Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about "Non-mechanical blast generators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

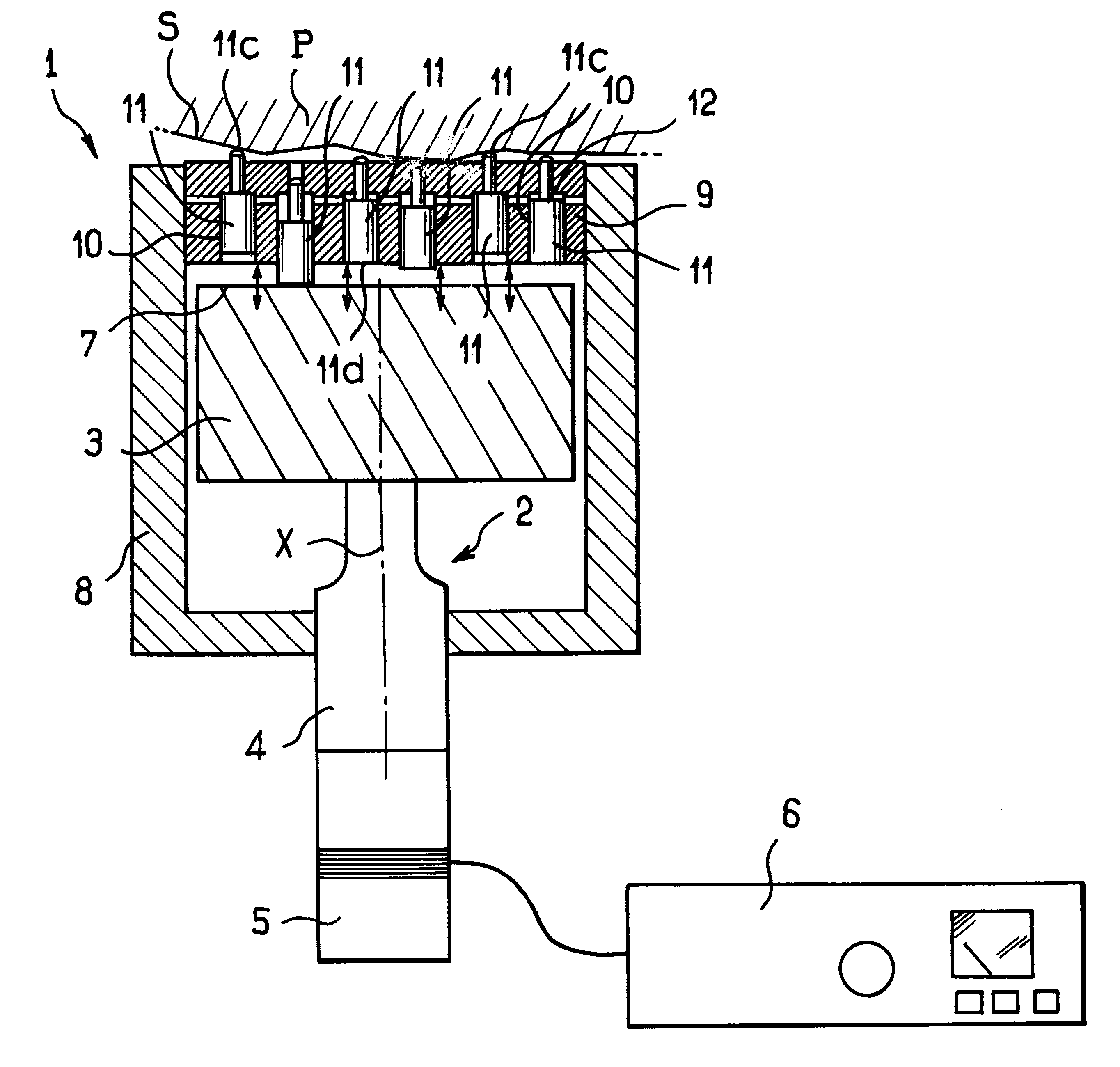

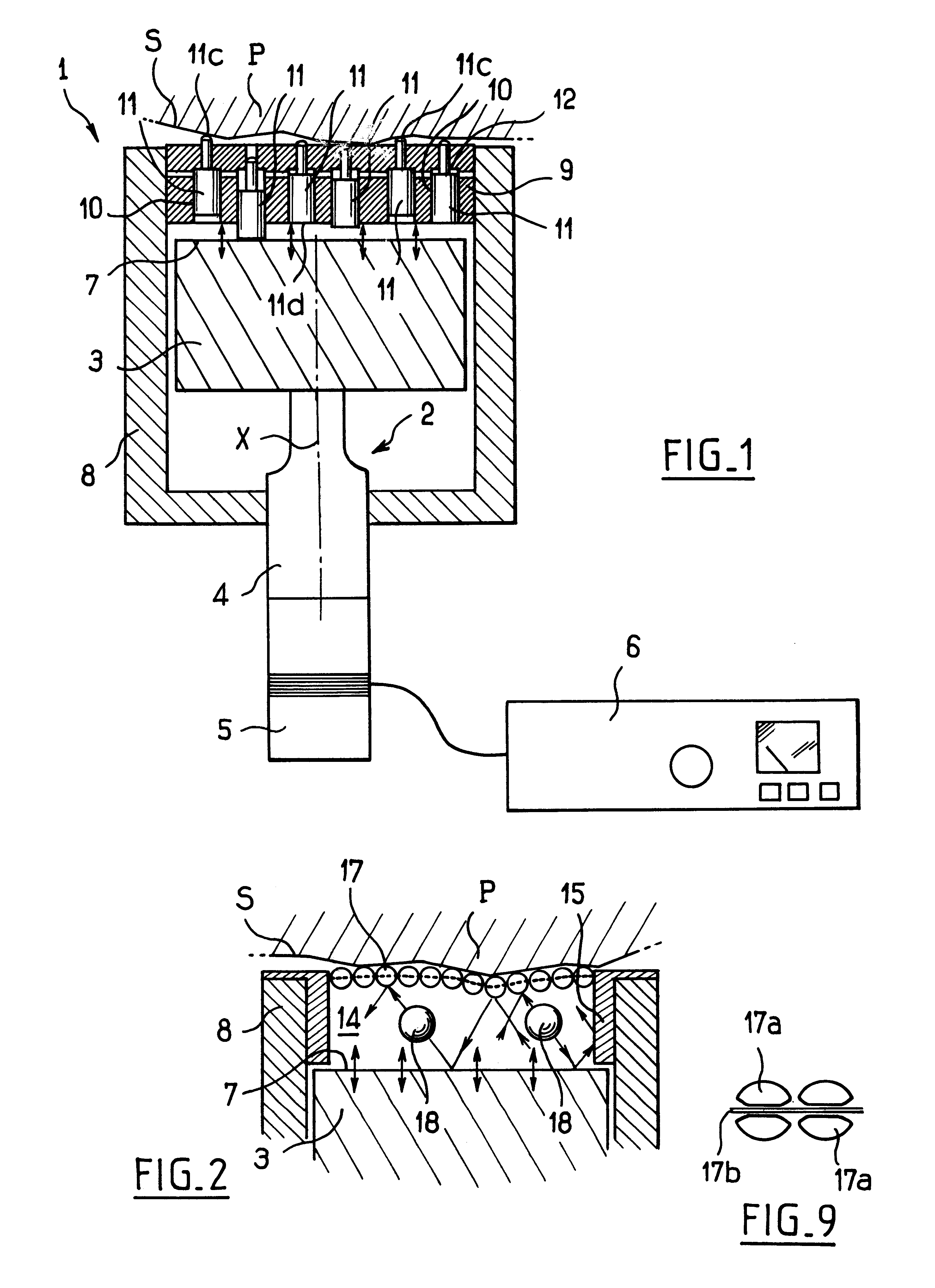

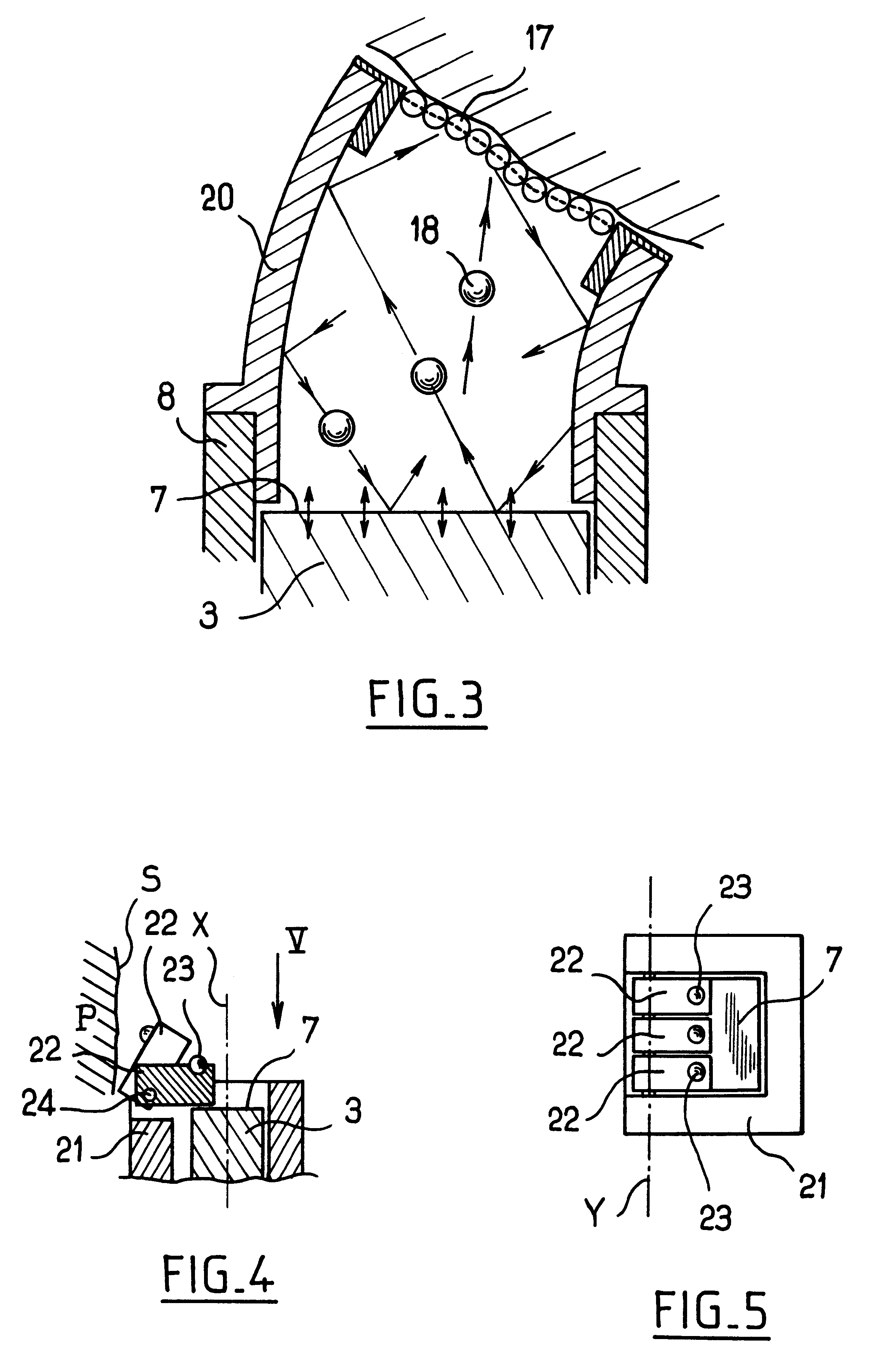

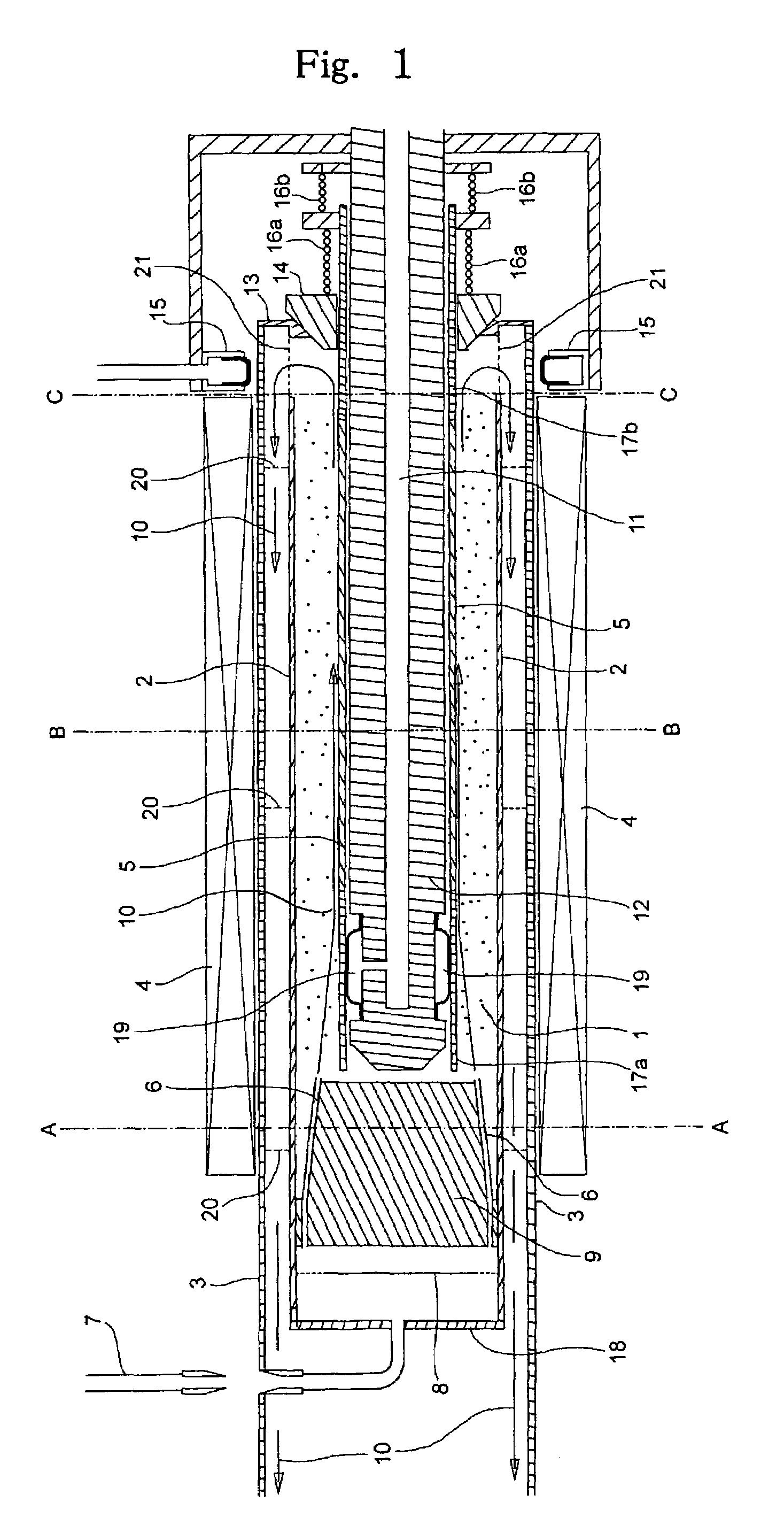

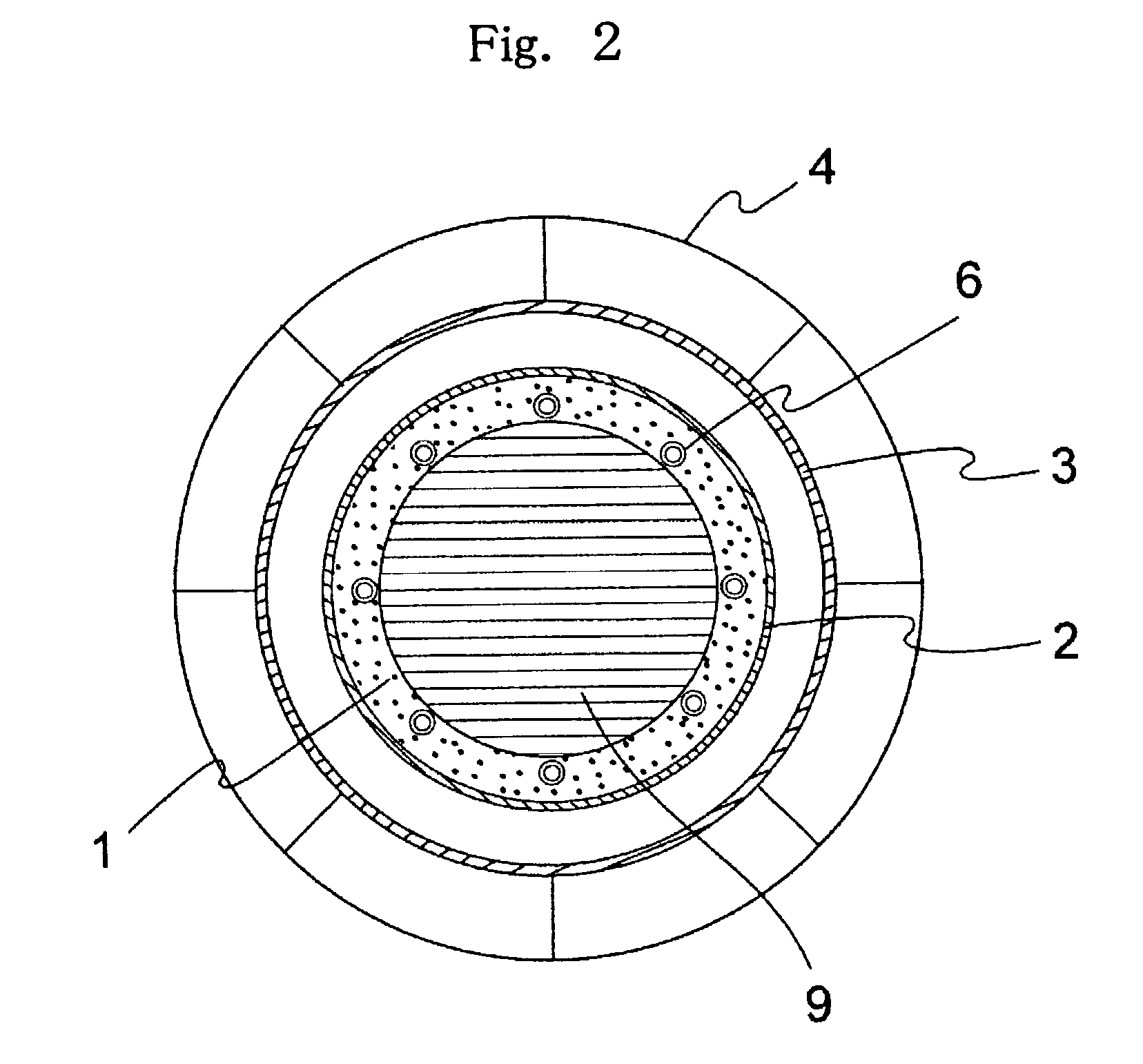

Apparatus for surface treatment by impact

InactiveUS6343495B1Quality improvementSimple treatmentNon-mechanical blast generatorsBurnishing machinesBiomedical engineeringProjectile

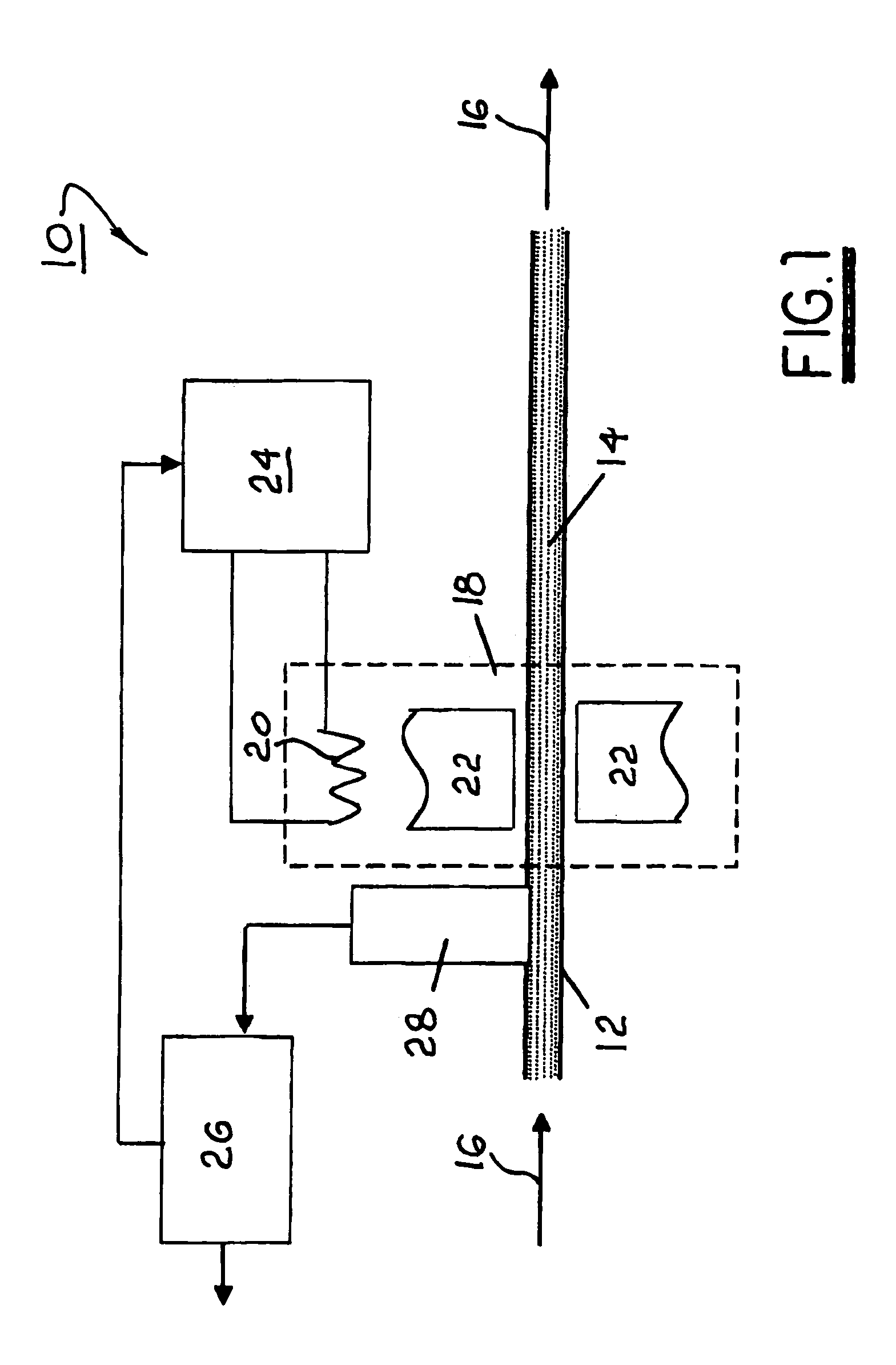

The invention relates to apparatus for surface treatment by impact, the apparatus comprising a vibrating surface and at least one projectile suitable for being projected towards the surface to be treated by said vibrating surface. The apparatus includes retaining means for keeping each projectile captive in the apparatus.

Owner:SONATS SOC DES NOUV APPL DES TECHN DE SURFACES

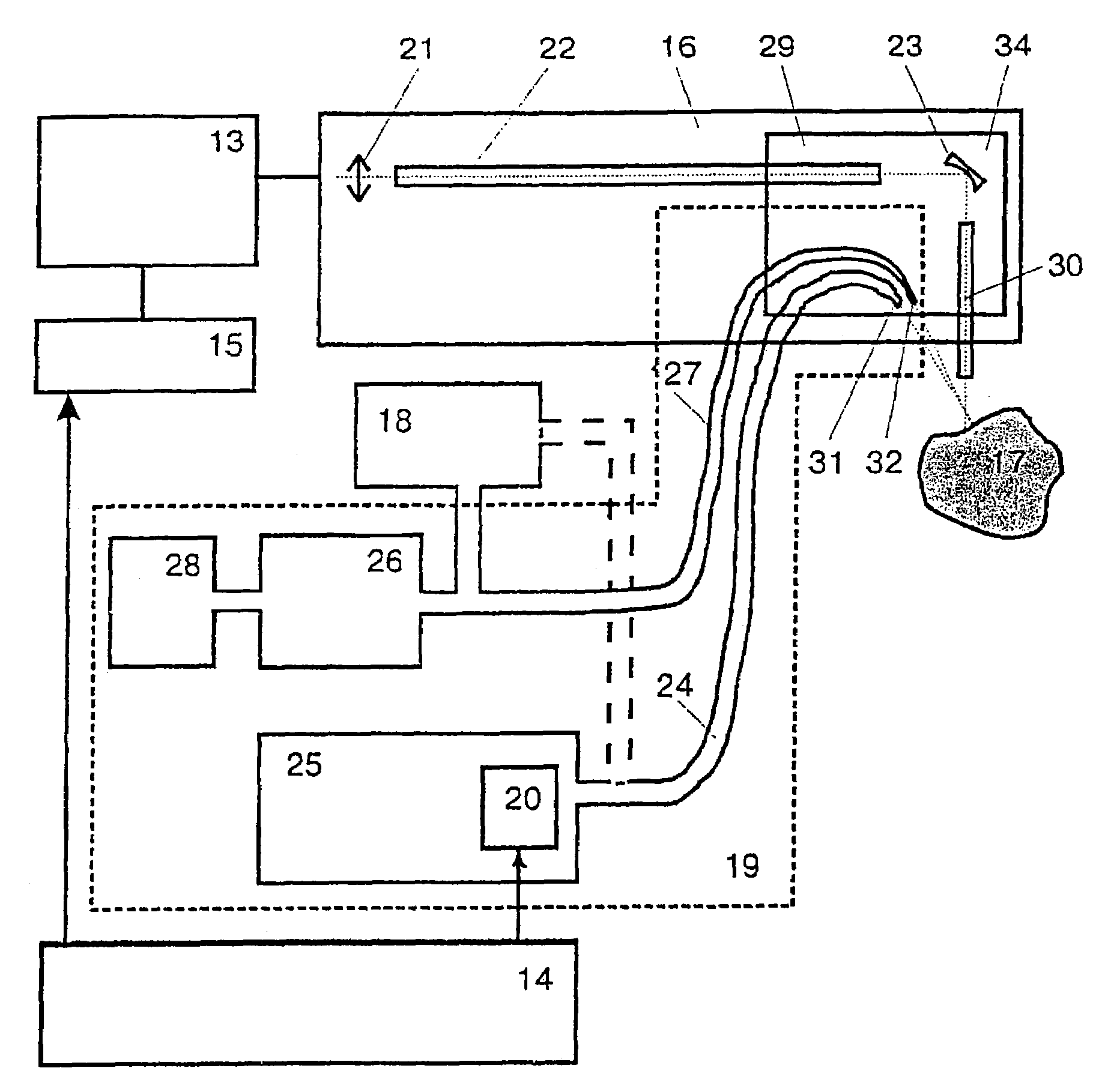

Methods and apparatus for light induced processing of biological tissues and of dental materials

InactiveUS7048731B2Efficient and accurate processingIncrease profitNon-mechanical blast generatorsTeeth fillingSelective ablationBiological tissue

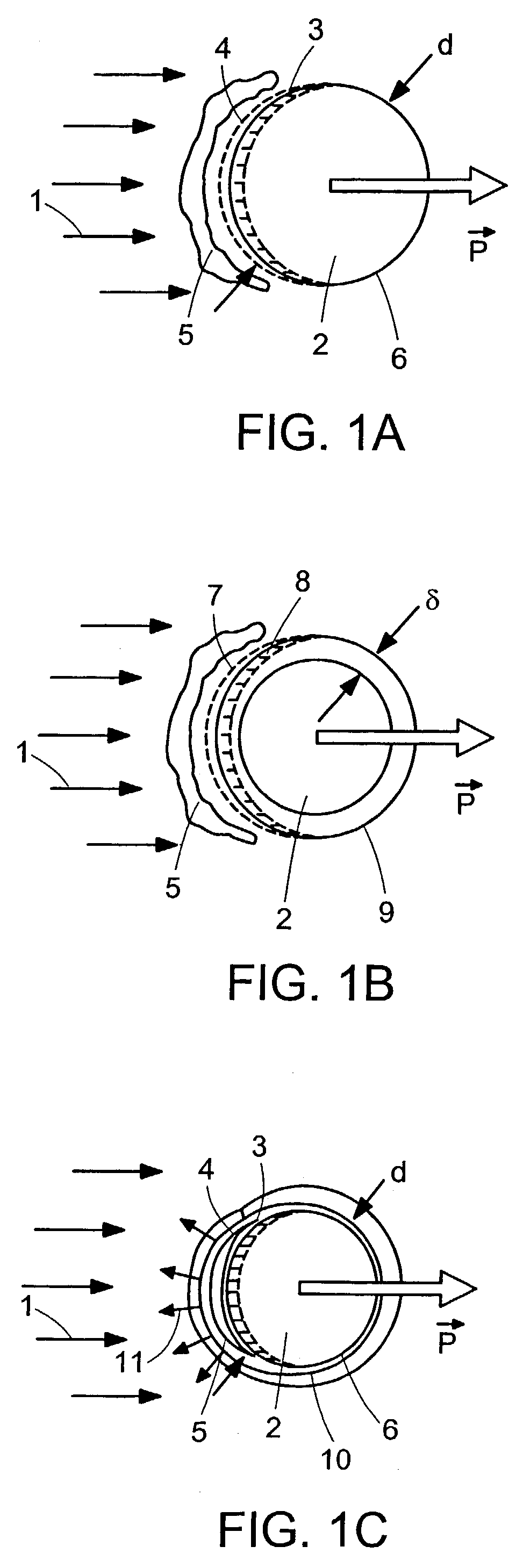

The invention relates to methods and apparatus for processing biological tissue and dental materials which involves providing or distributing a substance containing abrasive particles to an area in front of at least a portion of a surface of the tissue / material and irradiating both the substance and the portion of the surface with light from a selected source, the light being selected and delivered in a manner such that selective ablation is caused on the substance sufficient to force the abrasive particles under a selected pulse against the portion of the surface. Ablation may be of the particles themselves or the particles may be contained within a shell, with ablation being of the shell. The substance is preferably delivered as a series of distribution pulses with the light being delivered either continuously or as light pulses having a predetermined relationship to the distribution pulses.

