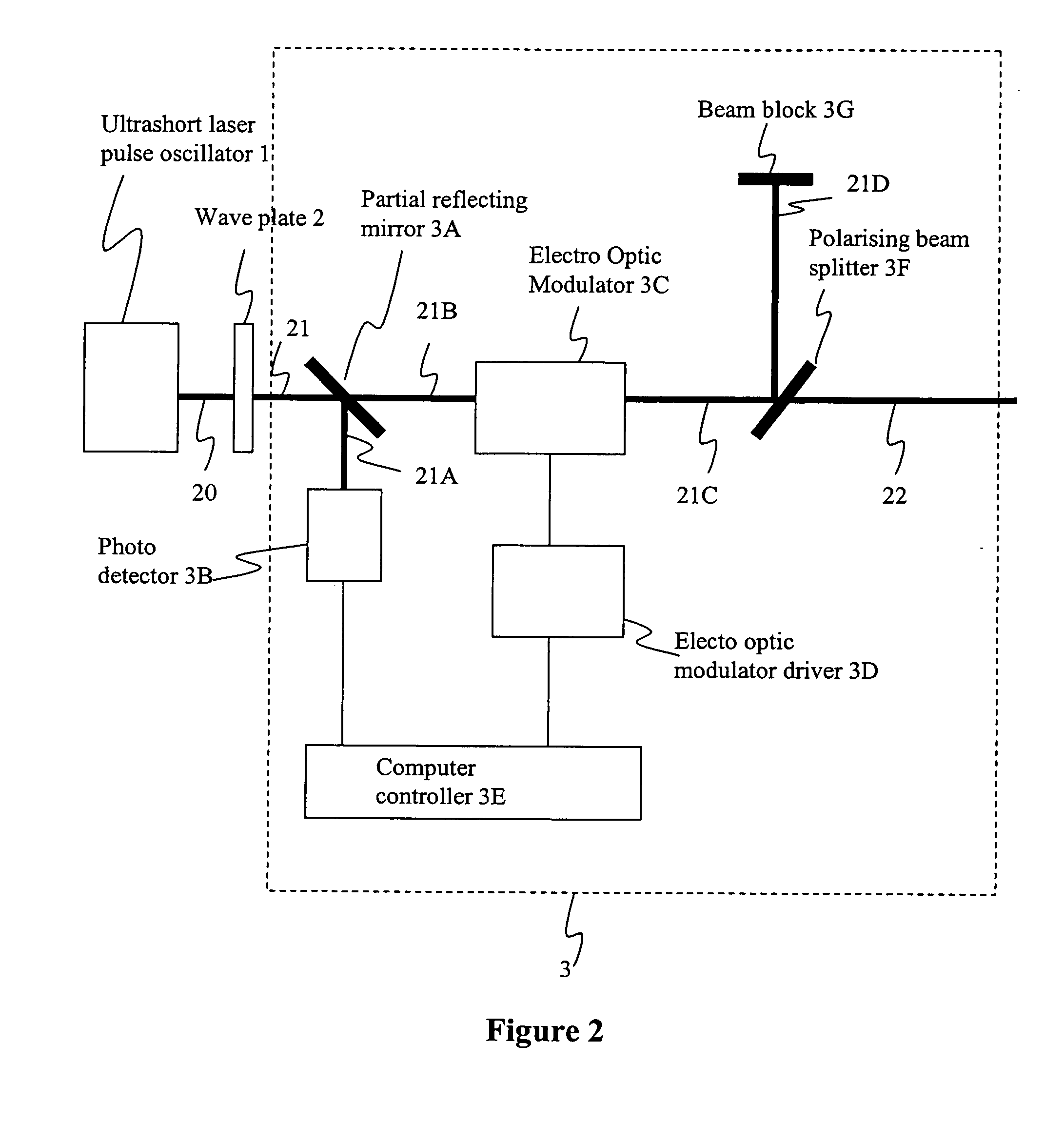

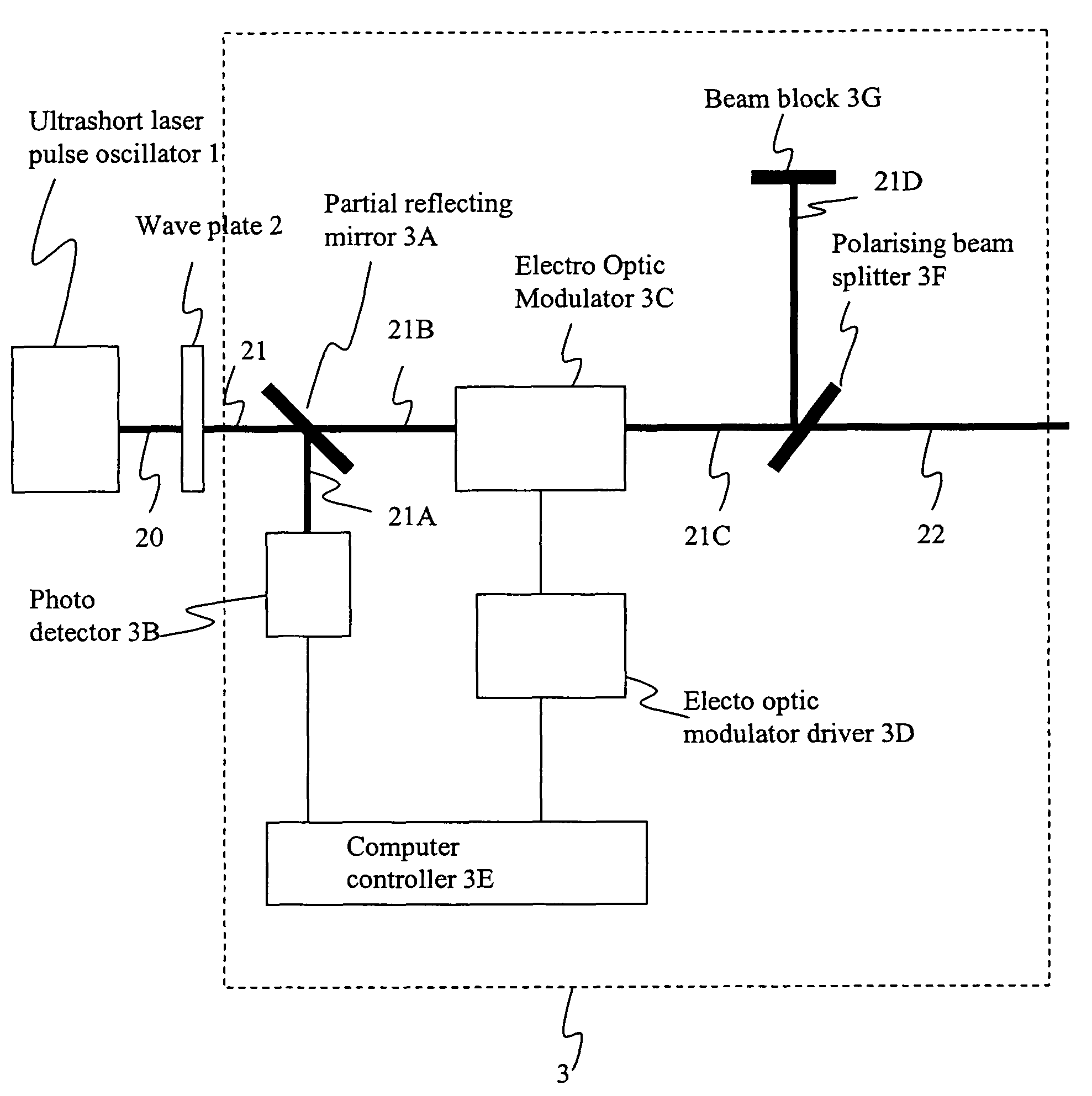

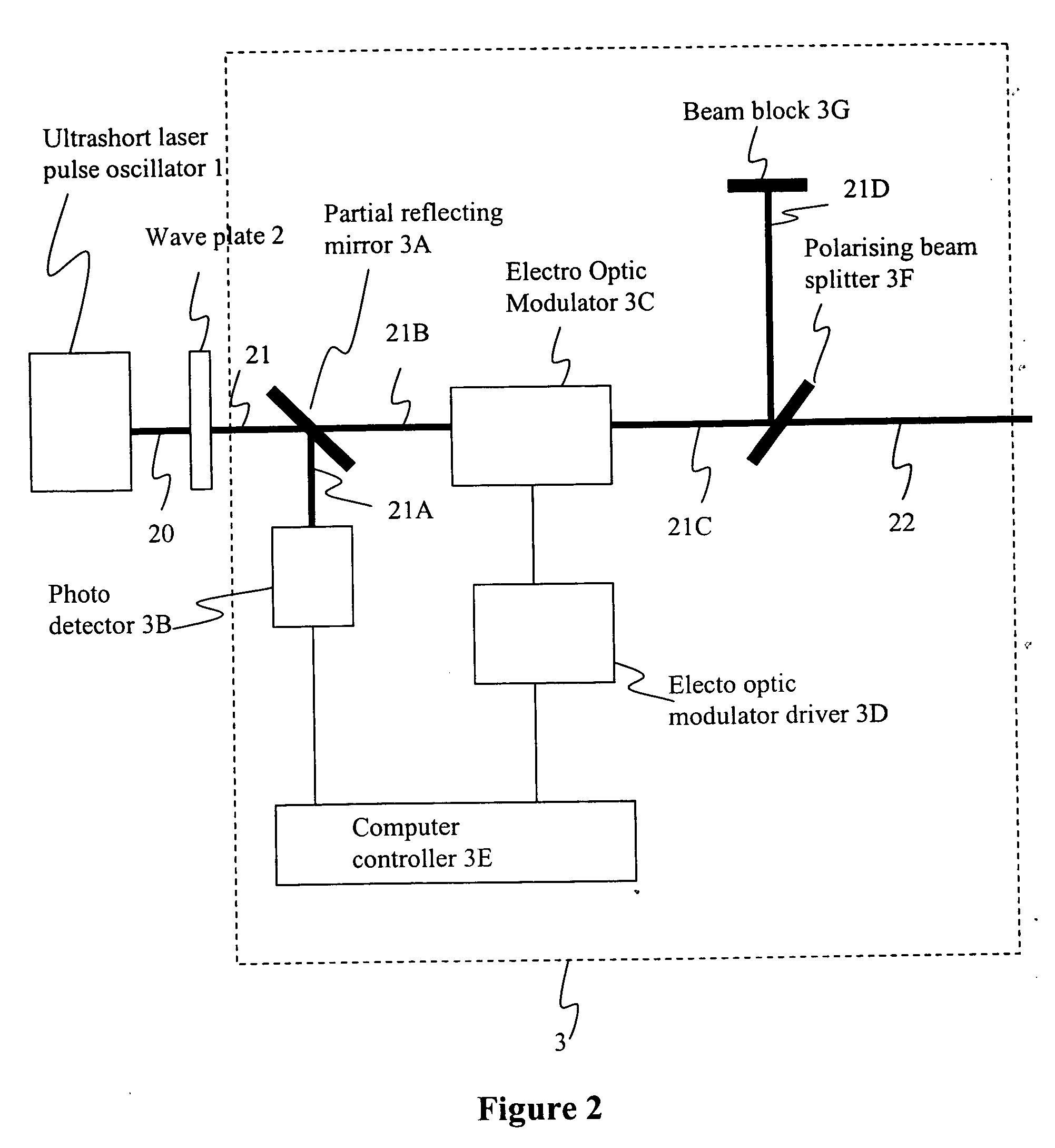

The present invention relates to the apparatus, system and method for dicing of semiconductor wafers using an ultrafast laser pulse of femtosecond and picosecond pulse widths directly from the ultrafast laser oscillator without an amplifier. Thin and ultrathin simiconductor wafers below 250 micrometer thickness, are diced using diode pumped, solid state mode locked ultrafast laser pulses from oscillator without amplification. The invention disclosed has means to avoid / reduce the cumulative heating effect and to avoid machine quality degrading in multi shot ablation. Also the disclosed invention provides means to change the polarization state of the laser beam to reduce the focused spot size, and improve the machining efficiency and quality. The disclosed invention provides a cost effective and stable system for high volume manufacturing applications. An ultrafast laser oscillator can be a called as femtosecond laser oscillator or a picosecond laser oscillator depending on the pulse width of the laser beam generated.

Owner:LASERFACTURING

Method and apparatus for dicing of thin and ultra thin semiconductor wafer using ultrafast pulse laser

InactiveUS7804043B2Minimize heating effectImprove machine qualityWelding/soldering/cutting articlesMetal working apparatusPicosecond laserBeam polarization

The present invention relates to the apparatus, system and method for dicing of semiconductor wafers using an ultrafast laser pulse of femtosecond and picosecond pulse widths directly from the ultrafast laser oscillator without an amplifier. Thin and ultrathin semiconductor wafers below 250 micrometer thickness, are diced using diode pumped, solid state mode locked ultrafast laser pulses from oscillator without amplification. The invention disclosed has means to avoid / reduce the cumulative heating effect and to avoid machine quality degrading in multi shot ablation. Also the disclosed invention provides means to change the polarization state of the laser beam to reduce the focused spot size, and improve the machining efficiency and quality. The disclosed invention provides a cost effective and stable system for high volume manufacturing applications. An ultrafast laser oscillator can be a called as femtosecond laser oscillator or a picosecond laser oscillator depending on the pulse width of the laser beam generated.

Owner:LASERFACTURING

Method and apparatus for laser trimming of resistors using ultrafast laser pulse from ultrafast laser oscillator operating in picosecond and femtosecond pulse widths

InactiveUS20060039419A1Eliminate effectHigh qualityLaser detailsResistor manufactureLaser trimmingSolid-state

Owner:LASERFACTURING

Laser machining apparatus with switchable laser system and laser machining method

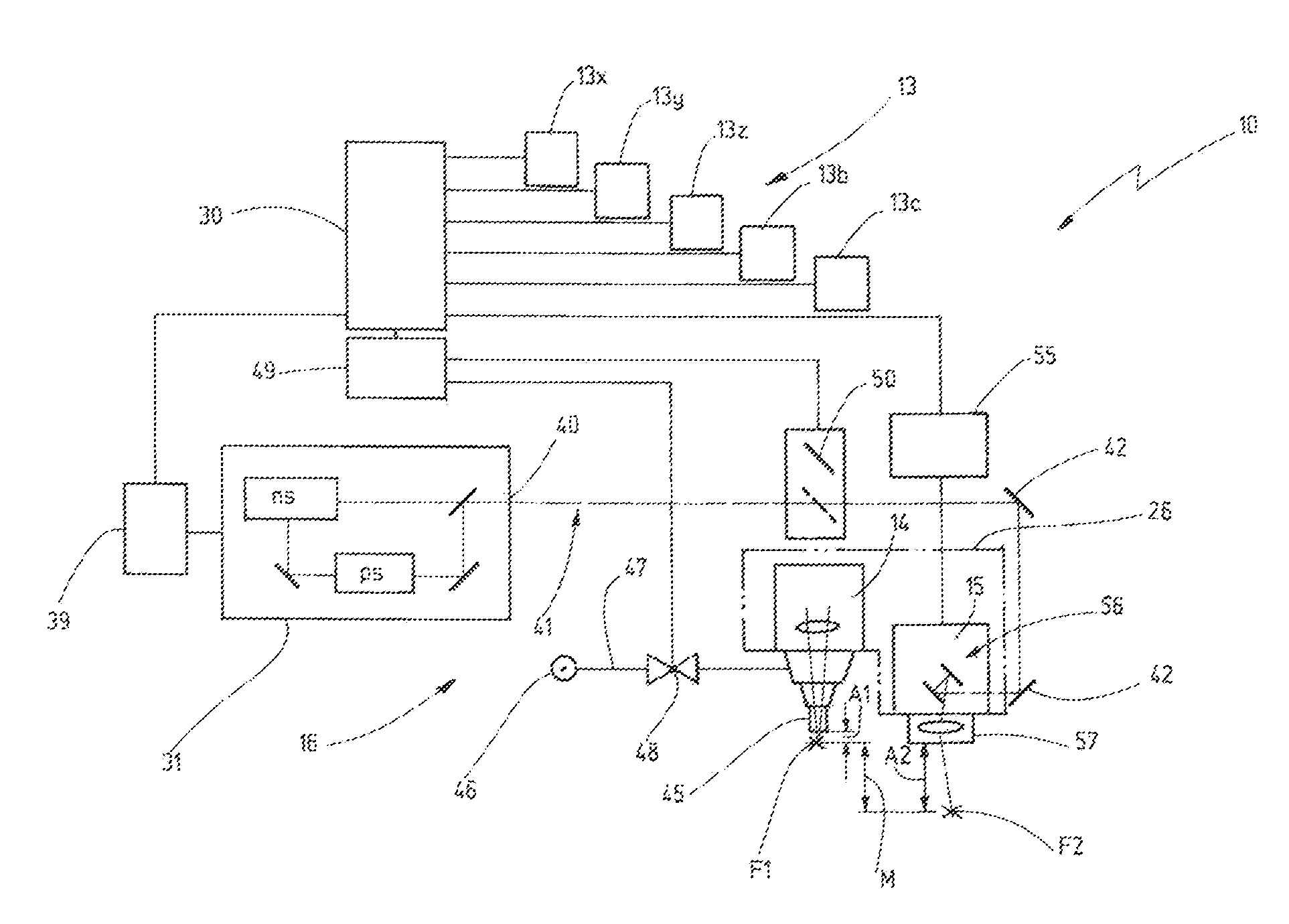

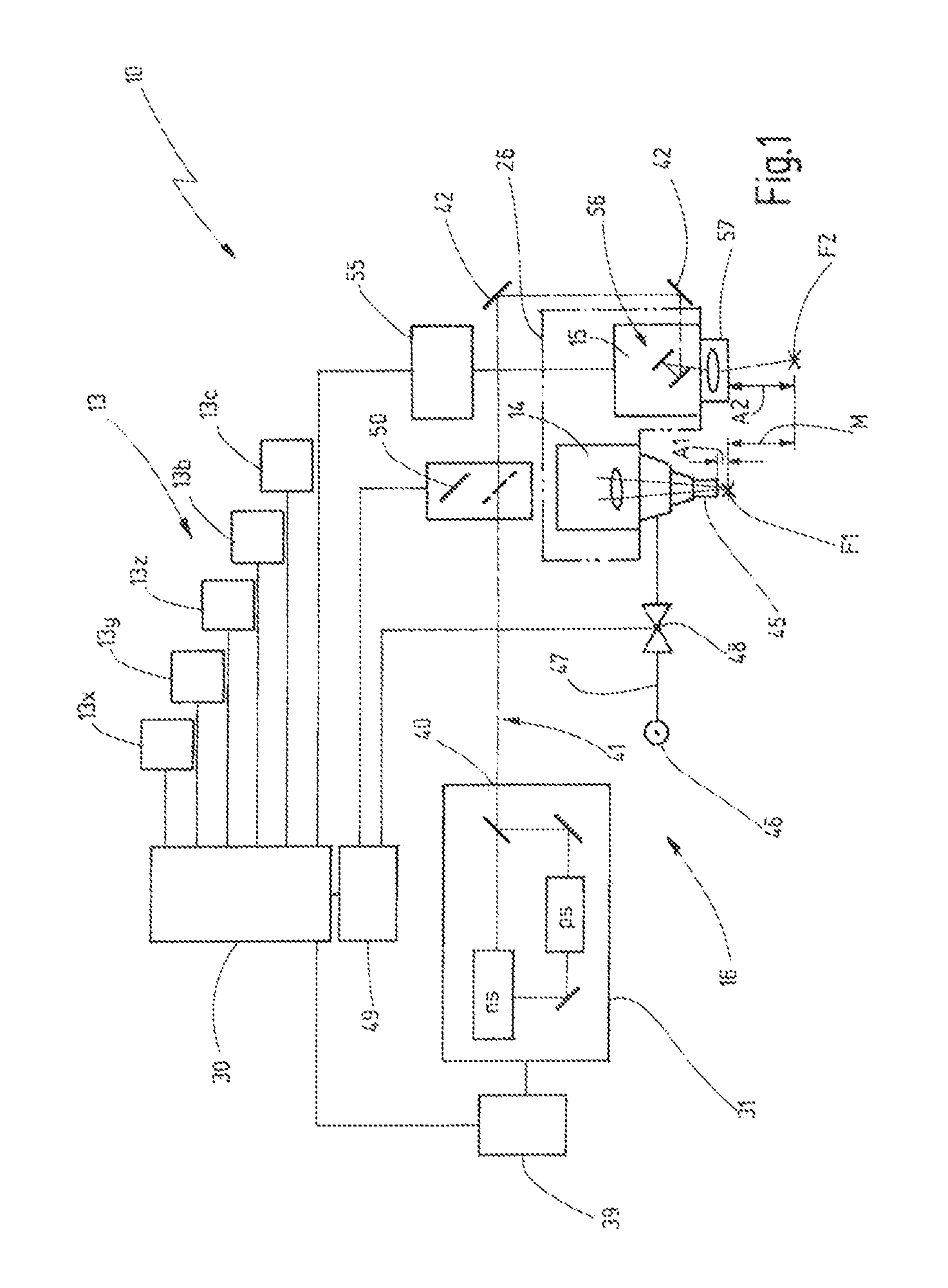

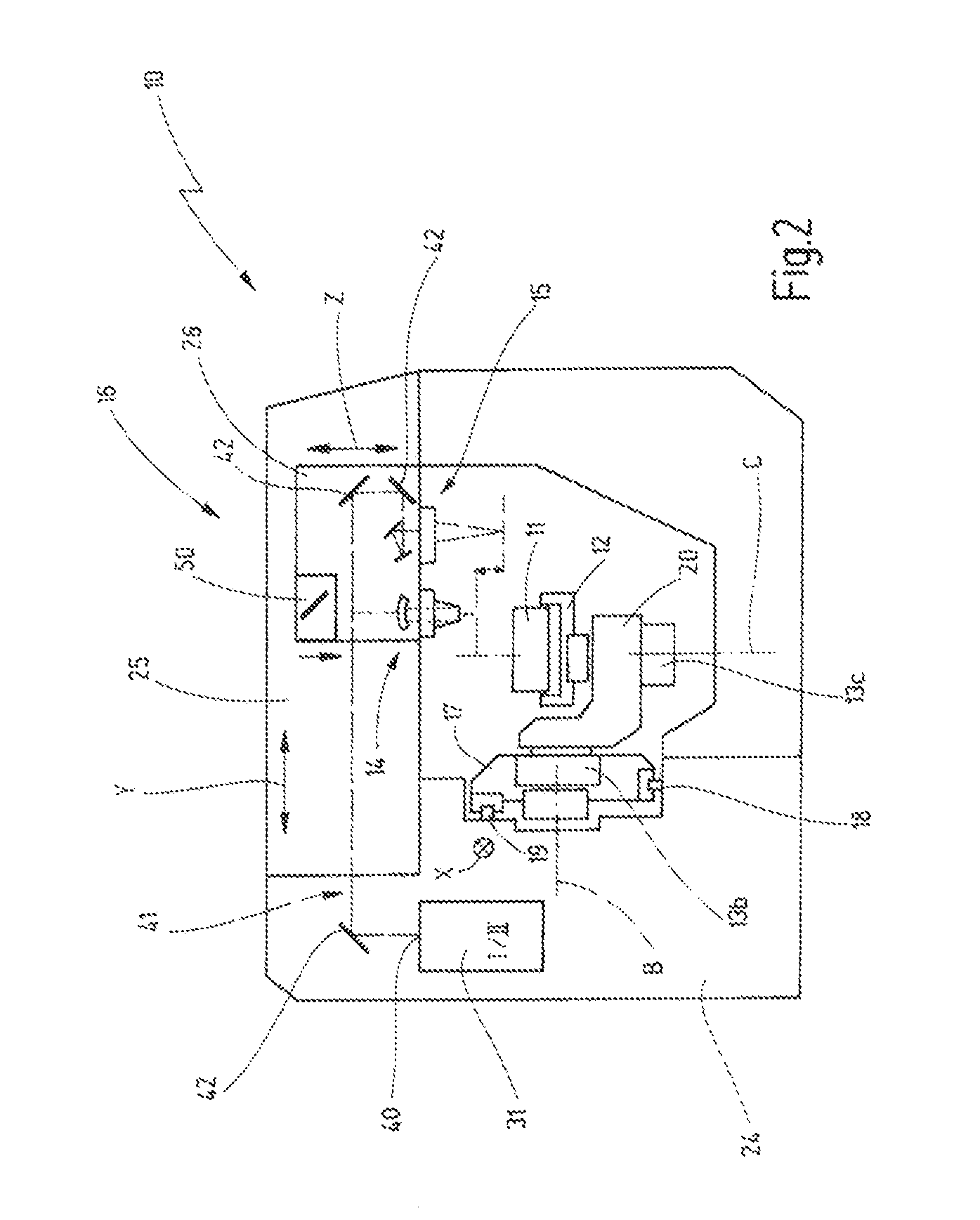

ActiveUS20120205356A1Improve machine qualityLittle powerMetal working apparatusLaser beam welding apparatusPulse durationPicosecond

A laser machining apparatus and method for producing from a workpiece a rotating cutting tool having a cutting edge and a flank. The laser machining apparatus works in two different operating modes. In the first operating mode, a first laser head is used for machining the workpiece at high advance speeds of the workpiece relative to the first laser head to form a rough desired contour with pulses having a duration in the nanosecond range resulting in laser melt cutting. Subsequently, the laser machining apparatus is operated in the second operating mode generating laser pulses with having a pulse duration in the picosecond range. In the second operating mode, a second laser head is activated by means of an optical scanner system and directs the laser pulses onto a two-dimensional pulse area on the surface of the workpiece, the material removal is accomplished by laser ablation.