Owner:LASER ABRASIVE TECH LLC

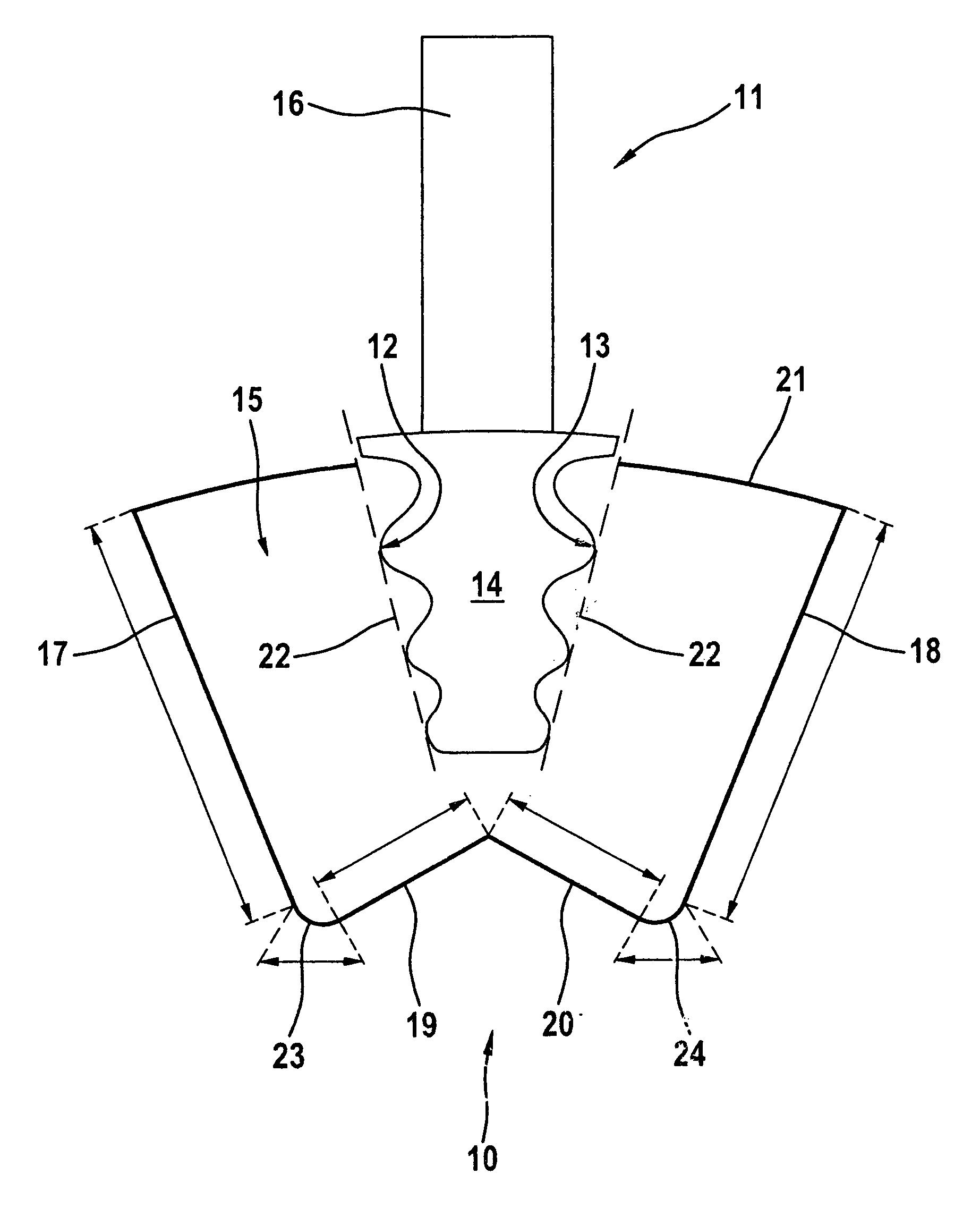

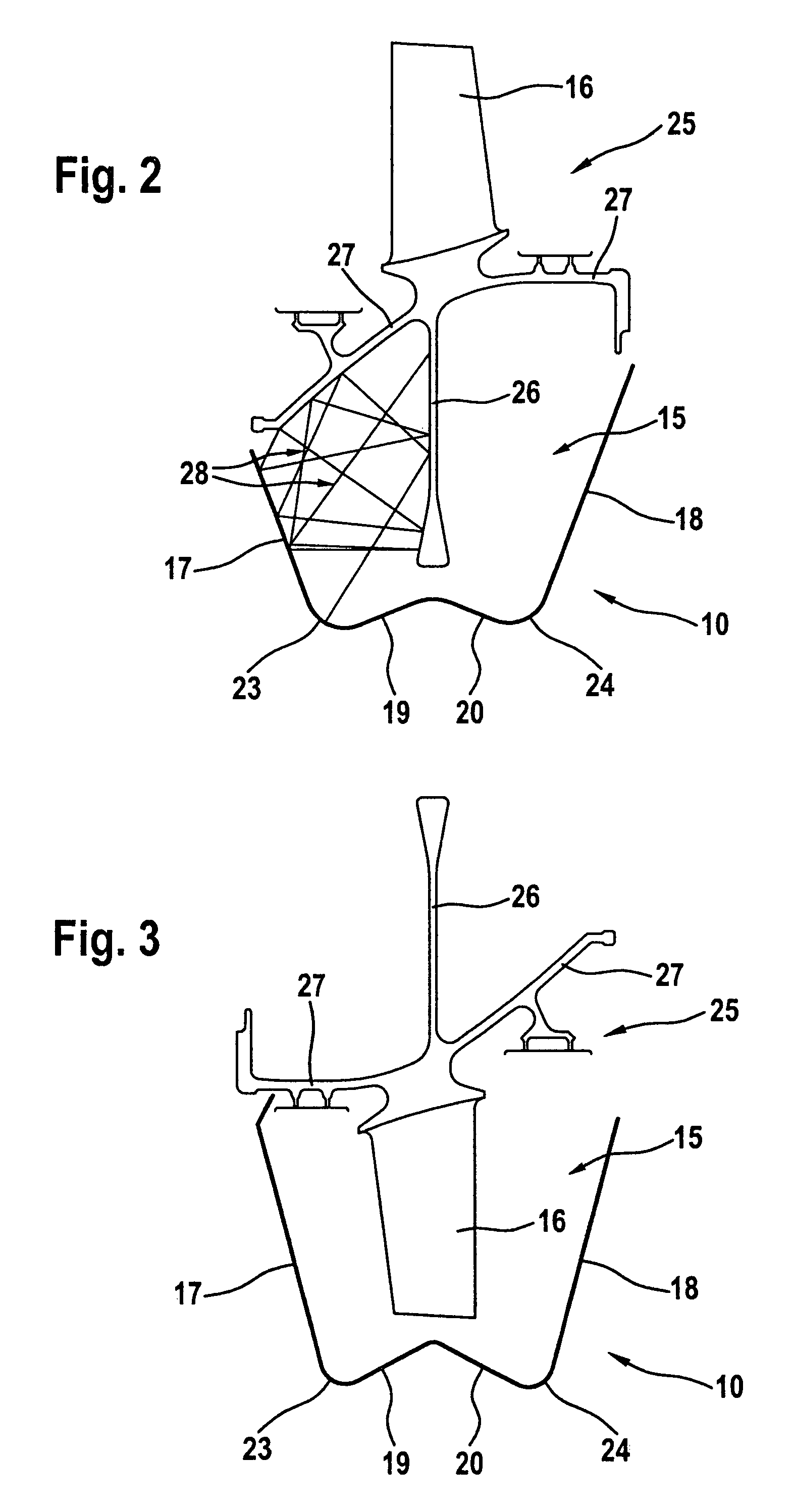

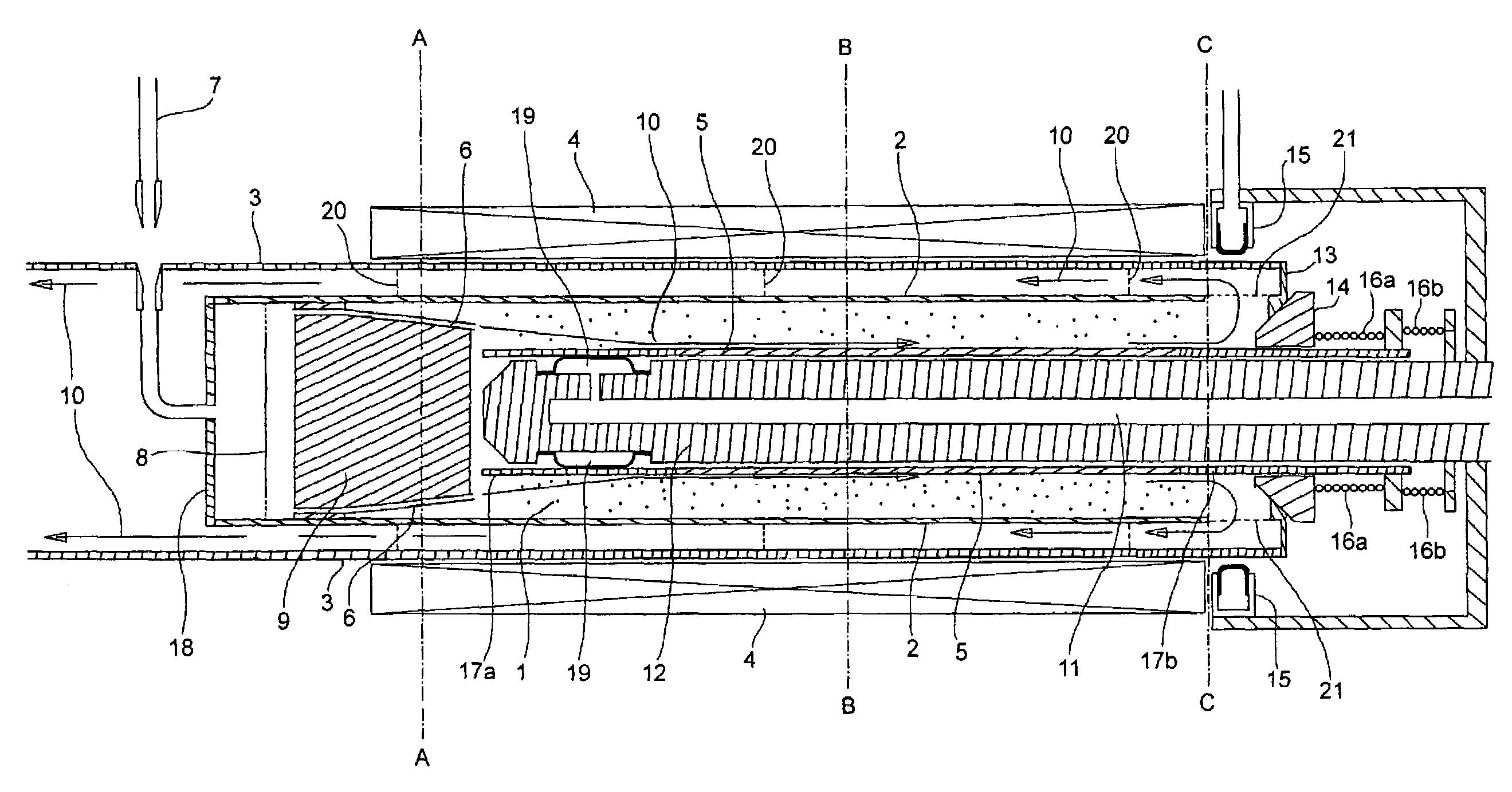

Delivery system for magnetorheological fluid

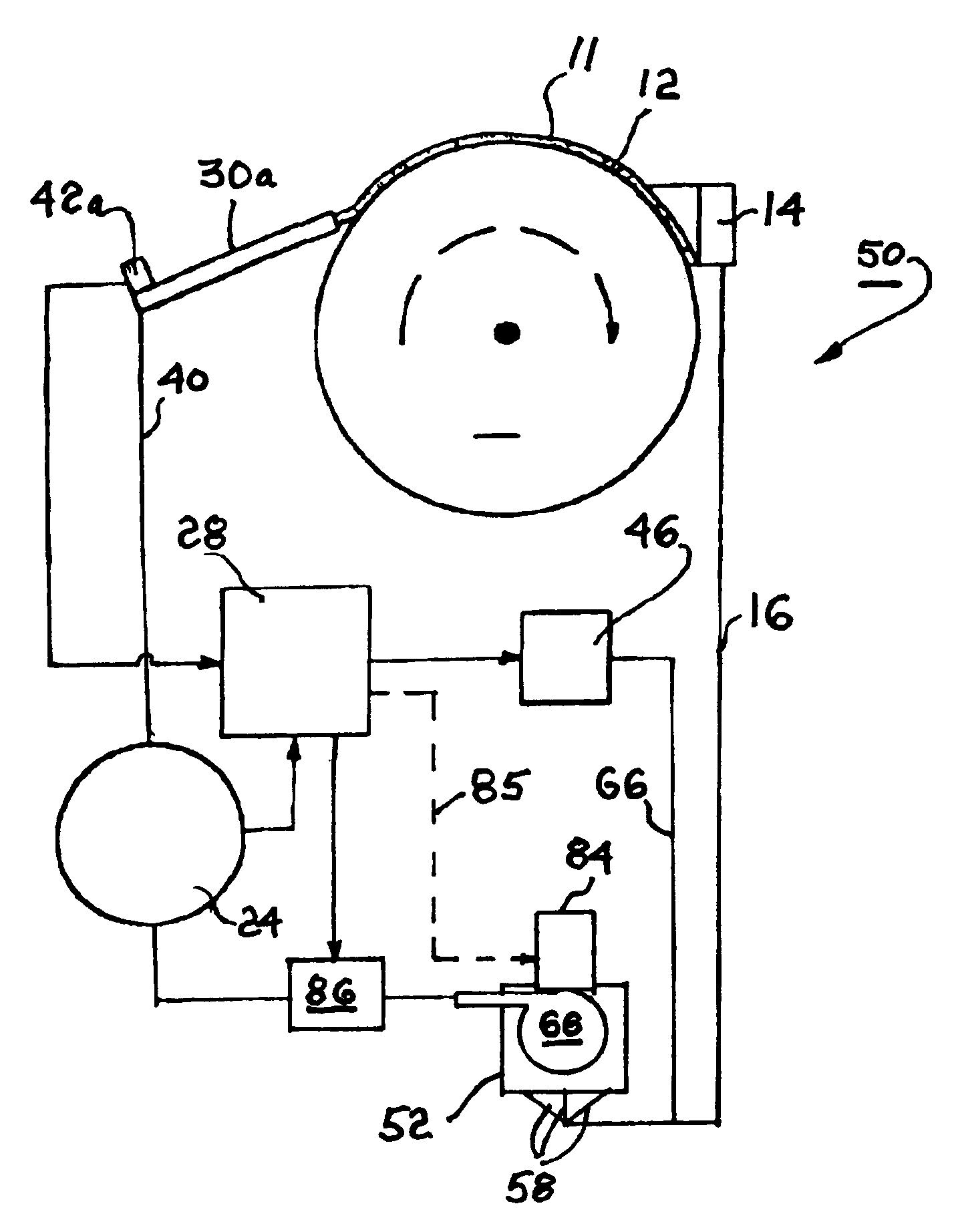

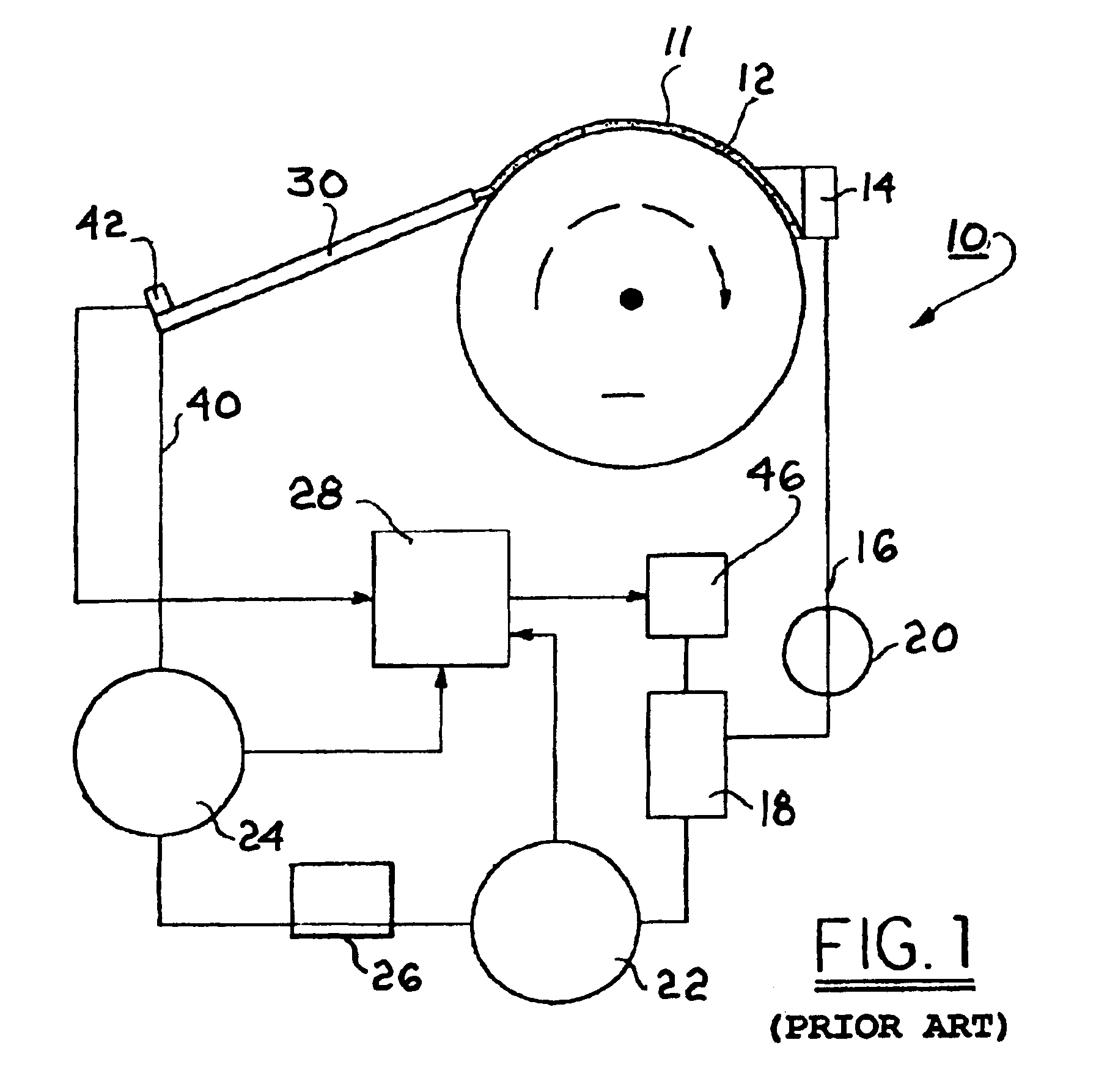

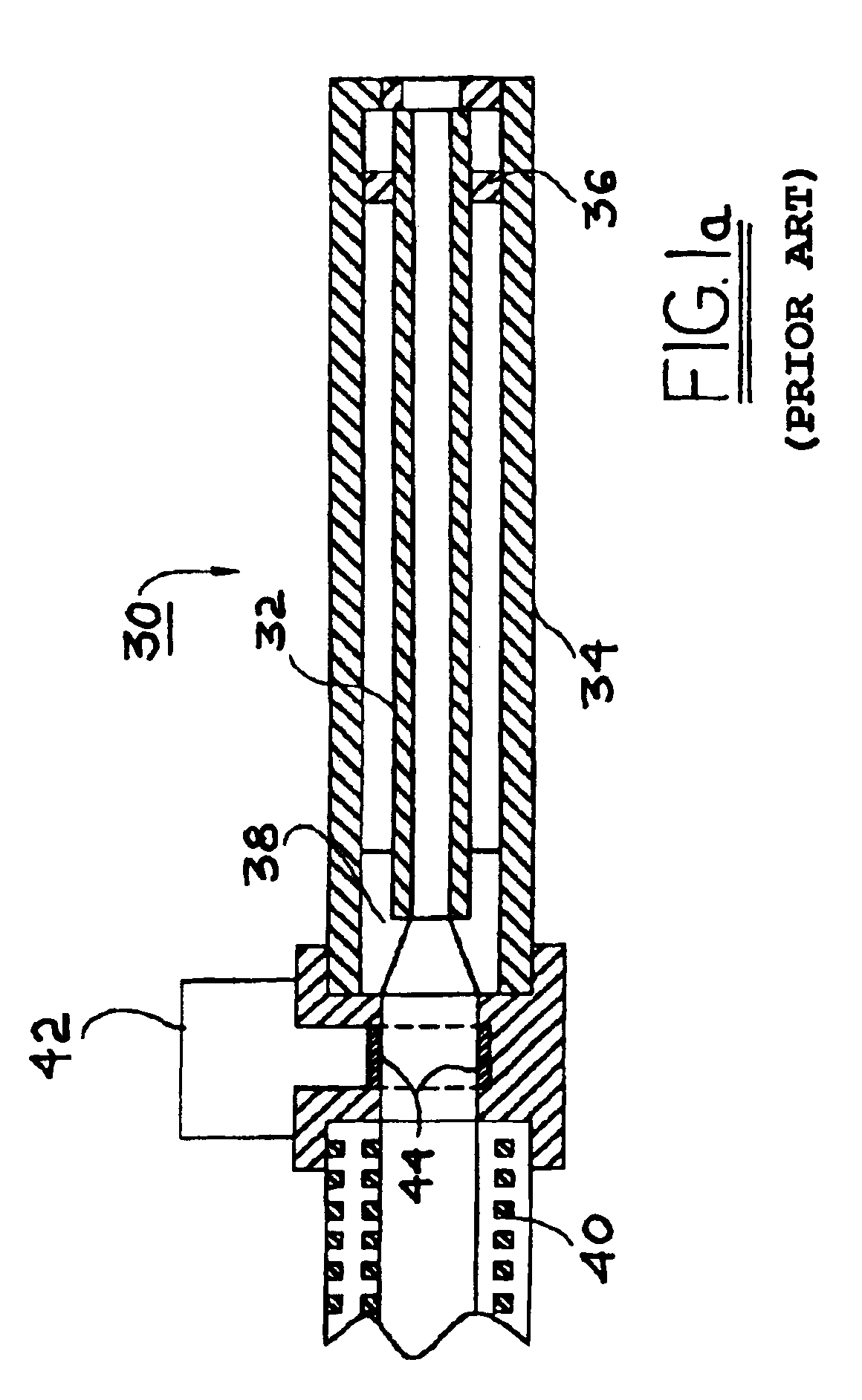

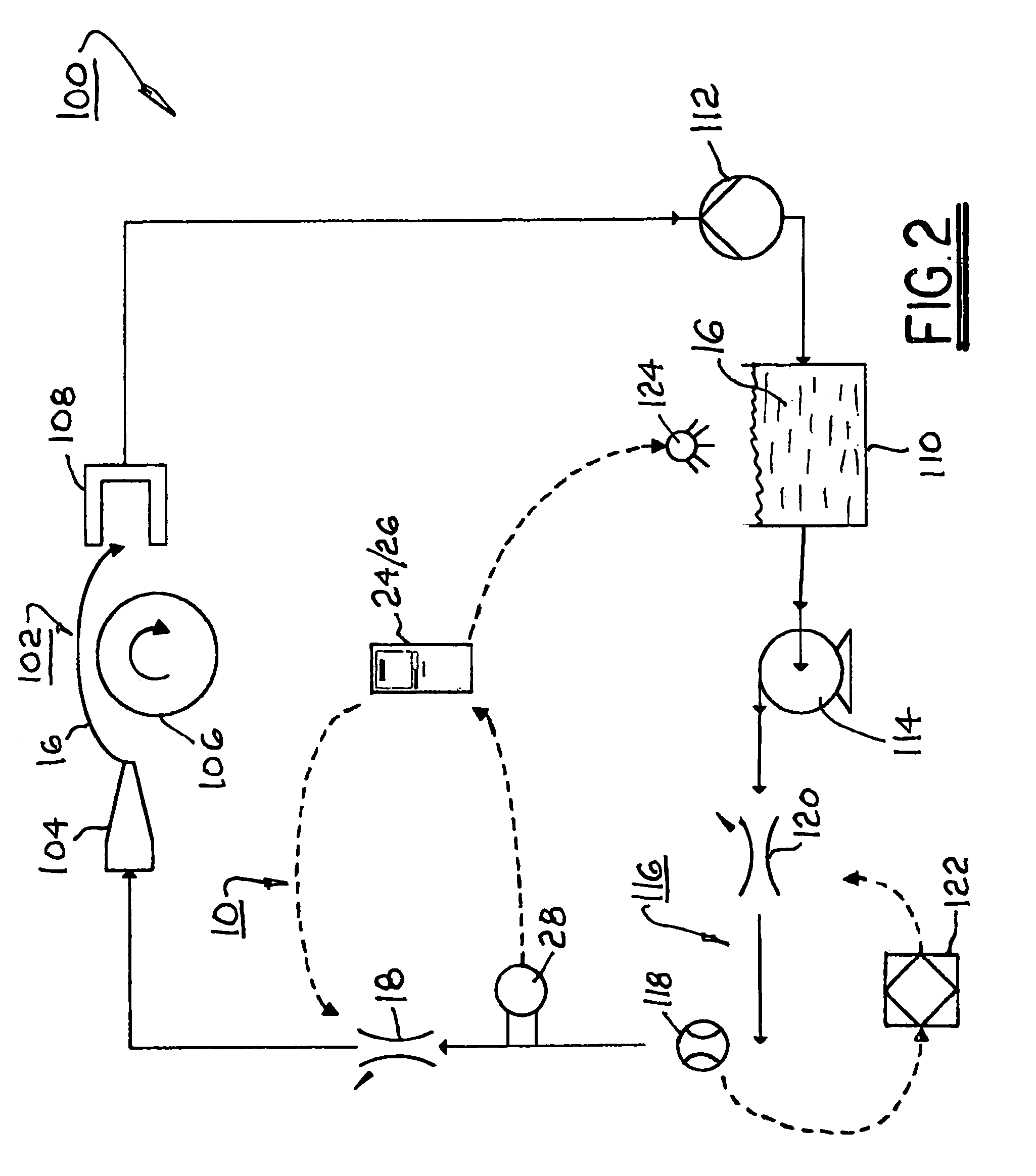

A magnetorheological fluid delivery system includes a mixing and tempering vessel. Fluid is admitted to the vessel via a plurality of tangential ports, creating a mixing of the fluid in the vessel and promoting homogeneity. Fluid may be reconstituted in the vessel by metered addition of carrier fluid. A fixed-speed centrifugal pump disposed in the vessel pressurizes the system. Fluid is pumped through a magnetic-induction flowmeter and a magnetic flow control valve having solenoid windings whereby MR fluid is magnetically stiffened to restrict flow. A closed-loop feedback control system connects the output of the flowmeter to performance of the valve. A nozzle having a slot-shaped bore dispenses MR fluid for re-use in the work zone. A planar-diaphragm flush-mounted pressure transducer at the entrance to the nozzle and flowmeter inferentially measure relaxed viscosity and provide signals to a computer for dispensing metered amounts of carrier fluid into the mixing vessel to assure correct composition of the reconstituted fluid as it is dispensed.

Owner:QED TECH INT

Deterministic magnetic jet-flow finishing method and apparatus

InactiveCN1470360AEasy to processIdeal stable removal functionNon-mechanical blast generatorsNumerical controlLiquid medium

The invention is a kind of decided magnetic radiating processing method. The piece and the nozzle for spraying magnetic rheology liquid are set on the numerical control platform, there sets a magnetic field. It controls the rheology performance of magnetic rheology liquid through controlling the special movement position of the piece and the direction-magnitude of the magnetic field, and controlsthe viscosity of the liquid and the spraying angle. Makes the liquid into anisotropic liquid media and processes the piece. The inventin includes numerical control platform with y axis, v axis, x axis, z axis and u axis, the piece is placed on y axis, v axis has a nozzle above it and u axis. There is controllable electromagnetic coil, z axis connects with u axis and x axis.

Owner:NAT UNIV OF DEFENSE TECH

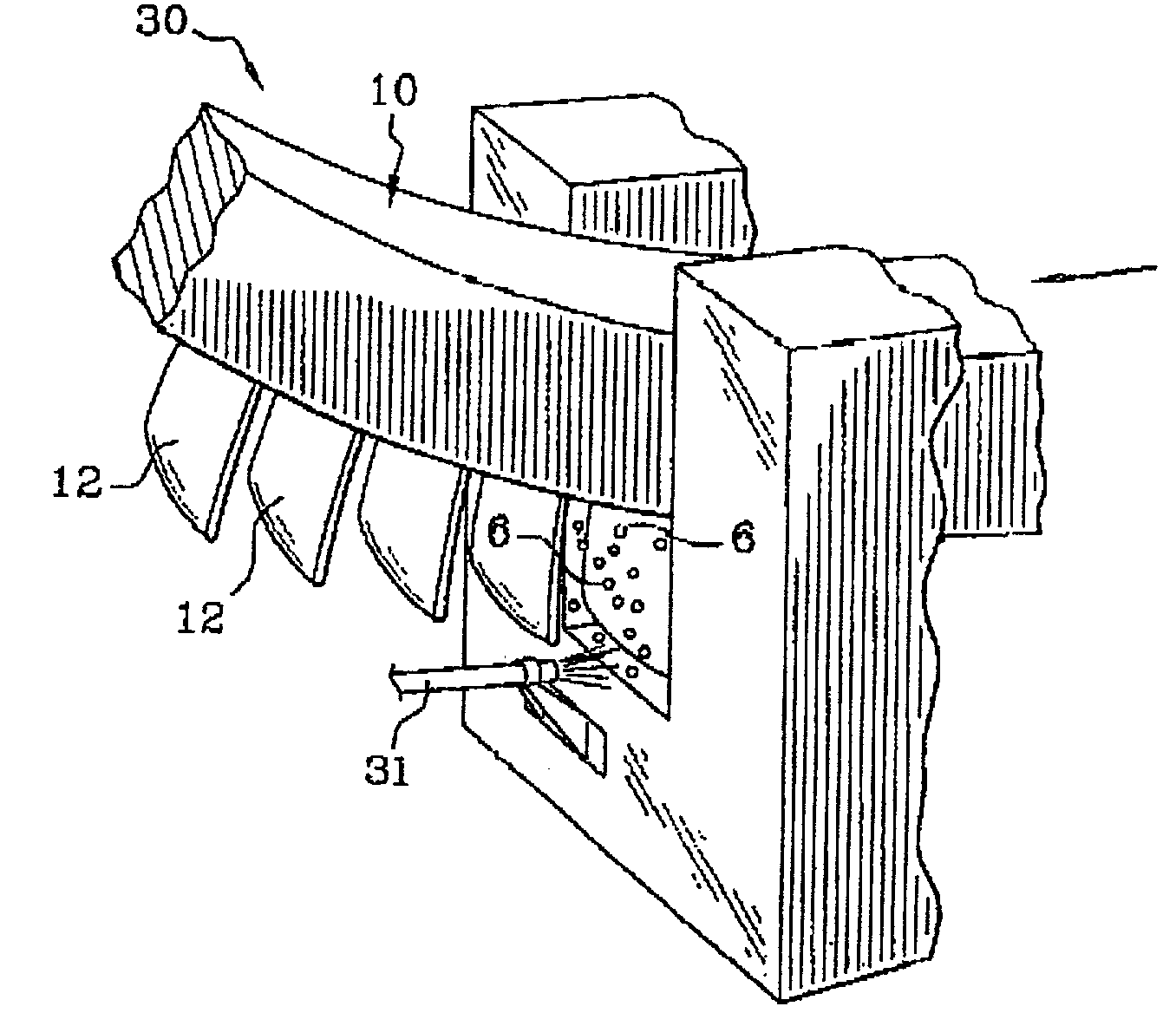

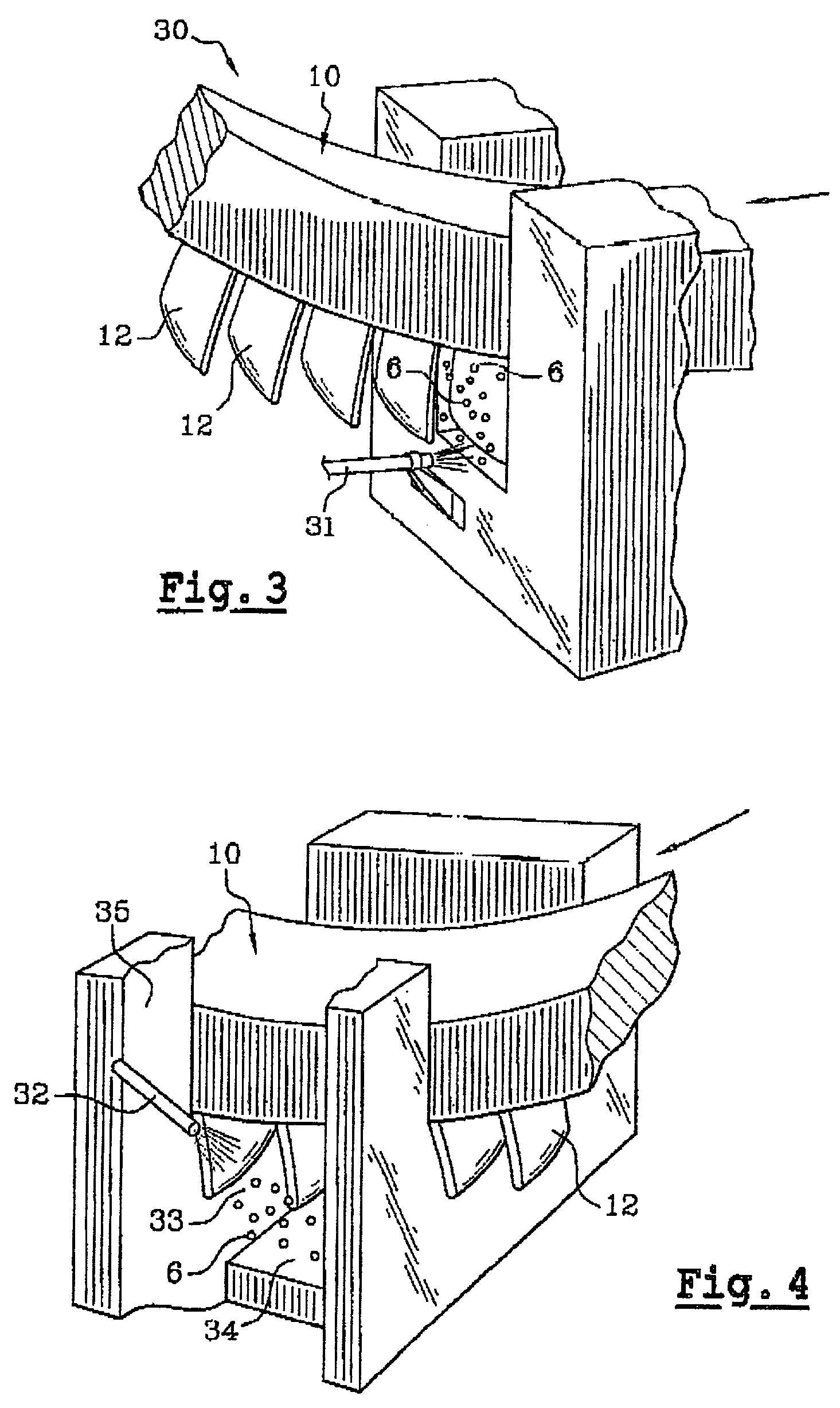

Method of shot blasting and a machine for implementing such a method

InactiveUS7028378B2Reduce usageHigh energyNon-mechanical blast generatorsBlade accessoriesEngineeringPeening

A part to be shot peened includes at least one thin wall (12″) defining two opposite main faces, the square root of the area of each face being greater than the mean distance between the two faces by a factor of at least five, and preferably by a factor of at least ten. According to the method, the part is caused to rotate at least intermittently relative to one or more vibrating surfaces, with at least one of the main faces being exposed to projectiles (6) set into motion by one or more of the vibrating surfaces, treatment taking place progressively on the face(s) so as to impart compression stresses thereto, with a portion only of the part being treated at any one time and with regions of the part preferably being exposed on several occasions to the projectiles, with relative rotation taking place between the exposures.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Micro-pore polishing equipment and micro-pore polishing process for abrasive particle flow

InactiveCN104149036AAchieve polishReduce roughnessNon-mechanical blast generatorsAbrasive blasting machinesParticle flowCavitation

The invention discloses micro-pore polishing equipment for an abrasive particle flow. The micro-pore polishing equipment comprises a clamp, a base plate, a through-hole-shaped cavitation cavity, a high-transparency laser protection lens, a laser device, a focusing lens and an abrasive material guide channel, wherein the clamp is used for clamping a workpiece and positioning a micro-pore to be polished in the workpiece; the base plate is mounted on the clamp; the cavitation cavity is arranged on the base plate and is correspondingly communicated with the micro-pore in the workpiece; the high-transparency laser protection lens covers one side, opposite to the workpiece, of the cavitation cavity; the laser device can generate a laser beam towards the cavitation cavity; the focusing lens is arranged between the laser device and the high-transparency laser protection lens and can be used for focusing the laser beam into the cavitation cavity; the abrasive material guide channel can be used for leading pressure abrasive particle fluid into the cavitation cavity. By adopting the micro-pore polishing equipment, laser is continuously and periodically focused on the fluid to form cavitation; generated great partial pressure and a jet flow for pushing the abrasive particle flow to the micro-pore are used for continuously pushing the abrasive particle flow to flow in the micro-pore at a high speed and abrade the pore wall of the micro-pore, so that the super-precision and high-efficiency polishing is carried out on the micro-pore. The invention further discloses a micro-pore polishing process for the abrasive particle flow. By using the method disclosed by the invention, the super-precision and high-efficiency polishing can be carried out on the micro-pore.

Owner:GUANGDONG UNIV OF TECH

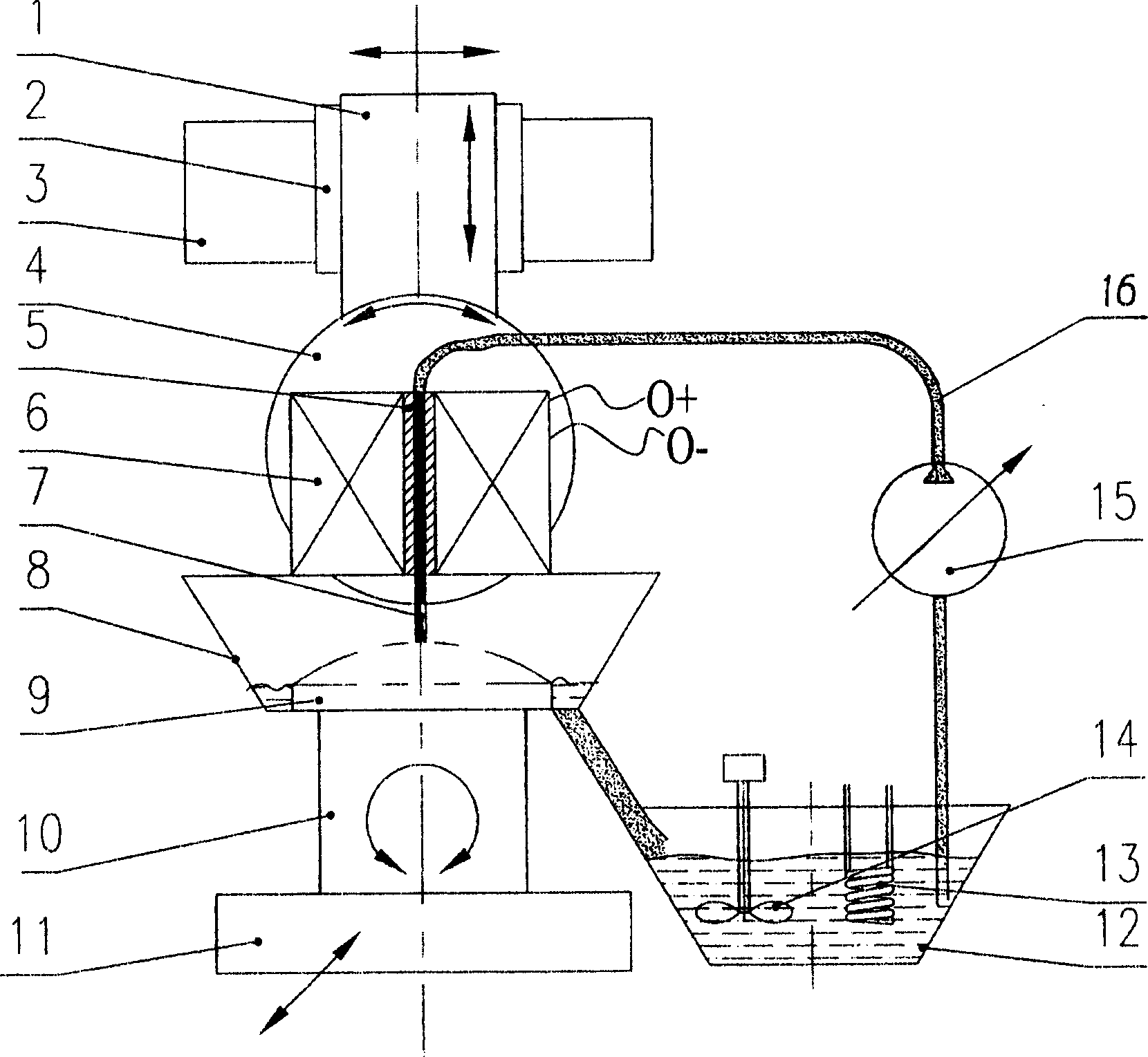

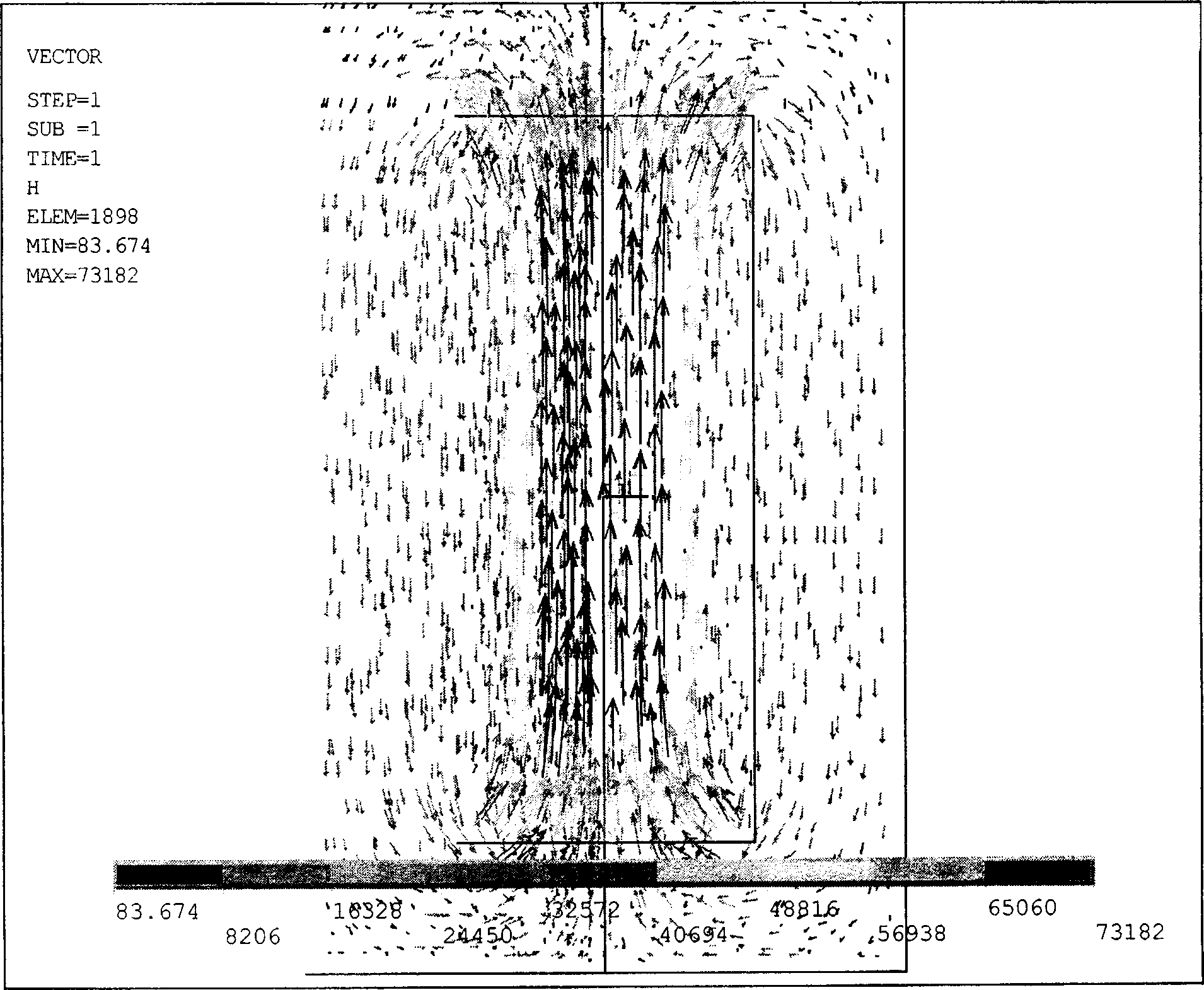

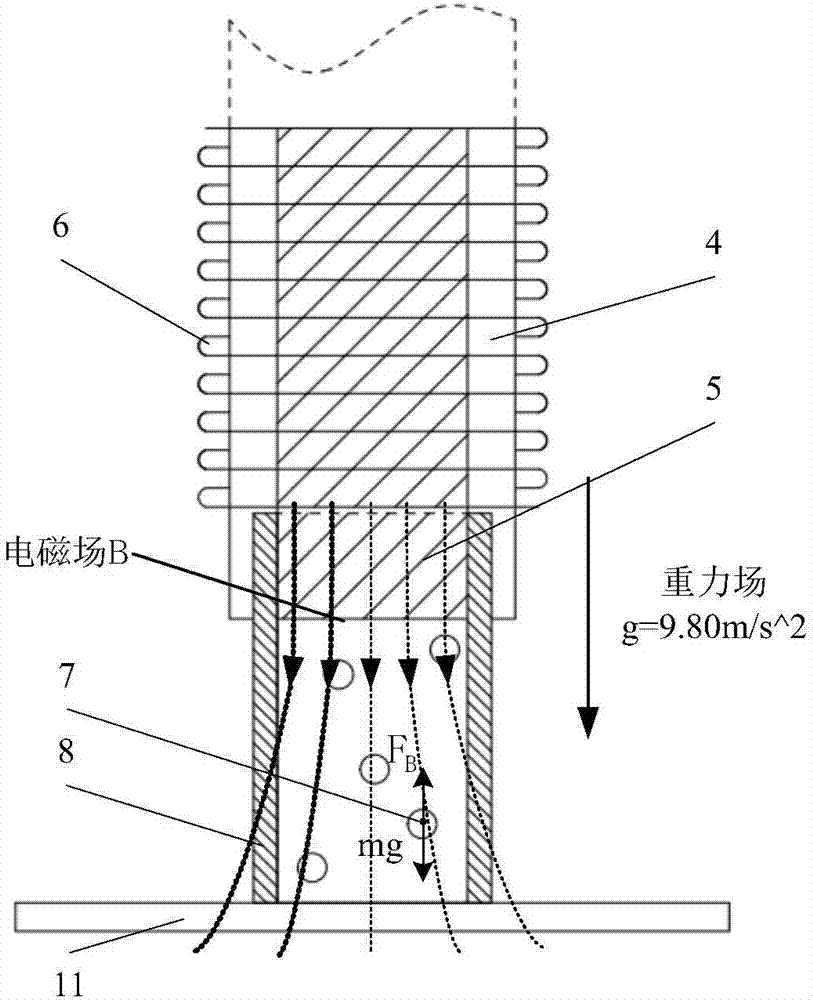

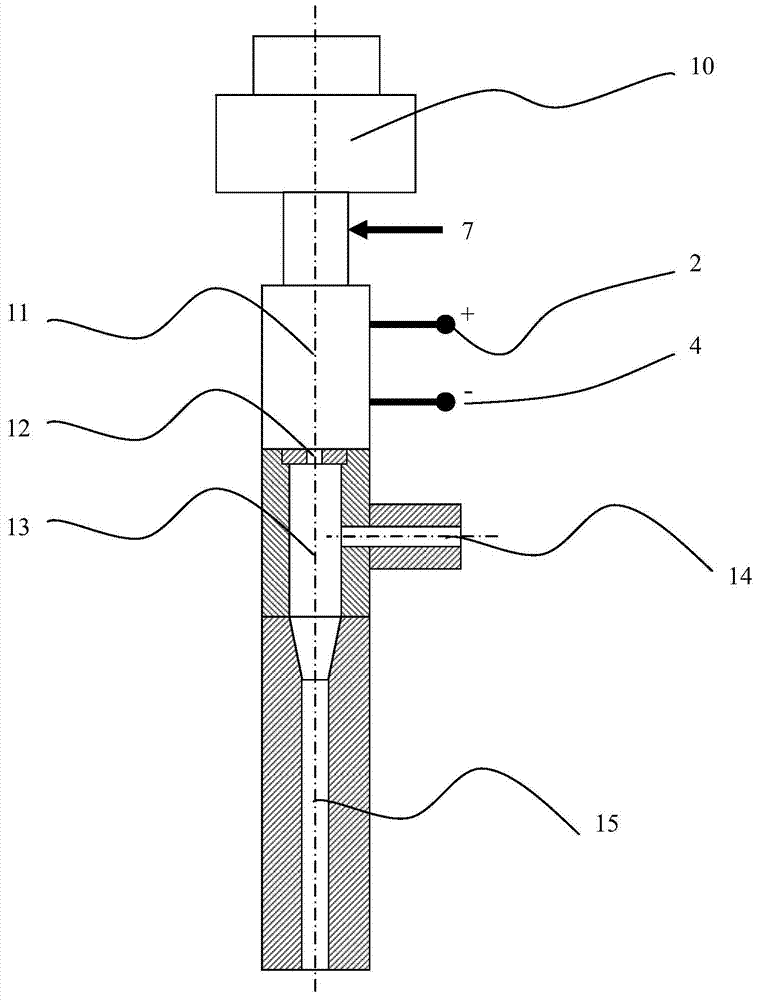

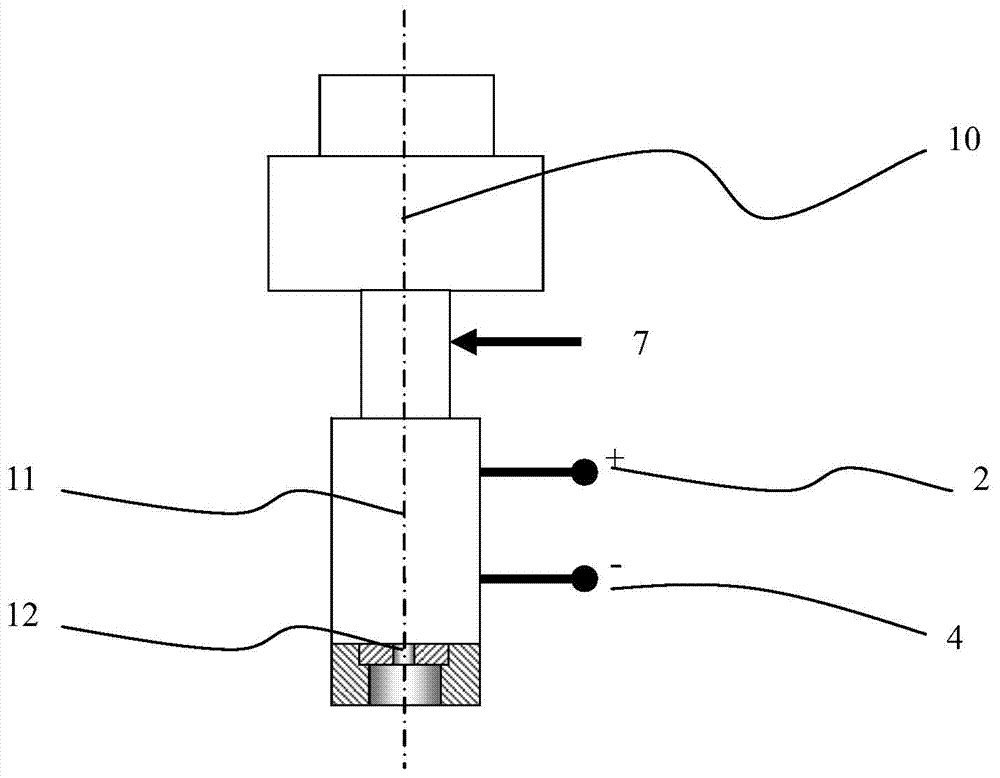

Electromagnetic-field-aided ultrasonic shot peening device and method

ActiveCN107336142AControl speedReduced strengthNon-mechanical blast generatorsAbrasive machine appurtenancesPower flowElectromagnetic field

The invention provides an electromagnetic-field-aided ultrasonic shot peening device and method. Through application of an electromagnetic field, shots are in a superimposed field of an electromagnetic field and a gravity field, and the intensity of the electromagnetic field is changed through change of the magnitude of a current so that the magnitude and direction of a resultant borne by the shots can be controlled; and in this way, the influence of the gravity field on the shots is eliminated according to different directions of a tool head relative to a workpiece, and the limitation that during conventional shot type ultrasonic shot peening treatment, the tool head can only be located below the workpiece to be treated and preferably over the workpiece to be treated is eliminated. The tool head can be located below the workpiece to be treated and can also located above the workpiece to be treated, and treatment of a workpiece in a complicated shape can be conveniently and flexibly achieved in any direction. Besides, through control over the magnitude of the electromagnetic force, the speed of the shots can be changed, and adjustment and control over the shot peening intensity can be achieved.