Owner:FRITZ STUDER AG

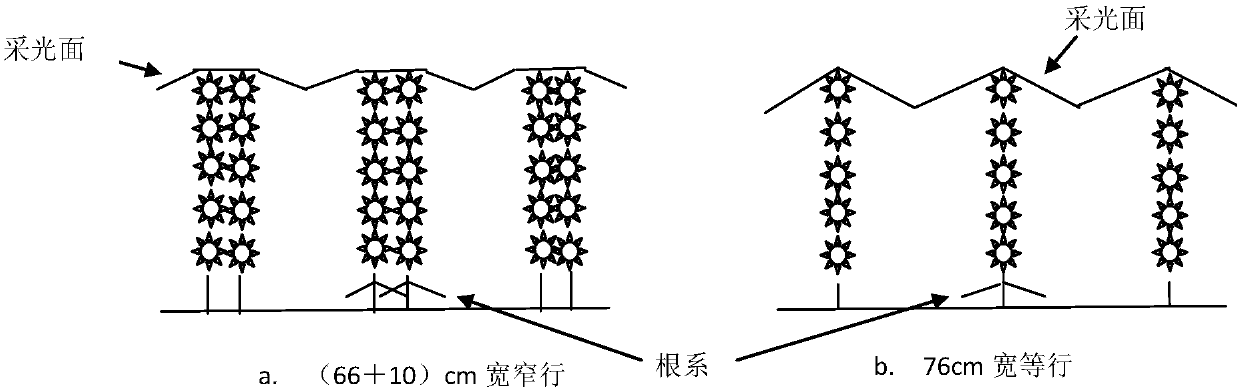

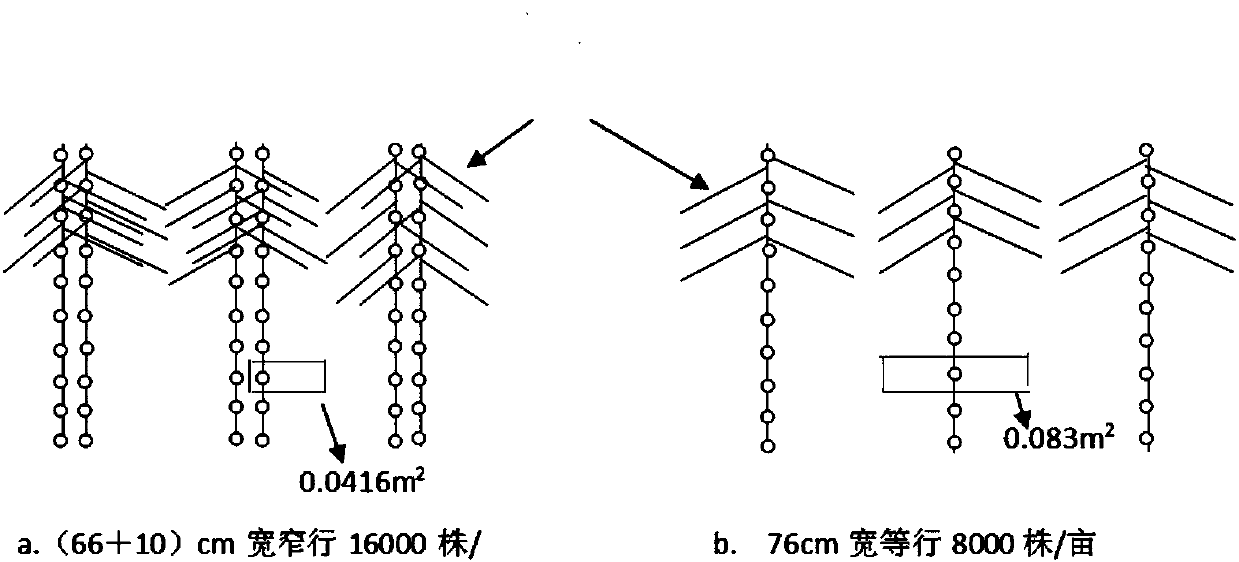

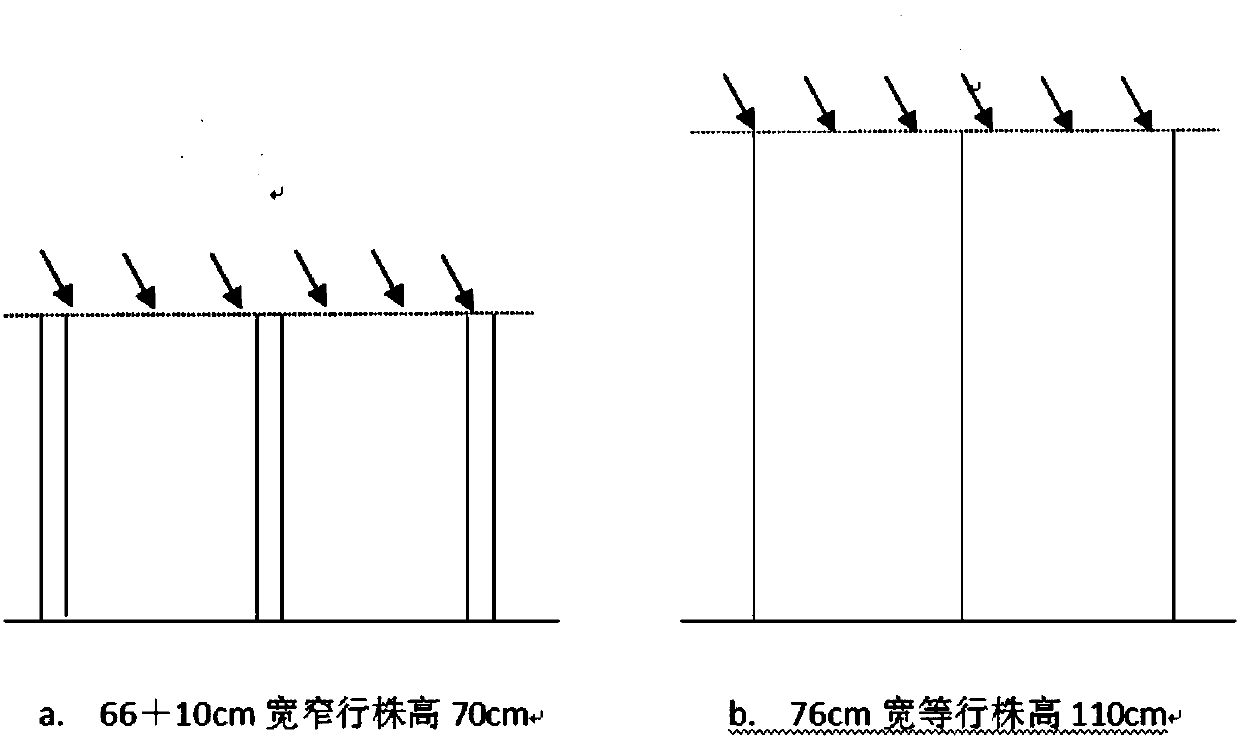

Production method for wide-early-superior raw cotton in cotton region in Northwest China

ActiveCN107996339AAvoid interspersedGood ventilation and light transmissionFertilising methodsCotton cultivationForeign matterAgricultural science

The invention discloses a production method for wide-early-superior raw cotton in a cotton region in Northwest China. The method includes the following steps of 1, fission type elite seed production,wherein variety selection,10-ten-thousand-times fission type seed reproduction, and grain selection according to the grain size are conducted; 2, planting in rows with the equal width and conducting the following matching technologies: the variety selection and rational early sowing technology, the edge film widening and lighting technology, the sowing row no-covering-soil and film no-covering-soil technology, the appropriate seedling water dropping technology, the first water late-drop technology, the plant-height increasing and appropriate tip pruning delay technology, and the cotton-flowering and boll-forming fertilizer re-application technology; 3, an early-sowing and early-ripening matching technology; 4, superior raw cotton quality control technologies which includes the technology of uncovering mulching films in the optimum period and preventing pollution, the technology of spraying an appropriate amount of disleave agent and ripener in the appropriate period, the technology ofremoving field weeds and foreign matters and the technology of harvesting in the appropriate period. The method is feasible, operation is simple and convenient, conversion from short-dense-early 'getting cotton by temperature' to tapping of the potential of light, temperature and environment resources is achieved, and support is provided for high-yield, high-efficiency and high-quality cotton.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

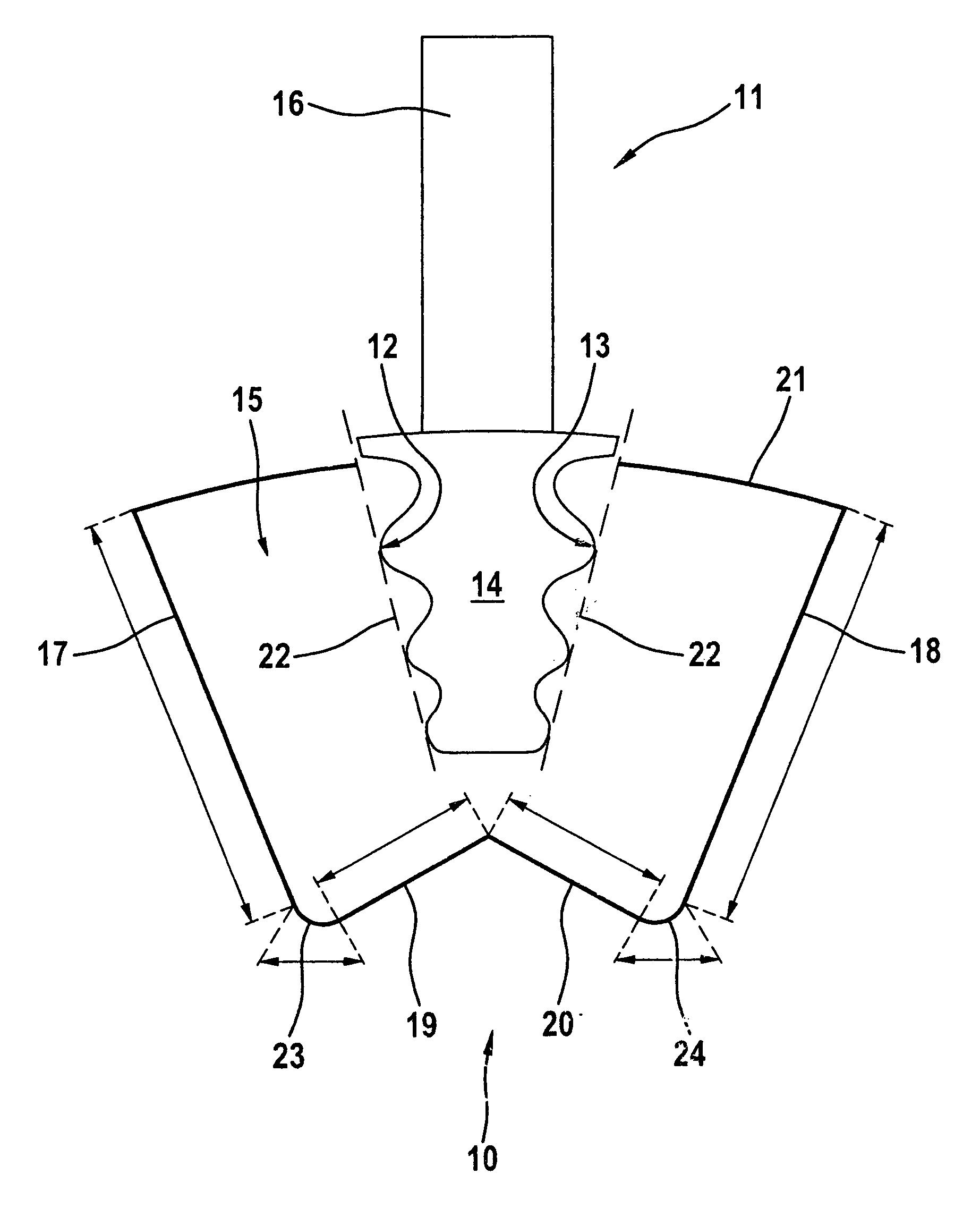

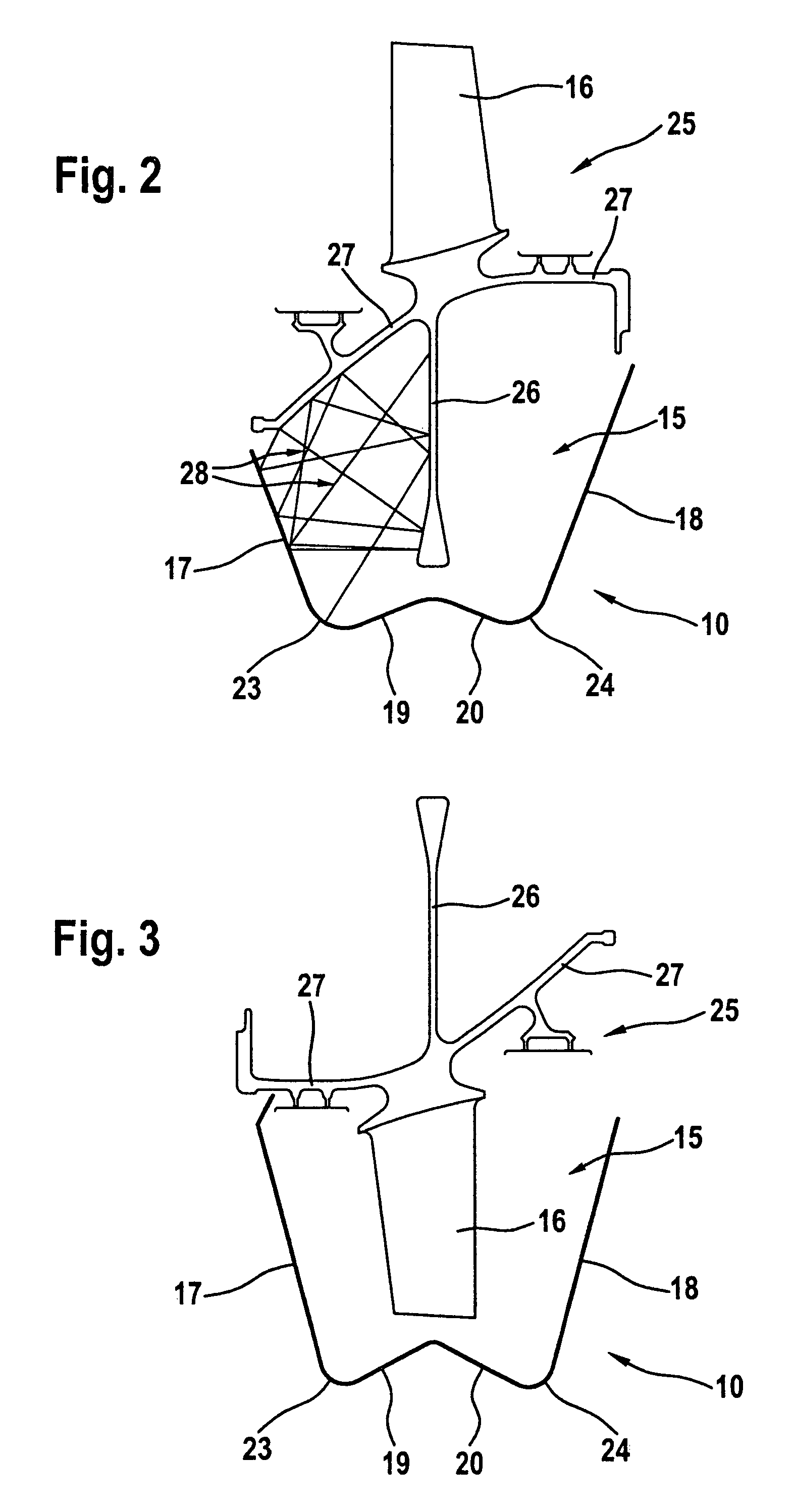

Device for surface blasting component

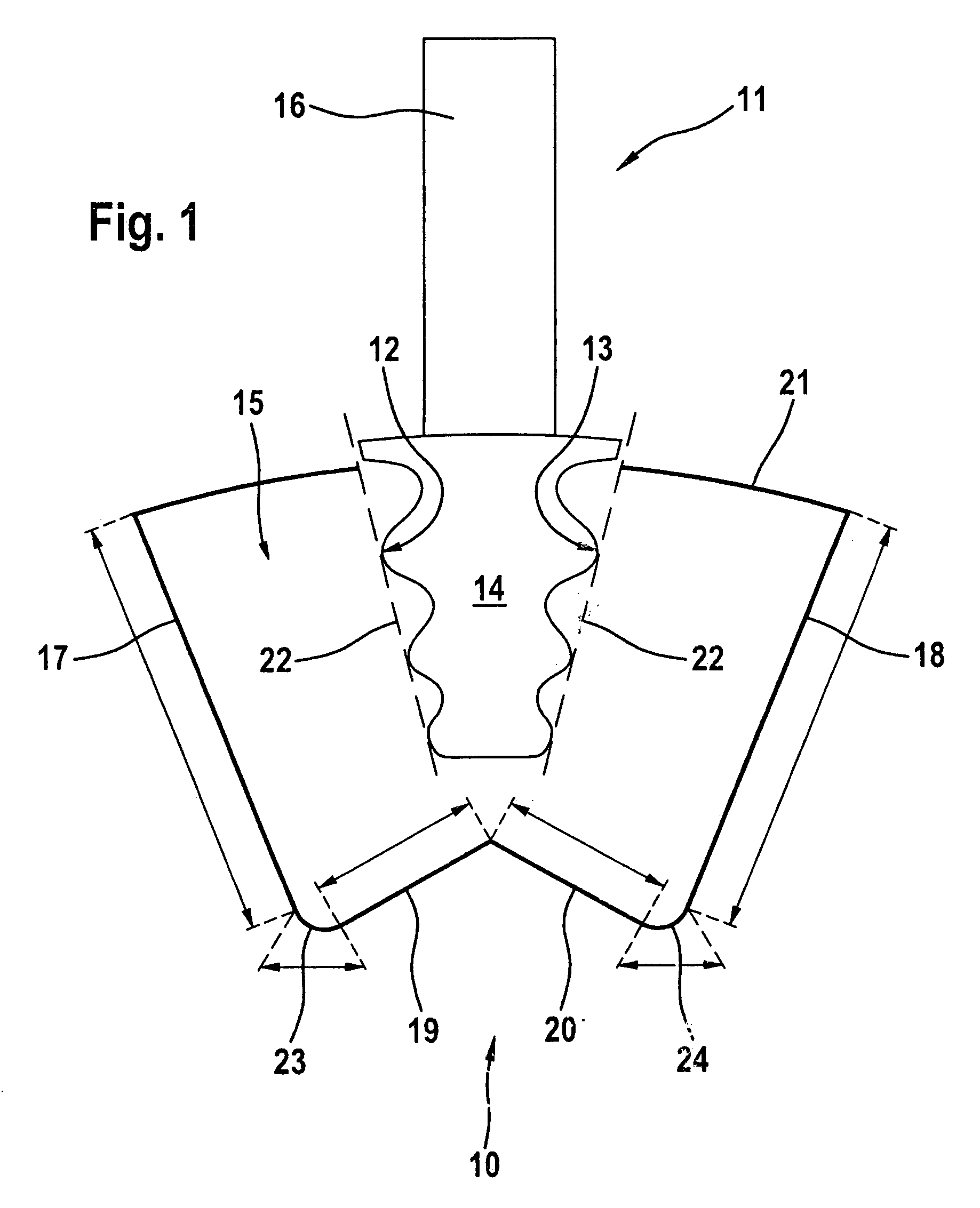

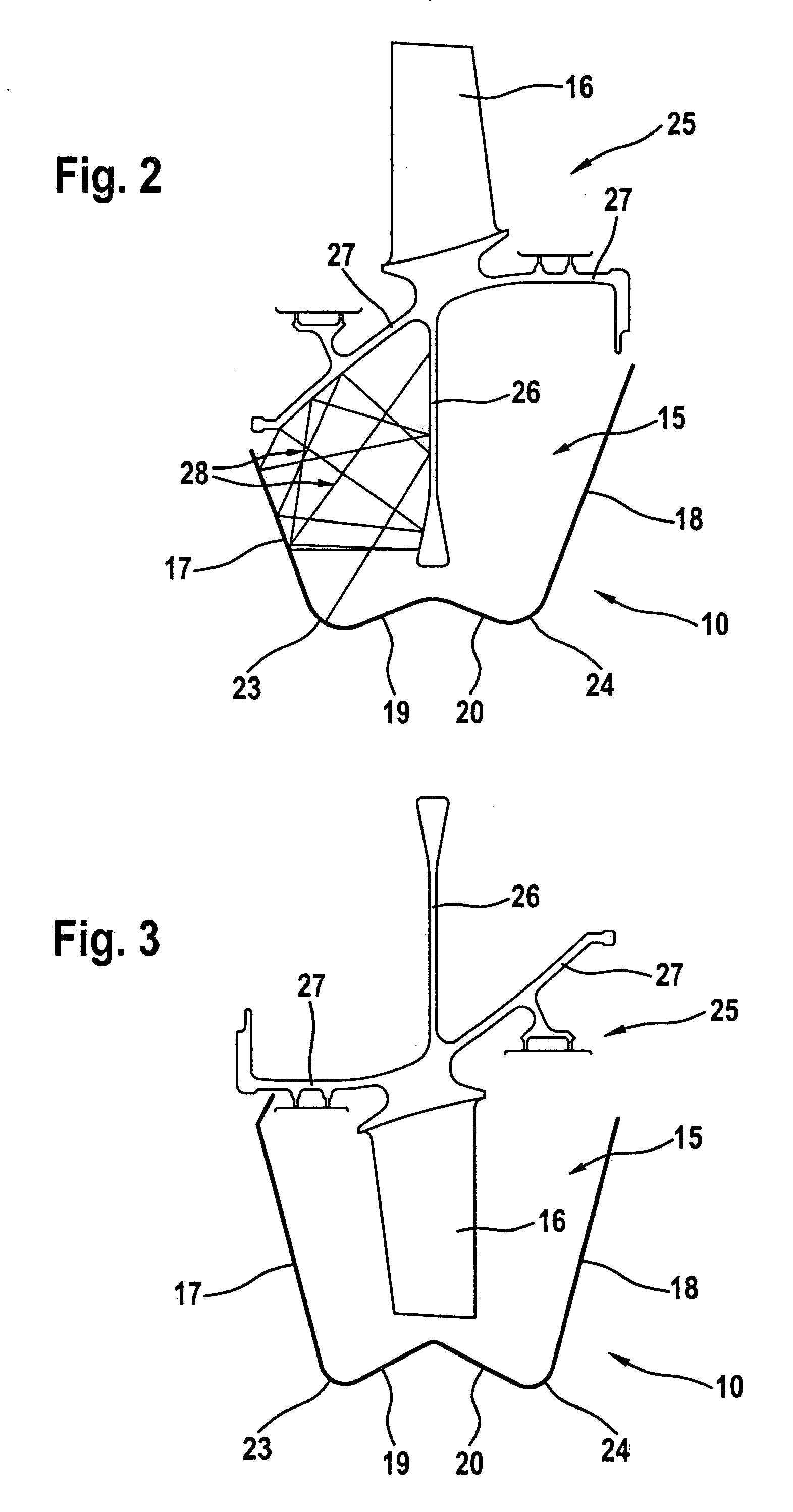

ActiveUS20060174483A1Improve efficiencyImprove machine qualityEdge grinding machinesNon-mechanical blast generatorsAbrasive blastingEngineering

A device for surface blasting, e.g., for ultrasonic shot blasting, components, e.g., gas turbine components, includes at least one vibrator having an oscillating surface, e.g., having at least one ultrasonic sonotrode, the or each oscillating surface of the or each vibrator being adjoined by a machining chamber for receiving a section to be blasted of the component to be machined. The machining chamber is bounded in its cross-section by at least three sides, e.g., by at least two substantially vertical sides and by at least one substantially horizontal side. At least the substantially vertical sides of the machining chamber are formed by oscillating surfaces of in each case one vibrator.

Owner:MTU AERO ENGINES GMBH

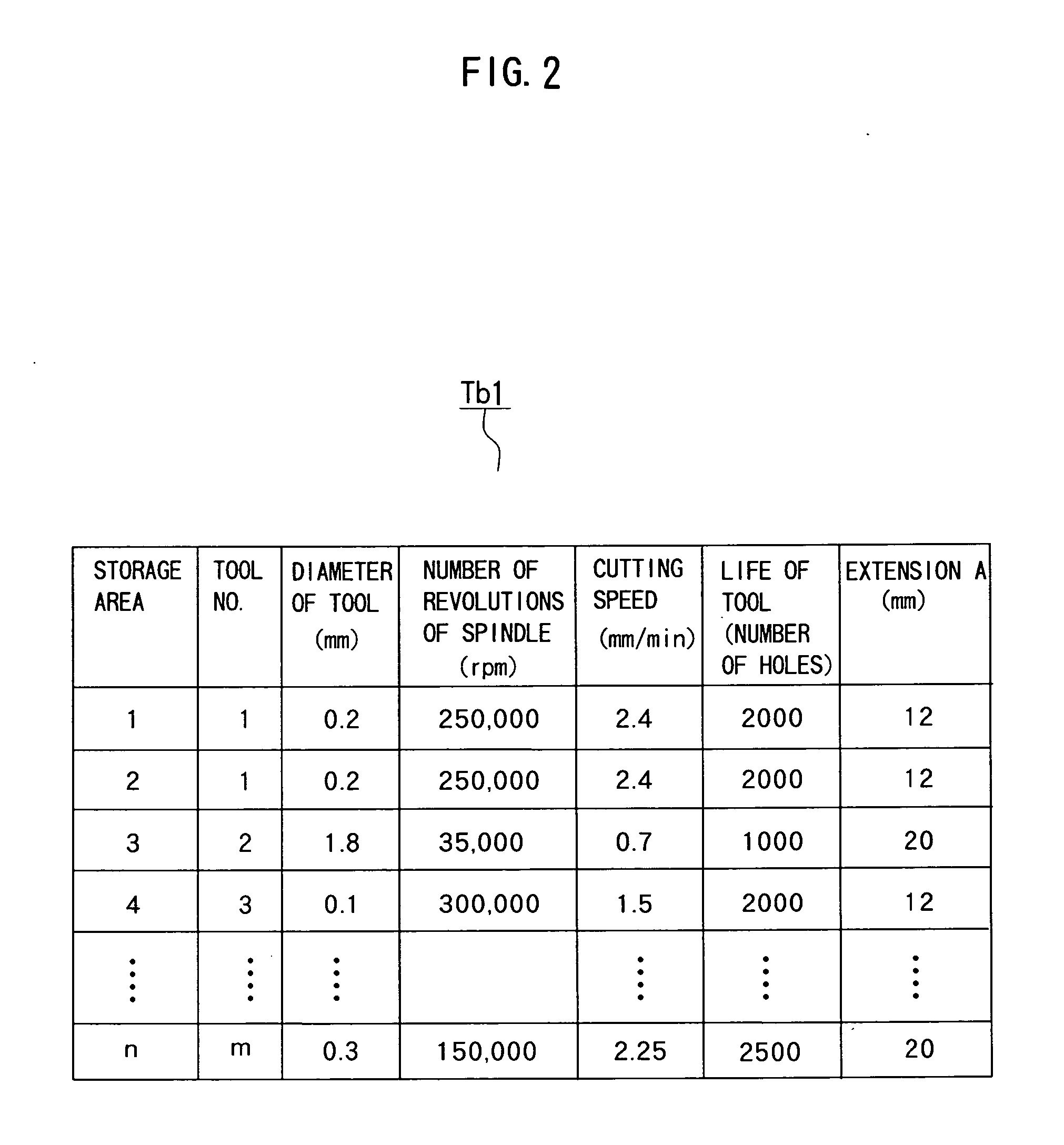

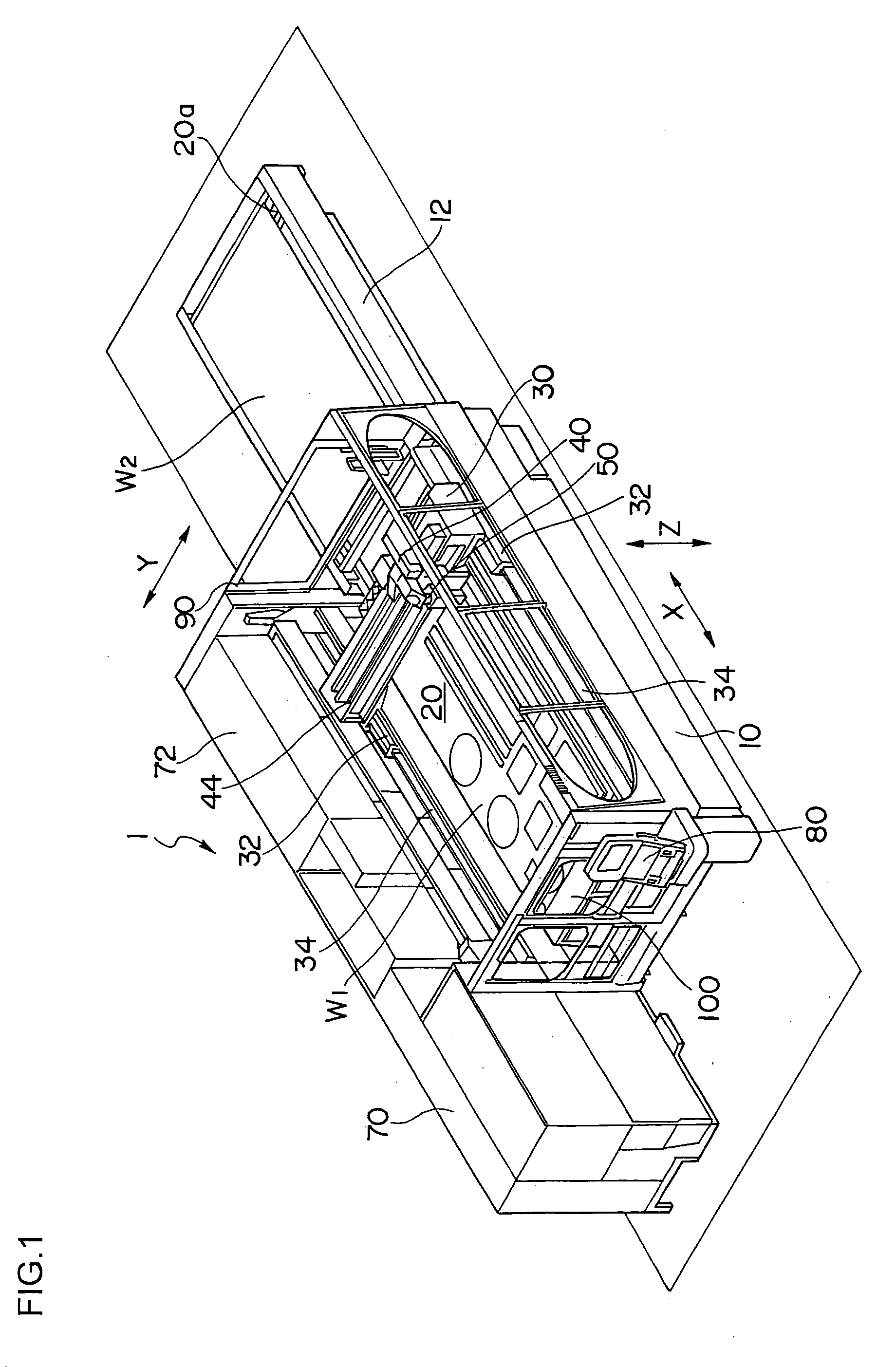

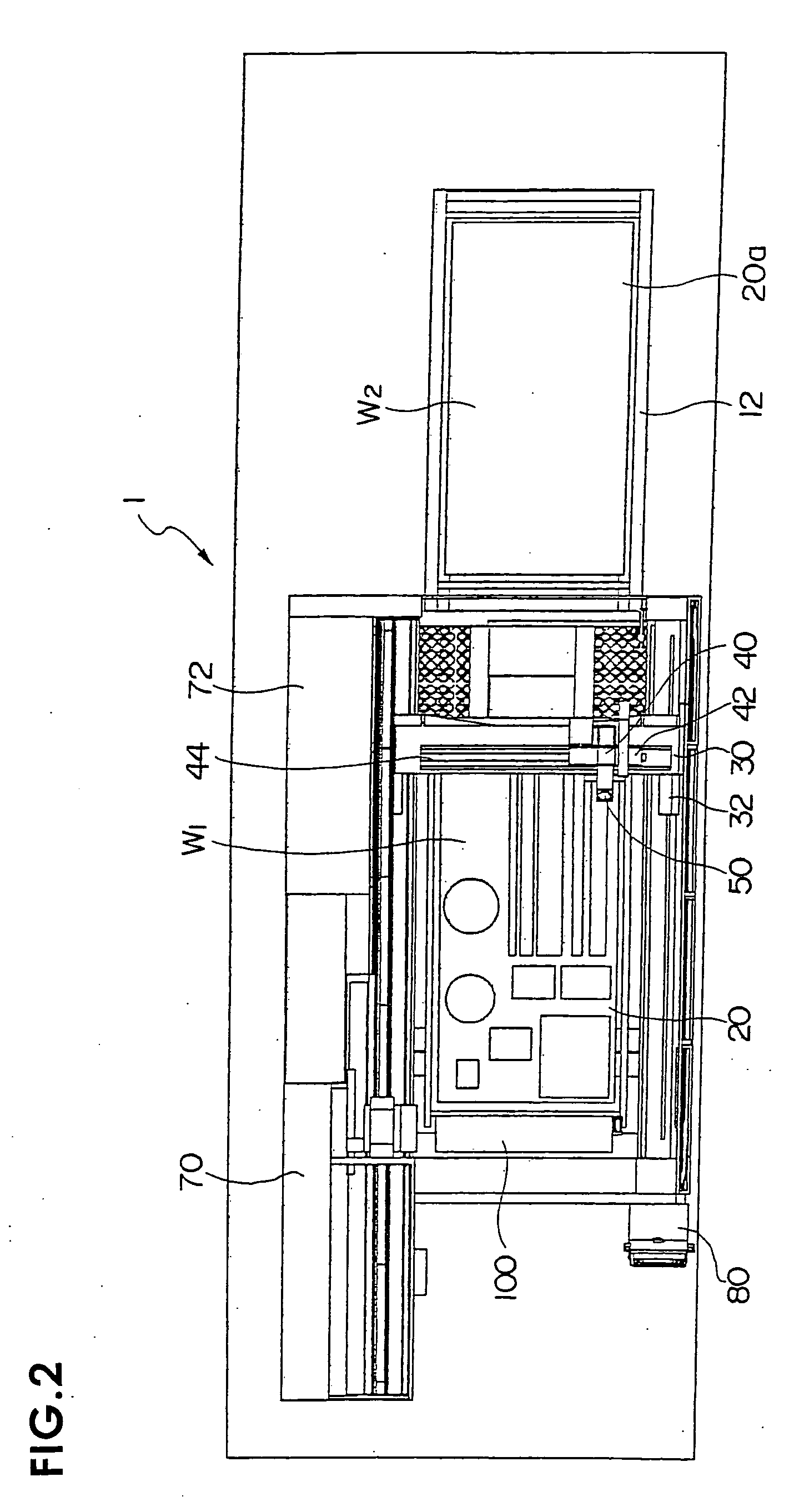

Printed board drilling method and printed board machining apparatus

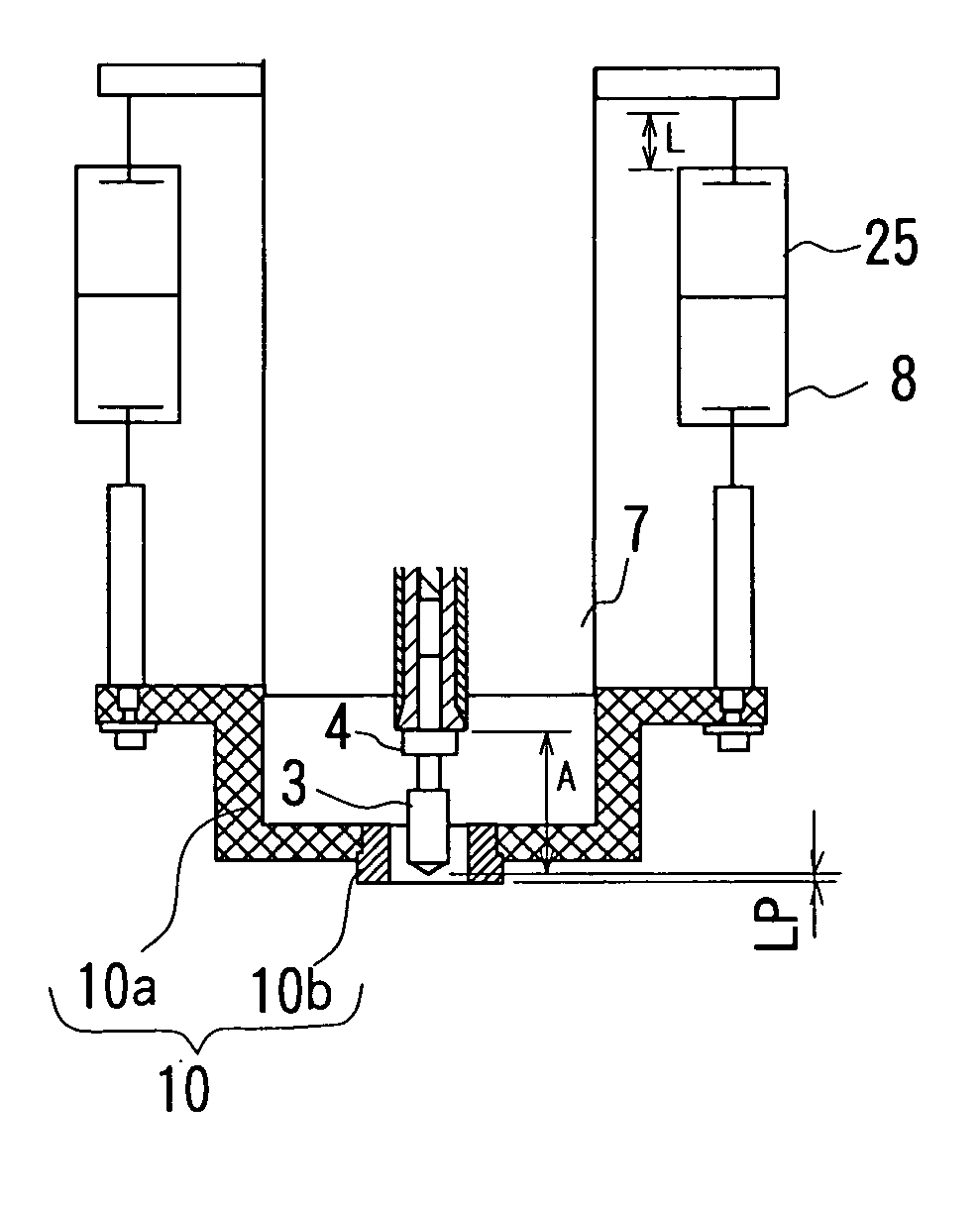

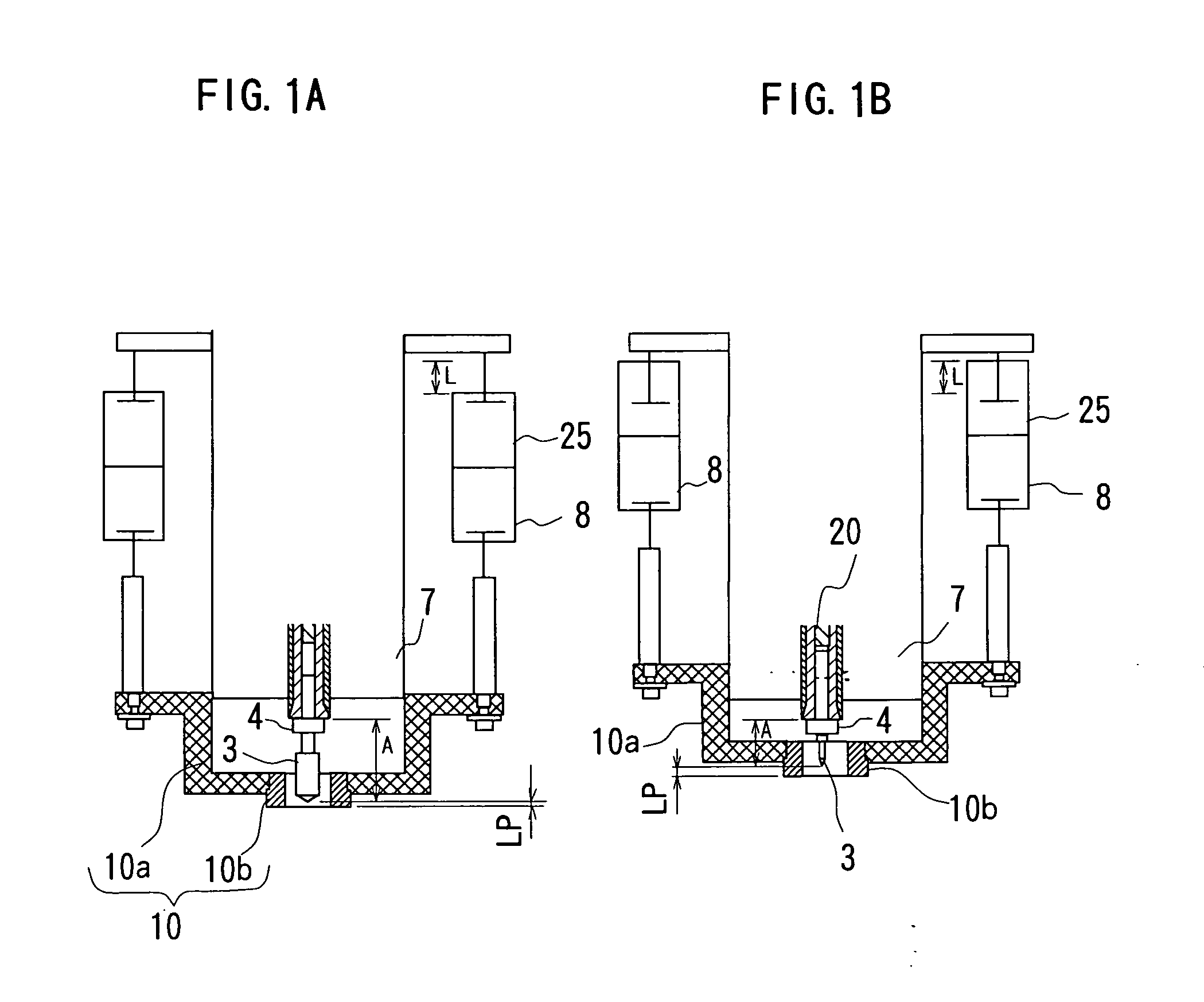

InactiveUS20050265797A1Improve machine qualityImprove work efficiencyAutomatic control devicesDrilling/boring measurement devicesEngineeringHole drilling method

There are provided a printed board drilling method and a printed board machining apparatus that are capable of improving machining quality, such positional accuracy of holes and true roundness of machined holes, and work efficiency by minimizing a runout of the tip of a drill. An extension of the drill extending out a spindle when the drill is held by the spindle is defined in advance per type or mode of use of each drill. One drill is selected among a plurality of drills corresponding to a shape of holes to be drilled in the printed board and the spindle is caused to hold the drill so that the selected drill extends out of the spindle by the extension corresponding to the selected drill. Then, the move of the spindle with respect to the printed board is controlled and the selected drill is rotationally driven by the spindle to drill the printed board.

Owner:HITACHI SEIKO LTD

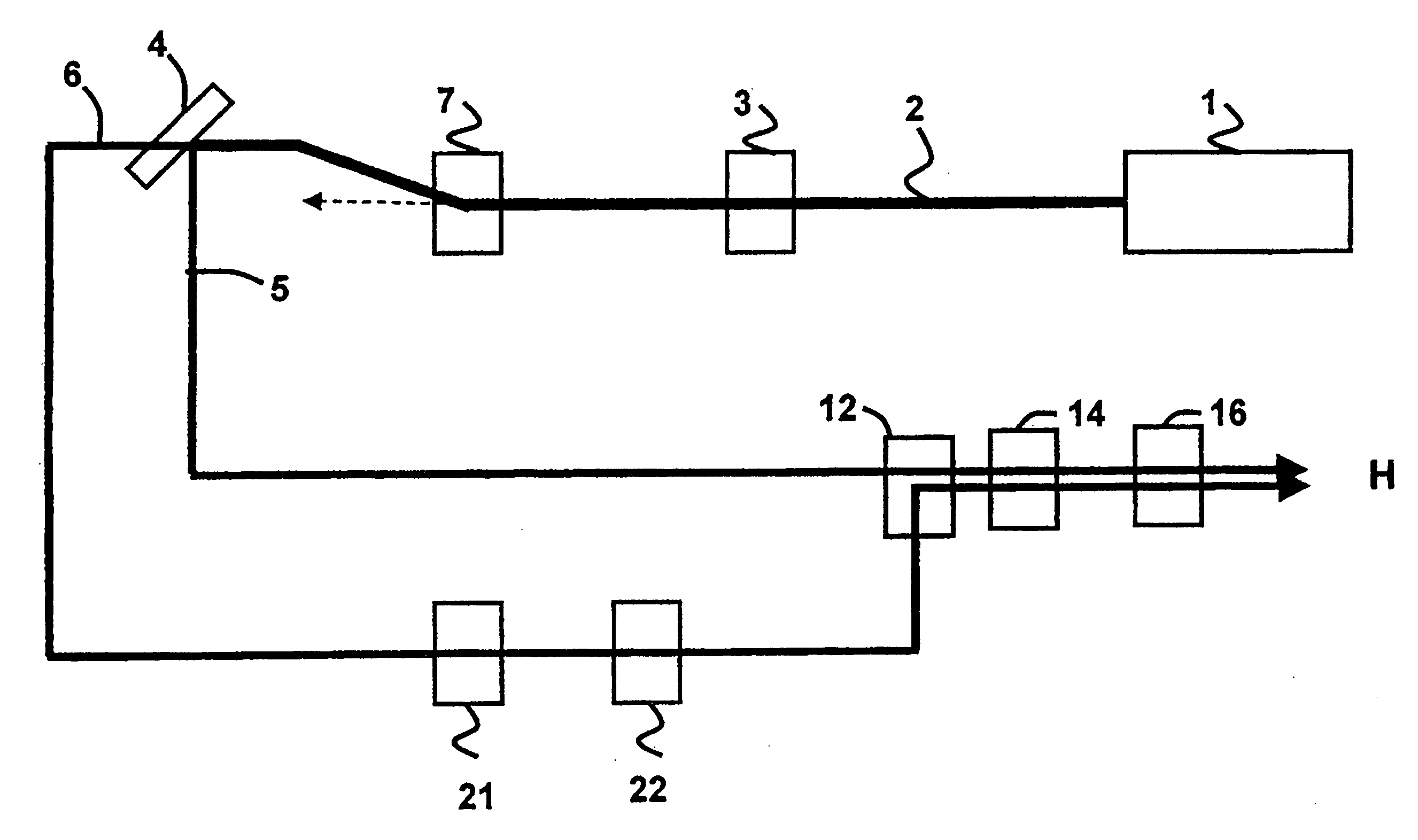

Laser machining method and laser machining apparatus

ActiveUS20070075059A1Quality improvementHeat inputLaser beam welding apparatusBeam splitterLaser processing

There is provided a laser machining method and a laser machining apparatus whose machining accuracy and quality excel without lowering machining efficiency. One hole is machined by a split beam that is a first pulsed laser beam and another split beam that is a second pulsed laser beam whose irradiation position is determined based on irradiation position of the first laser beam. In this case, the machining quality may be improved by machining the circular hole by equalizing circling directions and angular velocity of the split beams. A beam splitter splits a laser beam outputted out of one laser oscillator into the split beams and AOMs can time-share them.

Owner:HITACHI SEIKO LTD

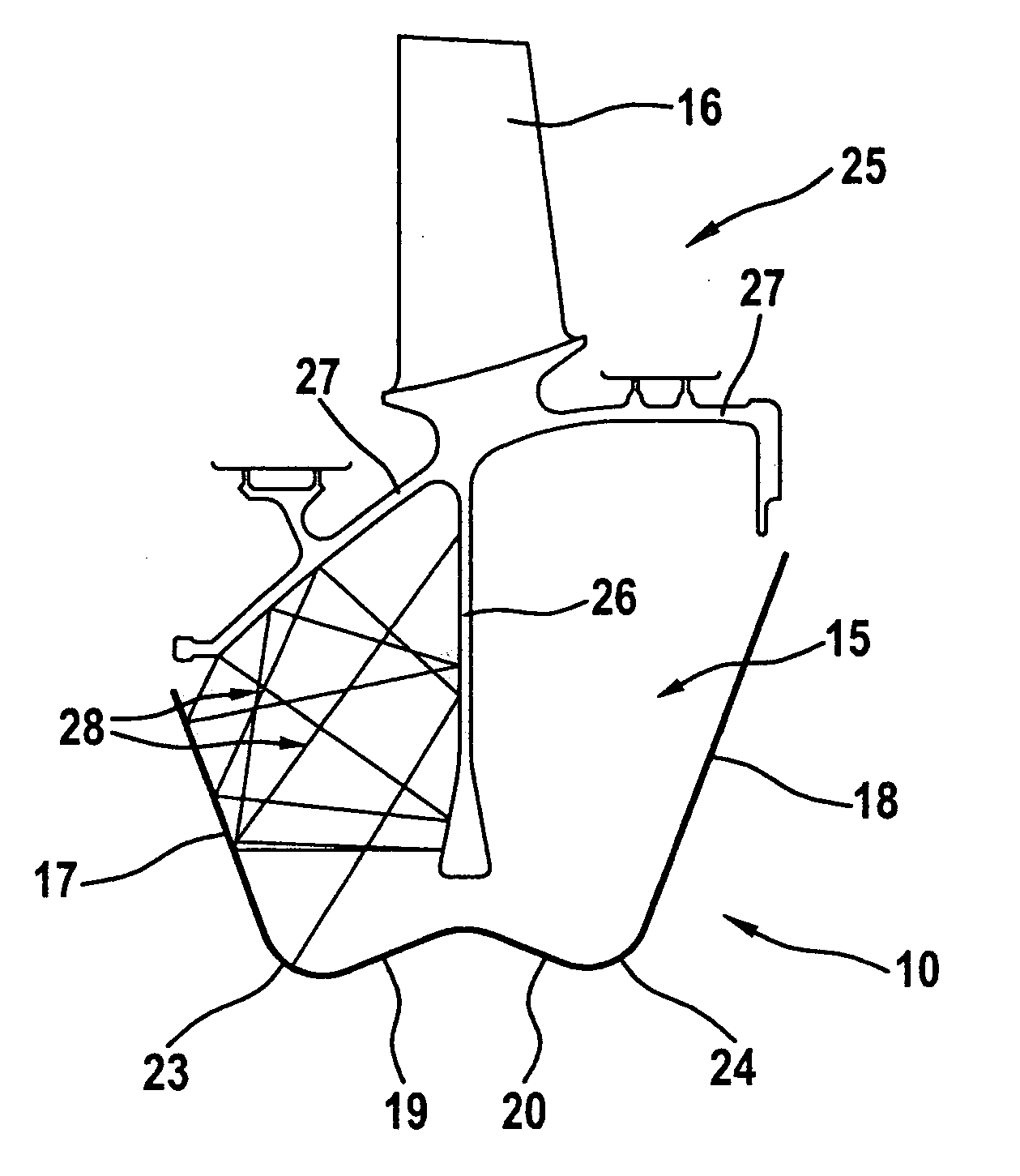

Device for surface blasting component

ActiveUS8091192B2Improve machine qualityImprove efficiencyEdge grinding machinesNon-mechanical blast generatorsAbrasive blastingMechanical engineering

A device for surface blasting, e.g., for ultrasonic shot blasting, components, e.g., gas turbine components, includes at least one vibrator having an oscillating surface, e.g., having at least one ultrasonic sonotrode, the or each oscillating surface of the or each vibrator being adjoined by a machining chamber for receiving a section to be blasted of the component to be machined. The machining chamber is bounded in its cross-section by at least three sides, e.g., by at least two substantially vertical sides and by at least one substantially horizontal side. At least the substantially vertical sides of the machining chamber are formed by oscillating surfaces of in each case one vibrator.

Owner:MTU AERO ENGINES GMBH

Nozzle checker for laser beam machine

InactiveUS20050263510A1Improve machine qualityQuality improvementOptically investigating flaws/contaminationLaser beam welding apparatusProtective glassesOptoelectronics

The invention provides a device which optically checks a nozzle tip of a laser machining tool. A camera unit 450 which is raised and lowered in opposing relation to a nozzle 65 of a laser beam machine has a camera chamber 454 and is sealed by protective glass 456, where the camera chamber 454 contains a CCD camera body 460 and lens 462. While a ring light 470 illuminates a surface of the nozzle 65, the CCD camera body 460 checks the nozzle 65 optically.

Owner:YAMAZAKI MAZAK KK

Self-feed differential planet flat turn disc

InactiveCN101279381AAvoid precisionSolve the precision problemBoring/drilling componentsAttachable boring/drilling devicesLinear motionReliable transmission

The invention relates to a self-feed differential planetary horizontal rotating disk, which can effectively solve the radial feed accuracy of a boring machine and improve the mechanical processing quality problem; the structure thereof is that: a boring and milling shaft is connected with the horizontal rotating disk by an end-surface key, the horizontal rotating disk and the boring and milling shaft simultaneously rotate, the boring and milling shaft is externally provided with a fixed wheel gear to be meshed with a planetary gear on the horizontal rotating disk, the fixed wheel gear and the planetary gear have the teeth difference, the rotation drives the planetary gear to rotate, the planetary gear is arranged on a planetary driving gear shaft, a driving gear is arranged on the same shaft, the driving gear is meshed with a driven gear on a worm drive shaft, a coaxial worm is arranged on the worm drive shaft, the coaxial worm is connected with a worm wheel, a worm is arranged on the worm wheel, a drive sliding plate is arranged on the horizontal rotating disk, a worm strip is arranged on the sliding plate, the worm is connected with the worm strip, the worm wheel drives the worm to rotate, thus driving the worm strip on the sliding plate to do the radial linear motion; the self-feed differential planetary horizontal rotating disk has simple structure, reliable transmission and convenient usage, which is a creation on the processing by a mechanical machine and has great economic benefits.

Owner:宋保通

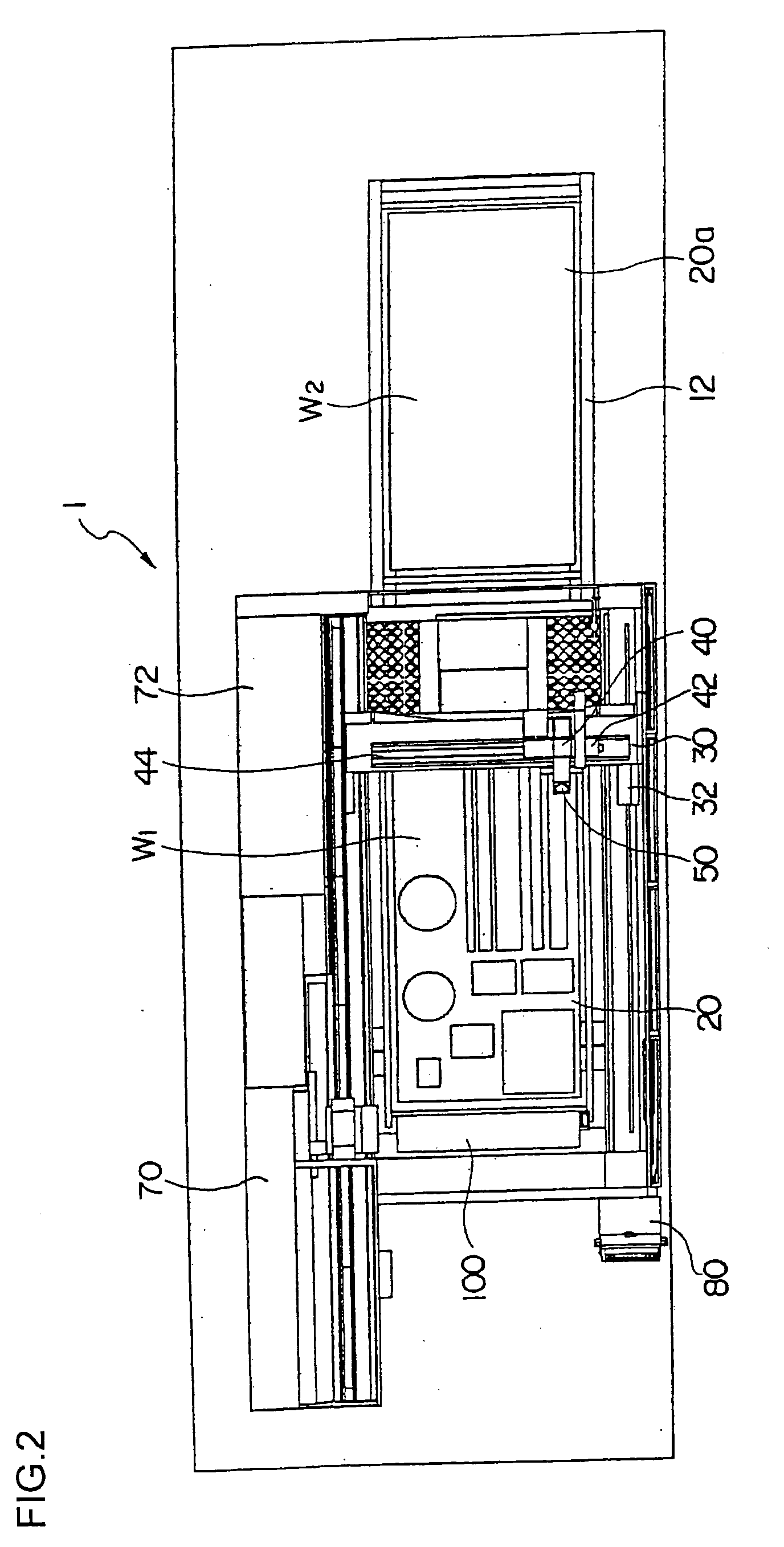

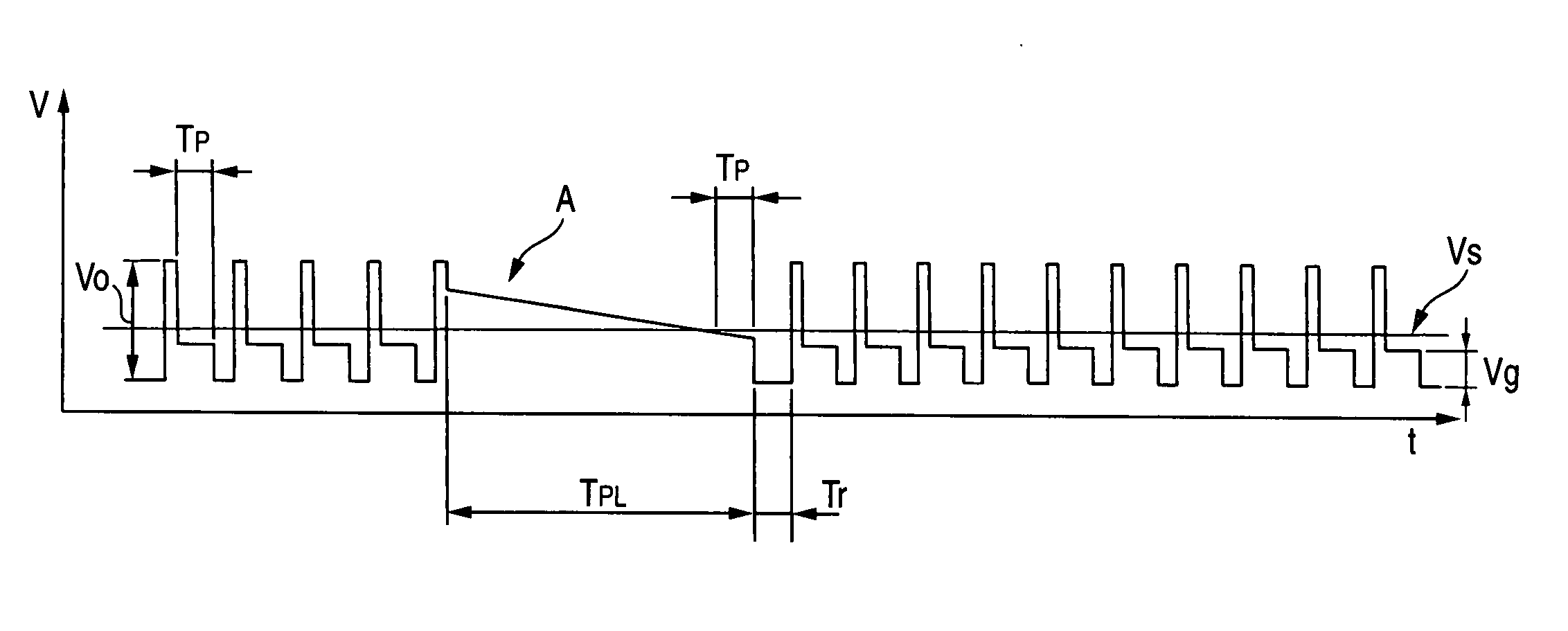

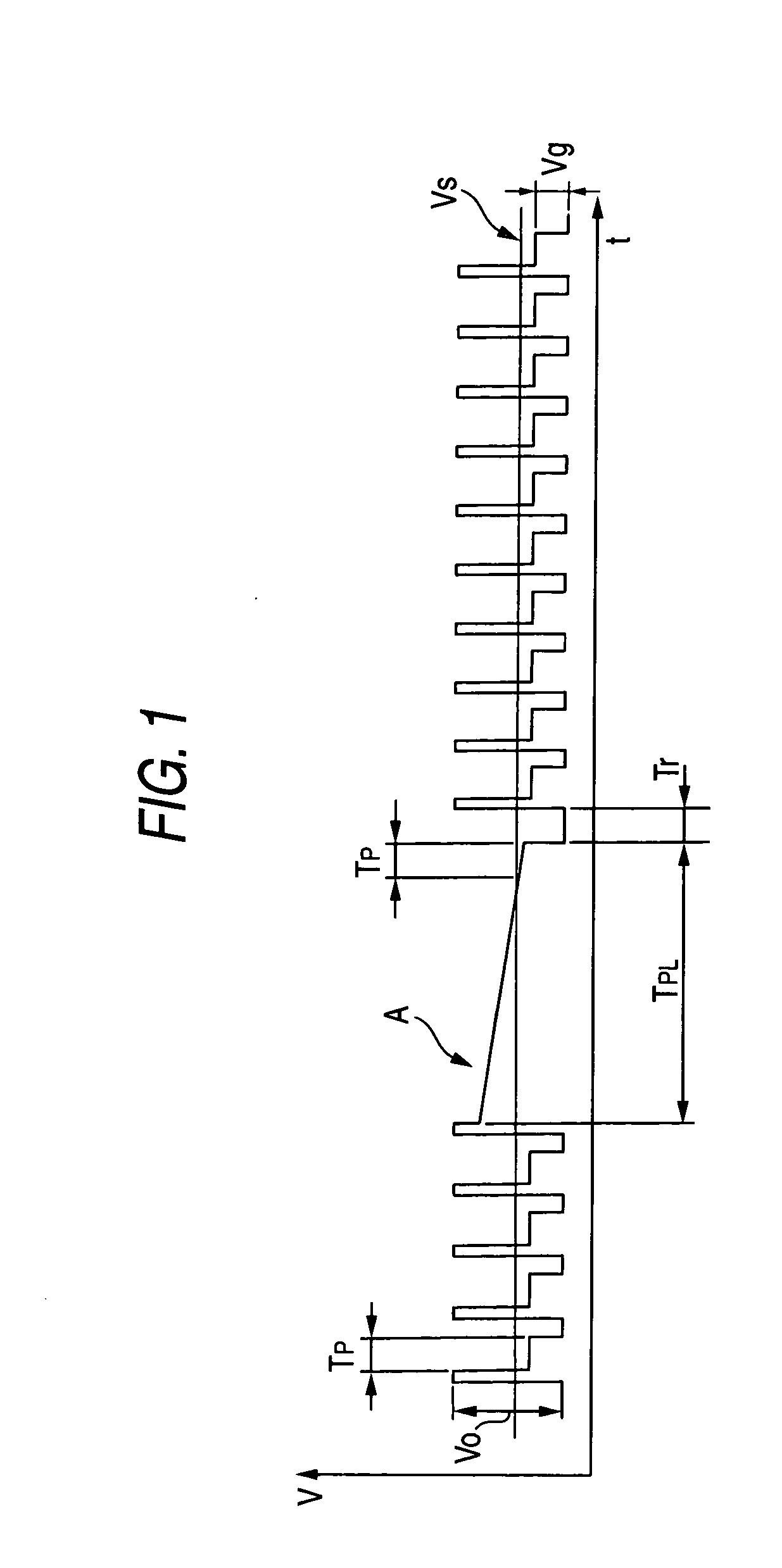

Method and system for electric discharge machining insulating material or high resistance material