Owner:SHANDONG UNIV

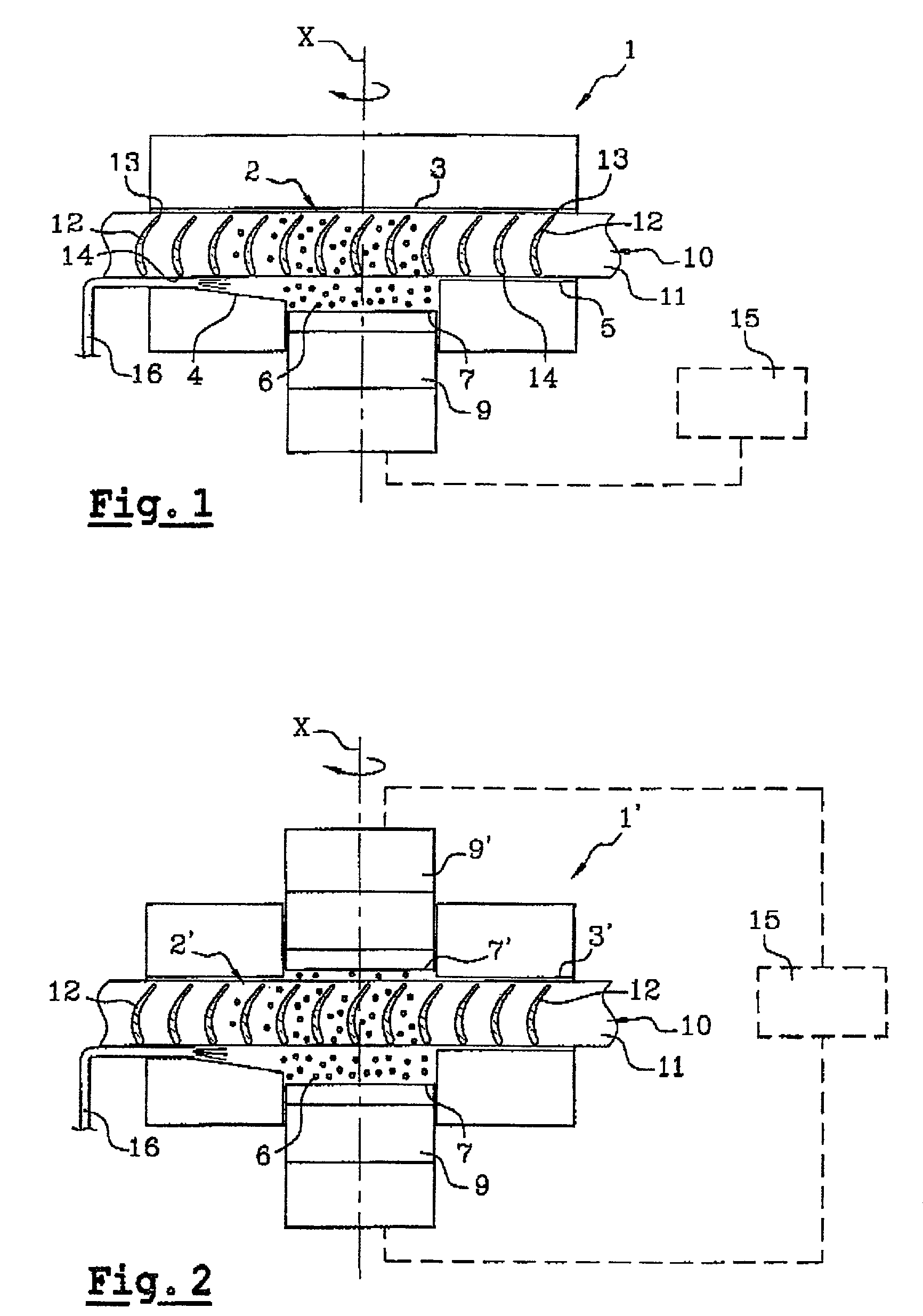

Device for surface blasting component

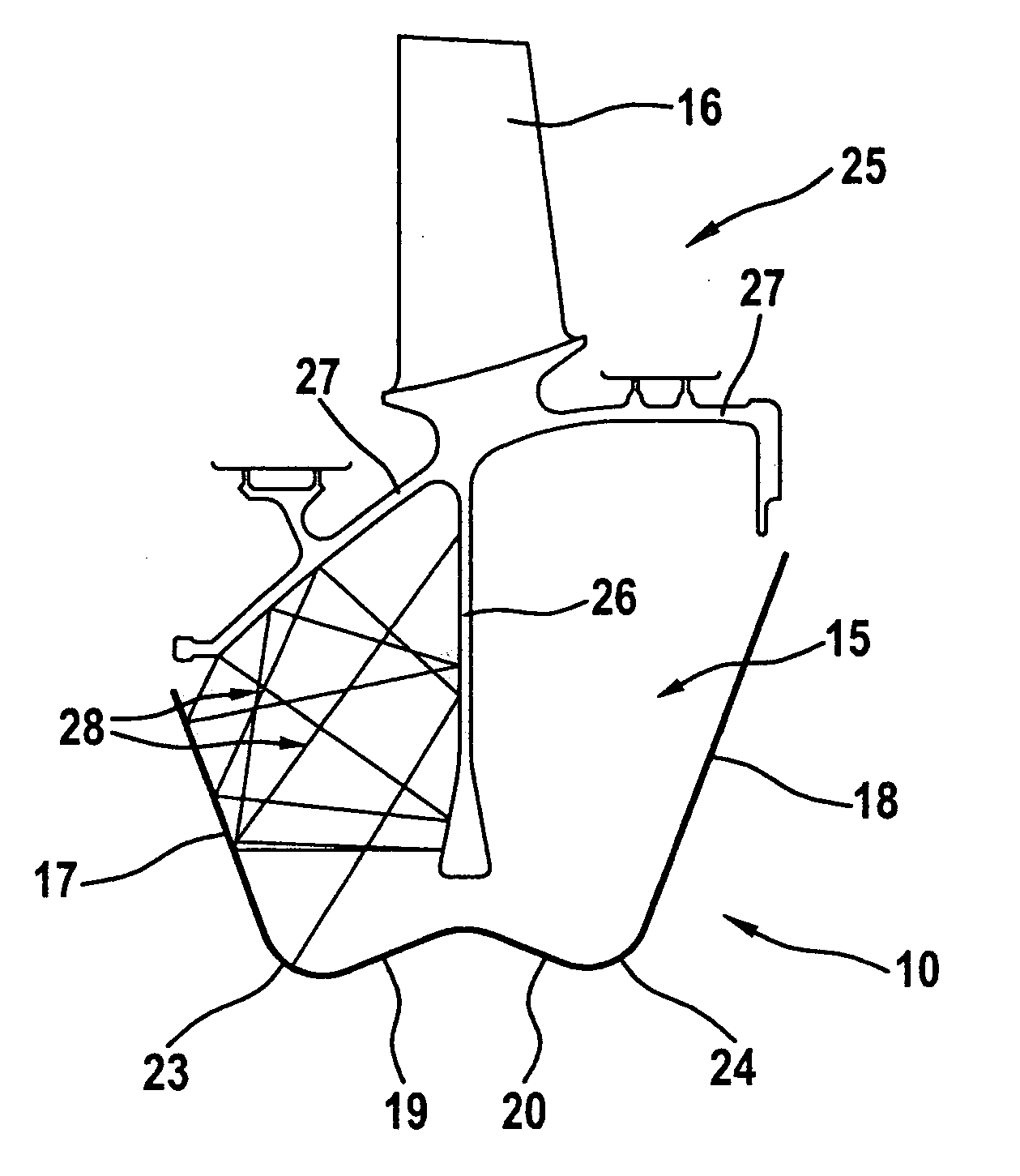

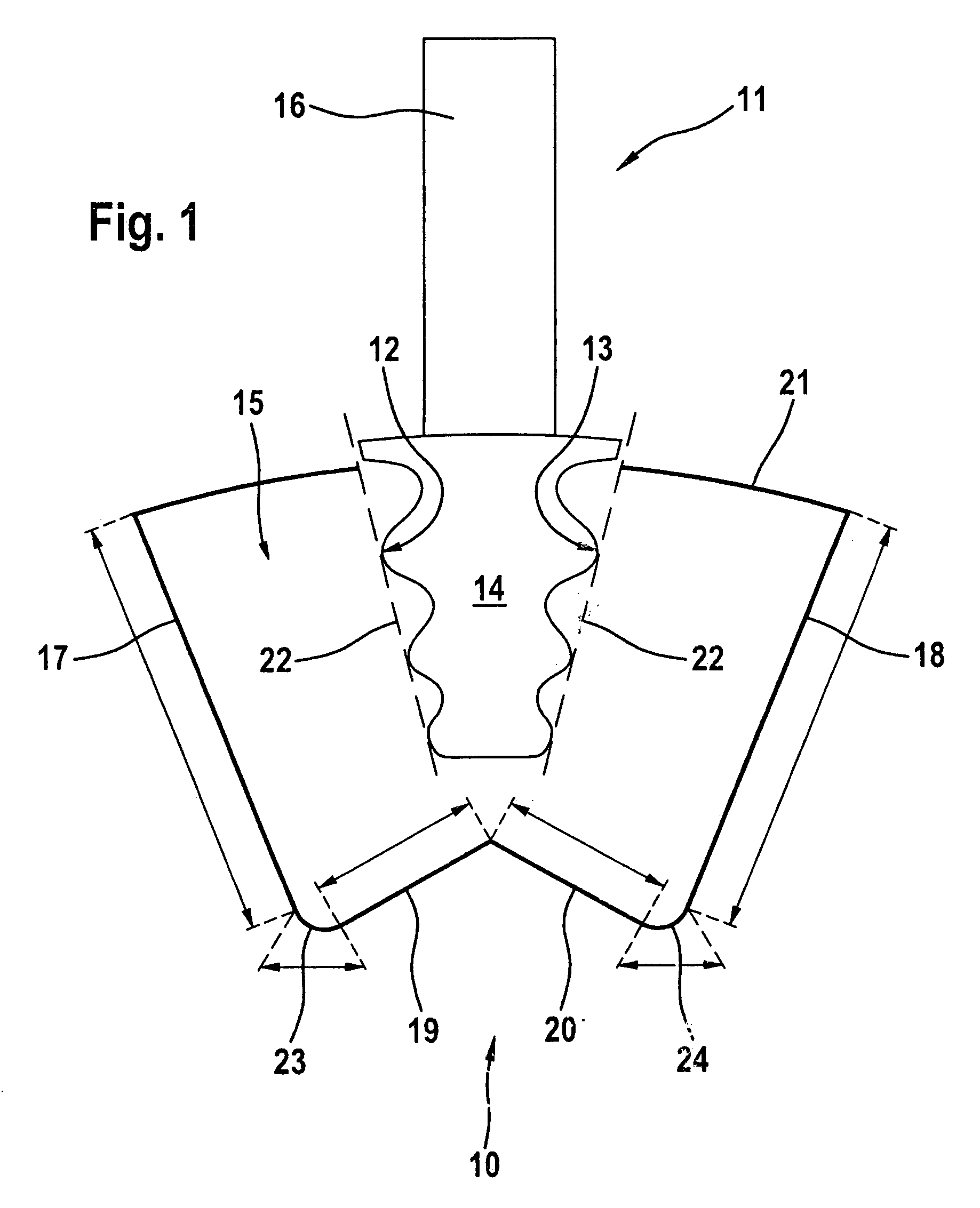

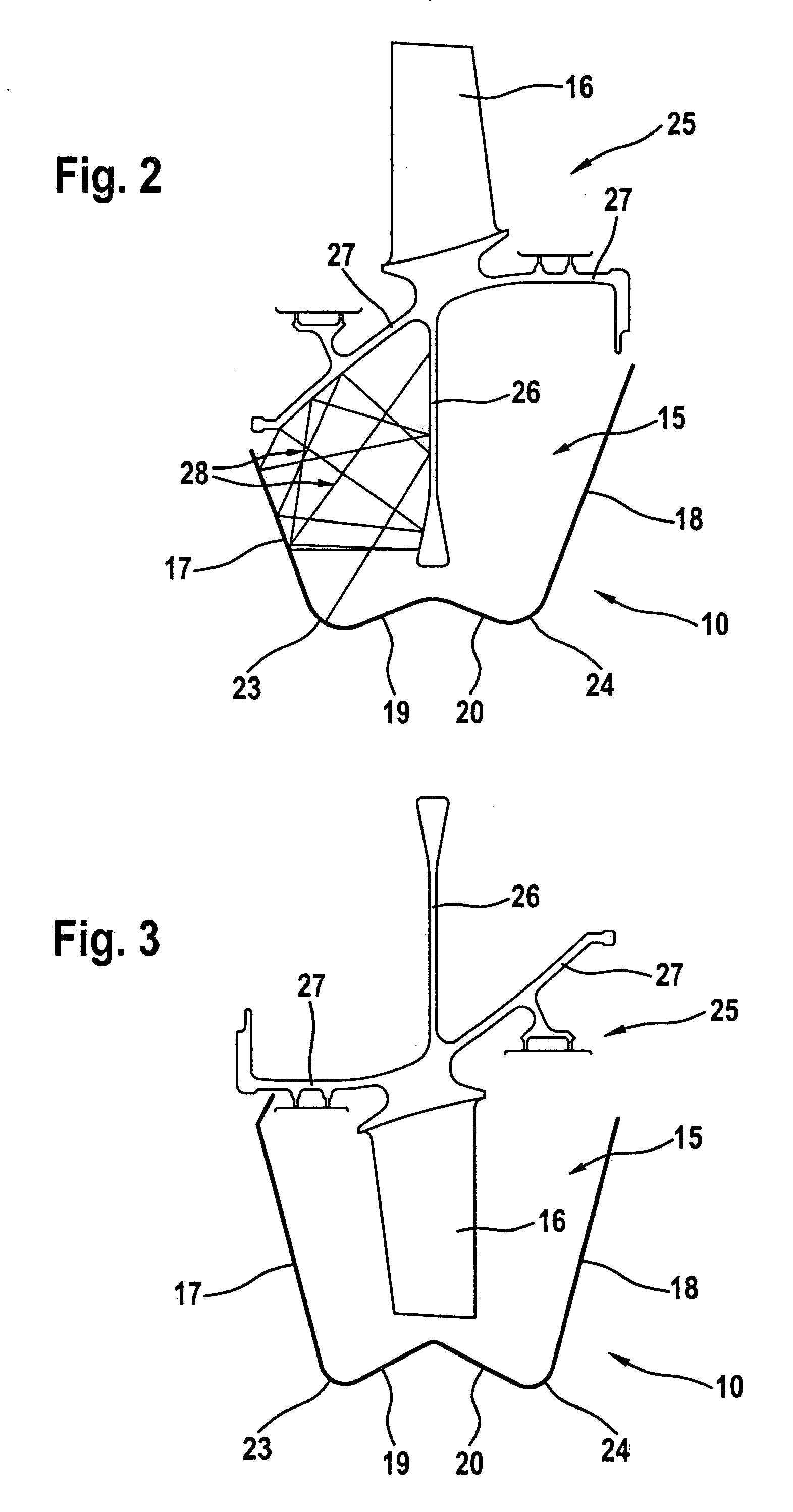

ActiveUS20060174483A1Improve efficiencyImprove machine qualityEdge grinding machinesNon-mechanical blast generatorsAbrasive blastingEngineering

A device for surface blasting, e.g., for ultrasonic shot blasting, components, e.g., gas turbine components, includes at least one vibrator having an oscillating surface, e.g., having at least one ultrasonic sonotrode, the or each oscillating surface of the or each vibrator being adjoined by a machining chamber for receiving a section to be blasted of the component to be machined. The machining chamber is bounded in its cross-section by at least three sides, e.g., by at least two substantially vertical sides and by at least one substantially horizontal side. At least the substantially vertical sides of the machining chamber are formed by oscillating surfaces of in each case one vibrator.

Owner:MTU AERO ENGINES GMBH

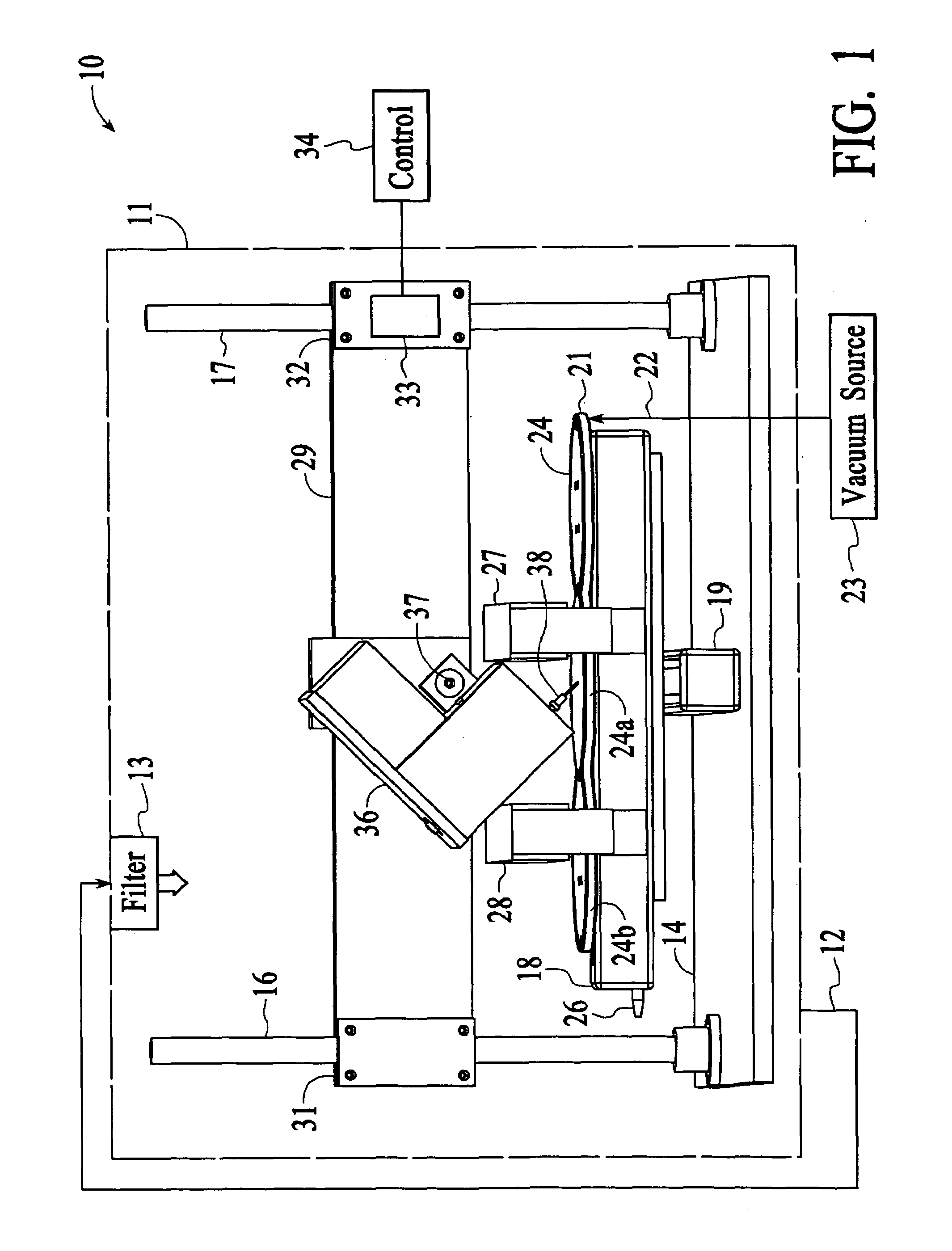

Methods for resist stripping and other processes for cleaning surfaces substantially free of contaminants

InactiveUS7297286B2Small footprintEasy to cleanNon-mechanical blast generatorsDecorative surface effectsResistEngineering

A method for manufacturing an article having polymeric residue that is to be removed during the manufacture of the article is disclosed. The article is introduced into a controlled environment of a processing tool having one or more processing chambers. Free radicals are generated from one or more reactant gases and introduced into at least one of the one or more processing chambers where they react with the polymeric residue. A cryogenic cleaning medium is supplied into at least one of the one or more processing chambers where the cryogenic cleaning medium removes the polymeric residue present after the free radicals react with the polymeric residue. The reactant gases are selected to facilitate removal of the polymeric residue with the cryogenic cleaning medium. The cryogenic cleaning medium is supplied with a pulsating flow via a nozzle implement that sweeps across the article. The pulsating flow may be generated via a piezo device or a rotating shaft with a hole the periodically enables or interrupts flow through a flow channel.

Owner:NANOCLEAN TECH

Device for surface blasting component

ActiveUS8091192B2Improve machine qualityImprove efficiencyEdge grinding machinesNon-mechanical blast generatorsAbrasive blastingMechanical engineering

A device for surface blasting, e.g., for ultrasonic shot blasting, components, e.g., gas turbine components, includes at least one vibrator having an oscillating surface, e.g., having at least one ultrasonic sonotrode, the or each oscillating surface of the or each vibrator being adjoined by a machining chamber for receiving a section to be blasted of the component to be machined. The machining chamber is bounded in its cross-section by at least three sides, e.g., by at least two substantially vertical sides and by at least one substantially horizontal side. At least the substantially vertical sides of the machining chamber are formed by oscillating surfaces of in each case one vibrator.