InactiveUS20050098541A1Stably machining a workpieceImprove machined surface qualityArc welding apparatusElectric circuitsHigh resistanceElectrical resistance and conductance

An electric discharge machine for machining a workpiece (2a) made of insulating material or other materials comprises: a first comparison member (17) for comparing voltage (V) between the electrodes of the electrode (1) and the workpiece (2a) with the first reference voltage (V1) which is set at a value close to electric power source voltage (V0) not higher than electric power source voltage (V0); a second comparison member (18) for comparing voltage (V) between the electrodes with the second reference voltage (V2) which is set at a value lower than the first reference voltage (V1); and a control member (19) for setting a short electric discharge pulse width (TP1) in the case where voltage (V) between the electrodes is lower than the second reference voltage (V2) according to the result of comparison conducted by the second comparison member (18) at a point of time when a predetermined period of time (T0) has passed from the time when voltage (V) between the electrodes becomes lower than the first reference voltage (V1) according to the result of comparison conducted by the first comparison member (17), and for setting a long electric discharge pulse width (TP2) in the case where the voltage between the electrodes is higher than the second reference voltage (V2). This electric discharge machine is capable of stabilizing the machining of the workpiece (2a) made of insulating material or other materials and also capable of enhancing quality of a machined face.

Owner:MITSUBISHI ELECTRIC CORP +1

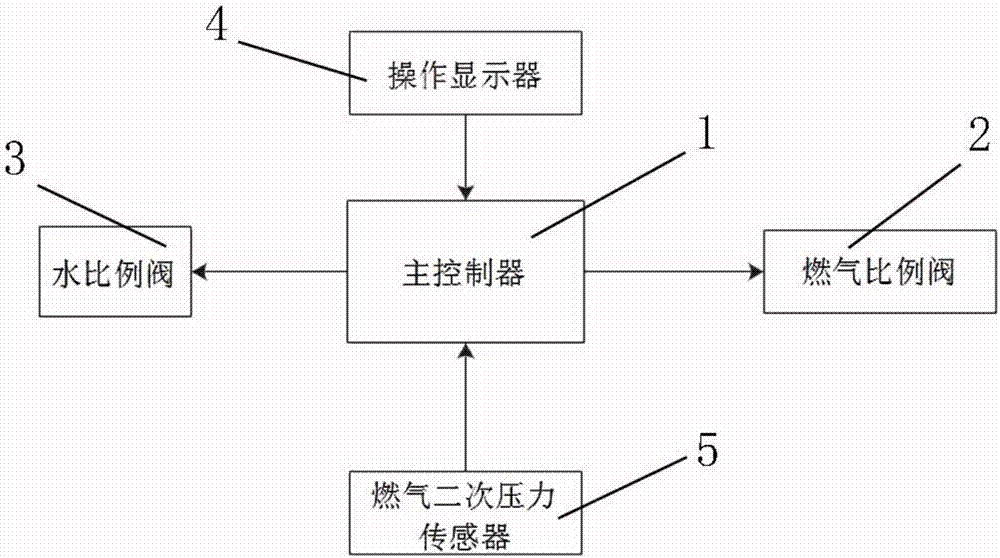

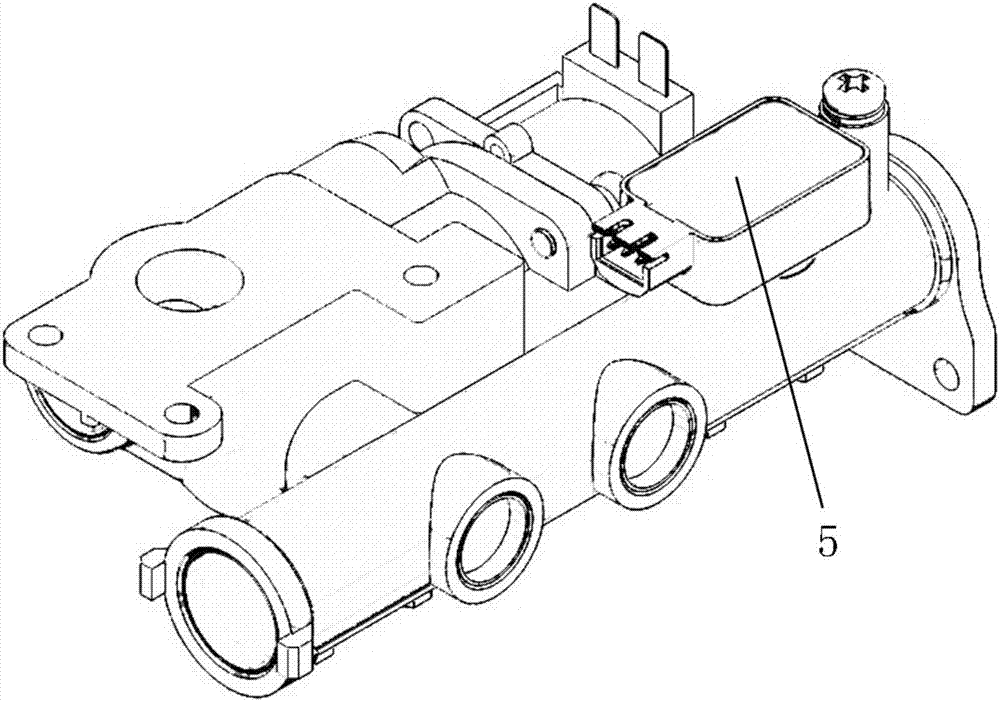

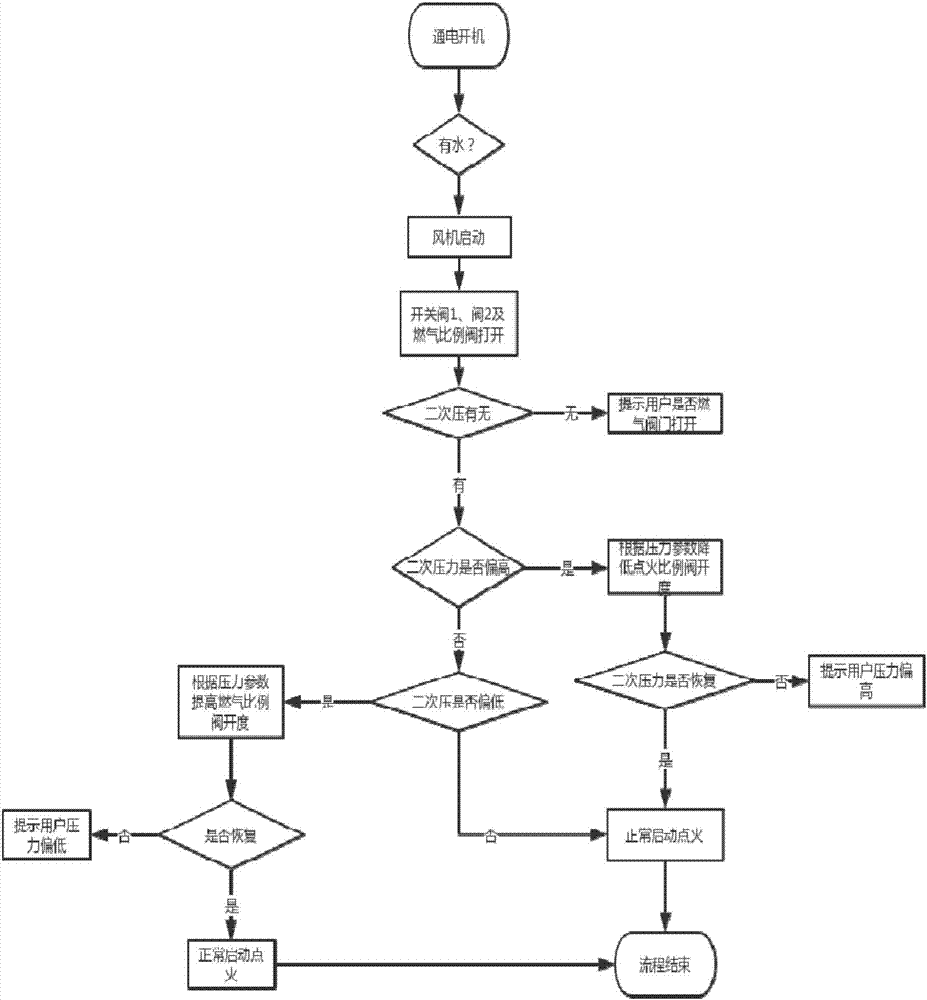

Gas water heater control system conducting adjustment according to gas secondary pressure

PendingCN106940090AEffective closeAvoid adding points of failureFluid heatersThermodynamicsControl system

The invention discloses a gas water heater control system conducting adjustment according to gas secondary pressure. The gas water heater control system comprises a master controller, and further comprises a secondary pressure sensor, a gas proportional valve and an operation display, all of which are connected with the master controller. The secondary pressure sensor is arranged behind functions of two switch stop valves of a square pipe and used for detecting gas secondary pressure, and the master controller stores gas secondary pressure values corresponding to different load states of a gas water heater. Under a certain load state, when it is detected that the secondary pressure is too high, the master controller controls the aperture of the gas proportional valve to be reduced; when the secondary pressure is too low, the master controller controls the aperture of the gas proportional valve to be increased; and when the secondary pressure is not detected, a user is reminded of whether a gas valve is opened or not through the operation display. According to the gas water heater control system conducting adjustment according to the gas secondary pressure, the secondary pressure sensor is additionally arranged behind the functions of the two switch stop valves of the square pipe, introducing of new device newly-increased fault points is avoided, and when gas leakage happens by accident, it can be guaranteed that a gas passageway is effectively closed.

Owner:GUANGDONG MACRO GAS APPLIANCE

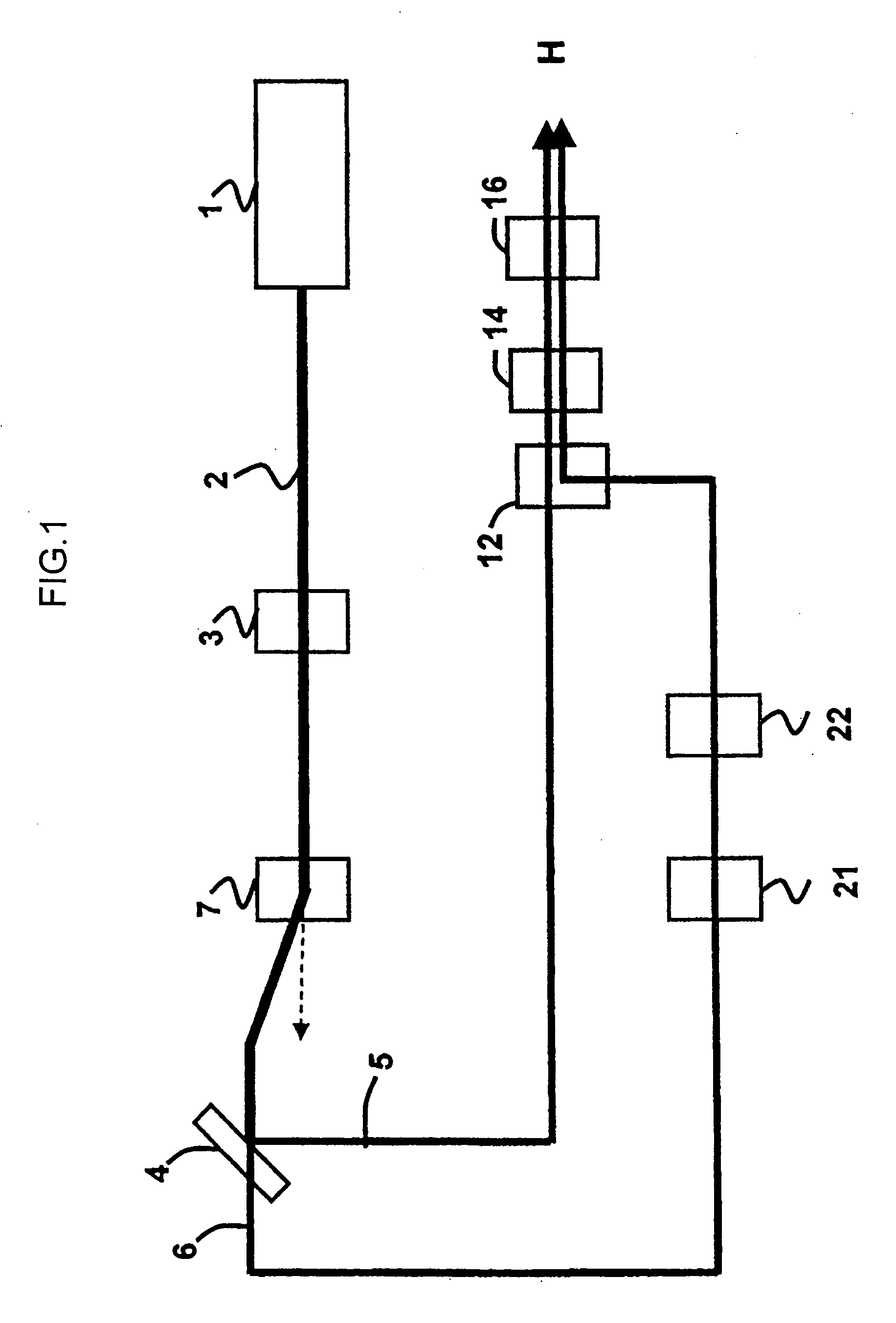

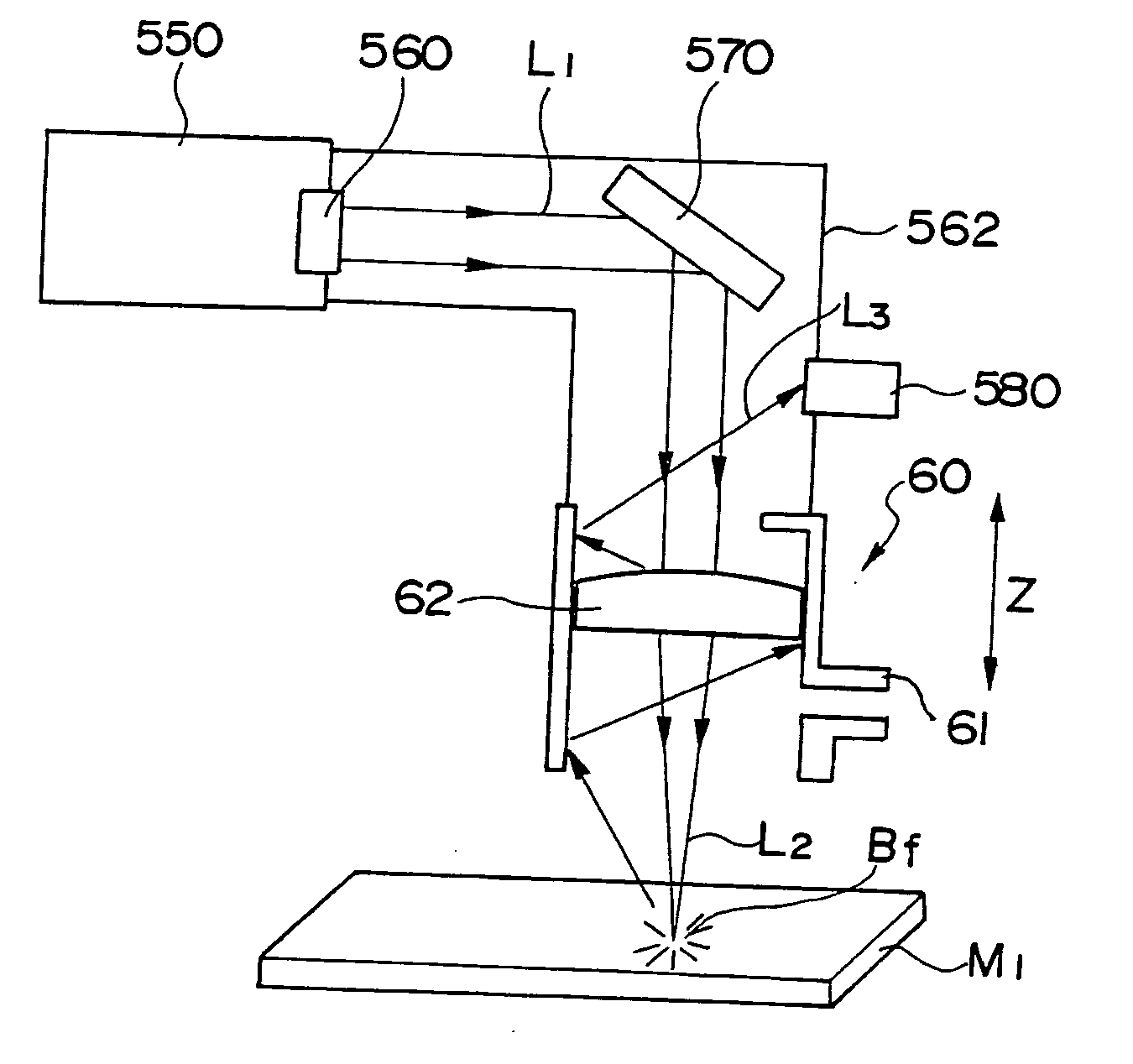

Focus adjuster for laser beam machine

ActiveUS20050263507A1Improve machine qualityLong operationLaser beam welding apparatusFocal positionOptoelectronics

The invention provides a focus adjuster for laser beam machine which adjusts focus by detecting reflected light of a laser beam in a laser beam machine. A laser beam outputted from a laser oscillator device 550 is reflected by a mirror 570 via an output mirror 560 and introduced into a laser machining tool. The laser beam collected by a machining lens 62 is reflected by a reflector plate M1 and sensed by a reflection detector 580. Automatic focus adjustment is achieved by sensing output of the reflected light as well as changes in focal position due to contamination of the machining lens 62.

Owner:YAMAZAKI MAZAK KK

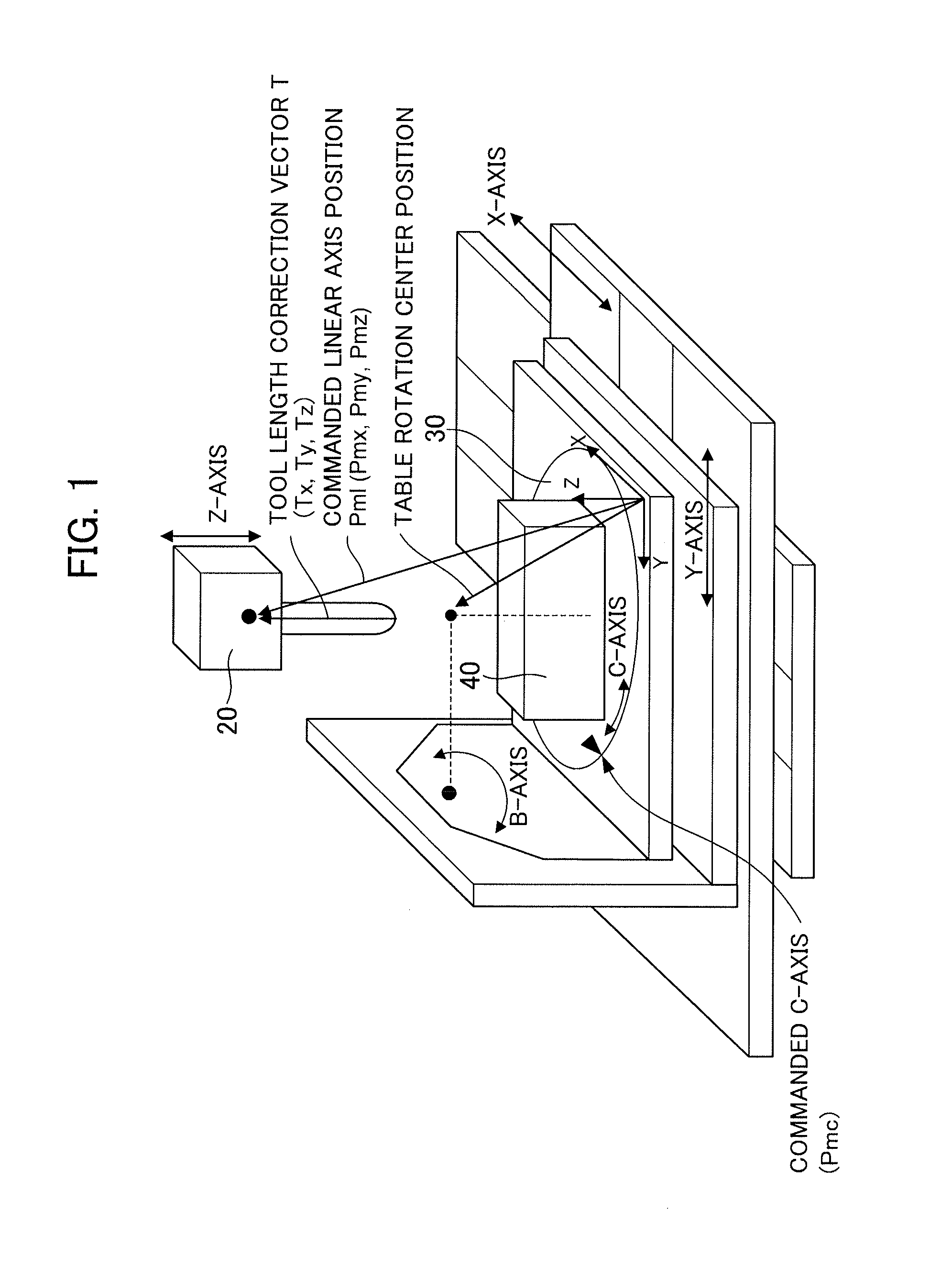

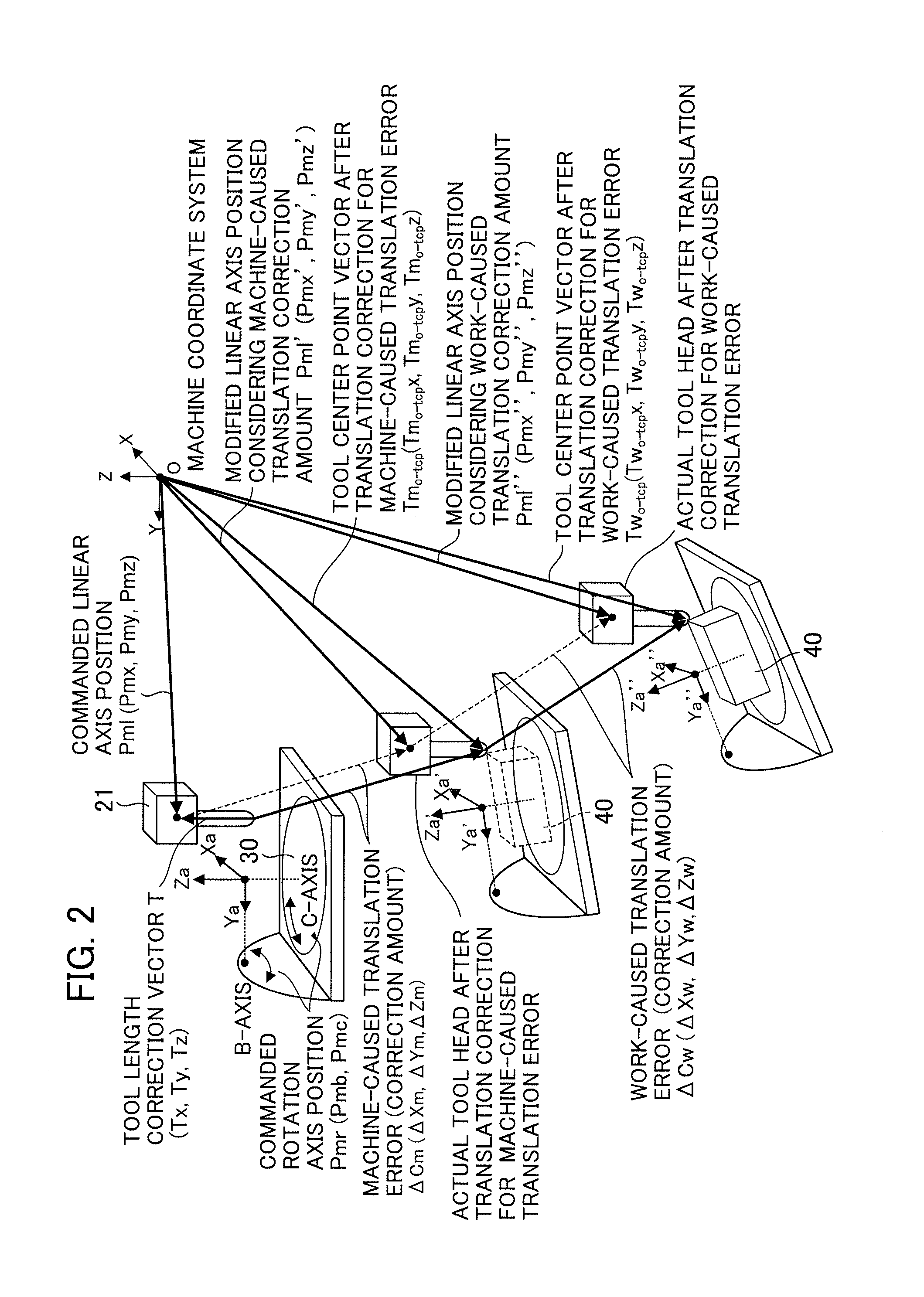

Numerical controller provided with function of correcting displacement error caused by work

ActiveUS20150177727A1Improve qualityImprove accuracySpecial data processing applicationsNumerical controlDisplacement errorTranslation error

A numerical controller uses a work lattice region setting unit and a rotation axis work lattice region setting unit to form lattice points for error correction and uses a work-caused translation correction amount setting unit to set a correction amount of a work-caused translation error. A work-caused translation correction amount calculation unit calculates a correction amount at a tool center point position, and a correction section of the numerical controller adds the work-caused translation correction amount to positions of three commanded linear axes for error correction.

Owner:FANUC LTD

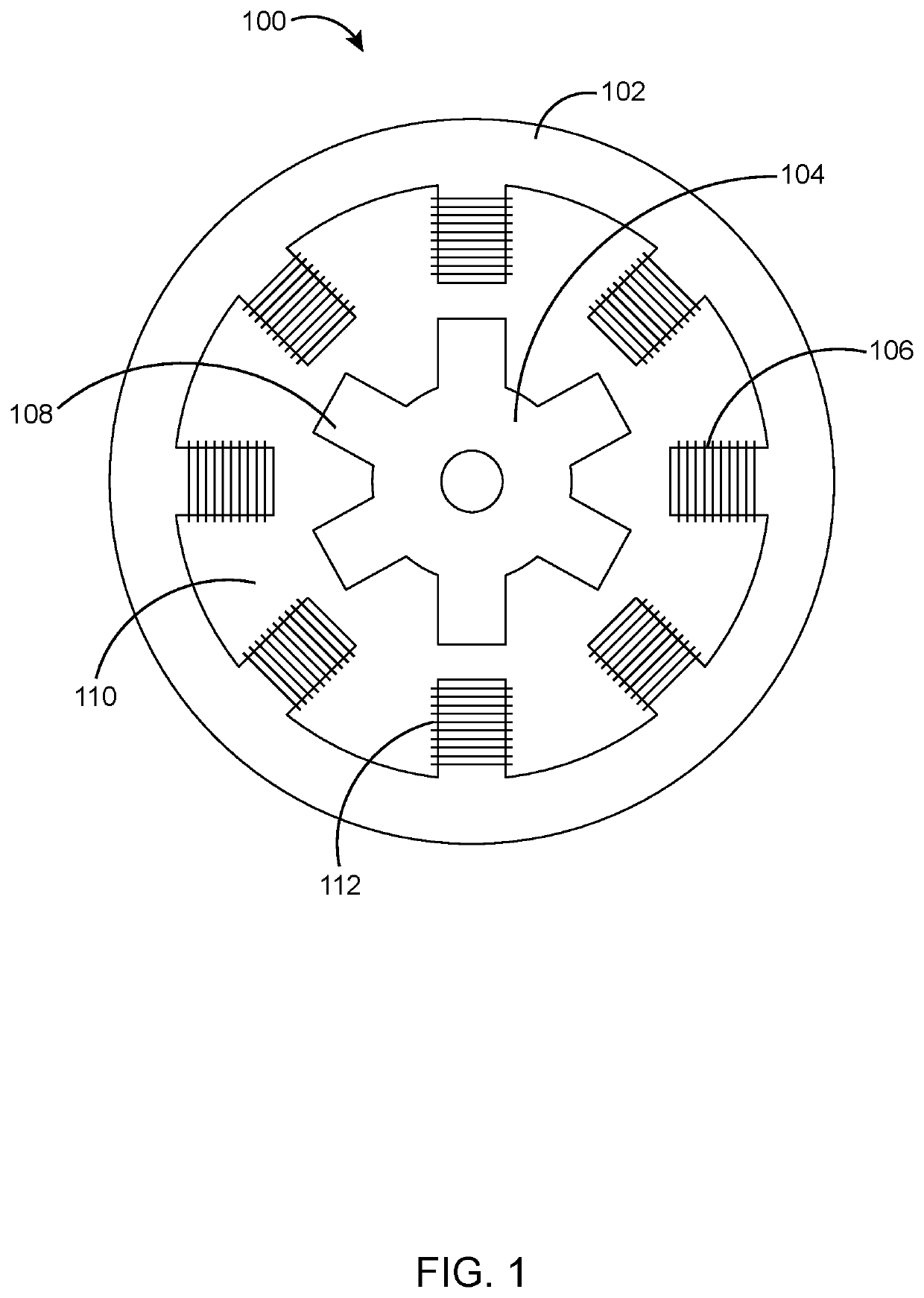

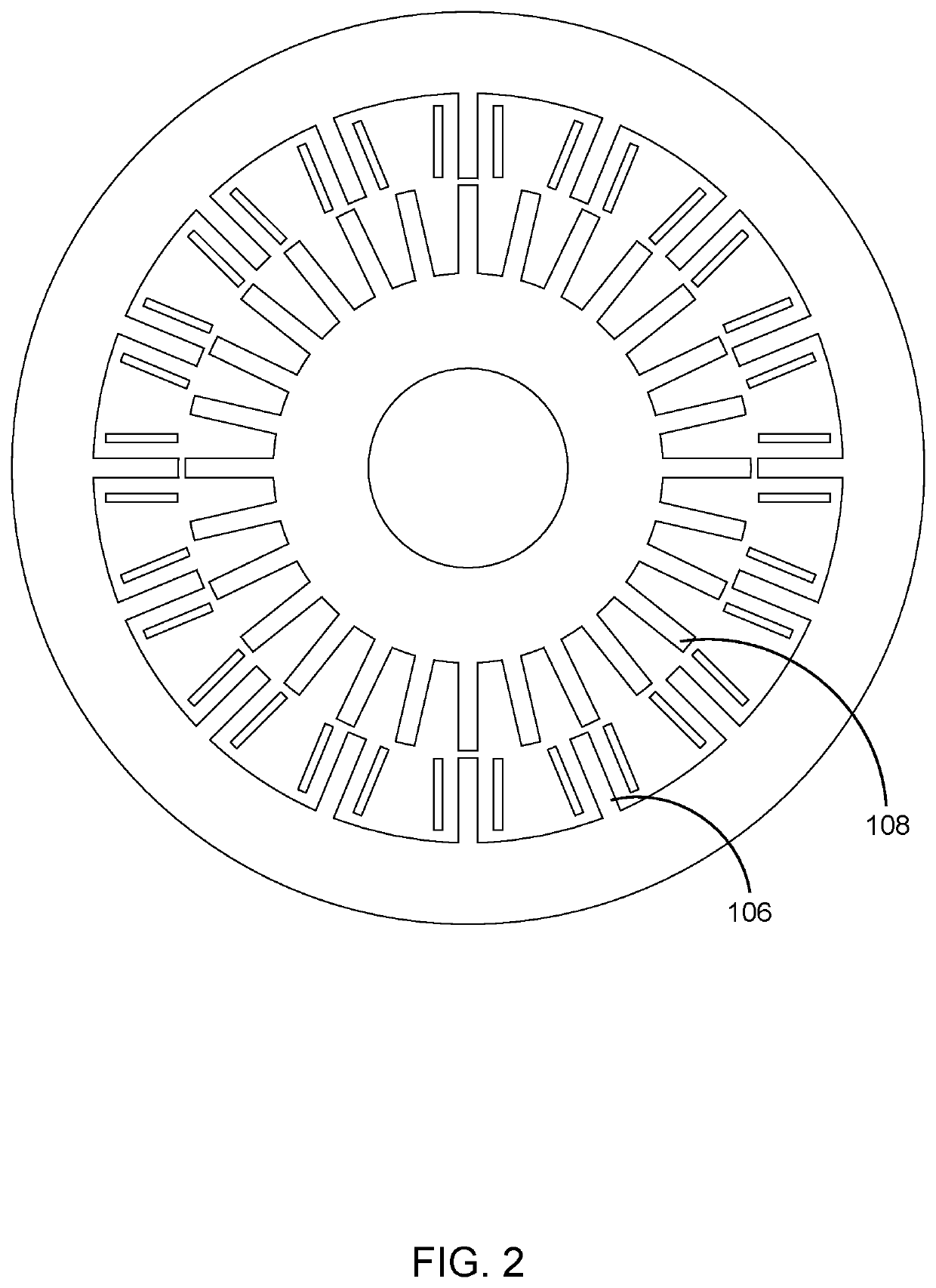

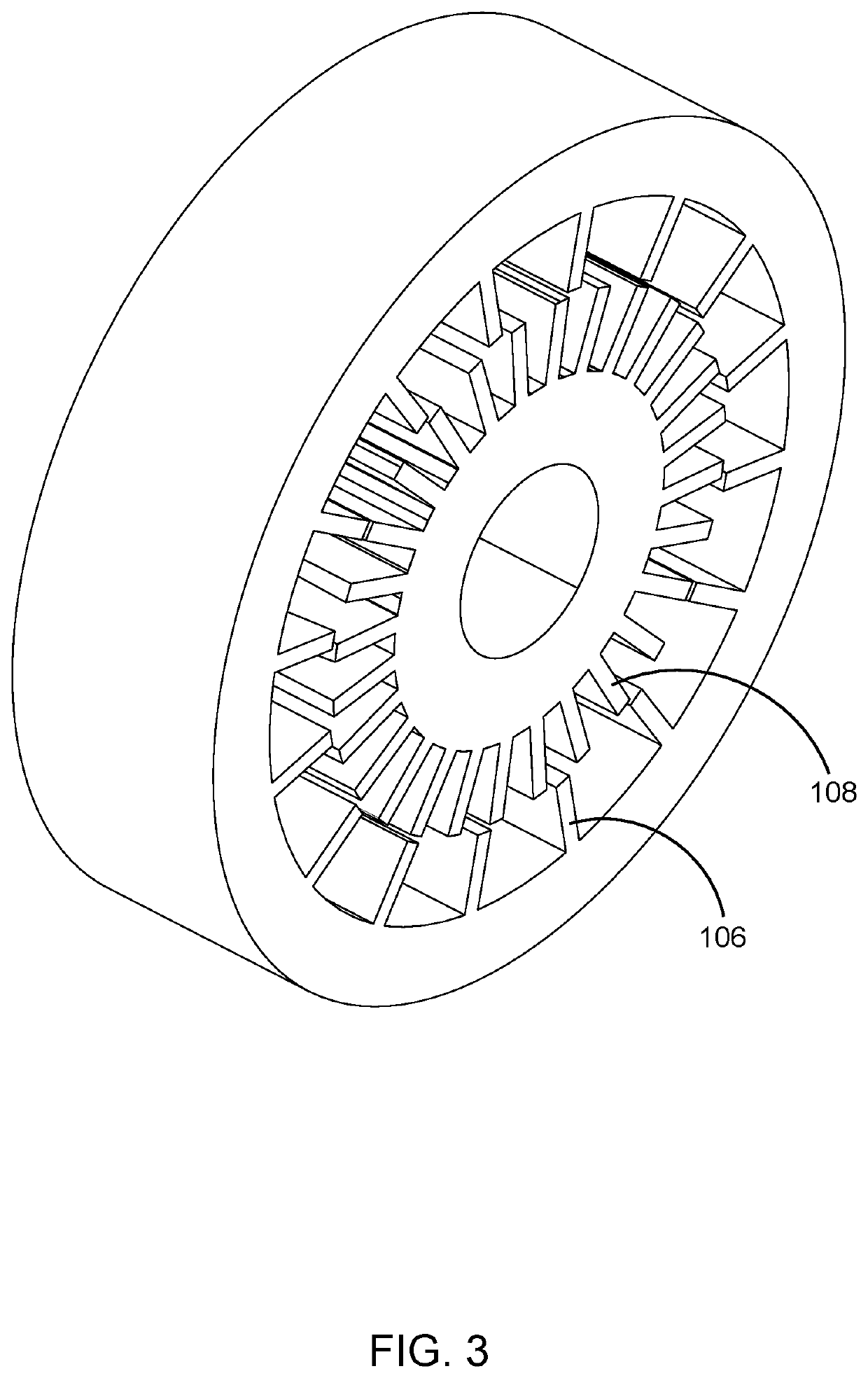

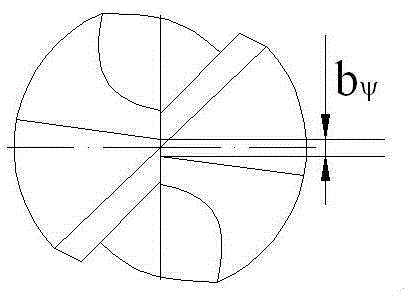

Low-noise, high rotor pole switched reluctance motor

ActiveUS10707798B2Minimal amountSmoother torque profileAC motor controlMagnetic circuitElectric machineMagnetic reluctance

The present embodiment is a high rotor pole switched reluctance machine (HRSRM) which provides a plurality of combinations of the number of rotor poles Rn and number of stator poles Sn utilizing a numerical relationship defined by a mathematical formula, Rn=2Sn−Fp, when Sn=m×Fp, wherein Fp is the maximum number of independent flux paths in the stator when stator and rotor poles are fully aligned, and m is the number of phases. The mathematical formulation provides an improved noise performance and design flexibility to the machine. The mathematical formulation further provides a specific number of stator and rotor poles for a chosen m and Fp. The HRSRM can be designed with varying number of phases. The HRSRM provides a smoother torque profile due to a high number of strokes per revolution.

Owner:TURNTIDE TECH INC

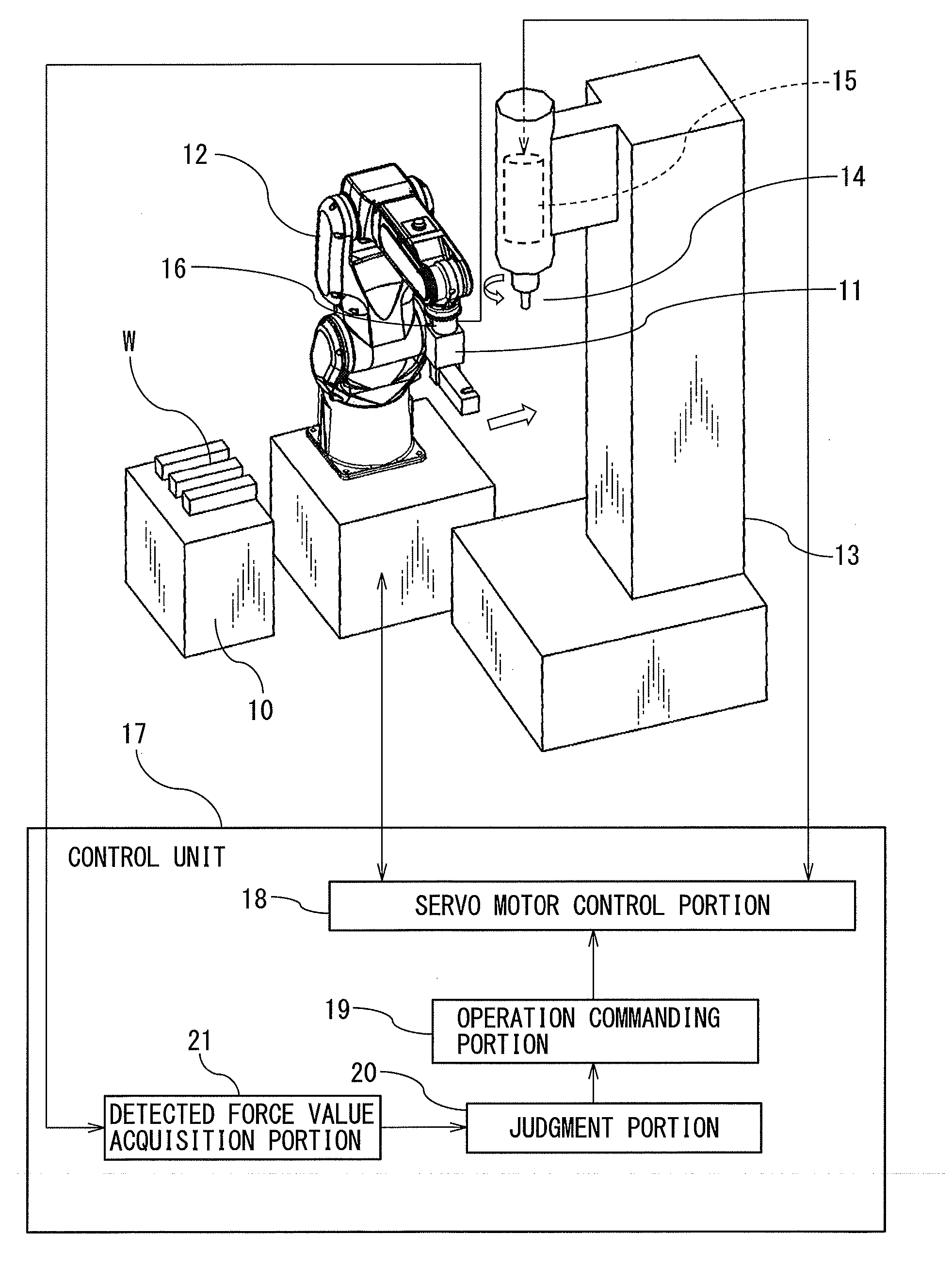

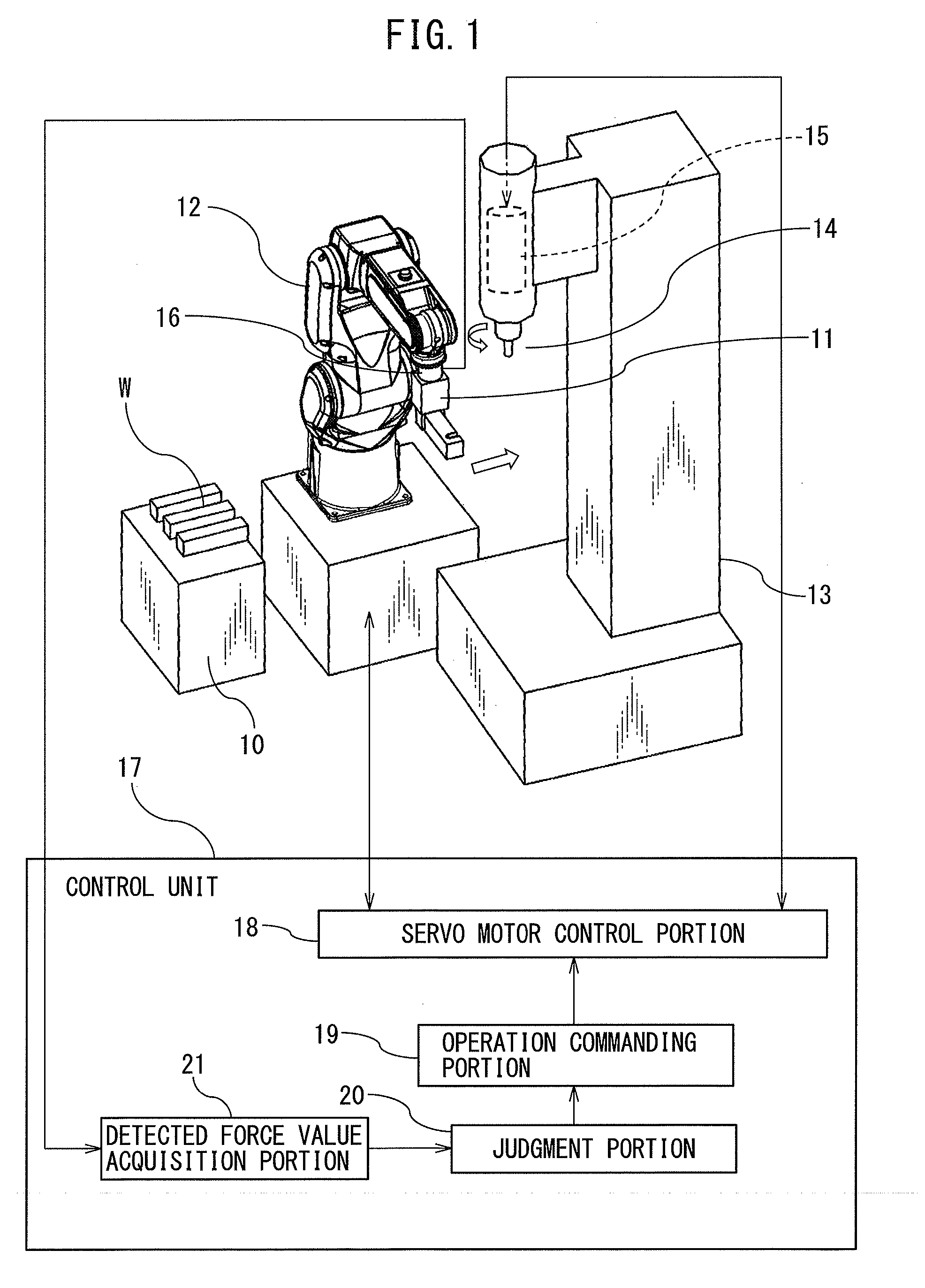

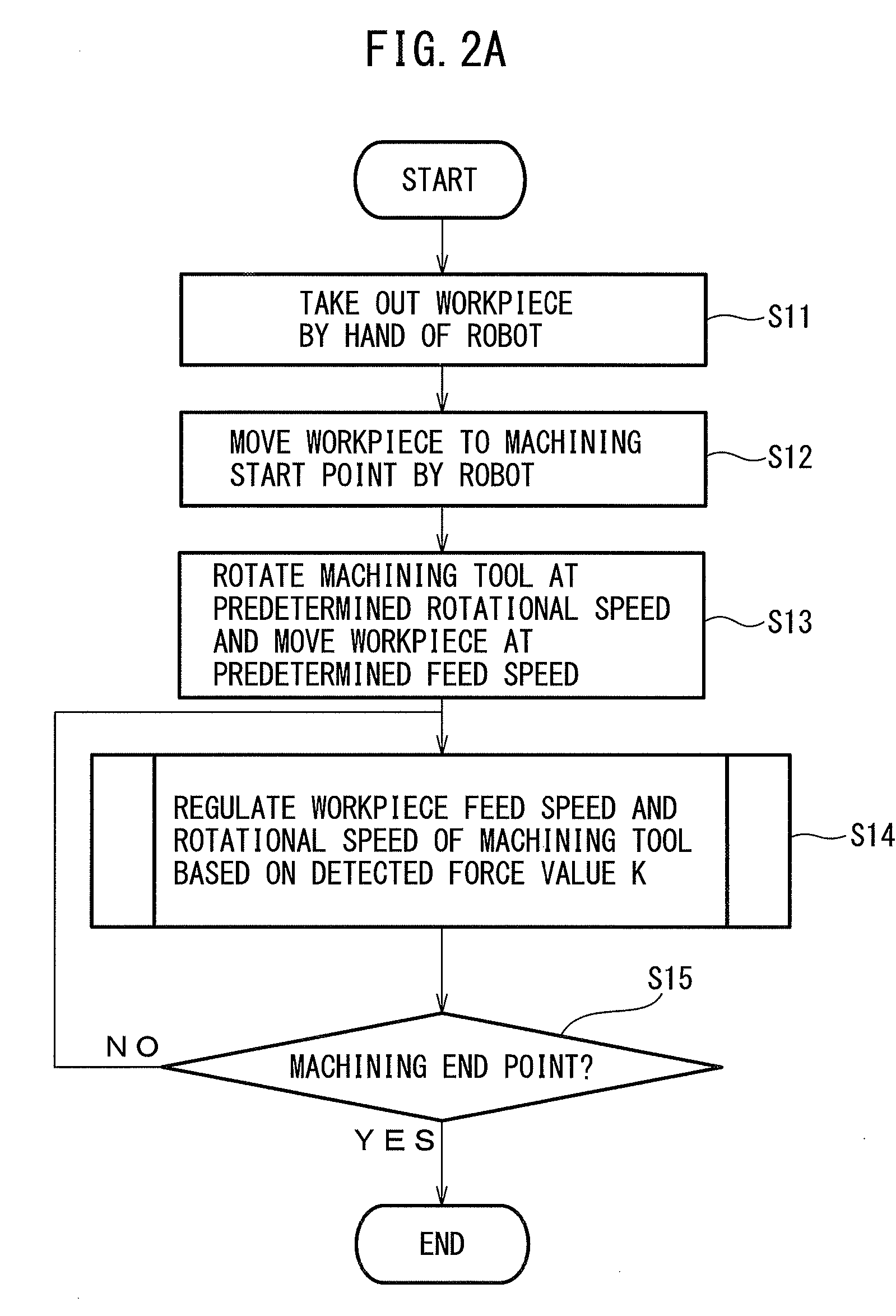

Machining system for adjusting number of revolutions of machining tool and feed speed of workpiece

ActiveUS20160332273A1Improve machine qualityQuality improvementProgramme controlProgramme-controlled manipulatorEngineeringLower threshold

A machining system of the present invention includes a robot having a hand, a processing machine to rotate a machining tool, a control unit which controls the processing machine and the robot so as to rotate the machining tool and press a workpiece held by the hand against the machining tool to thereby machine the workpiece, and a force sensor which detects force acting between the workpiece and the machining tool when the workpiece is pressed against the machining tool by the robot and is machined by the machining tool. The control unit regulates the workpiece feed speed of the robot and the rotational speed of the machining tool so that the force value detected by the force sensor is between a predetermined upper threshold and a predetermined lower threshold.

Owner:FANUC LTD

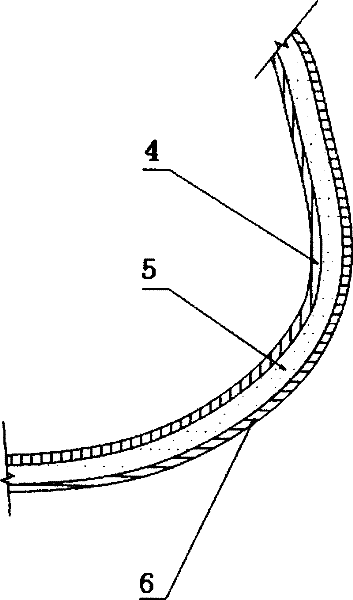

Engine fairing

InactiveCN102501977AImprove fitImprove reliabilityAircraft power plant componentsEconomic benefitsDry heat

The invention belongs to the field of power devices of helicopters, and relates to a detachable engine fairing of a helicopter and heat-insulation plates of the detachable engine fairing. The heat-insulation plates are respectively mounted on the left side and the right side of the engine fairing, each heat-insulation plate consists of an inner skin, a heat-insulation material and an outer skin, the inner skins and the outer skins are made of stainless steel, and black natural-dry heat-resistant paint is coated on outer surfaces of the inner skins and the outer skins. The engine fairing and the heat-insulation plates have excellent fitting property and reliability, and realize an excellent heat-insulation effect, requirements on temperature of the fairing are met, long-term problems of bulging, layering, even scorching and the like of an existing engine fairing due to the fact that the engine fairing contacts with high-temperature areas for a long time are solved, the integral quality of the helicopter is greatly improved, attendance rate of the helicopter is guaranteed, simultaneously, time and expenditure for maintaining the helicopter in an external field and replacing the engine fairing are saved, and the engine fairing has a remarkable economic benefit.