Owner:MTU AERO ENGINES GMBH

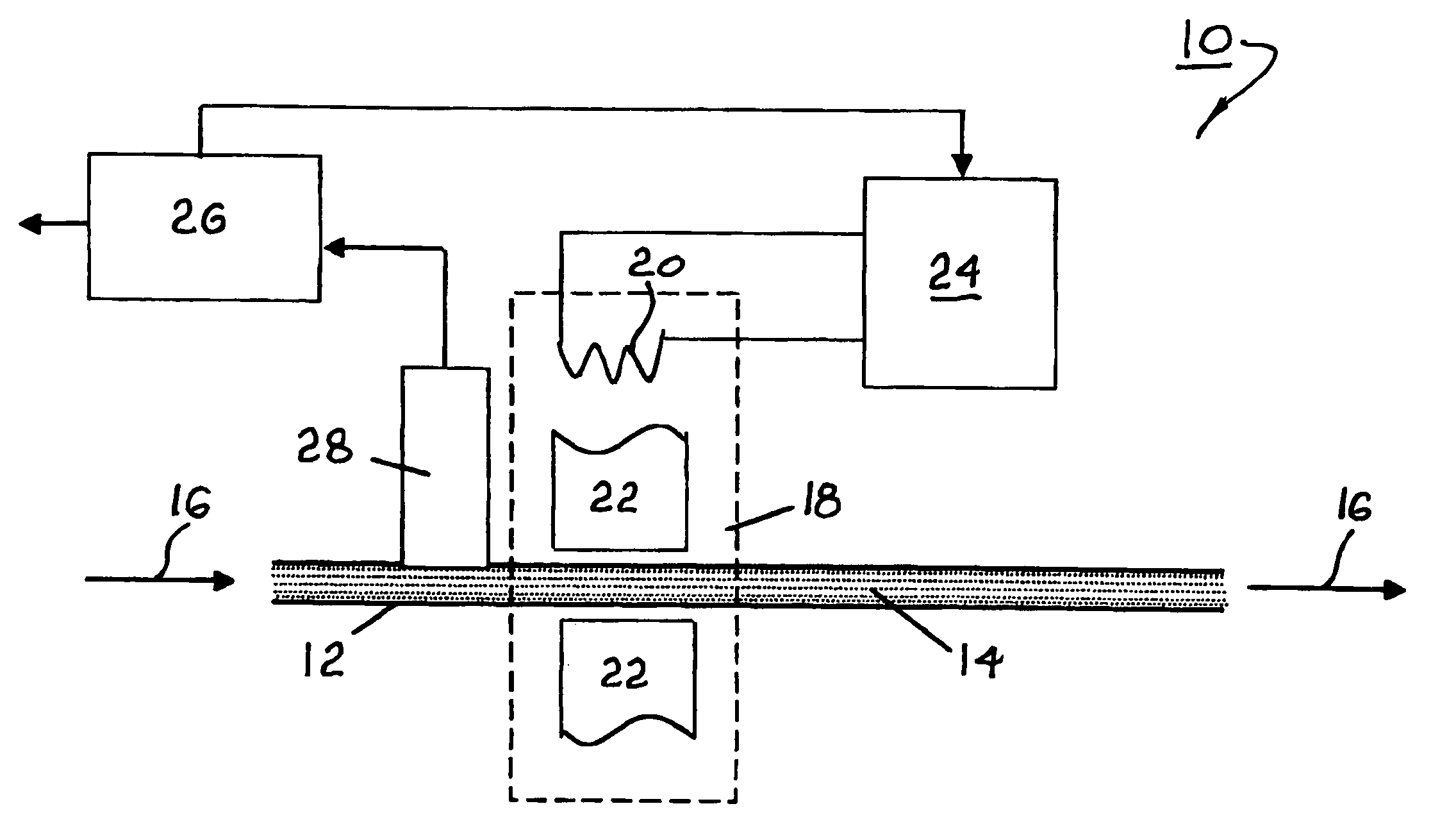

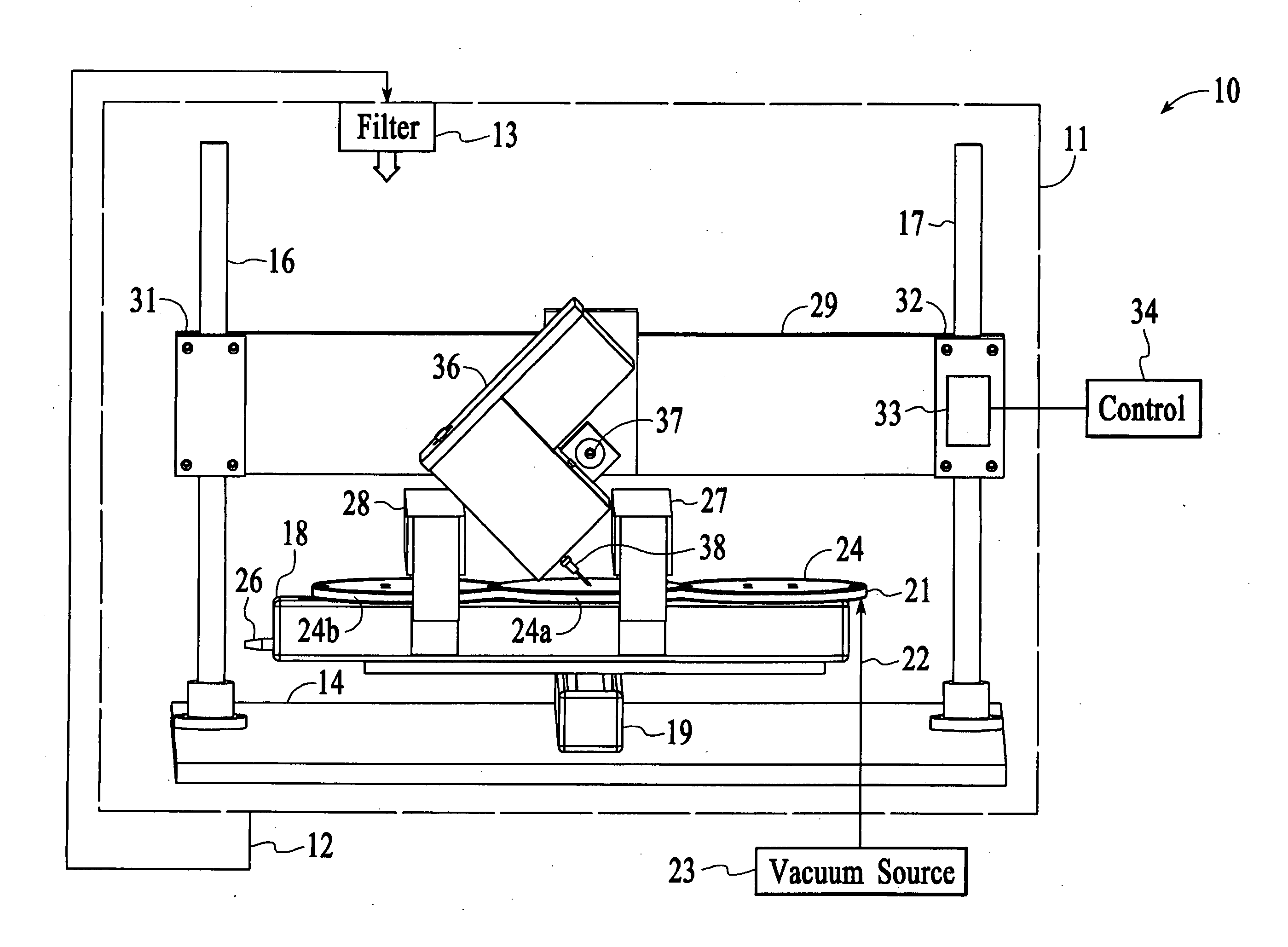

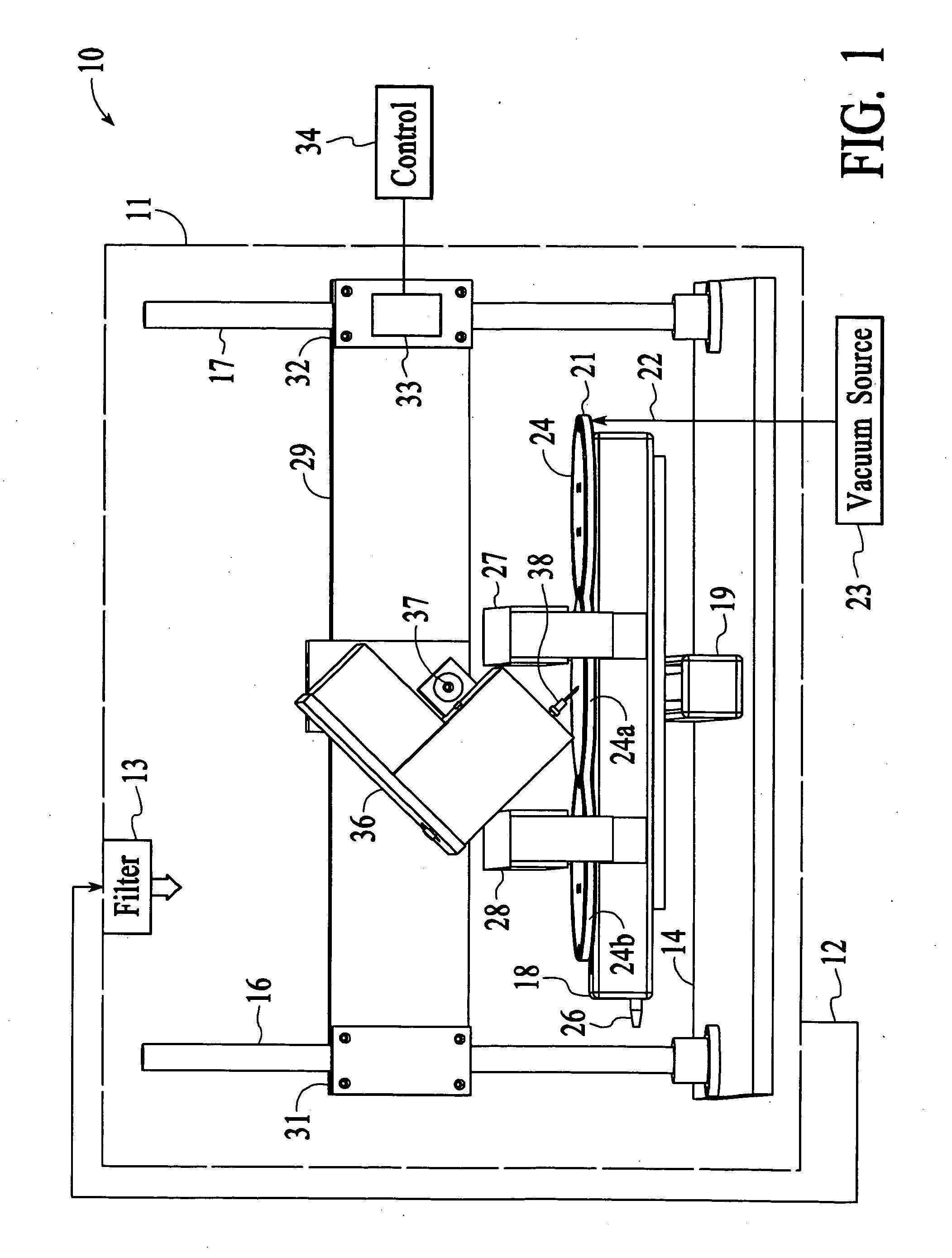

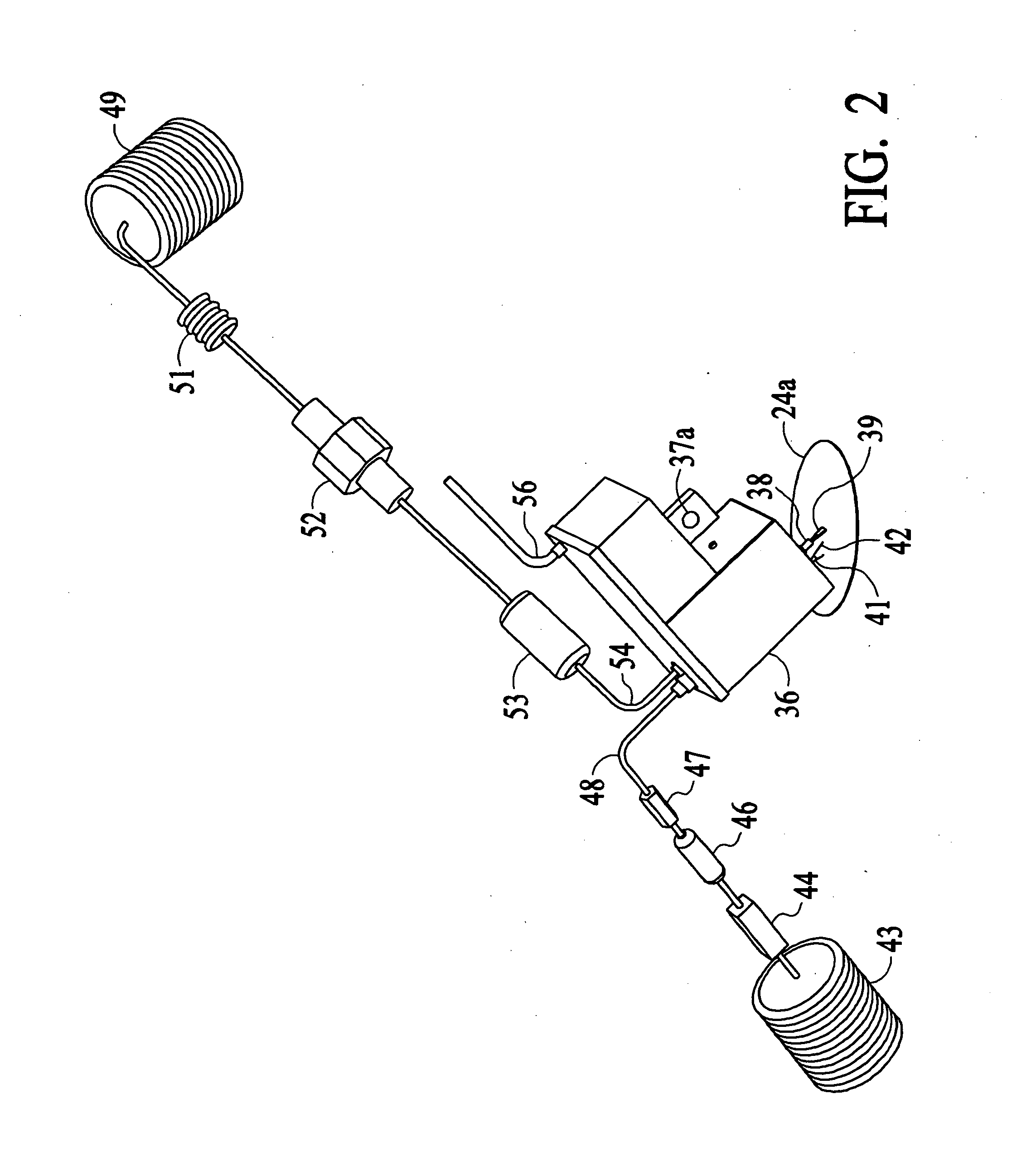

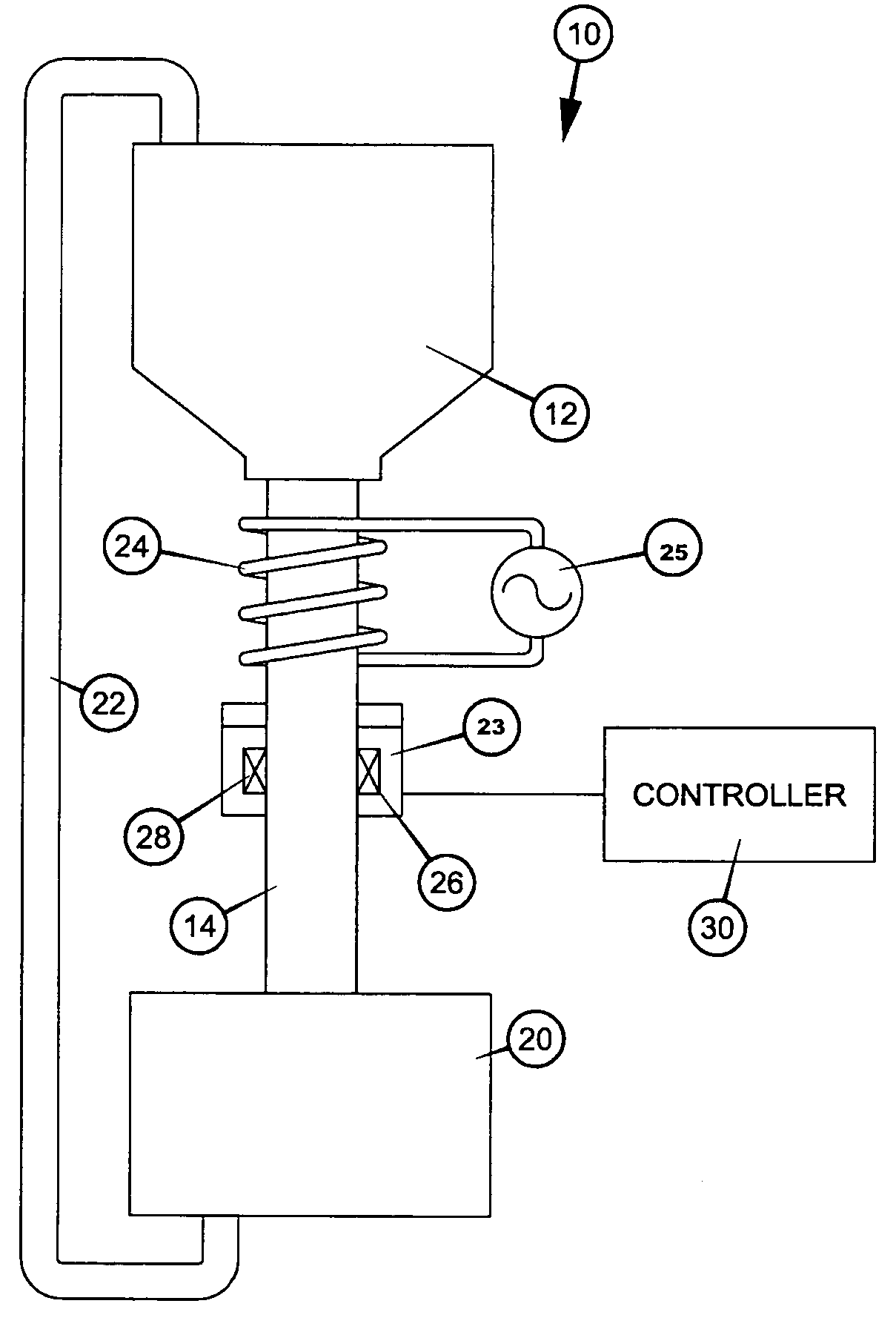

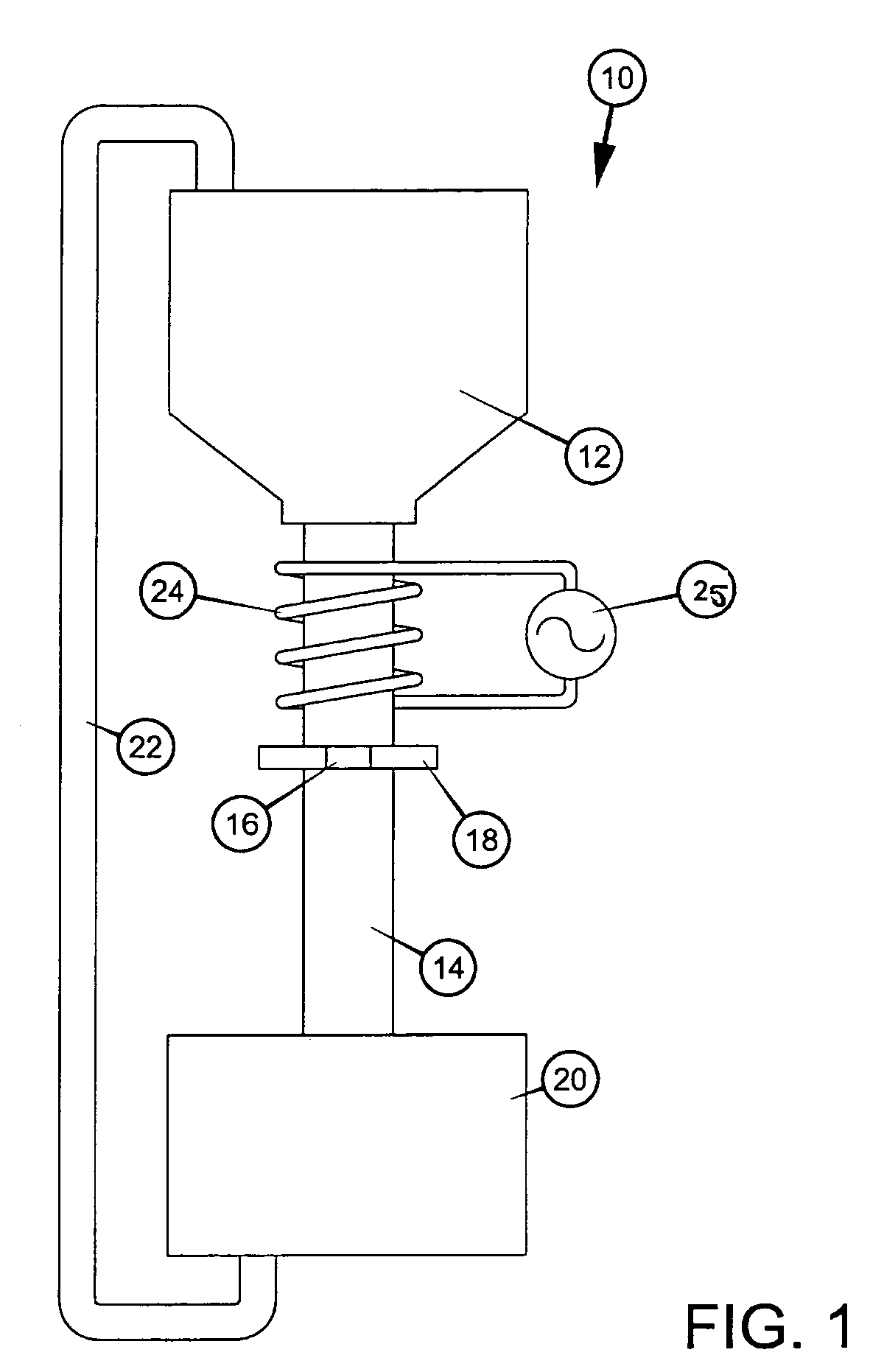

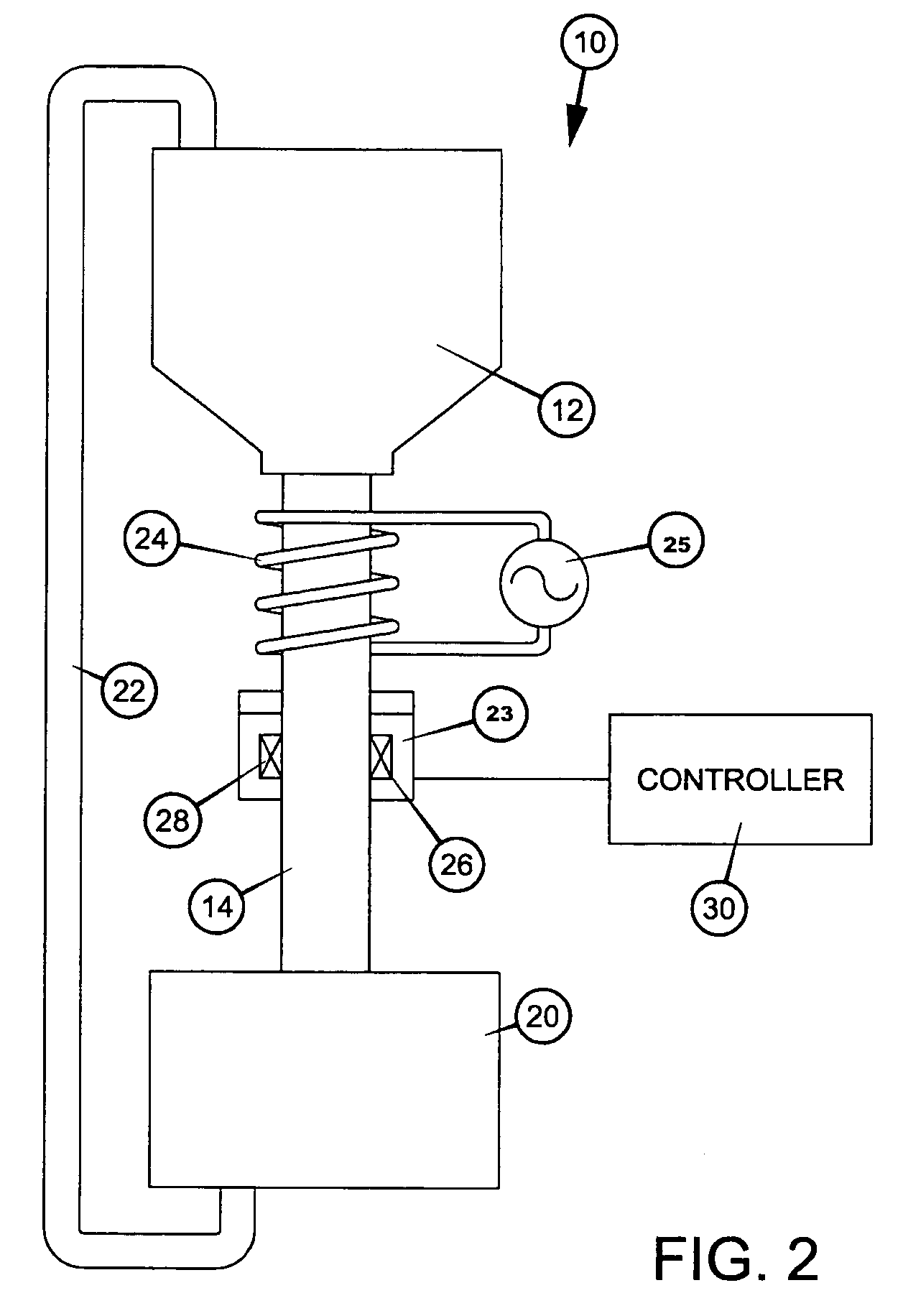

Method and apparatus for measuring and controlling solids composition of a magnetorheological fluid

InactiveUS6893322B2Edge grinding machinesOperating means/releasing devices for valvesApparent viscosityMagnetic valve

A system for dispensing magnetorheological fluid to an MR finishing machine includes a pump for pressurizing the system; a first magnetic valve for regulating MR fluid flow by magnetically varying the structure and apparent viscosity of the fluid through a first flow passage; a similar second magnetic valve magnetically controlling a second flow passage in line with the first valve and flow passage; a pressure sensor disposed between the first and second valves; and an electronic control means. MR fluid flow through the system is controlled to a predetermined flow rate solely by the first valve. When the second valve is deactivated, a reference pressure is determined and saved. When the second valve is activated, a second pressure is determined and saved. From the pressure difference, the solids concentration of the fluid is determined, and a computer algorithm adds a calculated amount of water to the fluid reservoir as needed. The second valve is deactivated, and the measurement cycle is repeated, as may be desired.