Owner:HARBIN

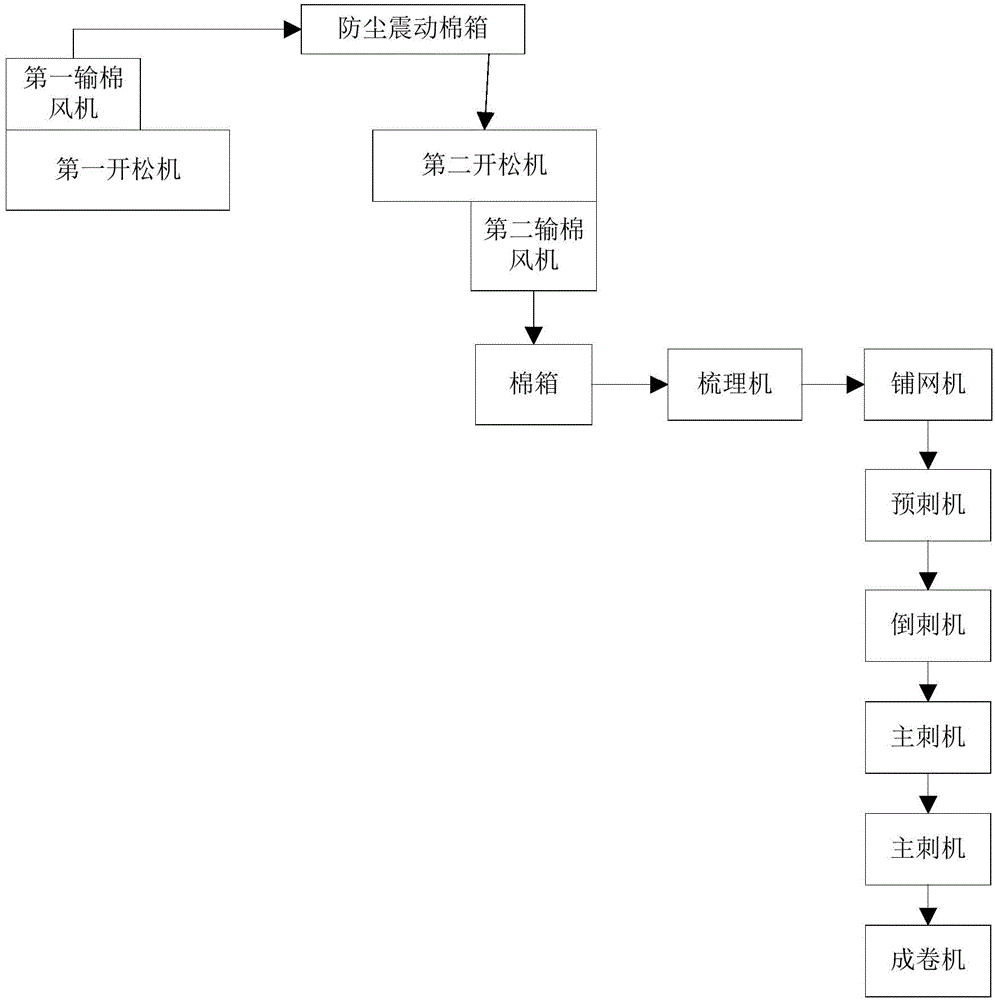

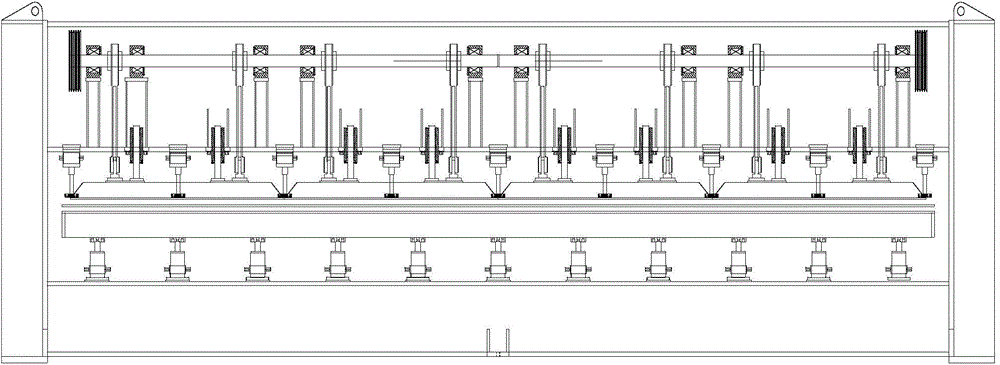

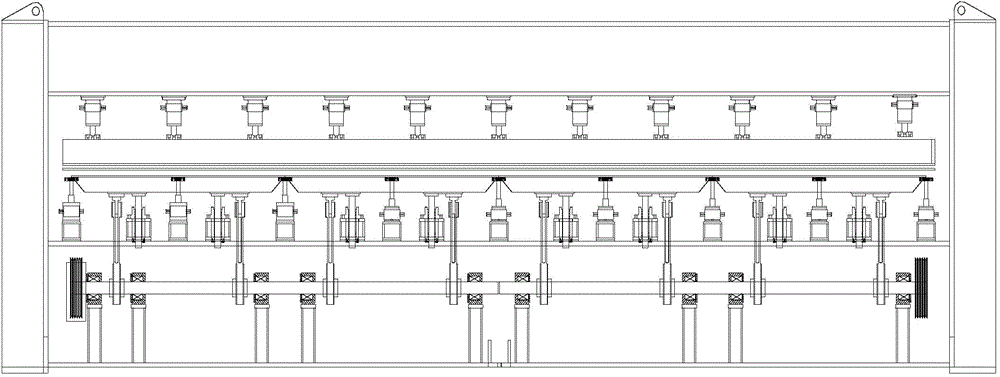

Non-woven cloth production line

ActiveCN104131417AImprove finished product qualityCause secondary pollutionContinuous processingFibre feedersProduction linePunching

The invention discloses a non-woven cloth production line which comprises an opening device, a combing machine, a lapping machine, a needle-punching device and an uncoiler, wherein the opening device, the combing machine, the lapping machine, the needle punching device and the uncoiler are sequentially connected. The opening device comprises a first opening mechanism and a second opening mechanism, the first opening mechanism comprises a first opening machine and a first cotton conveying fan connected with the first opening machine, the second opening mechanism comprises a second opening machine and a second cotton conveying fan connected with the second opening machine, and a dust proof vibrating cotton box is disposed between the first opening machine and the second opening machine; the needle-punching device comprises a pre-needling machine, a reversing needling machine and at least one main needling machine, the pre-needling machine, the reversing needling machine and the at least one main needling machine are sequentially connected, the pre-needling machine and the main needling machine are respectively provided with an upper fulcrum parking portion, each upper fulcrum parking portion comprises an auxiliary transmission mechanism and a pneumatic mechanism, and the auxiliary transmission mechanism and the pneumatic mechanism of each upper fulcrum parking portion are arranged on one side of the machine frame. The production line is smooth in connection, and the surface of produced non-woven cloth is smooth, uniform in weight and thickness and good in air permeability.

Owner:QINGDAO KAISHUO MACHINERY TECH CO LTD

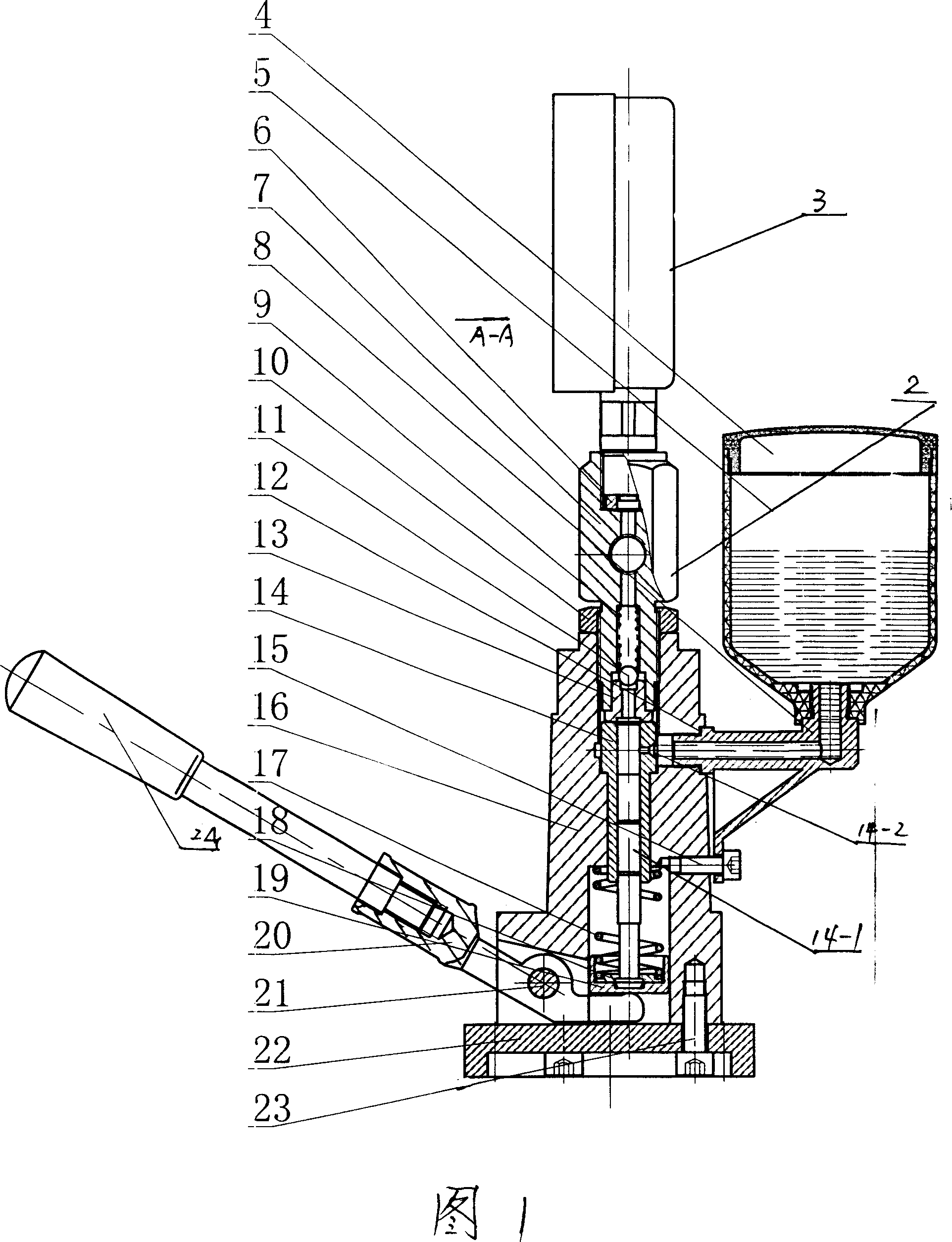

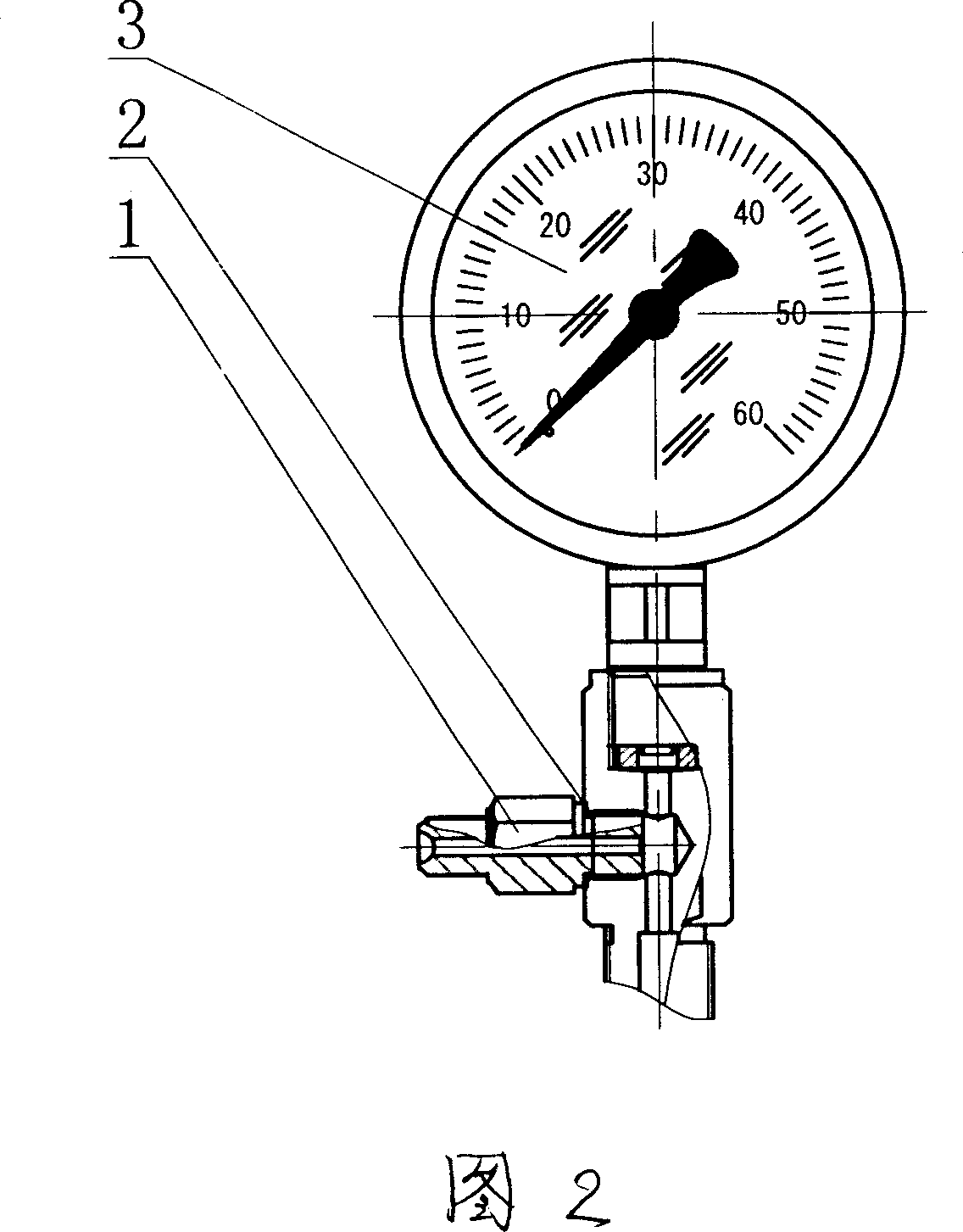

Gravity flow type oil spout mouth detector

InactiveCN1920514AExtended service lifeImprove detection qualityEngine testingFuel injection apparatusGravity flowSteel ball

The invention relates to an artesian ejector detector, which comprises: correcting connector, sealing ring, pressure meter, oil cup cover, oil cup, red copper pad, pressure meter connector, oil cup base, fixing nut, steel ball, sealing pad, valve base, plug muffle, piston, positioning screw, machine base, spring, baffle ring, piston support disc, lever, pin, base, screw, and handle, wherein the oil cup base is connected to the oil cup to be arranged at the upper end of oil inlet; the through hole of oil cup base is Phi 4-20mm. Since the oil cup is at the upper end of oil inlet, it uses artesian method, and it enlarges the oil inlet, the piston will contain oil always, to lubricant the piston and plug muffle, without dead clamp, to improve the reliability and 300% of producing efficiency. The invention can improve the detecting quality and the service life.

Owner:上海运畅机电科技有限公司

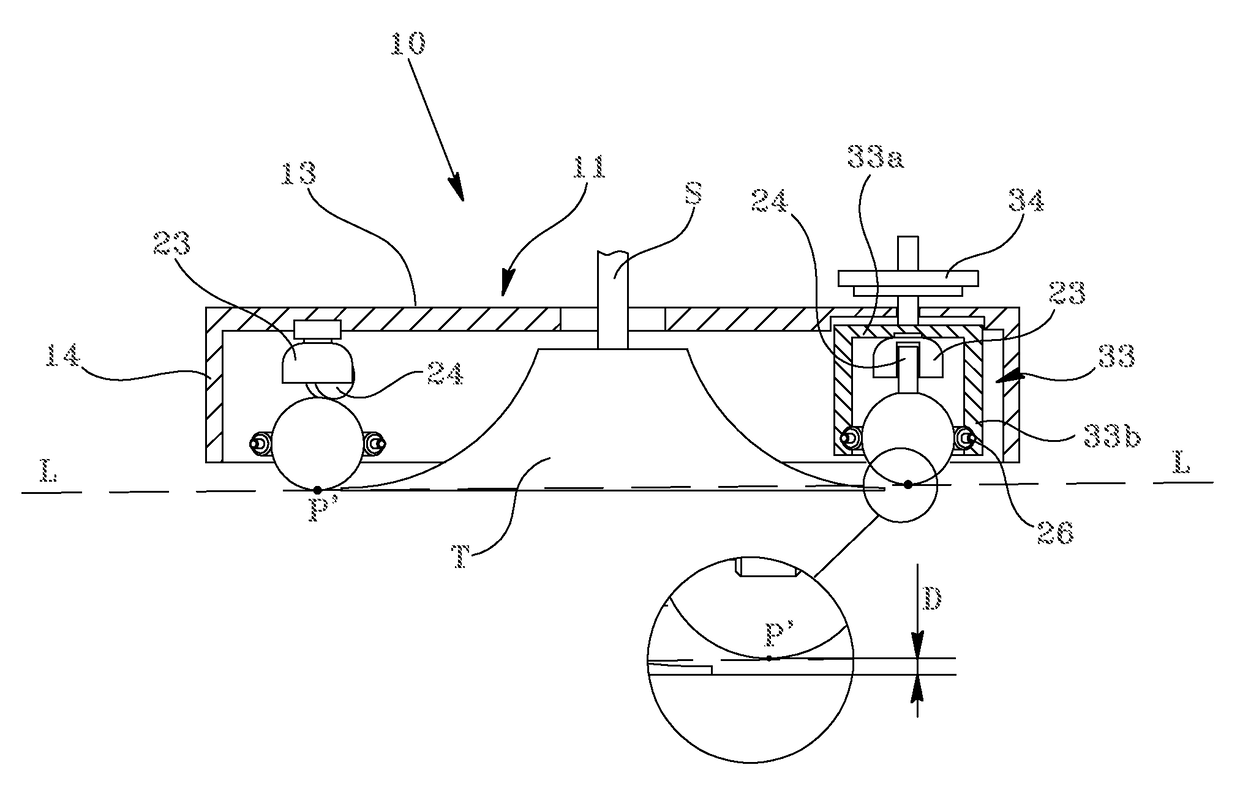

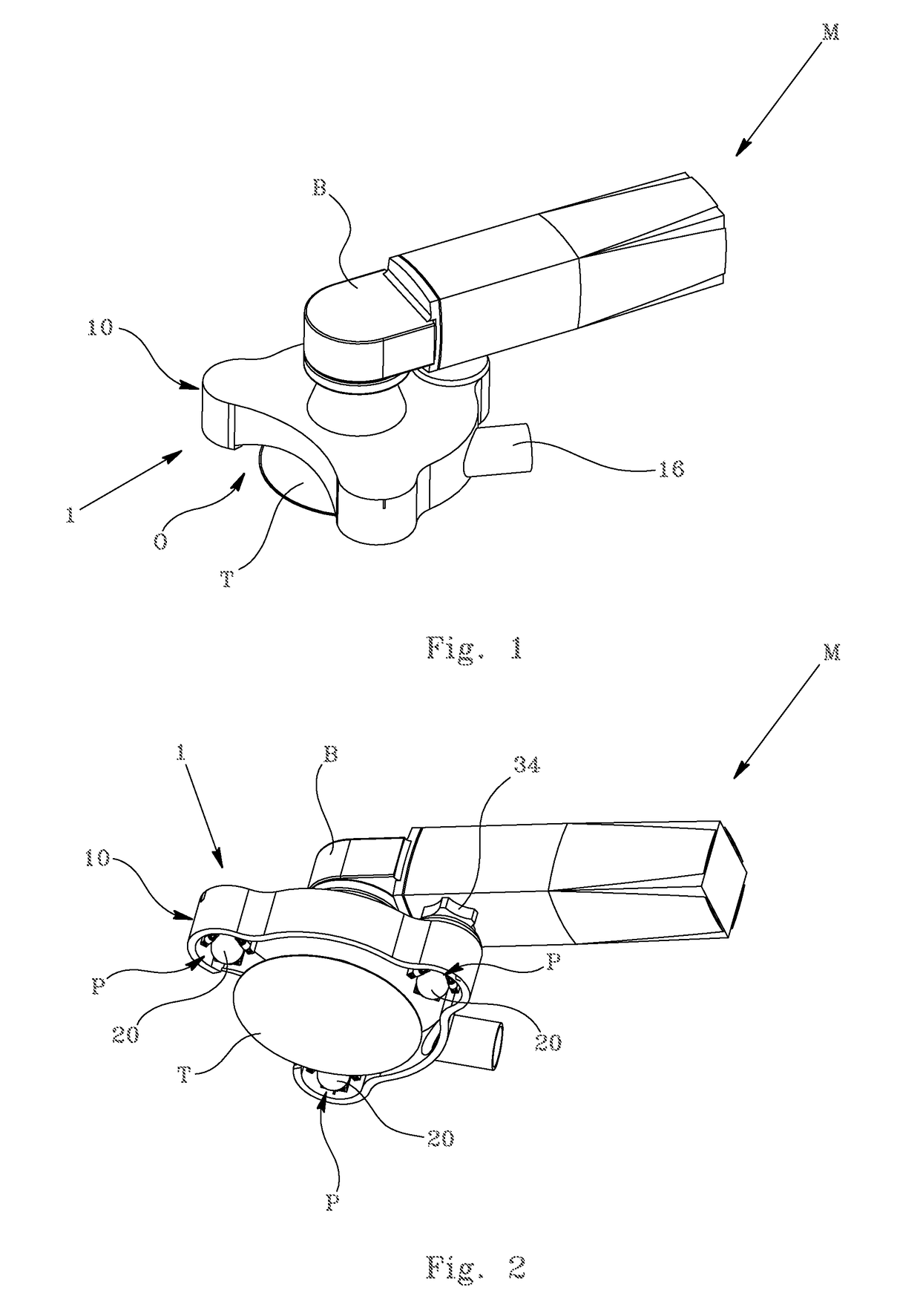

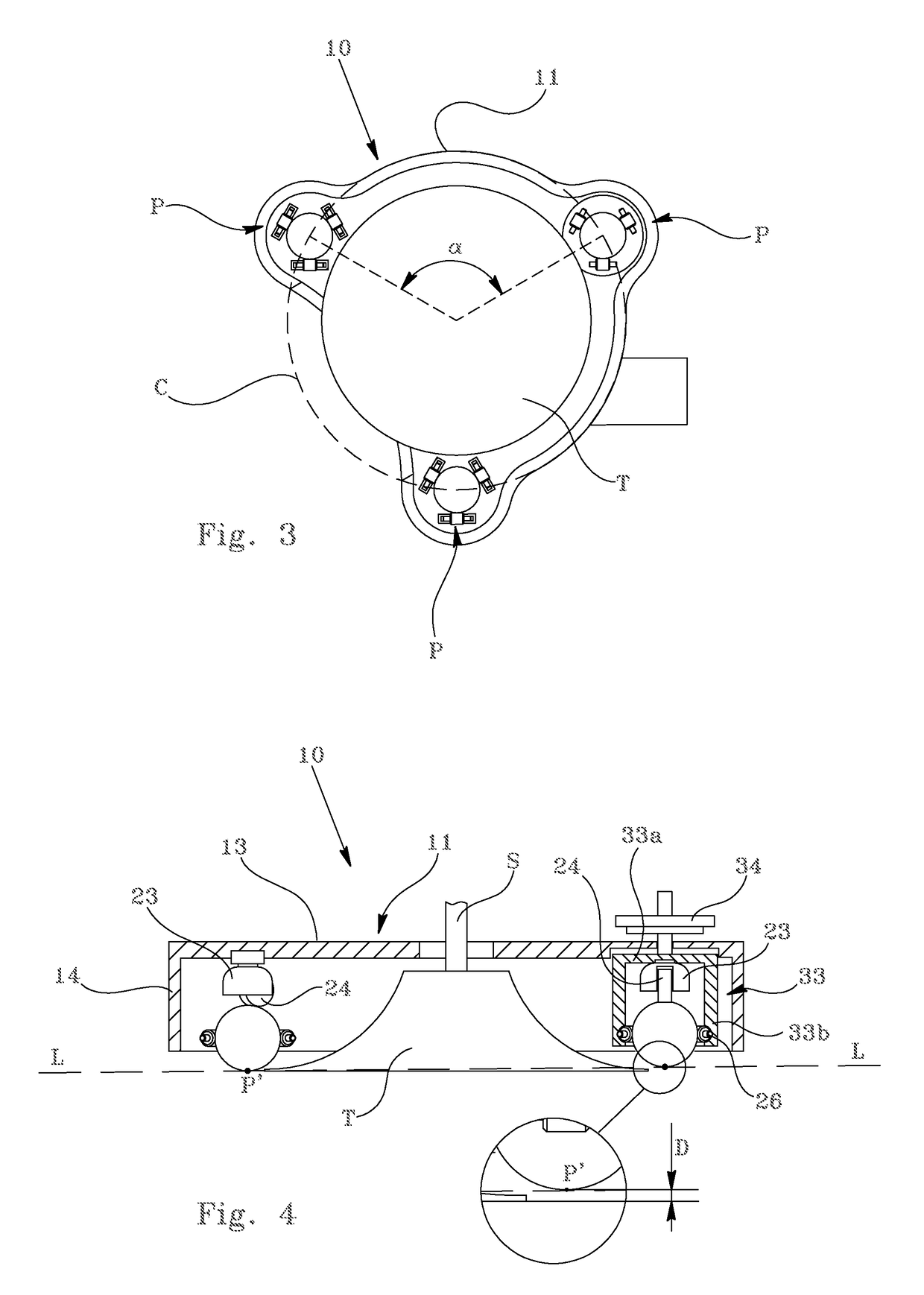

Base for sanding machines, grinding machines or the like

InactiveUS9975215B2Improve machine qualityEasy to useGrinding carriagesCastorsEngineeringMechanical engineering

A base for sanding machines, grinding machines or the like includes a body (10) connectable to a machine (M) or integral therewith, the body (10) being provided with at least three supports (P) arranged in such a manner that their ends (P′) lie on a plane (L) and configured in such a manner that at least one tool (T) of the machine projects at least partly beyond the plane (L) by a portion (D), the body (10) being provided with elements adapted to vary the position of the plane (L) with respect to the tool (T).