Owner:QED TECH INT

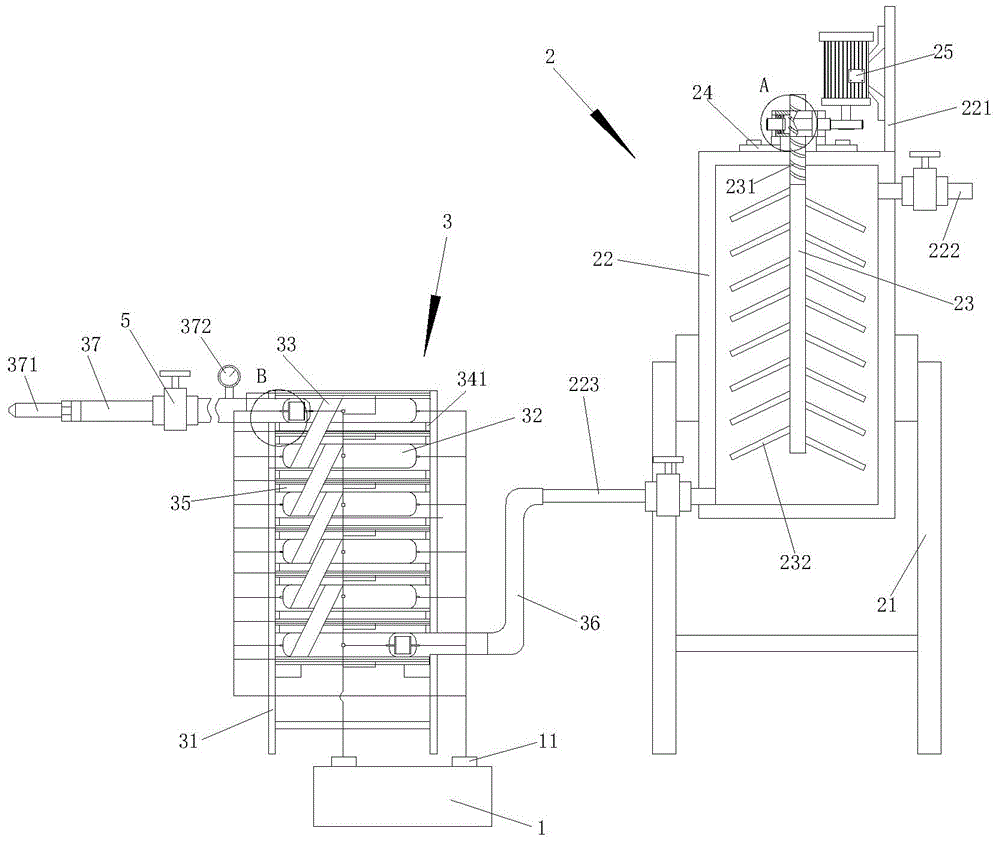

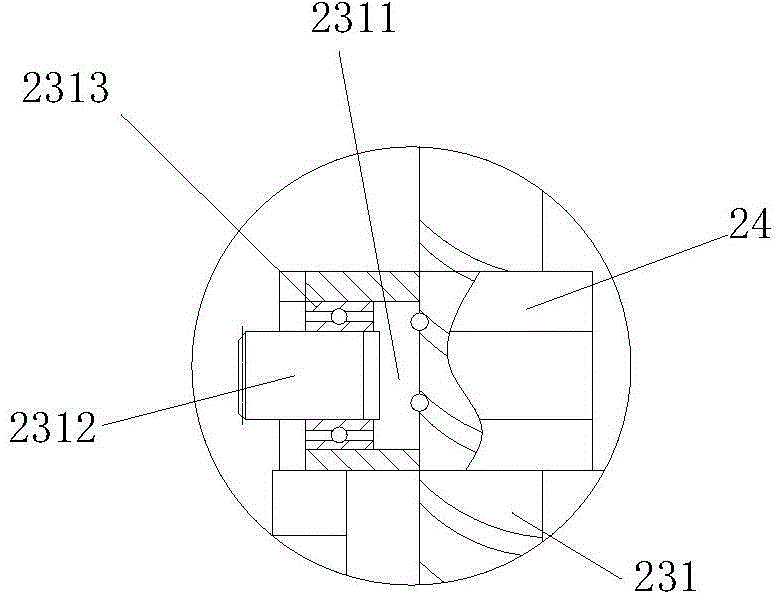

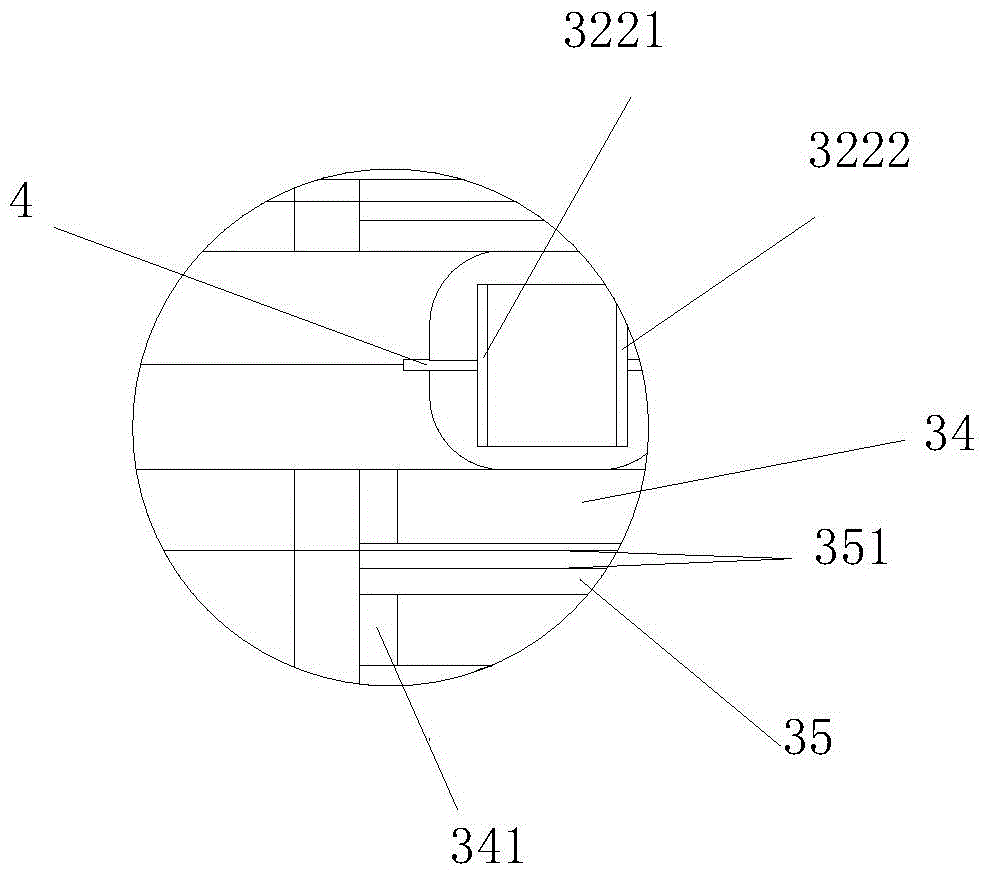

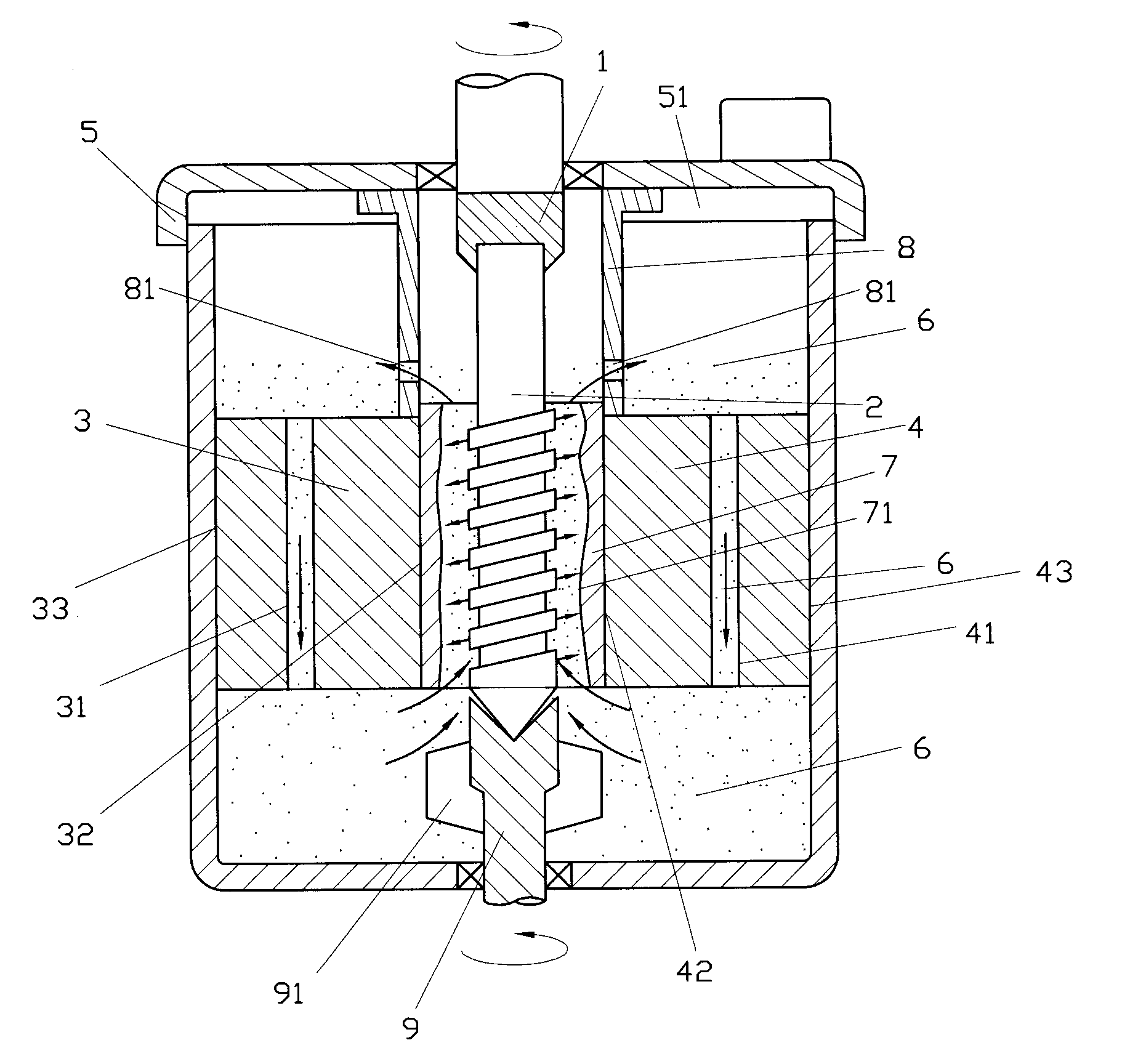

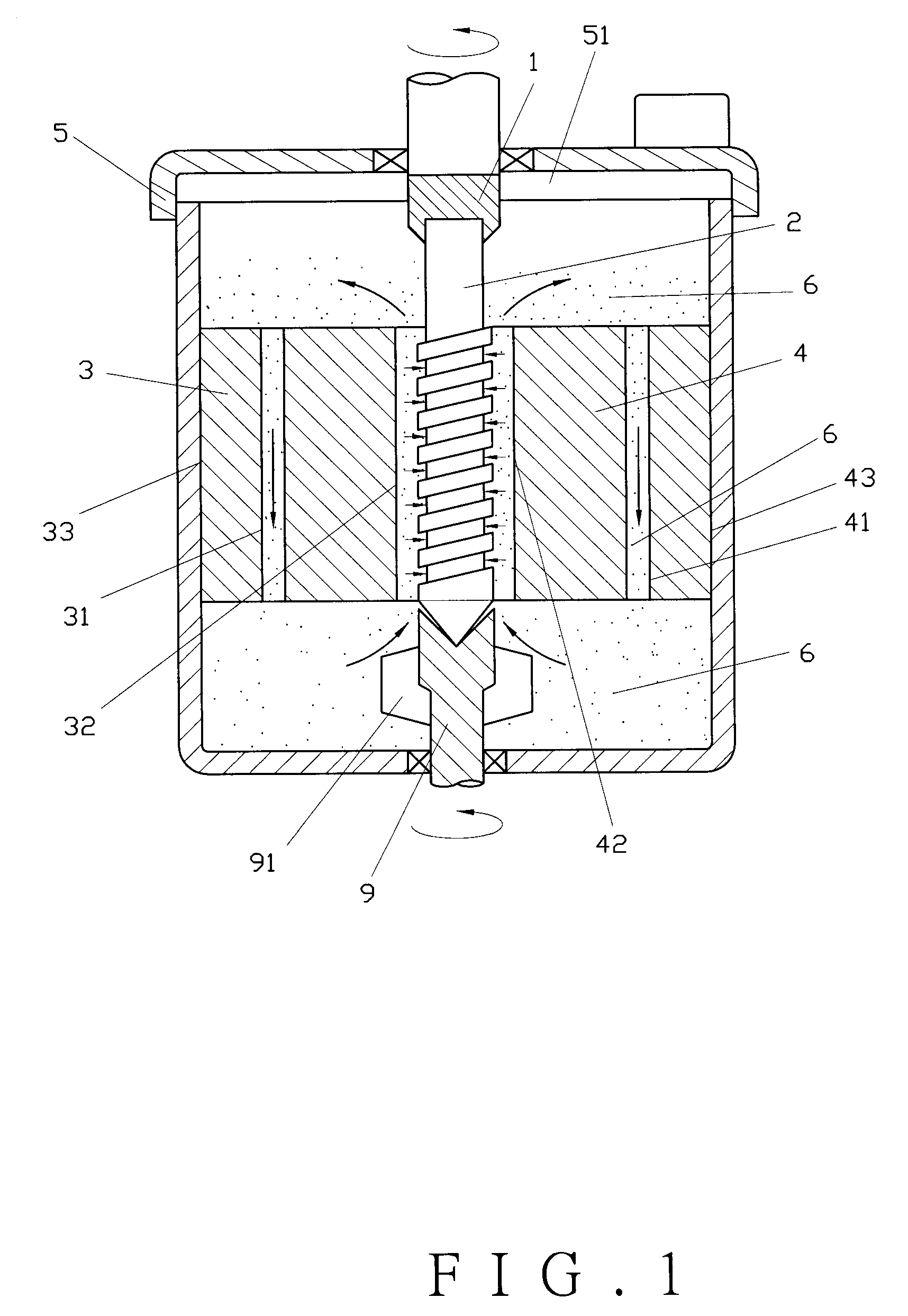

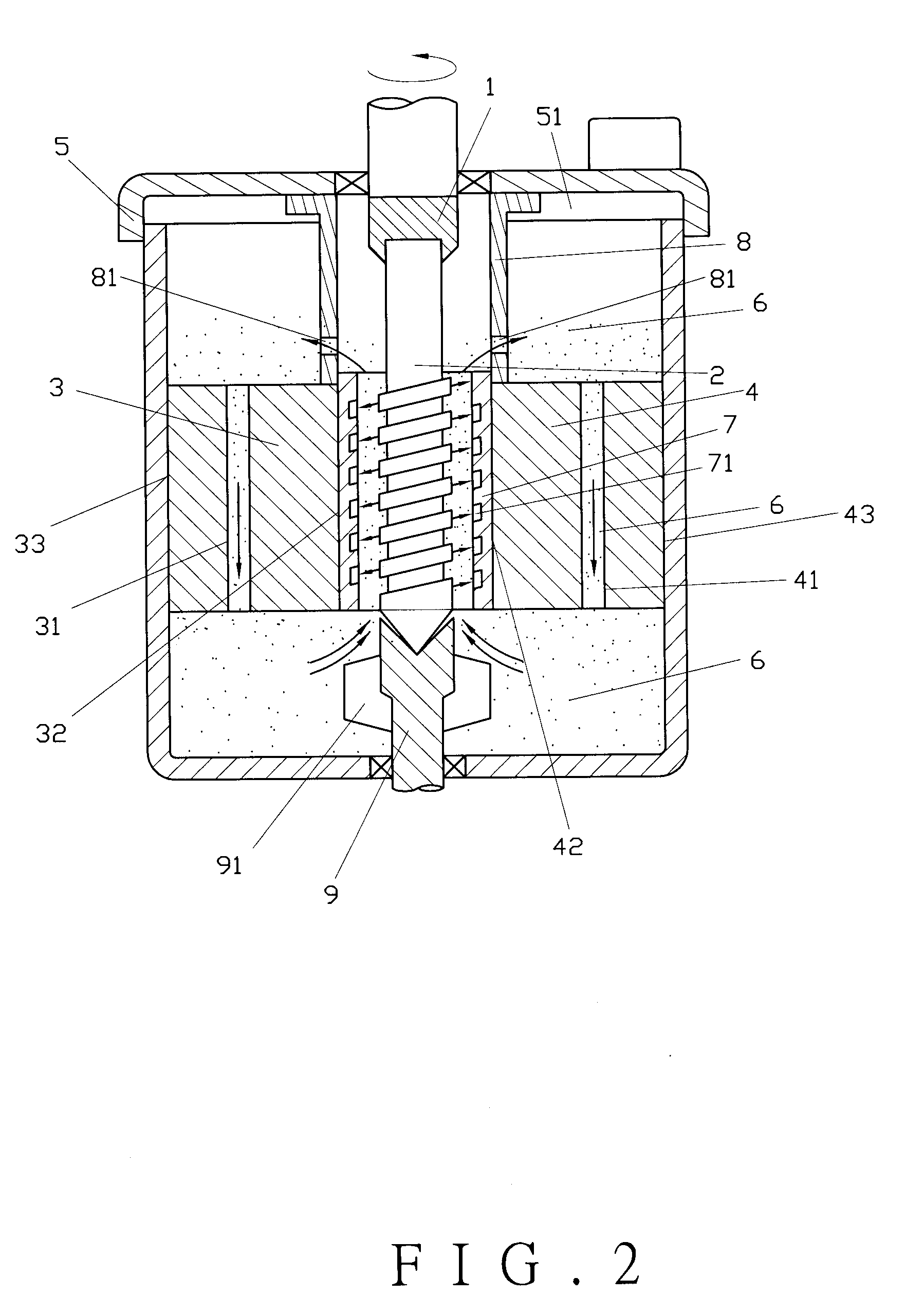

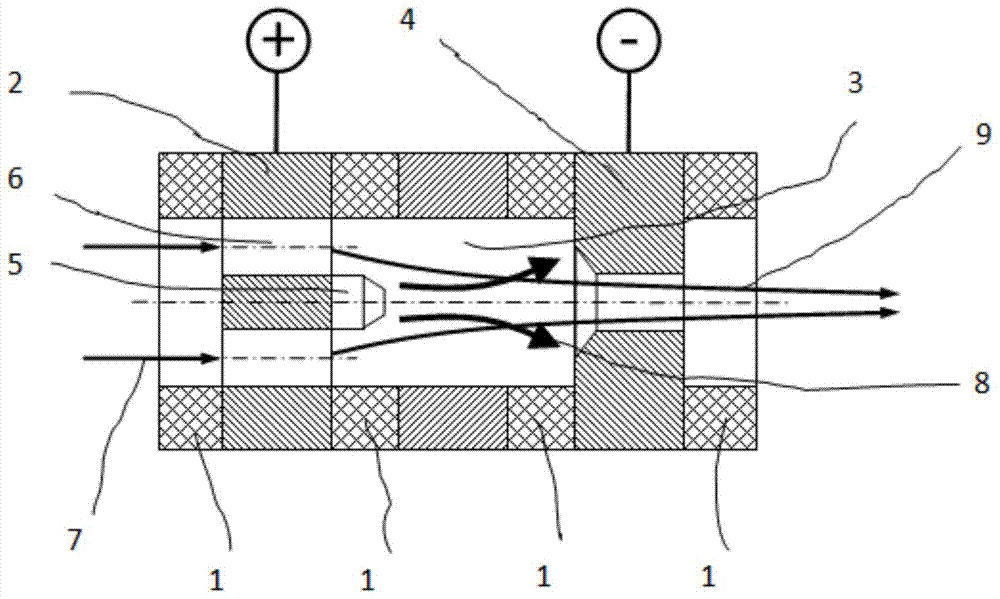

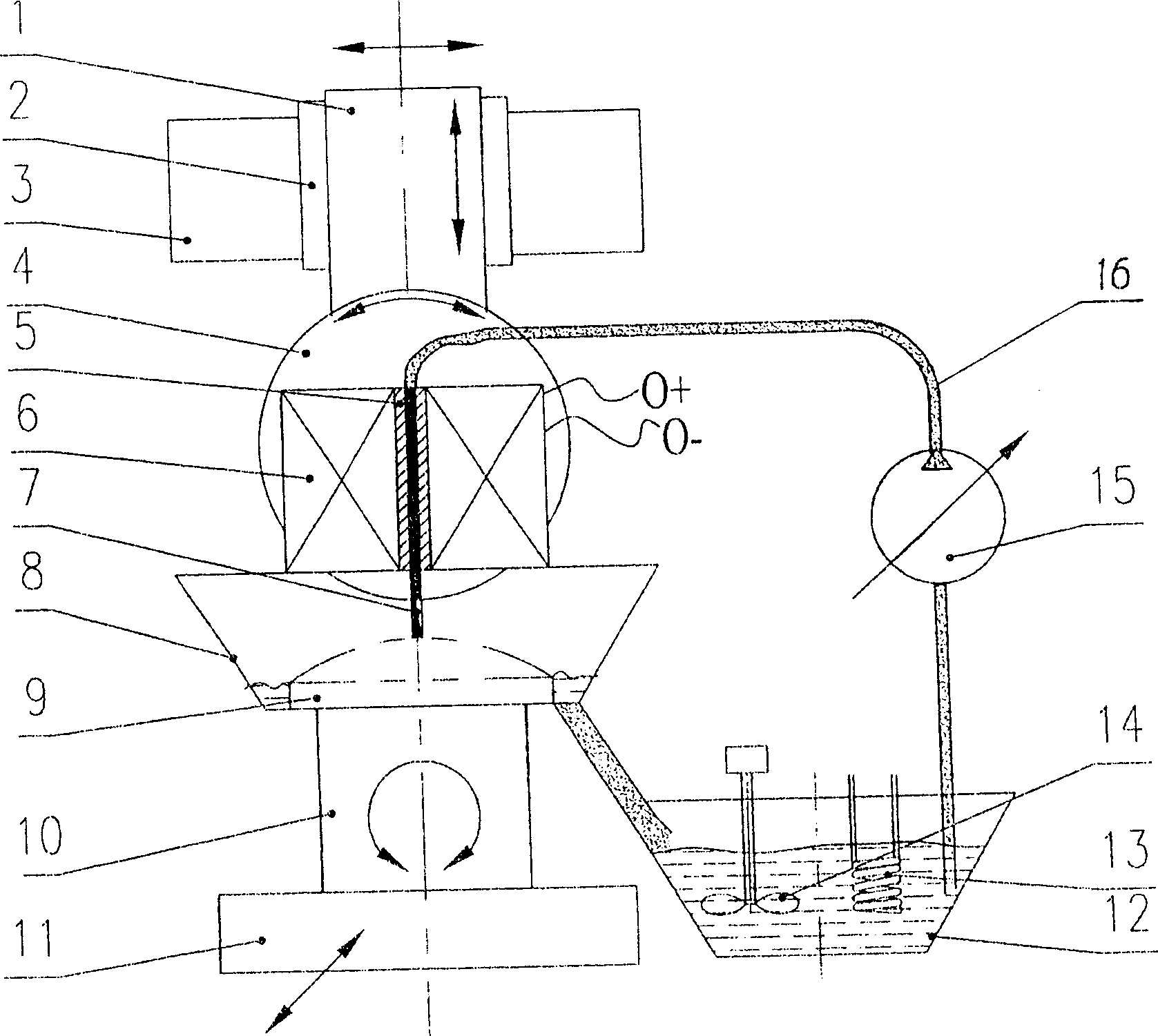

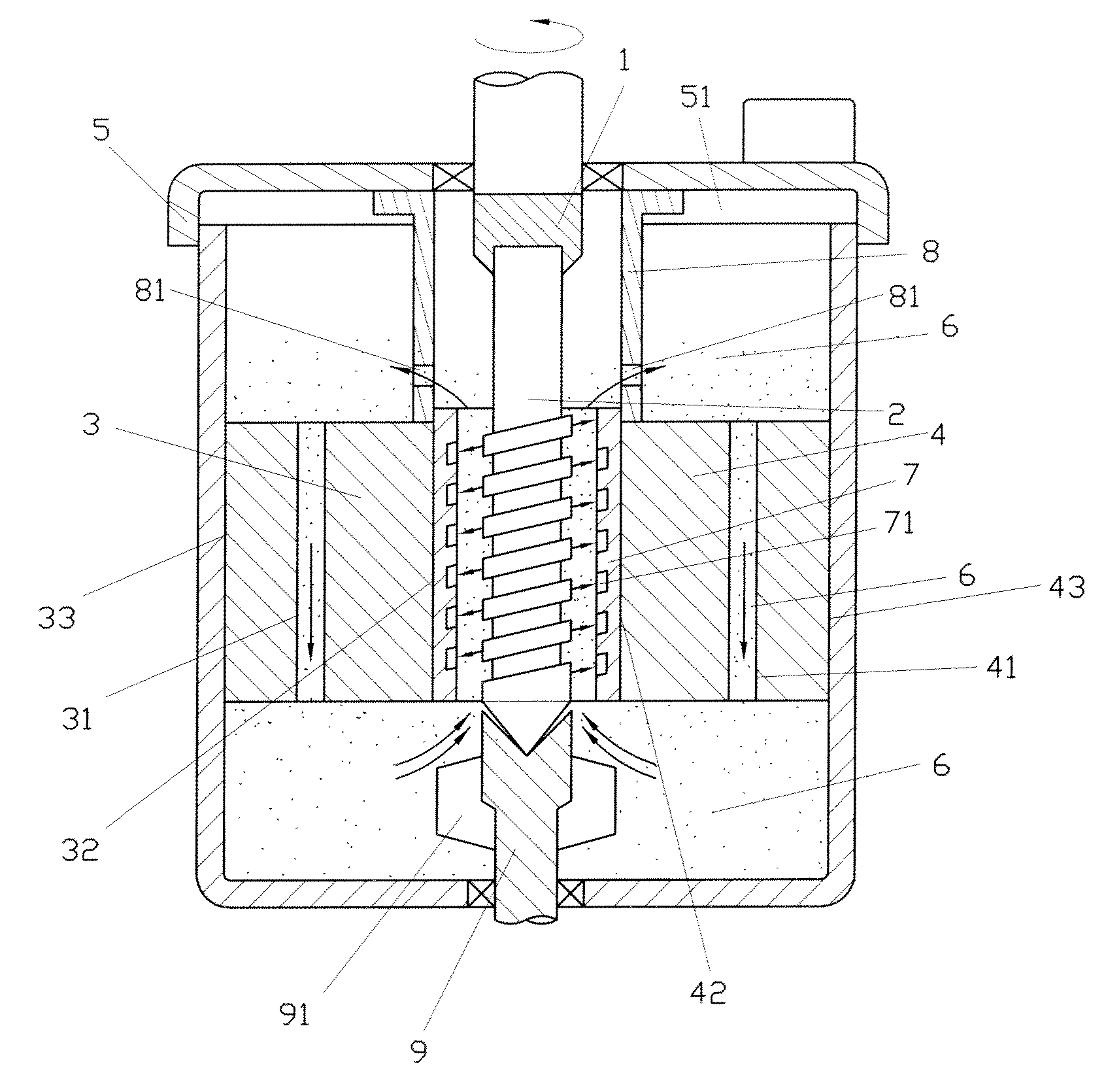

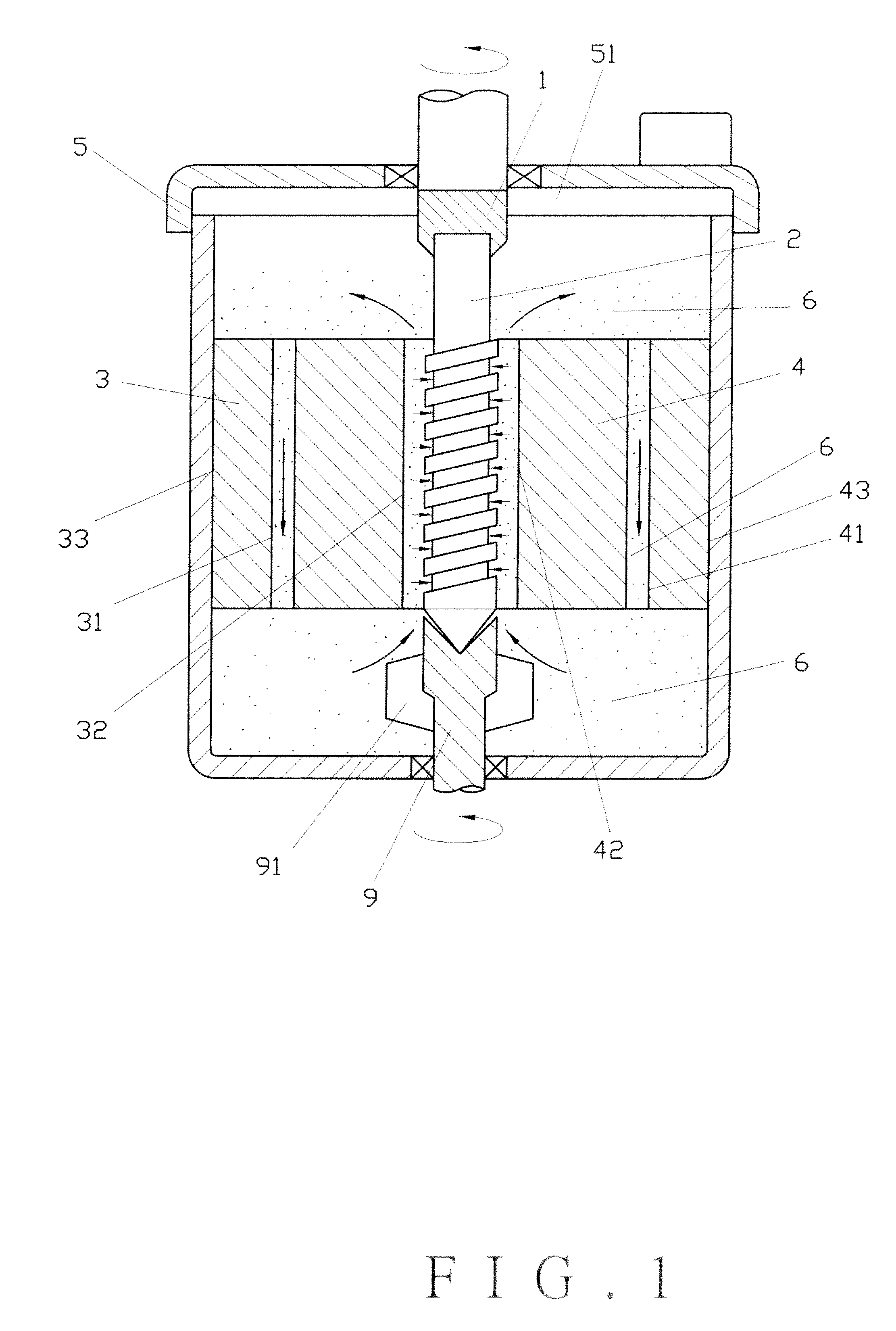

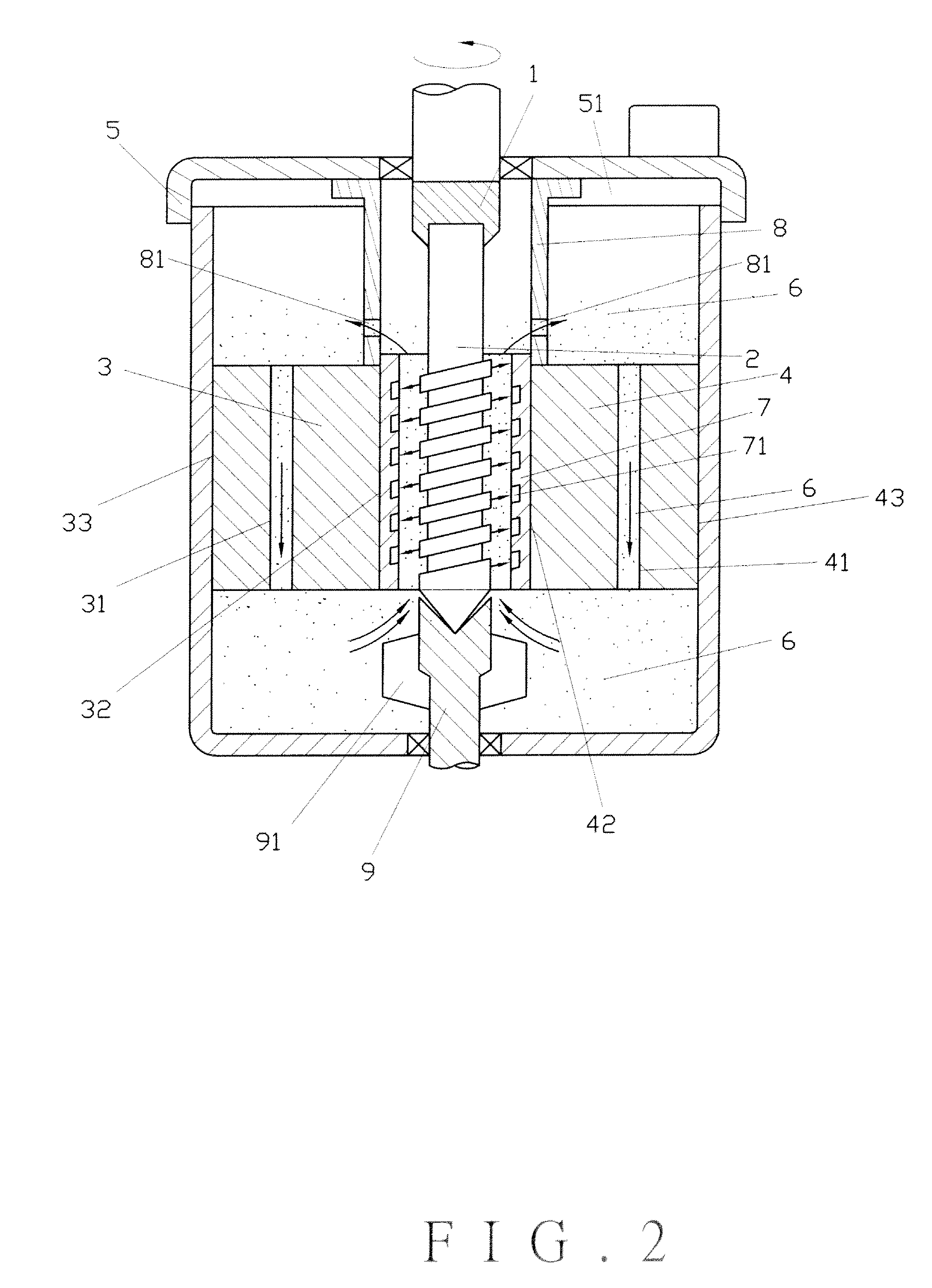

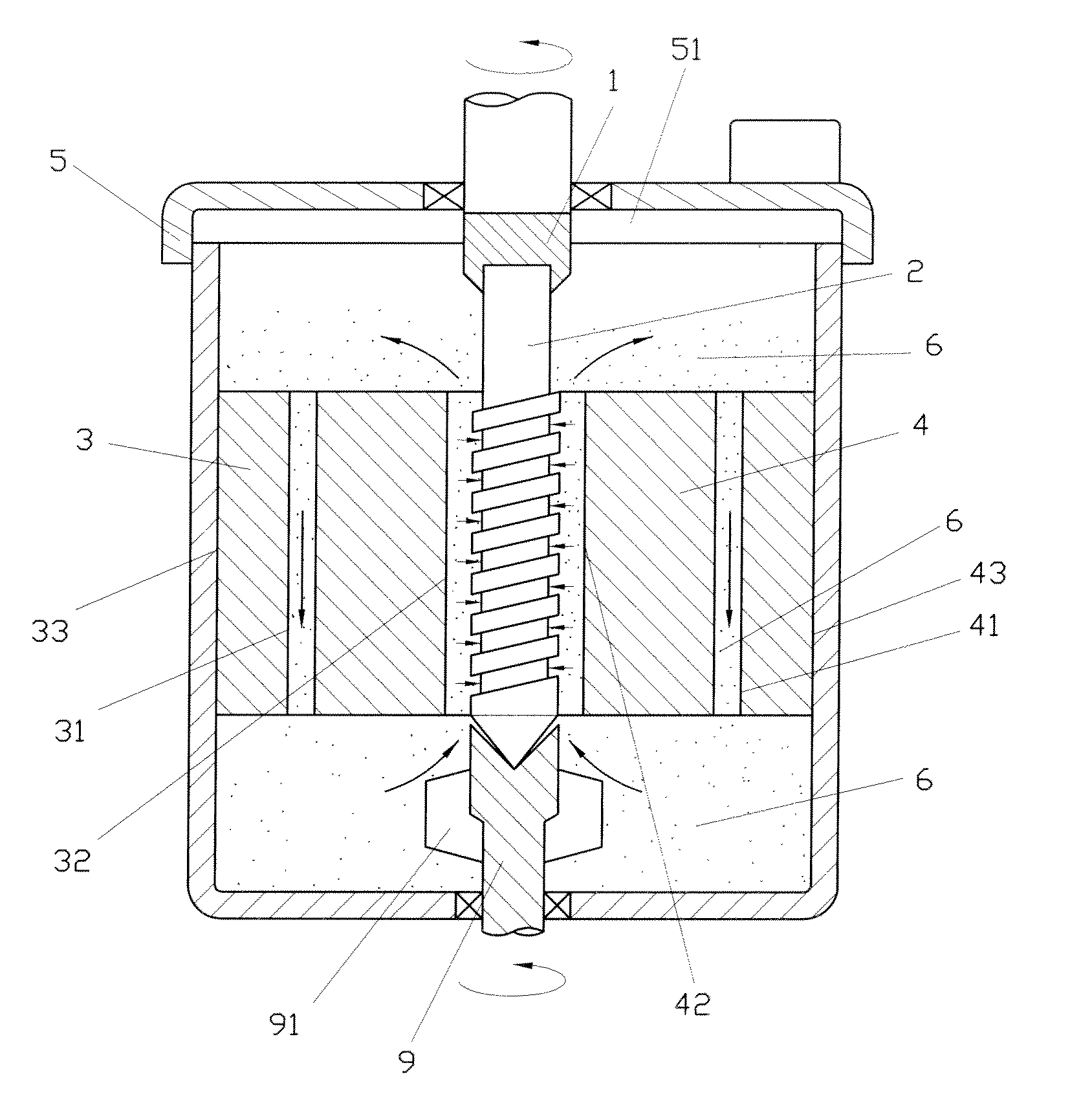

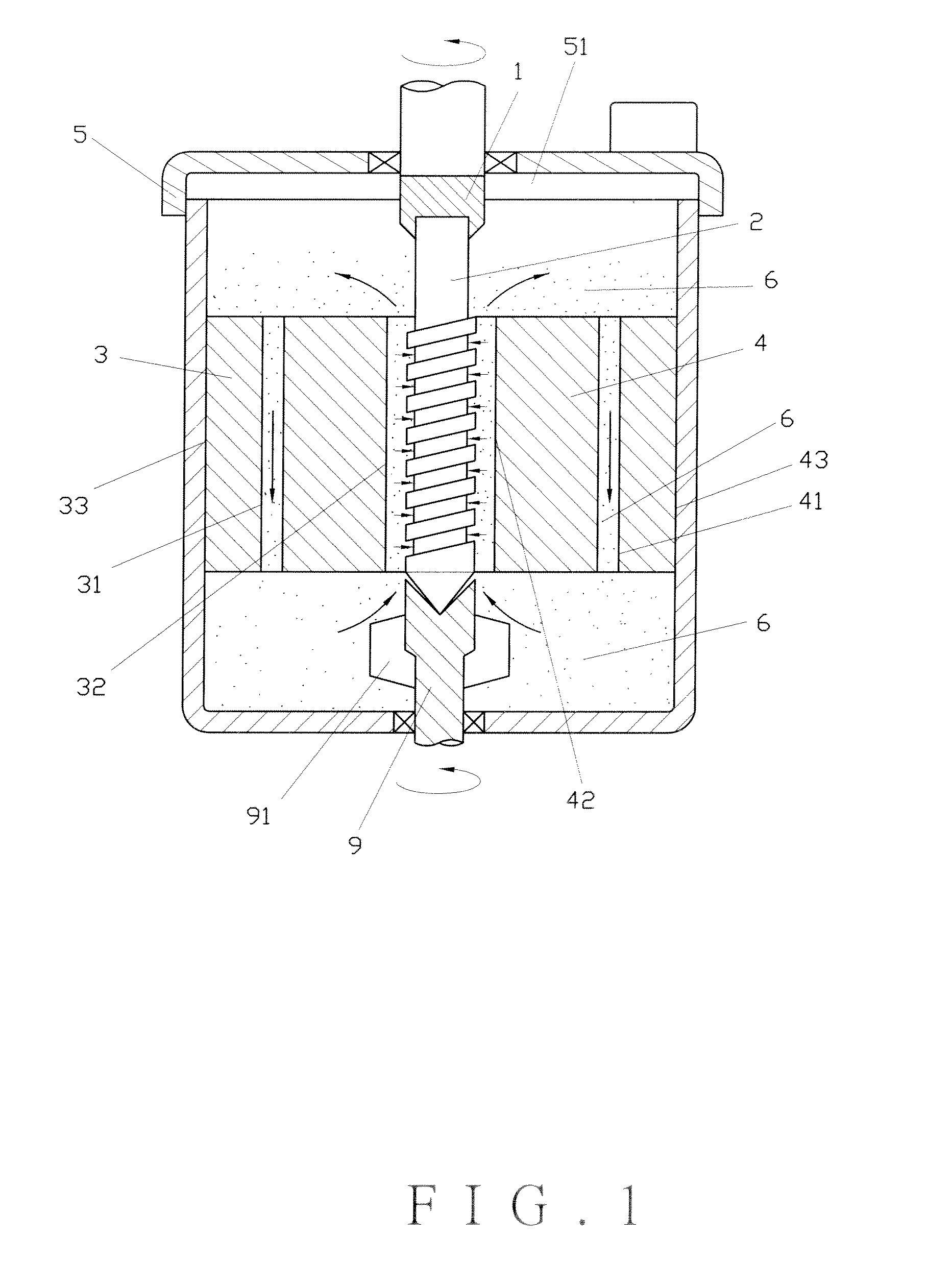

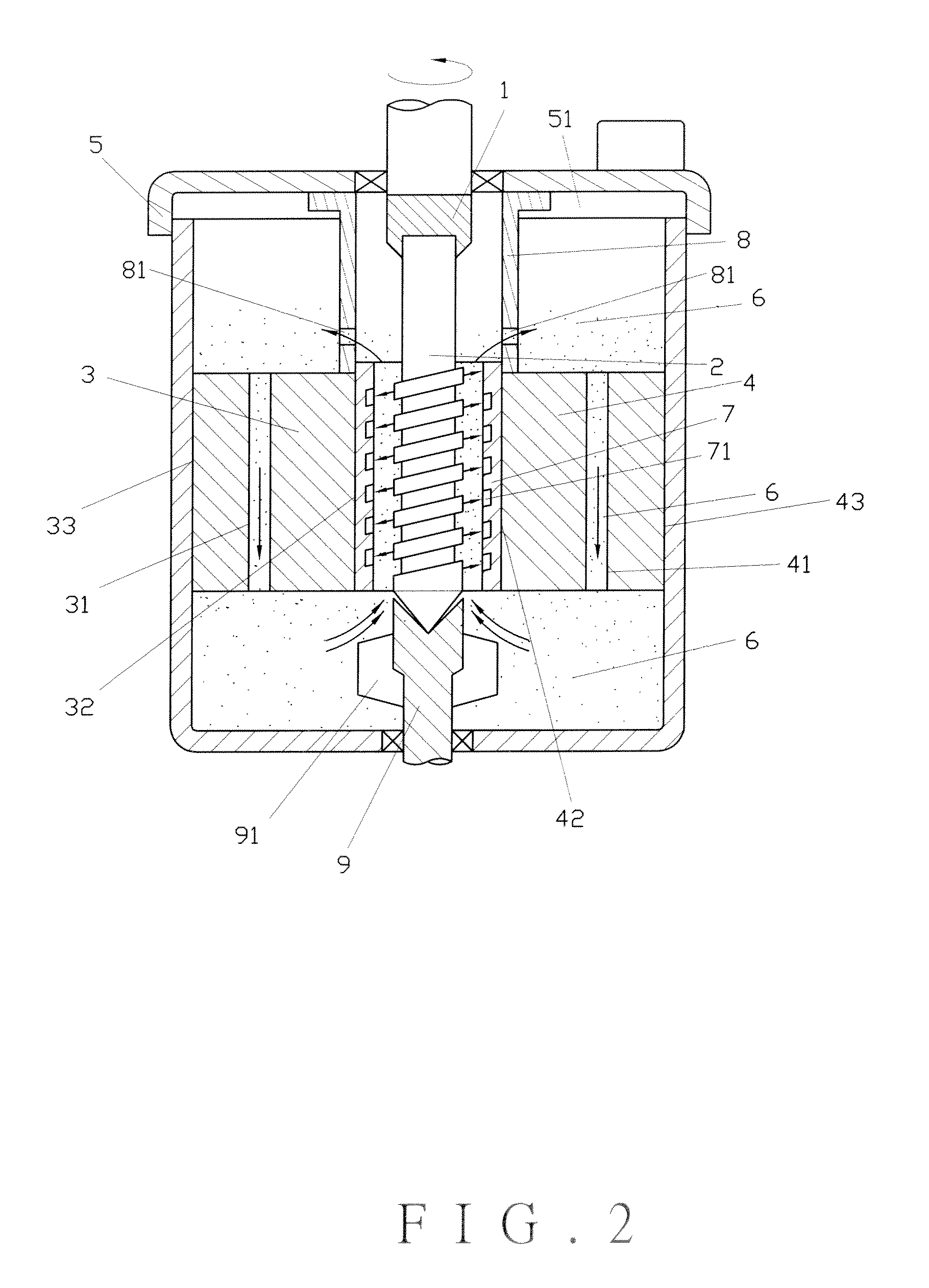

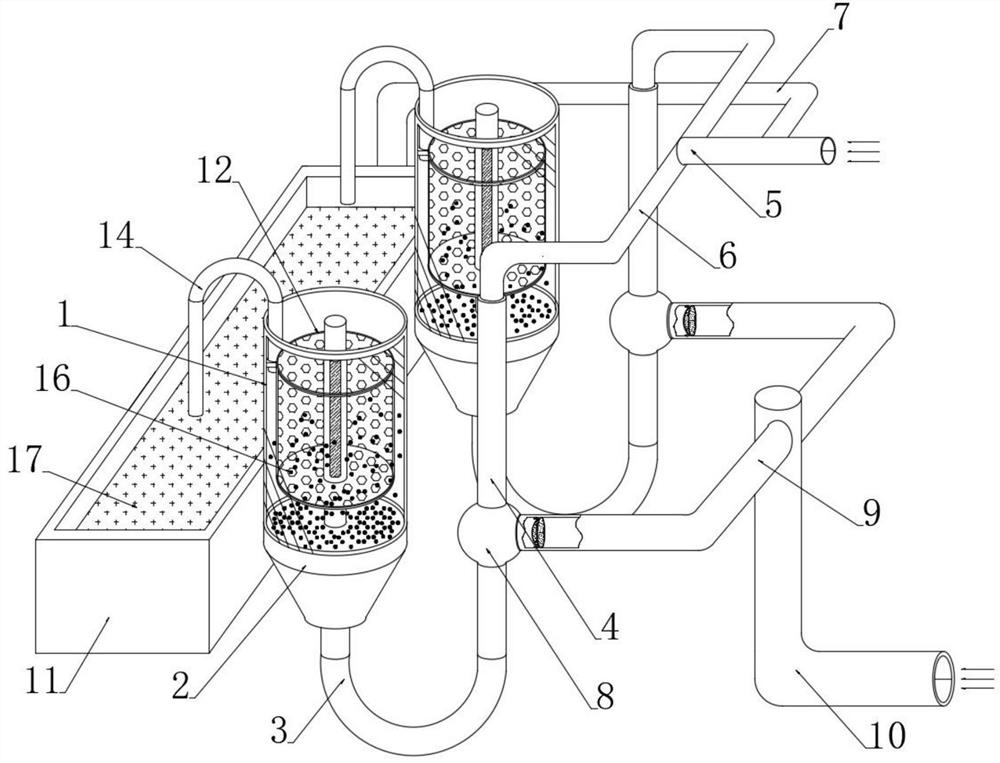

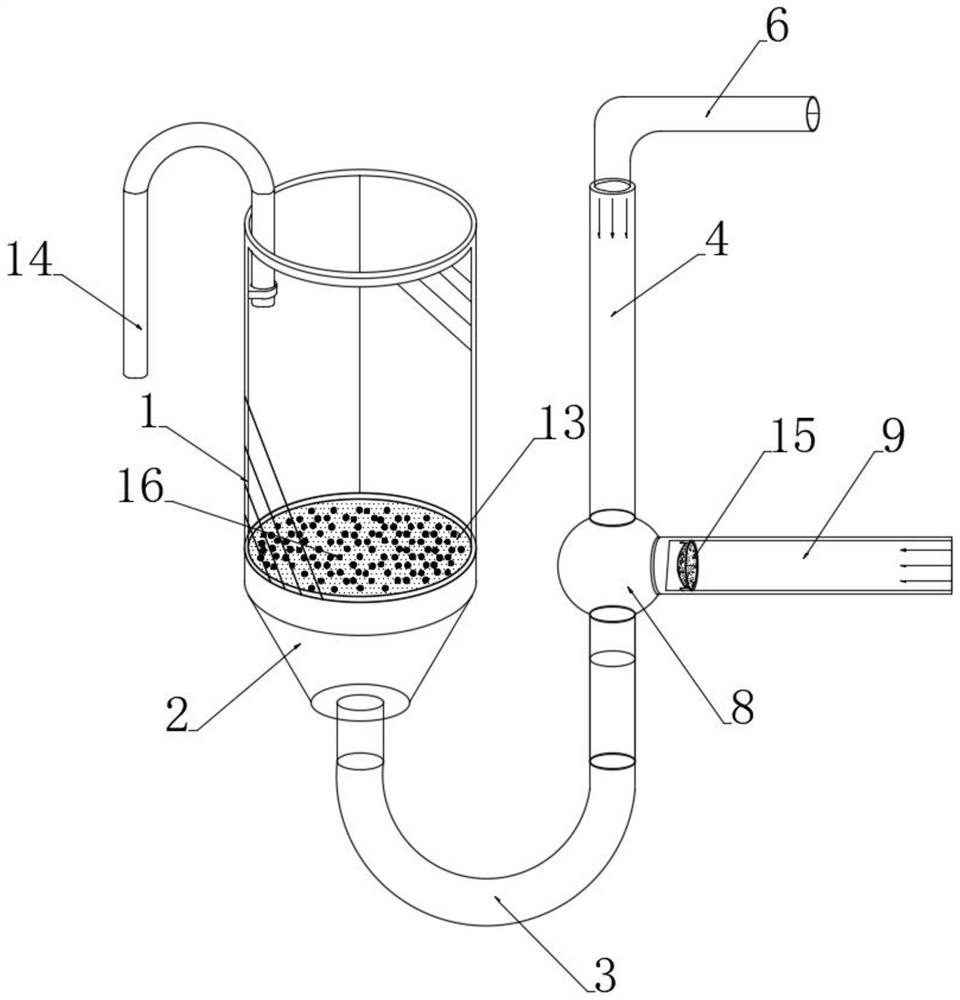

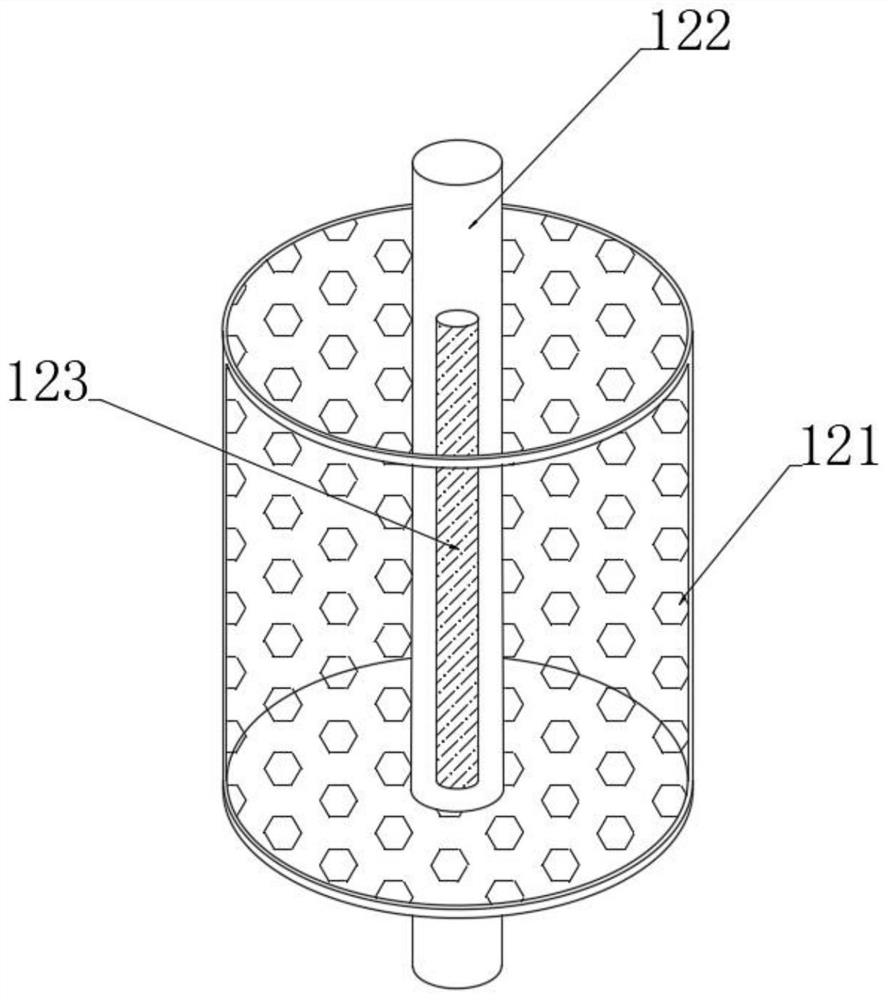

Suspension abrasive magnetic fluid jet generating device

ActiveCN104128891AAccelerate helpsReduce usageNon-mechanical blast generatorsEngineeringMagnetic isolation

The invention discloses a suspension abrasive magnetic fluid jet generating device comprising an electric generator, a stirring device and a magnetic fluid acceleration device, wherein the stirring device comprises a support frame, a suspension abrasive box, a stirring rod, a fixed seat and a motor, the upper end of the stirring rod is fixedly connected with a leading screw, the leading screw is provided with a leading screw seat; the magnetic fluid acceleration device comprises a fixed frame, accelerating tubes, an inclined tube, a magnetic isolation plate, a superconducting iron core, a connecting pipe and a jet