Owner:UNIBASE SPA

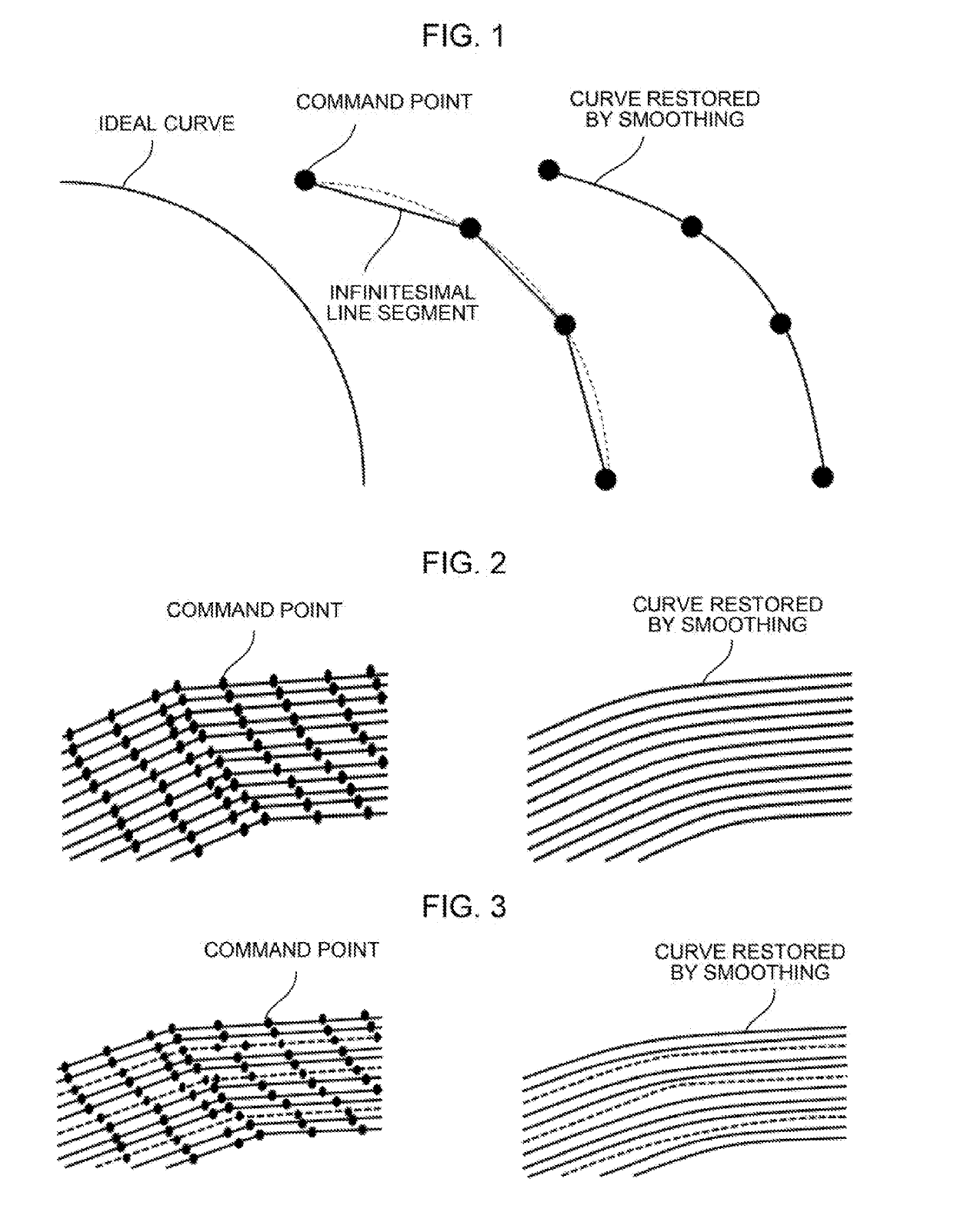

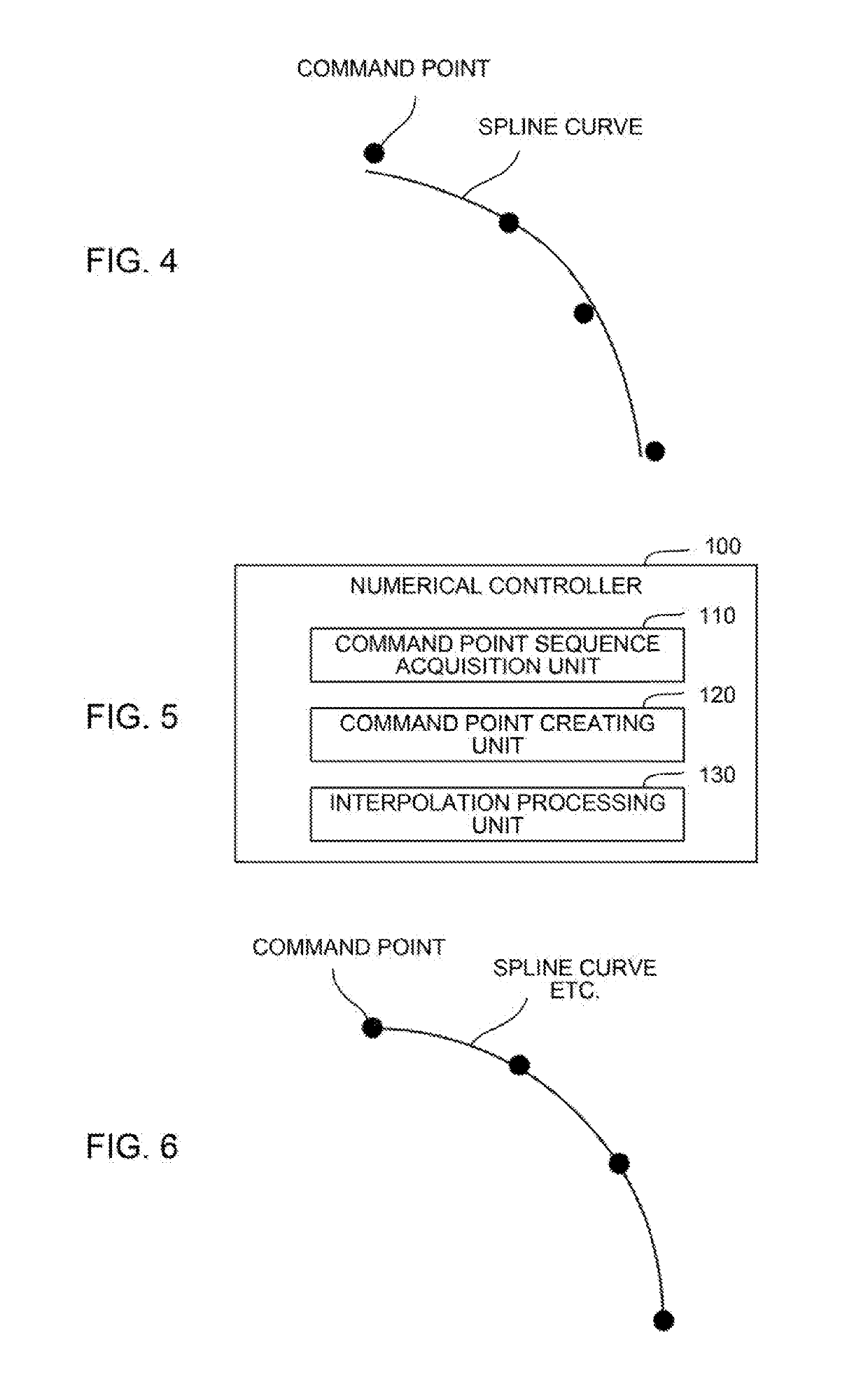

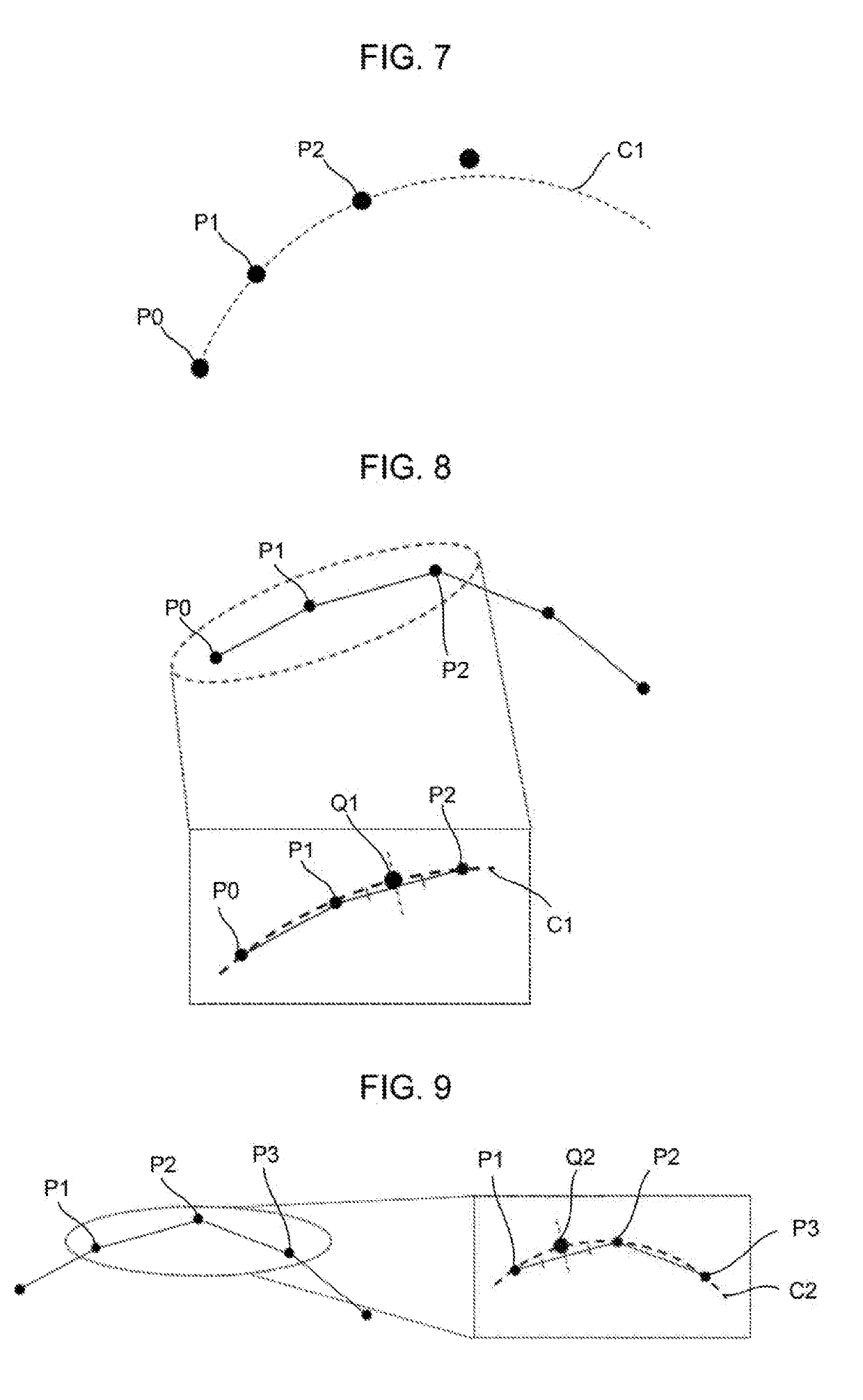

Numerical controller

ActiveUS20190101888A1Improve machine qualityTotal factory controlNumerical controlLine segmentTool path

A numerical controller that creates a tool path from a plurality of command points includes: a command point sequence acquisition unit that acquires an existing command point sequence; a command point creating unit that creates at least one additional command point, based on the existing command point sequence; and an interpolation processing unit that interpolates the existing command point sequence and the additional command point to create the tool path. The command point creating unit outputs, as the additional command point, an intersection point Q1 between an arc C1 passing through consecutive three command points, P0, P1 and P2, in the existing command point sequence and a perpendicular bisector of a line segment whose end points are P1 and P2.

Owner:FANUC CORP

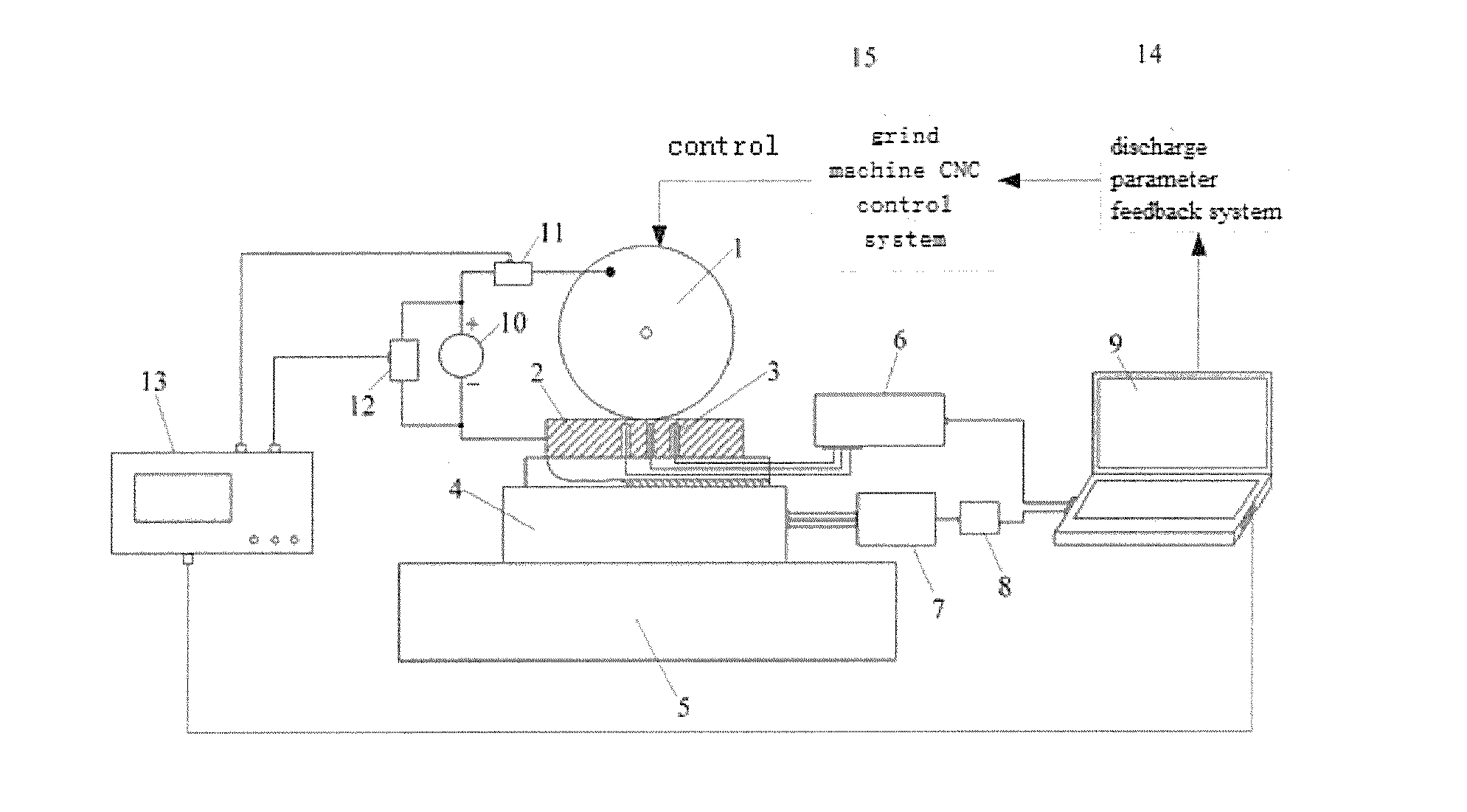

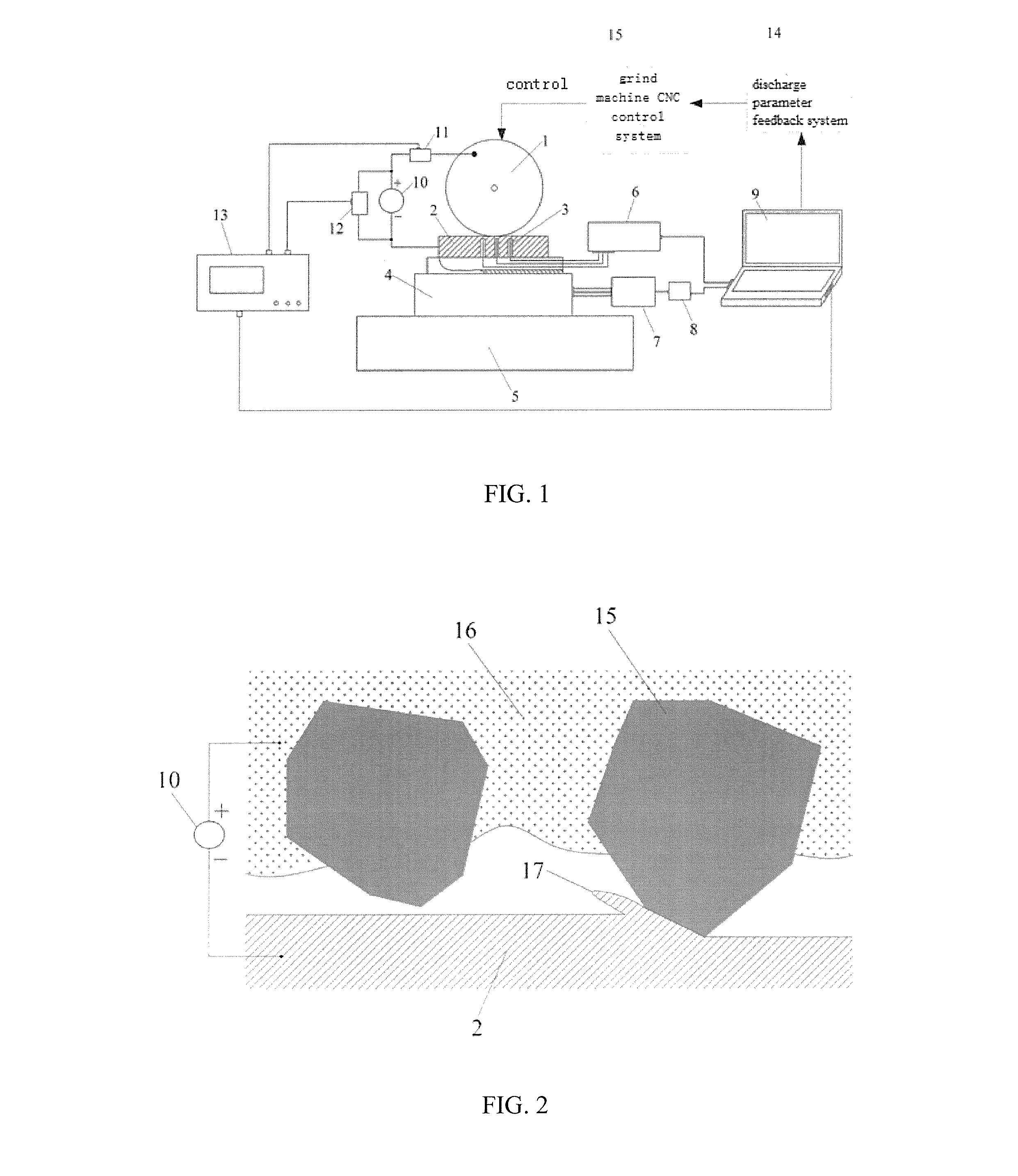

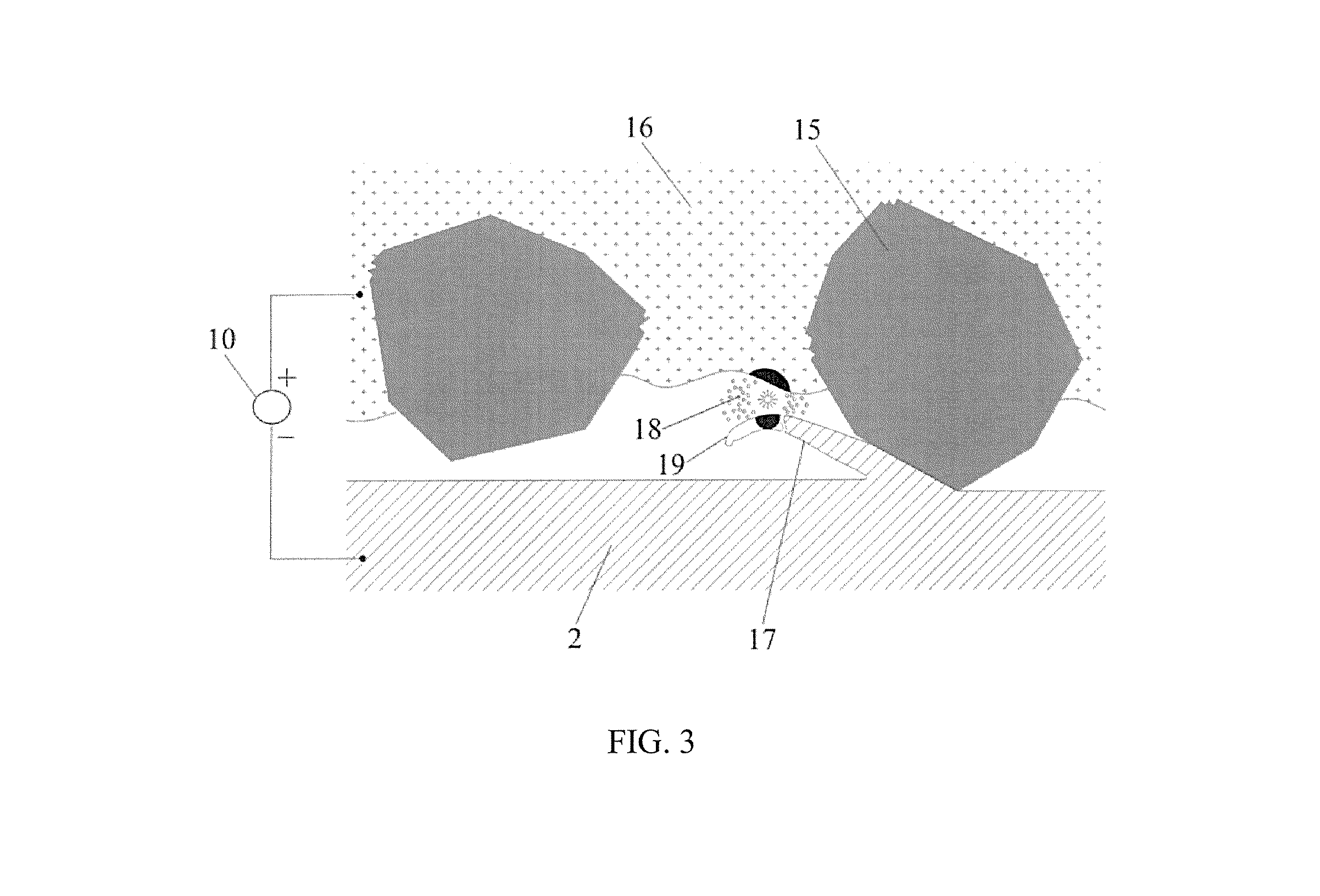

Intelligent Grinding Device for Short Pulse Electrical Melt Chip Removal Cooling

ActiveUS20170014967A1Reducing grinding forceReduce grinding temperatureGrinding feed controlGrinding machinesEngineeringPulse power supply

An intelligent grinding device for short pulse electrical melt chip removal cooling, includes a diamond grinding wheel, a pulse power supply, a force meter sensor, thermocouple in a hole of work piece for measuring machining temperature, a voltage sensor, a current sensor, a temperature collecting card, a charge amplifier, a force meter, a digital oscilloscope and a discharge parameter feedback adjustment system. The pulse power supply has a positive pole connecting with the grinding wheel, and a negative pole connecting with the work piece. The voltage sensor and the current sensor respectively put collected discharge voltage and current wave of the discharge circuit to be stored in a display terminal through the digital oscilloscope. The thermocouple connects with the display terminal by the temperature collecting card.

Owner:SOUTH CHINA UNIV OF TECH

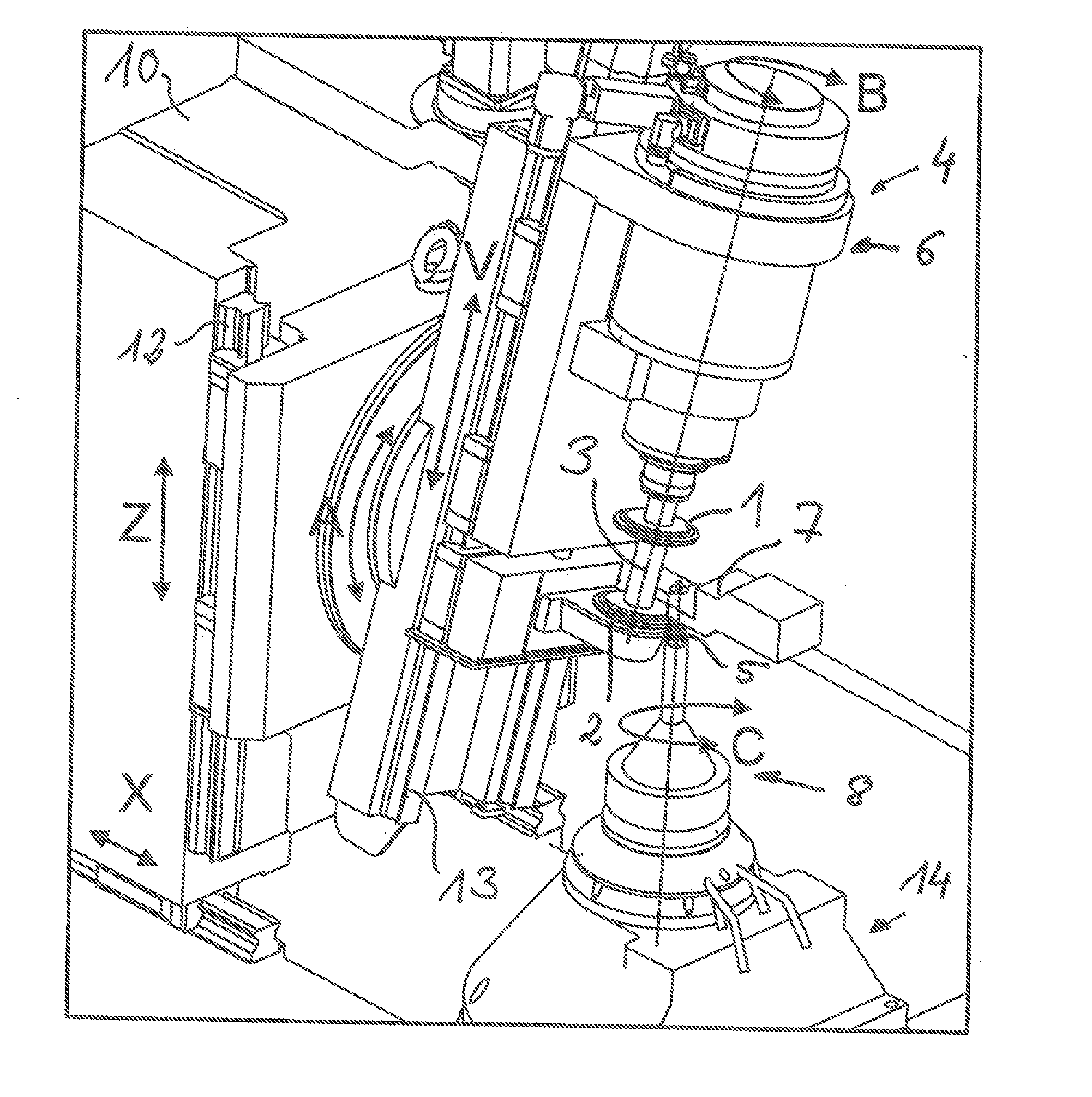

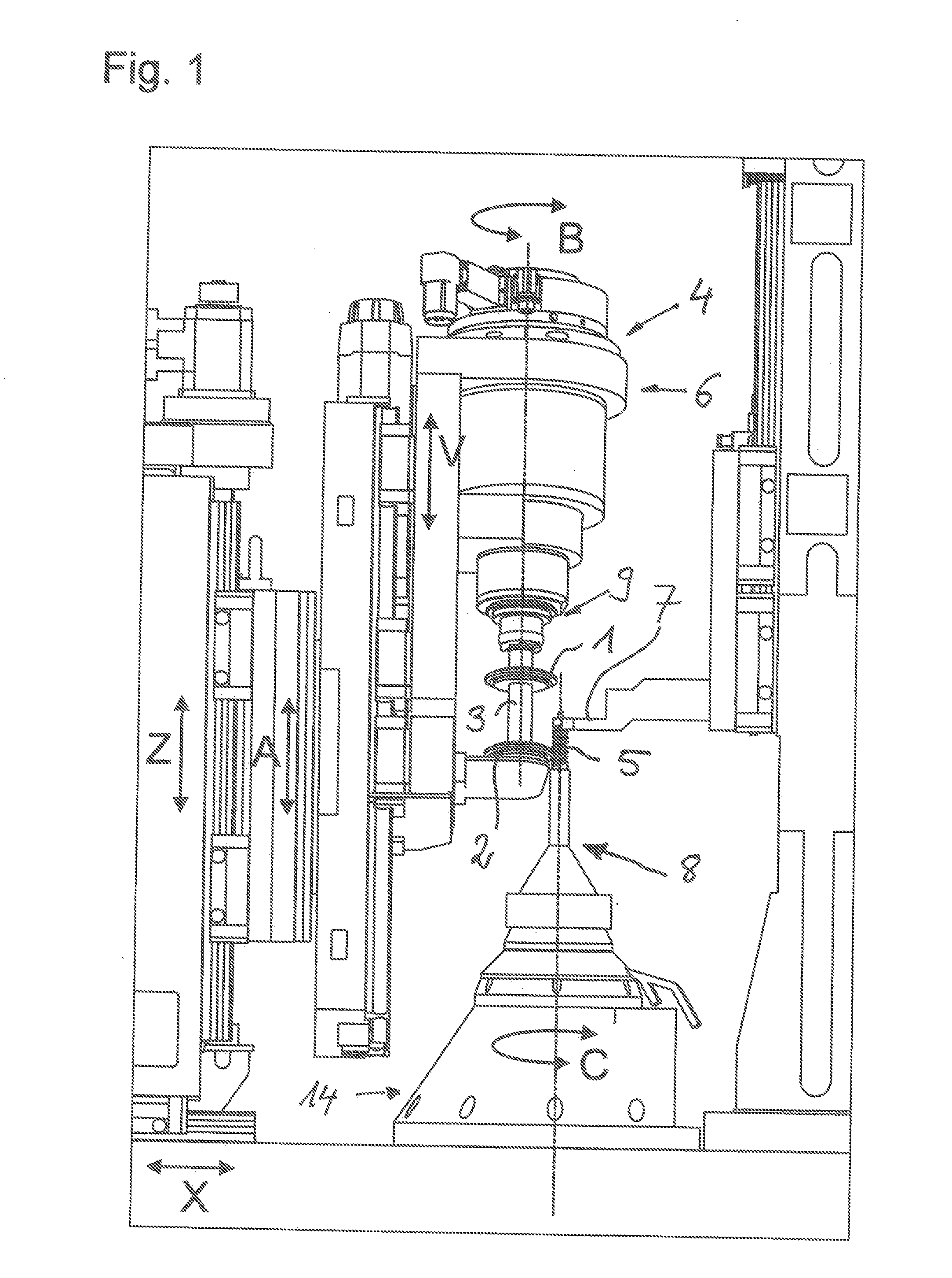

Machining head for a gear cutting machine and method for toothing a workpiece, in particular a worm shaft or toothed rack

InactiveUS20160250701A1More accommodatingImprove machine qualityGear teeth manufacturing toolsGear-cutting machinesHobbingGear wheel

Owner:LIEBHERR VERZAHNTECHNIK GMBH

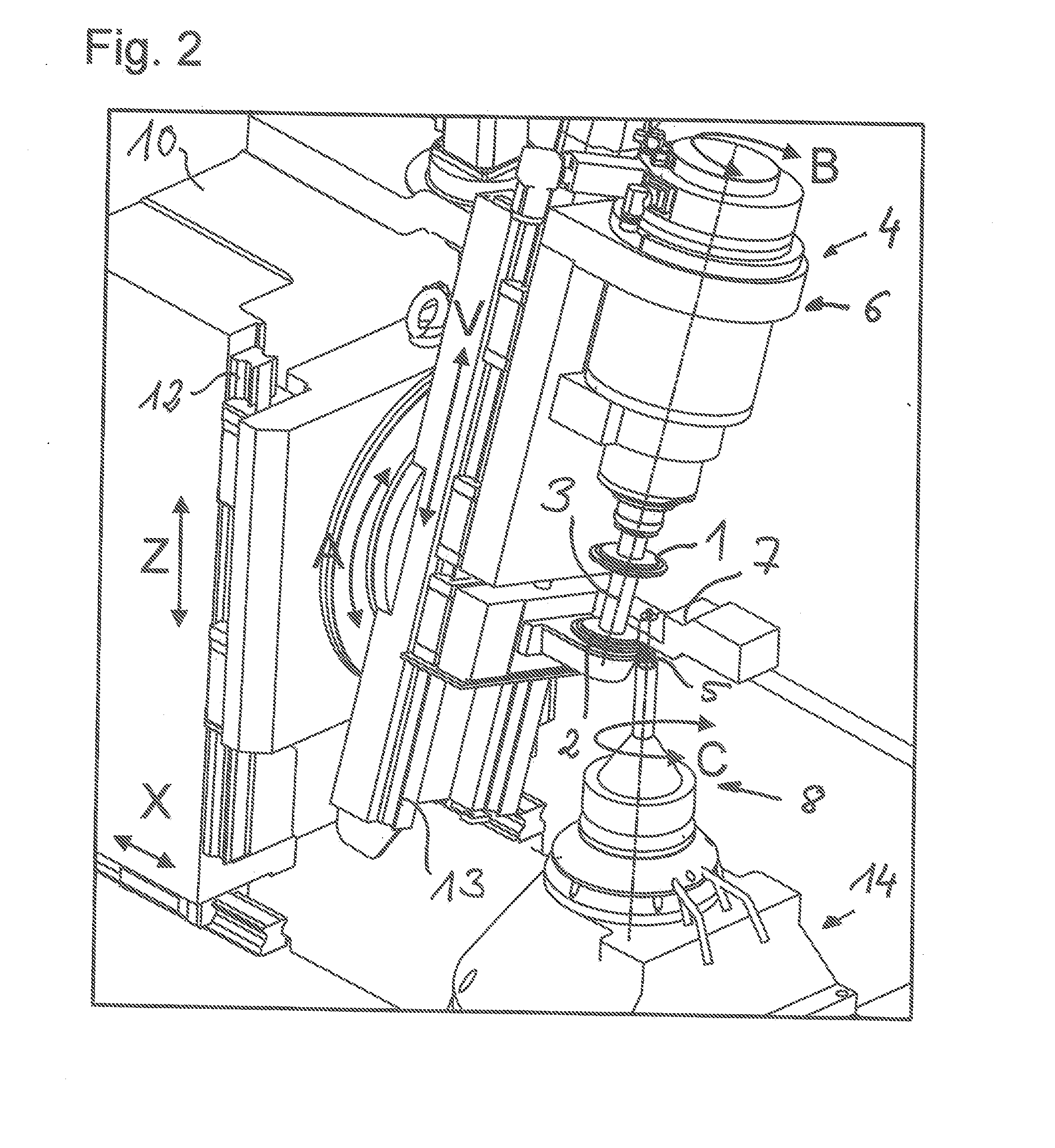

Method for controlling an industrial processing machine

InactiveUS6993412B2Easy to processIncrease speedComputer controlSimulator controlControl engineeringProcess engineering

A method and system for describing a three-dimensional path of an industrial processing machine, such as a machine tool, a robot and the like, is disclosed. According to the disclosed method and system, the path is described by a curve that includes at least one interpolation, wherein at least one interpolation parameter is a function of an angle along the three-dimensional path.