pipe, wherein each accelerating tube is composed of a guide bend pipe and a straight pipe, the inclined tube, the superconducting iron core and the magnetic isolation plate are arranged between adjacent accelerating tubes. Through arrangement of the stirring device and the magnetic fluid acceleration device, uniform mixing and acceleration of a suspension abrasive magnetic fluid mixture can be both facilitated, and the suspension abrasive magnetic fluid jet generating device does not need to use a pumping station, a pressurizer and other components so as to help to reduce the leakage problem brought by hydraulic components, and also helps to reduce the use of steel and iron material components.

Owner:淮北市华明工业变频设备有限公司

Apparatus and method for spiral polishing with electromagnetic abrasive

InactiveUS20100105298A1Improve liquidityEasy to manufactureEdge grinding machinesNon-mechanical blast generatorsEngineeringElectromagnet

An apparatus and method for spiral polishing with electromagnetic abrasive has adopted the principle of electromagnetic and magnetic abrasive along with a lead screw to polish the inner or outer surface of a precise screw or a complicated part. The apparatus includes a clamp, a lead screw, a first electromagnet, and a second electromagnet assembled in an airtight space, wherein the airtight space is filled with magnetic abrasive which is driven by the rotation of the lead screw and the electromagnetic function to polish a processed part in a regular shape or in an irregular shape.