Owner:SIEMENS AG

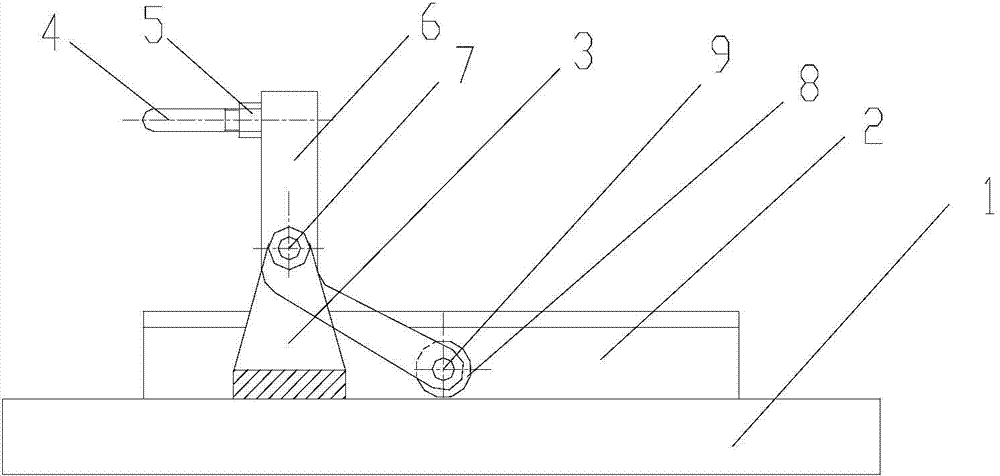

Rotary lever type locating device for end face rough milling of engine body with dry cylinder sleeve

ActiveCN104117868AOptimizing rough milling operationsImproved positioning methods and positioning devicesPositioning apparatusMetal-working holdersEngineeringEconomic benefits

The invention relates to a rotary lever type locating device for end face rough milling of an engine body with a dry cylinder sleeve. The rotary lever type locating device comprises a clamp bottom plate. A sizing block is fixedly arranged on the clamp bottom plate. A support is arranged on the sizing block. The support is connected with a rotary lever through a rotary pin. An adjustable supporting rod is arranged at one end of the rotary lever through a locking nut and located above the sizing block and is parallel to the sizing block. The adjustable supporting rod is perpendicular to the rotary lever. The other end of the rotary lever is provided with a locating roller through another rotary pin. By the adoption of the rotary lever type locating device for end face rough milling of the engine body with the dry cylinder sleeve, the end face rough milling process of the engine body with the dry cylinder sleeve is optimized, the locating mode and the locating device of a special clamp for the end face rough milling process of the engine body with the dry cylinder sleeve are improved, correct locating is achieved, it is guaranteed that the wall thickness of the cylinder sleeve machined through the follow-up cylinder sleeve boring process is even, the machining quality of the engine body is improved, the rejection rate of machining is reduced, and the economic benefit of an enterprise is improved.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Copper tube nitrogen charging and welding method and nitrogen charging and welding control device

InactiveCN103331538AProper flowImprove machine qualityWelding/cutting auxillary devicesAuxillary welding devicesNitrogenBottle

The invention relates to a copper tube nitrogen charging and welding method and a nitrogen charging and welding control device. The welding method includes the following steps: a first step of parameter setting, a second step of welding, and a third step of last welding. In the parameter setting step, the pressure value of nitrogen charging is set no more than 0.05MPa, and a flow value of nitrogen charging is correspondingly set according to the cross section area of a copper tube. In the welding step, nitrogen is charged in the copper tube for welding according to parameters set in the first step. In the last welding step, flow of the nitrogen is reduced to no less than 1L / min. The invention further relates to the welding control device using the welding method. The welding control device comprises a nitrogen bottle, a pressure reducing valve, a pressure meter, a nitrogen pipe and a gas flow meter. In a practice base or a laboratory, according to the technical scheme, the oxidation phenomenon caused during welding of the copper tube is effectively prevented. The method and device can be popularized and applied to the industrial fields such as welding of air conditioner cooling pipelines, prevents an oxidation layer from being formed in a tube, reduces the fault rate of a cooling system, and improves quality of air conditioning products.

Owner:QINGDAO TECHN COLLEGE

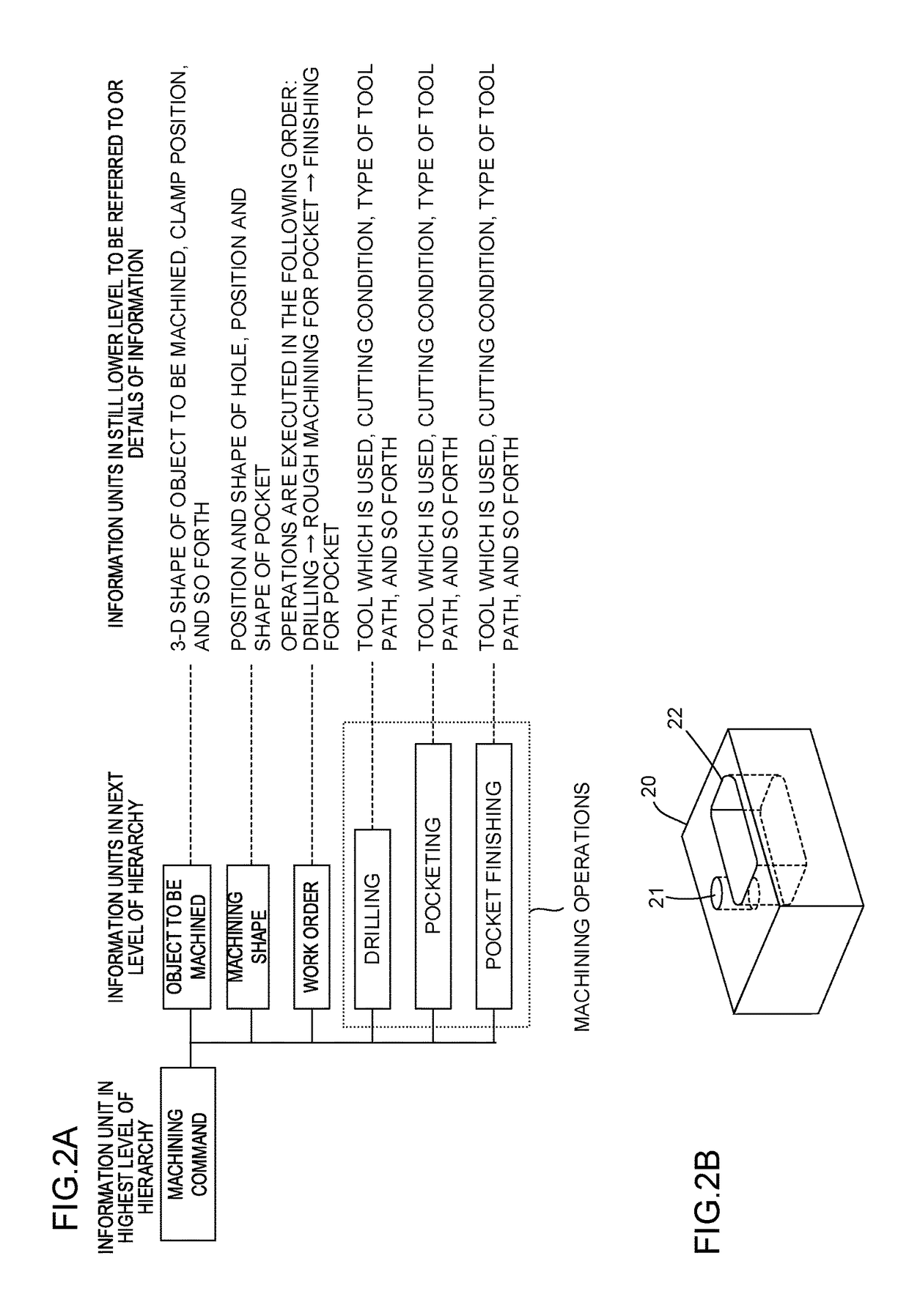

Cad/cam-cnc integrated system

ActiveUS20180032058A1Improve machine qualityReduce processing timeProgramme controlComputer controlSystem configurationCam

A CAD / CAM-CNC integrated system, configured with devices related to processes from design of a product to machining and including CAD, CAM and a CNC machine tool, has a shared database that stores information collected during machining or a change made to a machining command by an operator in association with structured information of the machining command. The information collected from a machining site is fed back to the CAM via the shared database, and the fed back information is analyzed to update the machining technique information, thereby making it easy to make use of the know-how accumulated in the machining site.

Owner:FANUC LTD

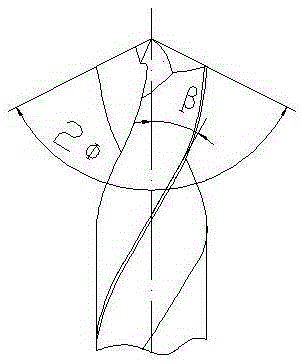

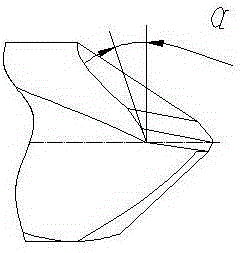

Hole machining drill bit and hole machining method suitable for carbon fiber composite materials

ActiveCN105345098AAddress and avoid stratificationSolve and avoid even the phenomenon of tearingTransportation and packagingWorkpiecesMicrometerSurface roughness

The invention discloses a hole machining drill bit and a hole machining method suitable for carbon fiber composite materials. The diameter of the drill bit is 6 mm, the drill point angle of the drill bit is 96 degrees, the helix angle of the drill bit is 28 degrees, the relief angle of the drill bit is 25 degrees, the length of a chisel edge is 0.028 time of the diameter of the drill bit, and the roughness of the surface of a front tool face and the surface of a rear tool face of the drill bit is 0.65 micrometer. The specific using method comprises the steps that the rotation speed of the drill bit is set to be 2350 r / min, and the feeding speed is set to be 0.018 mm / r. By means of the hole machining drill bit and the hole machining method, the phenomena that burrs occur at an inlet, and layering even fracture occurs at an outlet in the machining process of the carbon fiber composite materials are effectively avoided, the machining precision of the carbon fiber composite materials is effectively improved, and the product qualification ratio of the machining of the carbon fiber composite materials is increased; the connection and assembling quality of aerospace and national defense equipment is improved, and the quality of the whole equipment is effectively improved.

Owner:HUNAN UNIV OF SCI & TECH

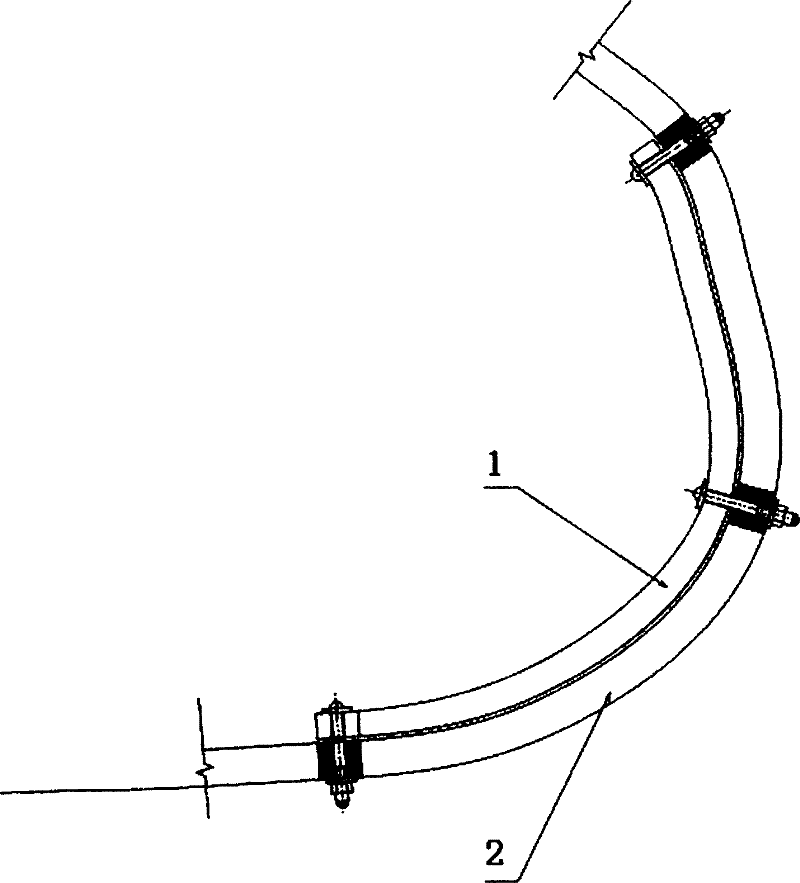

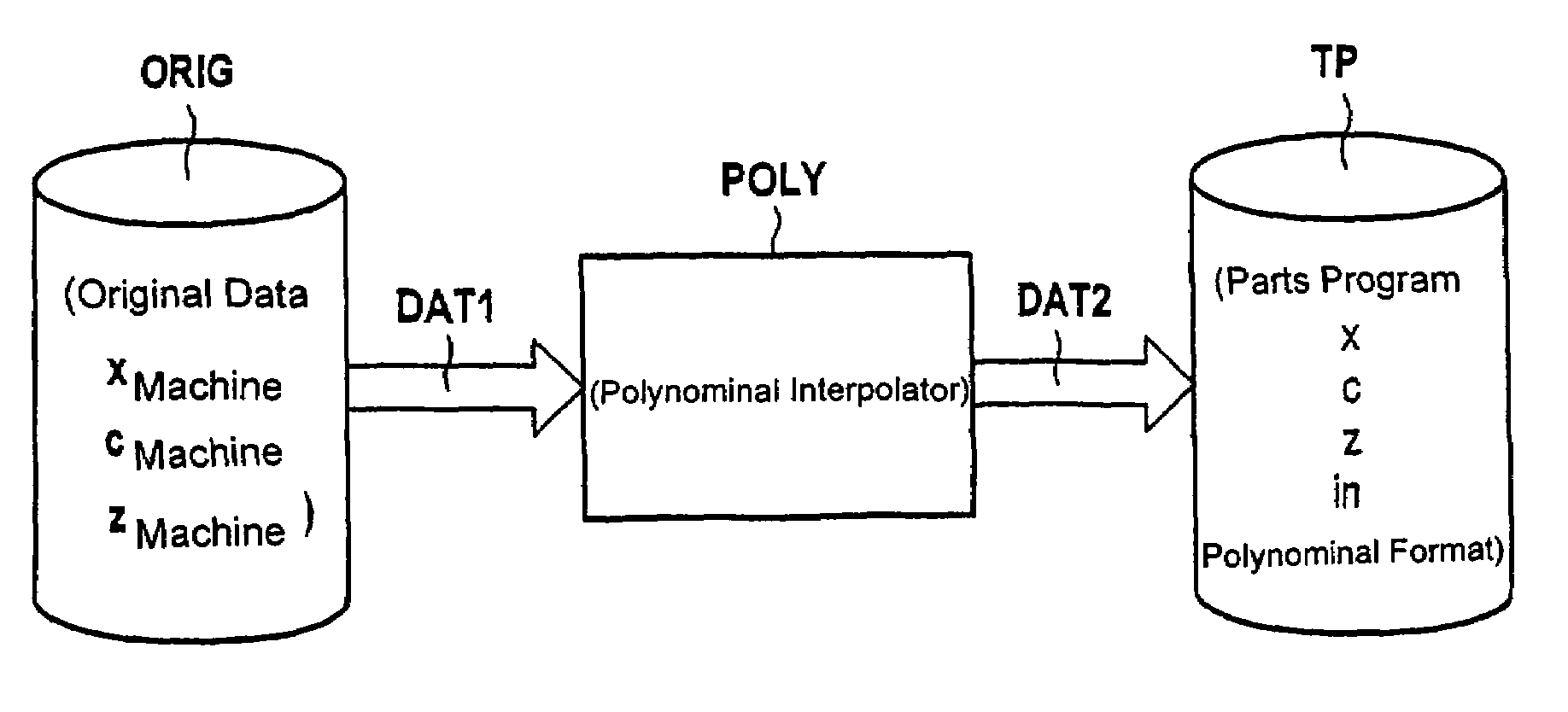

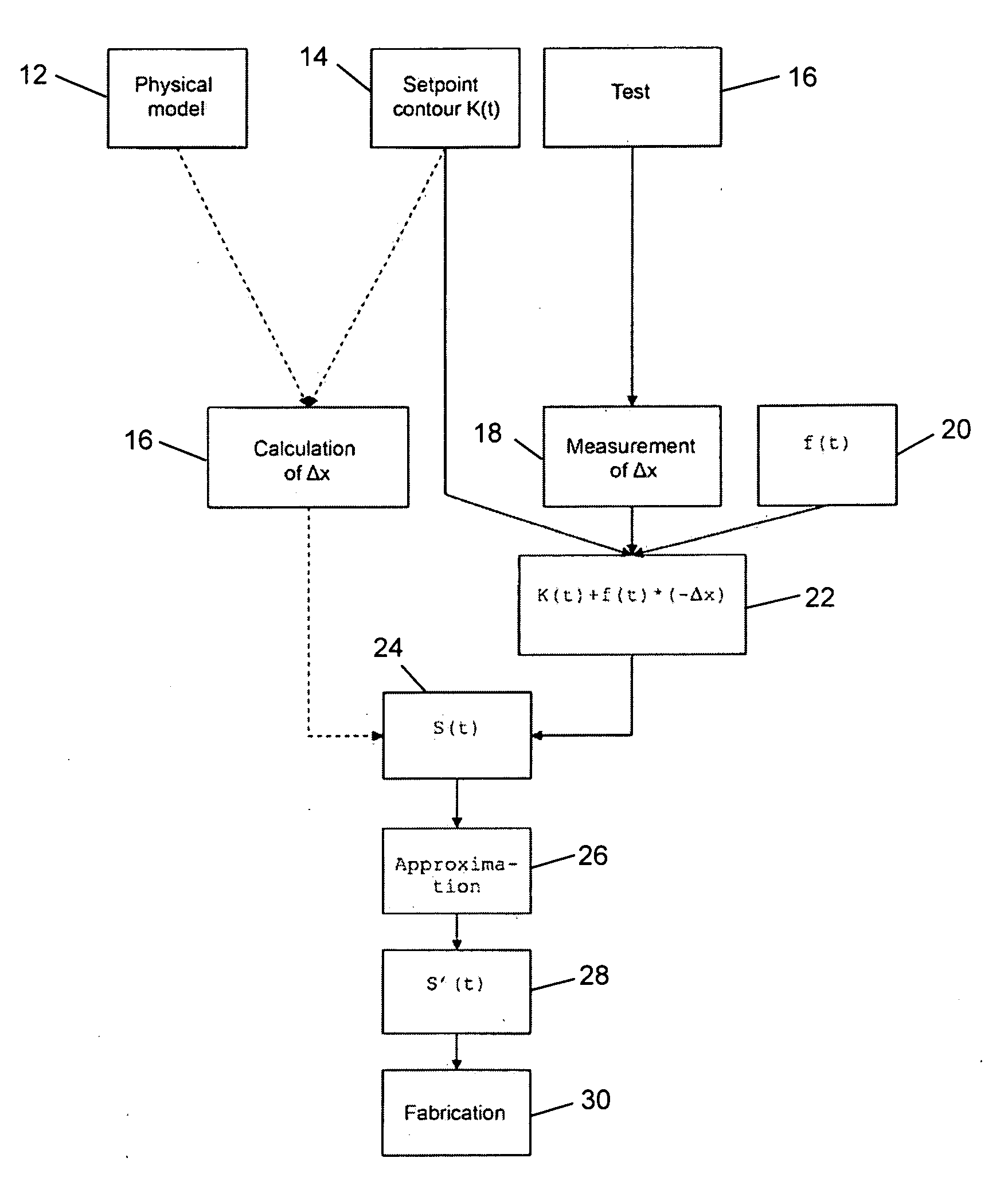

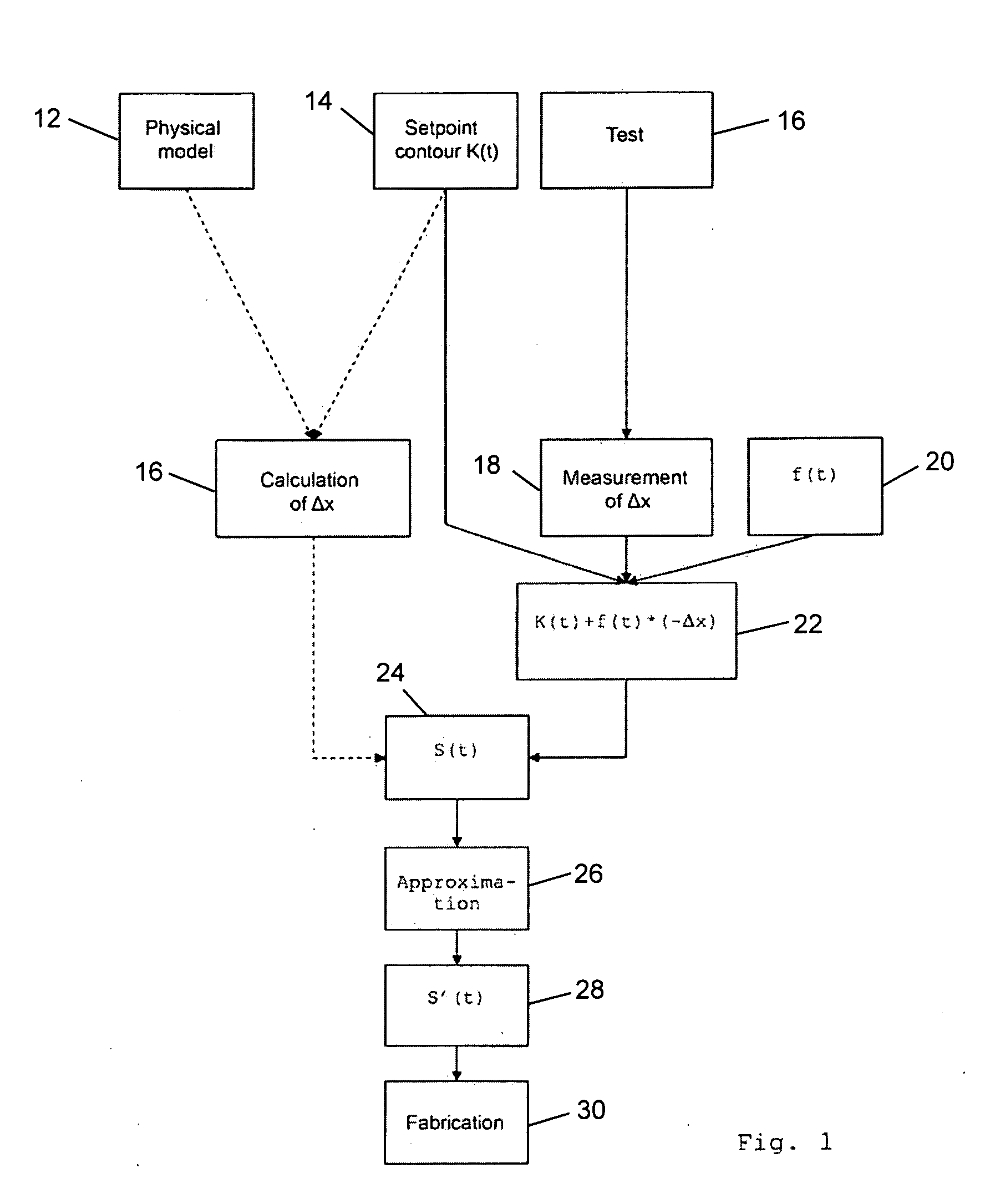

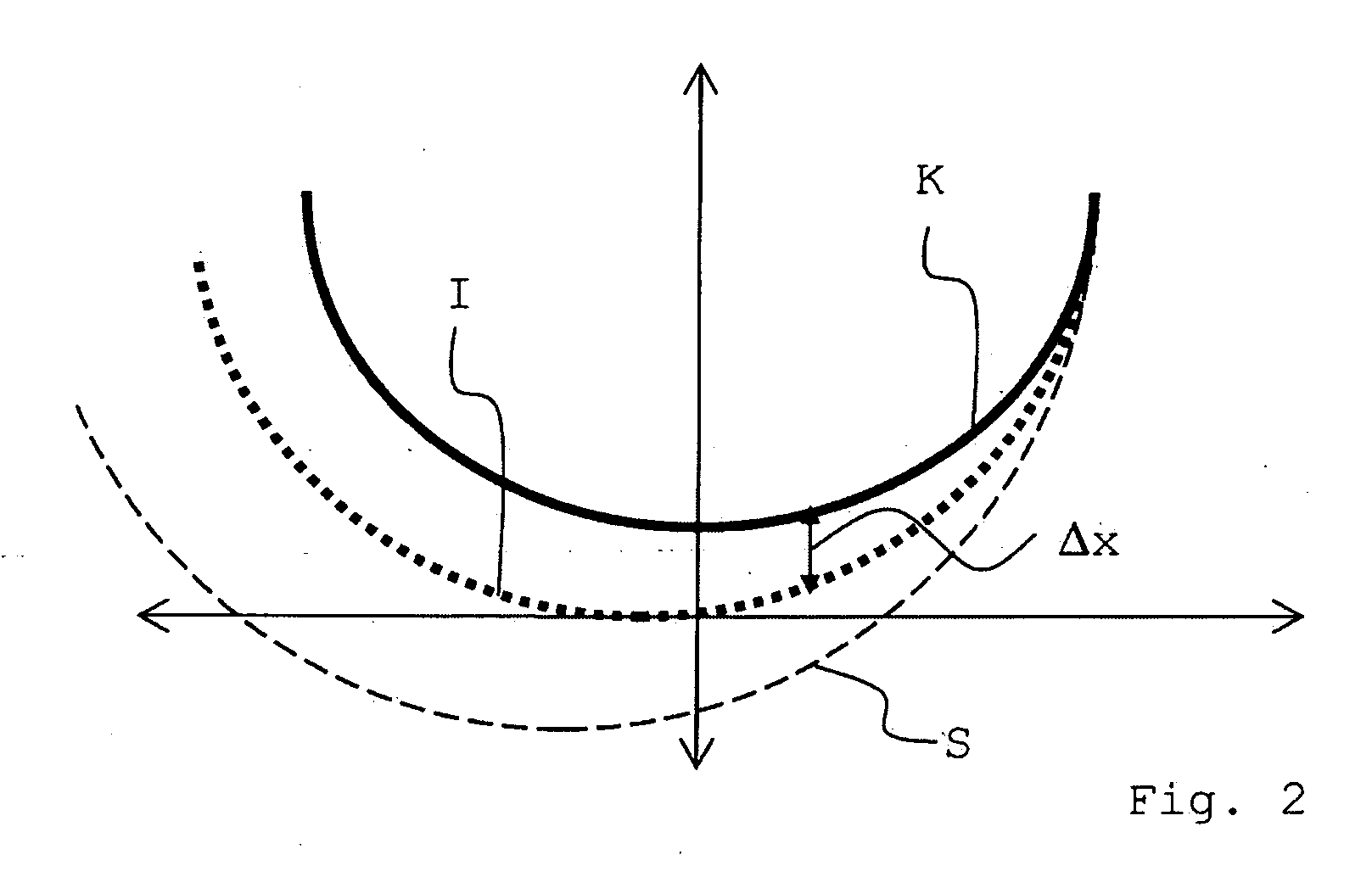

Method for near-net-shape machining of curved contours

InactiveUS20090215361A1Requirement for numberFabrication can be reducedProgramme controlComputer controlPresent methodEngineering

A method relating to near-net-shape machining of curved contours such as those occurring, for example, in the fabrication of blades for propulsion engines and the like is described. Accordingly, the shape error in curve grinding is minimized by suitable compensation functions, in particular by interpolating and approximating cubic splines. The present method minimizes the number of tests required to set up a grinding machining operation and thus the number of semifinished products required to do so. At the same time, rejects in fabrication of curved workpieces are reduced by increasing the machining quality. The use of complex chucking devices is avoided and cutting performance is maximized.

Owner:MTU AERO ENGINES GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com