Owner:SOUTHERN TAIWAN UNIVERSITY OF TECHNOLOGY

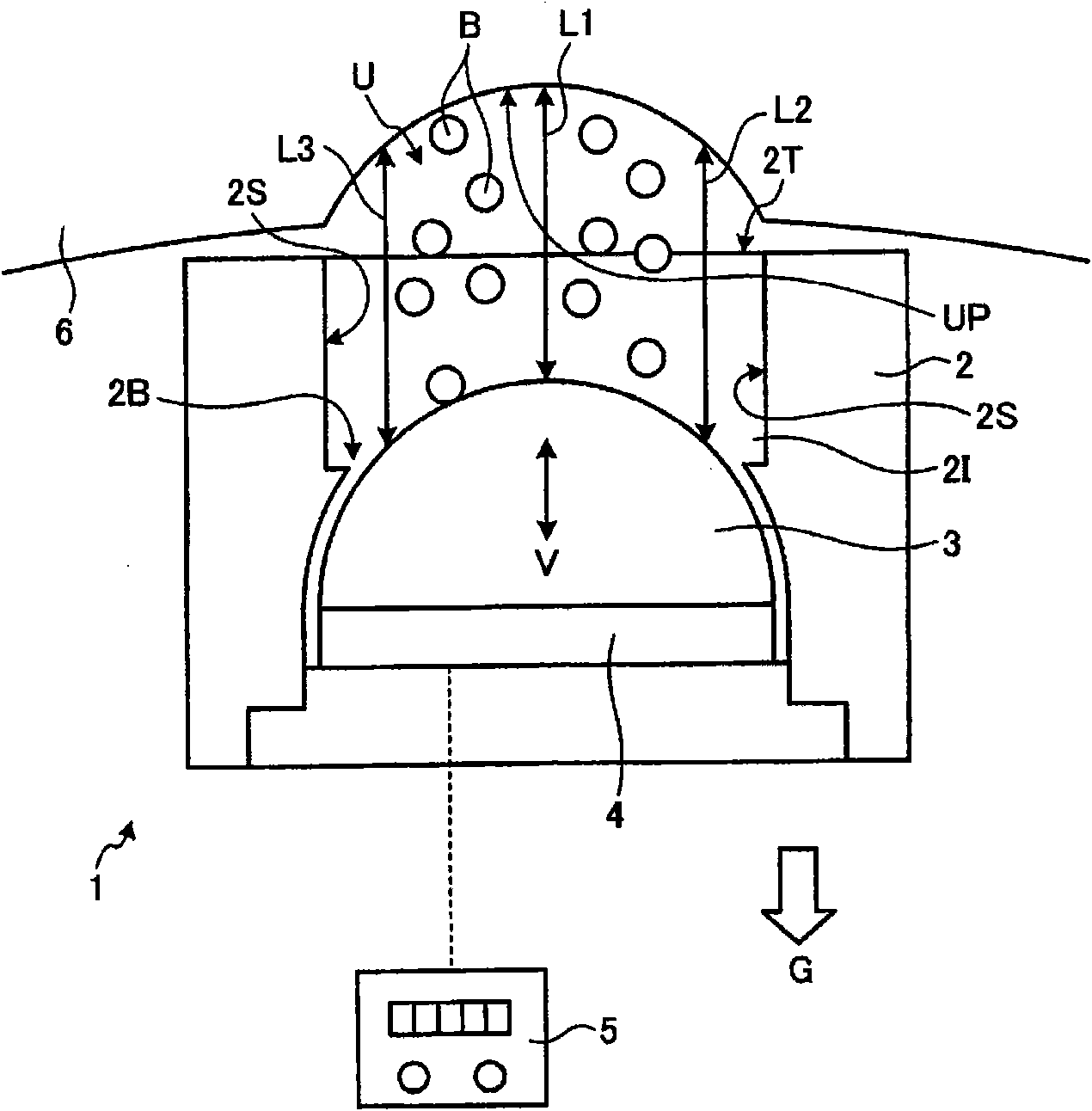

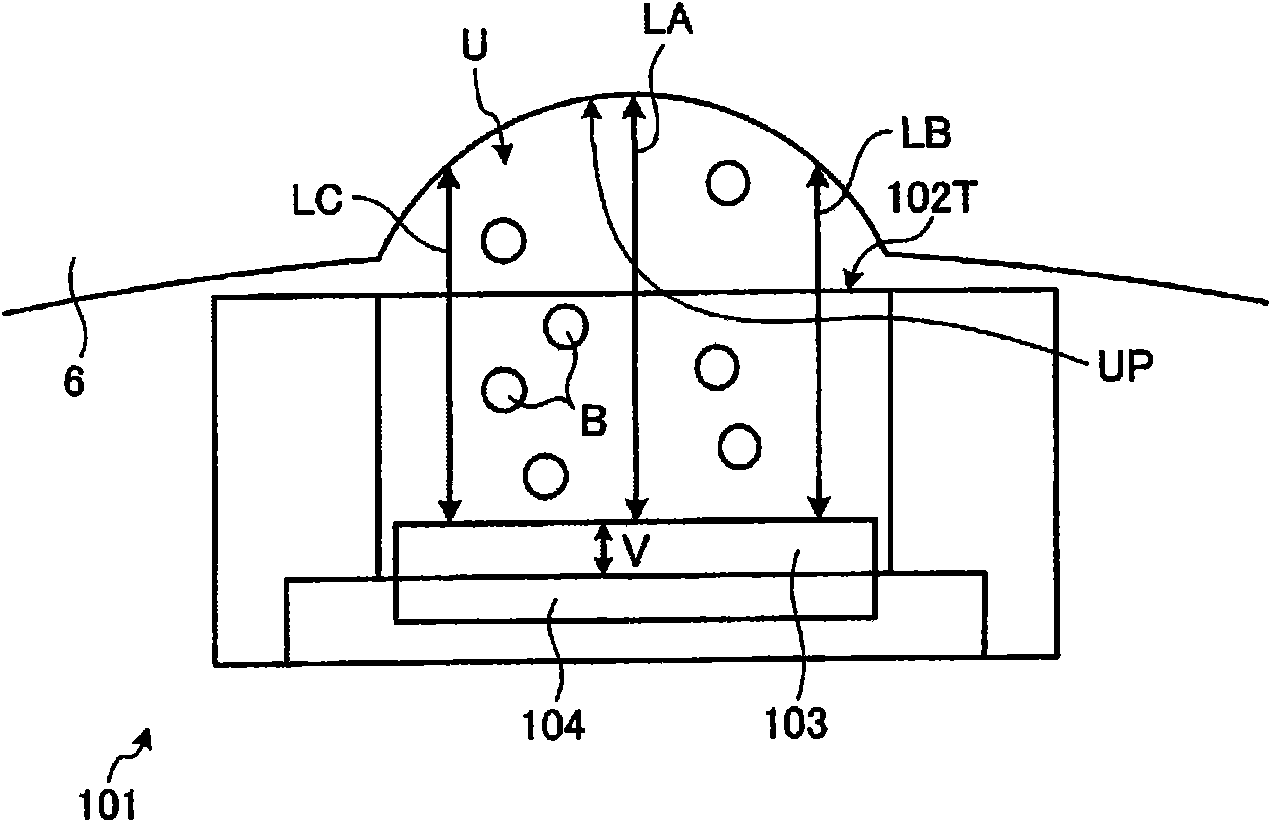

Shot peening device and oscillator for shot peening

InactiveCN101909821ACurb Construction InconsistenciesInhibition ConsistencyEdge grinding machinesImpeller wheelsPeeningMaterials science

A shot peening device (1) is equipped with a containment vessel (2) that stores shot material (B) used in shot peening, and performs shot peening of a worksite surface (UP) by the containment vessel (2) moving to the shot peening worksite (U). The shot peening device (1) is equipped with an oscillator (3). An oscillation means (4) that imparts kinetic energy to the shot material (B) in the container interior (2I) is mounted on the oscillator (3). The external shape of the oscillator (3) is formed into a shape matched to the shape of the worksite surface (UP) of the worksite (U).

Owner:MITSUBISHI HEAVY IND LTD

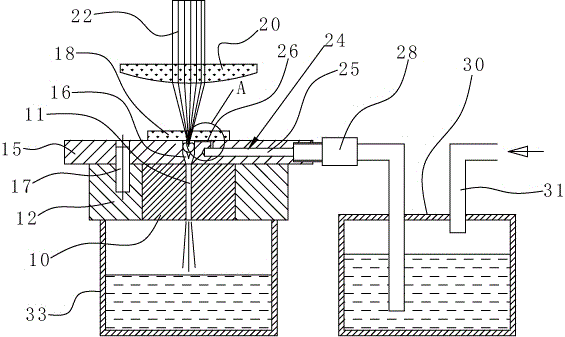

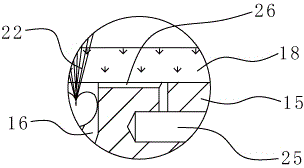

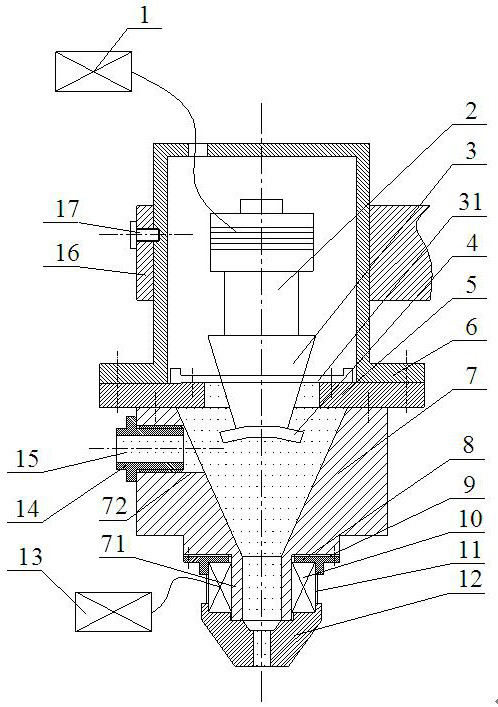

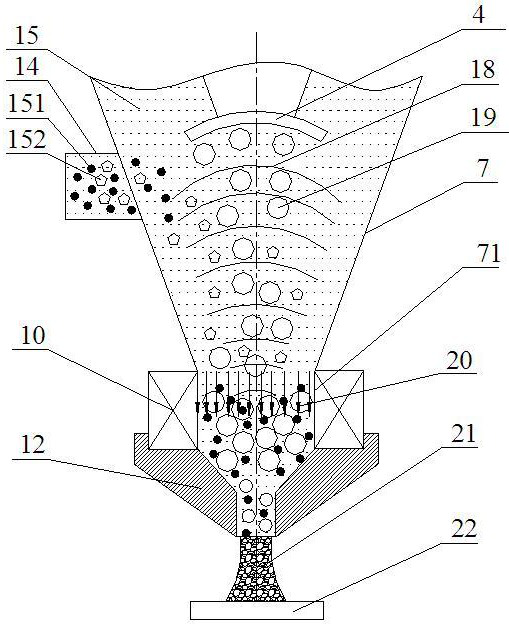

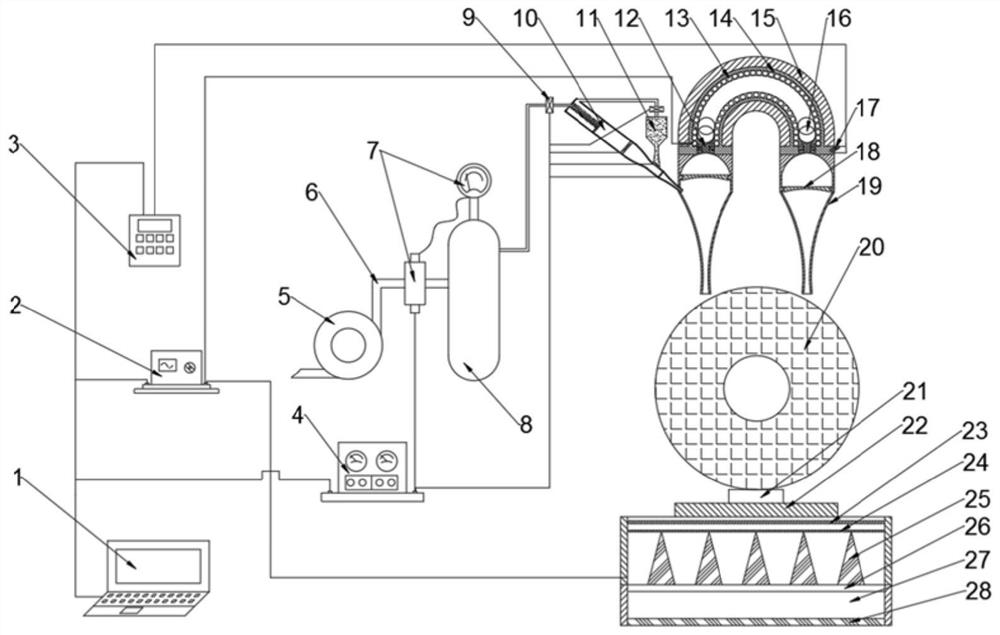

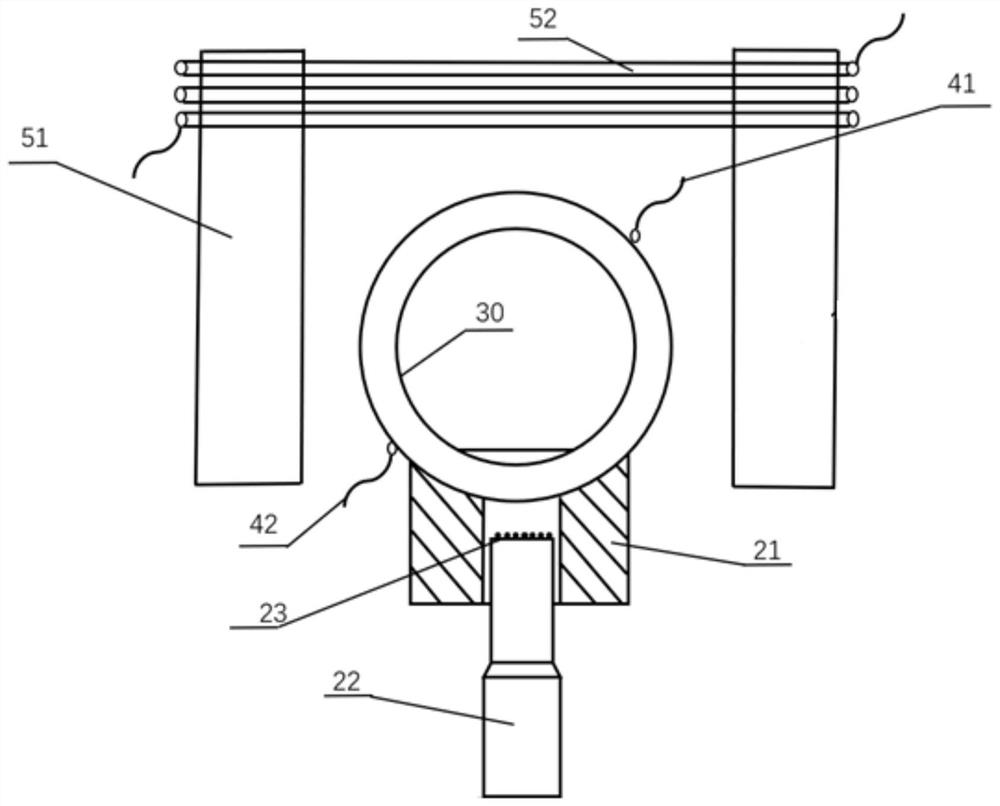

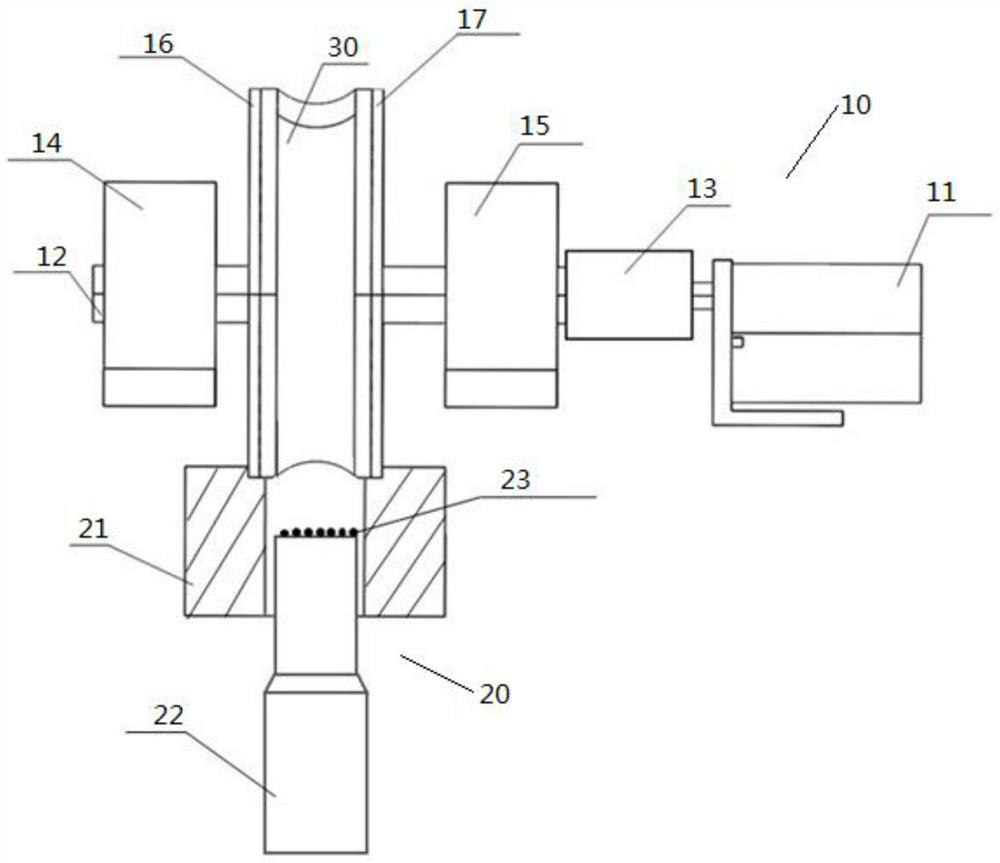

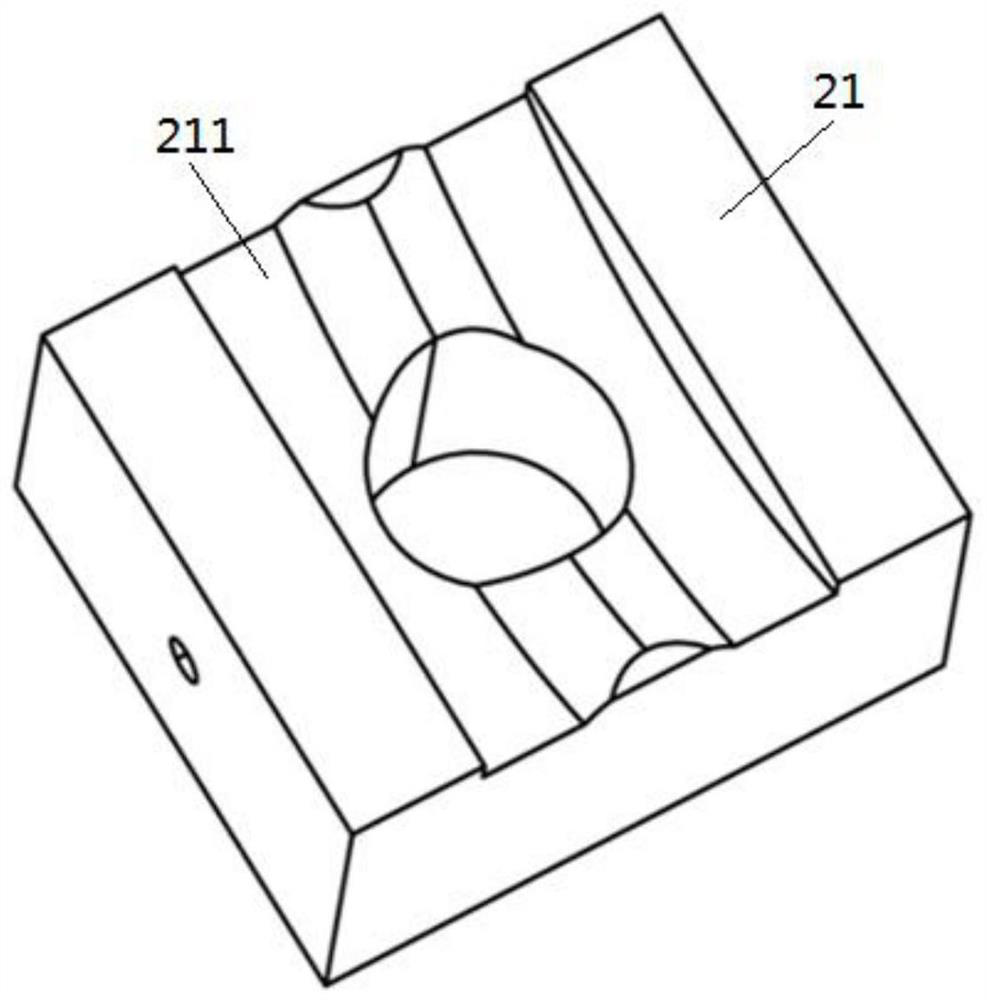

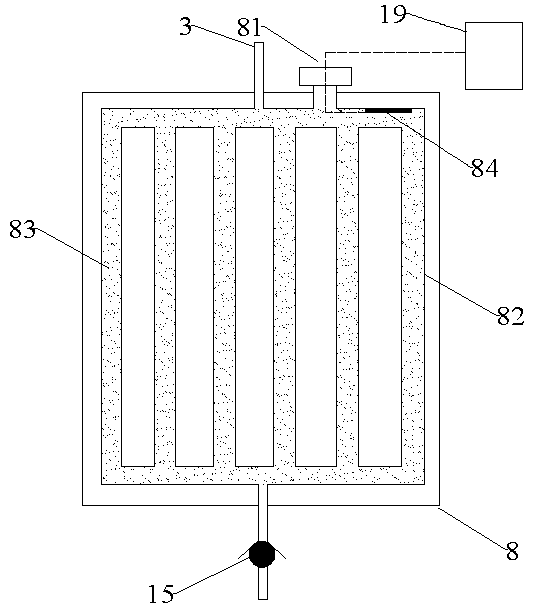

Acoustic-magnetic coupling cavitation auxiliary liquid jet polishing device and using method

PendingCN112157596AEnhanced impact hardening efficiencyAvoid premature collapseNon-mechanical blast generatorsAbrasive blasting machinesLiquid jetUltrasonic cavitation

The invention belongs to the field of liquid jet polishing, and particularly relates to an acoustic-magnetic coupling cavitation auxiliary liquid jet polishing device and a using method. The problemsof insufficient cavitation bubble impact energy and low bubble transport efficiency in an ultrasonic cavitation assisted liquid jet polishing process are solved, and the acoustic-magnetic coupling cavitation auxiliary liquid jet polishing device comprises an ultrasonic generator, a piezoelectric transducer, an amplitude-change pole, an acoustic lens, a cavity cover, an outer sleeve, a conical cavity, an electromagnetic coil frame, a gasket, an electromagnetic coil, a magnetic isolation sleeve, a jet flow nozzle, a magnetic field power supply and a liquid inlet connector. According to the ultrasonic cavitation assisted liquid jet polishing device and the using method, cavitation bubbles are prevented from collapsing and perished in advance, and the ultrasonic cavitation assisted liquid jetpolishing efficiency is improved.

Owner:TAIYUAN UNIV OF TECH

Methods for resist stripping and other processes for cleaning surfaces substantially free of contaminants

InactiveUS20050127037A1Avoid lostIncrease vacuumNon-mechanical blast generatorsDecorative surface effectsResistEngineering

A method for manufacturing an article having polymeric residue that is to be removed during the manufacture of the article is disclosed. The article is introduced into a controlled environment of a processing tool having one or more processing chambers. Free radicals are generated from one or more reactant gases and introduced into at least one of the one or more processing chambers where they react with the polymeric residue. A cryogenic cleaning medium is supplied into at least one of the one or more processing chambers where the cryogenic cleaning medium removes the polymeric residue present after the free radicals react with the polymeric residue. The reactant gases are selected to facilitate removal of the polymeric residue with the cryogenic cleaning medium. The cryogenic cleaning medium is supplied with a pulsating flow via a nozzle implement that sweeps across the article. The pulsating flow may be generated via a piezo device or a rotating shaft with a hole the periodically enables or interrupts flow through a flow channel.

Owner:NANOCLEAN TECH

Method and apparatus for improving media flow

ActiveUS7291058B2Reduced flow capabilityReduces and eliminates effect of magneticNon-mechanical blast generatorsLayered productsSand blastingEngineering

The flow of media in shot peening, blast cleaning, and similar equipment is improved by applying a time varying magnetic field to the media to thereby degauss the media, allowing the media to flow through equipment without clogging and clumping due to magnetic attraction between the media.

Owner:ELEKTRONIK

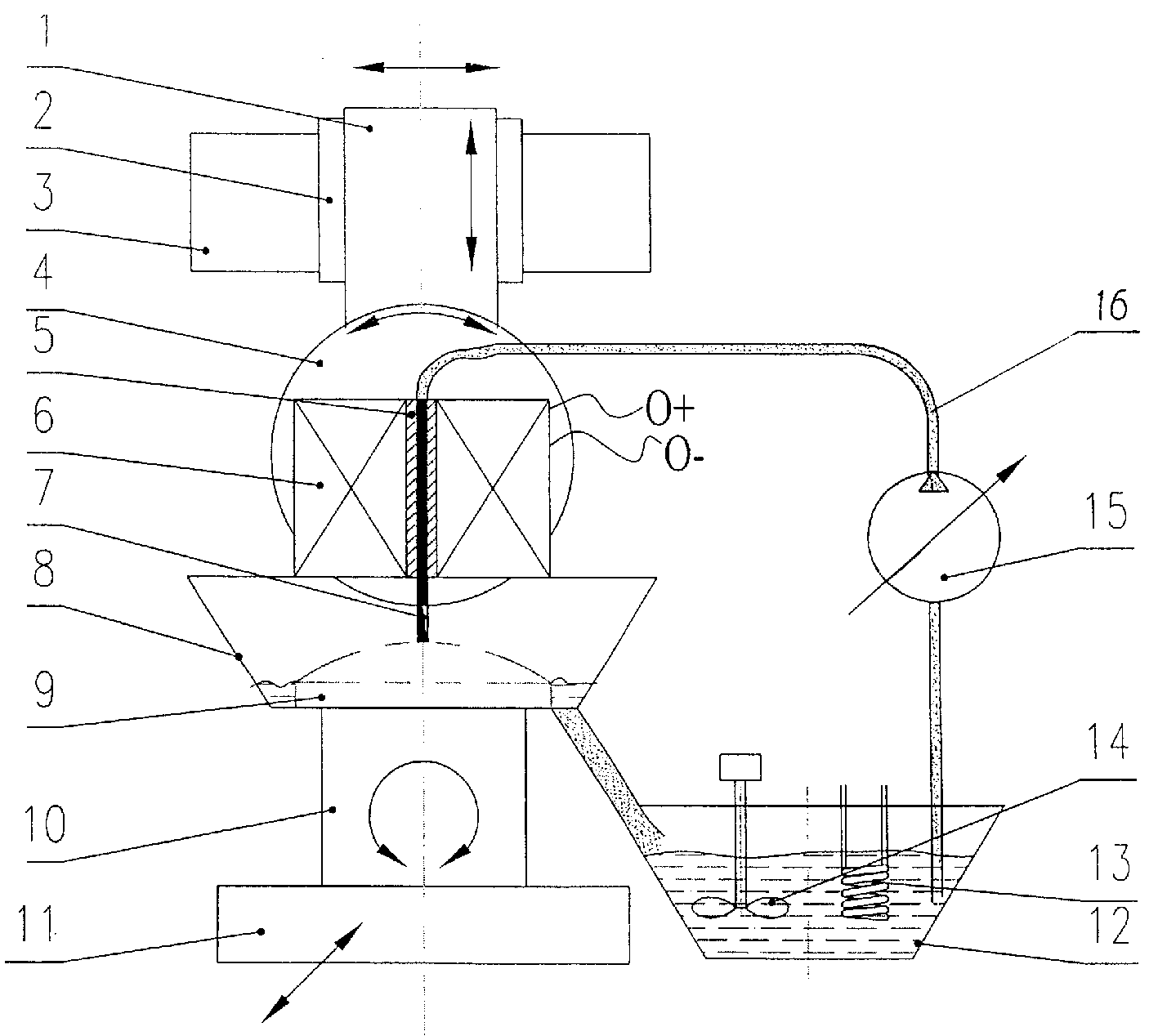

Surface roughening treatment method of object being treated, and apparatus therefor

InactiveUS6960118B2Stable mass productionGood quality and stabilityEdge grinding machinesPolishing machinesMaterials scienceSurface roughening

Disclosed are a method of causing abrasive grains to collide against and contact with an object being treated to form surfaces of the object being treated into a matte, specifically, a rotational magnetic field is applied on magnetic abrasive grains to cause the same to vibratingly move at random to collide against and contact with an object being treated to obtain a matte.

Owner:AOKI MOTOHISA

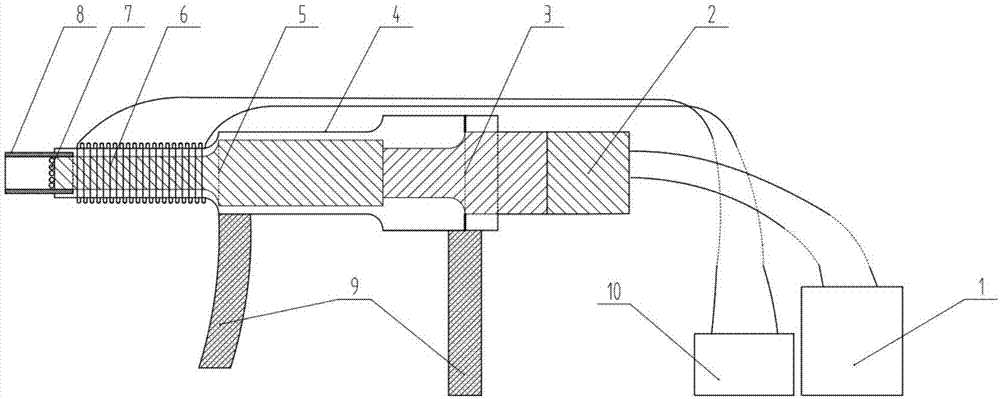

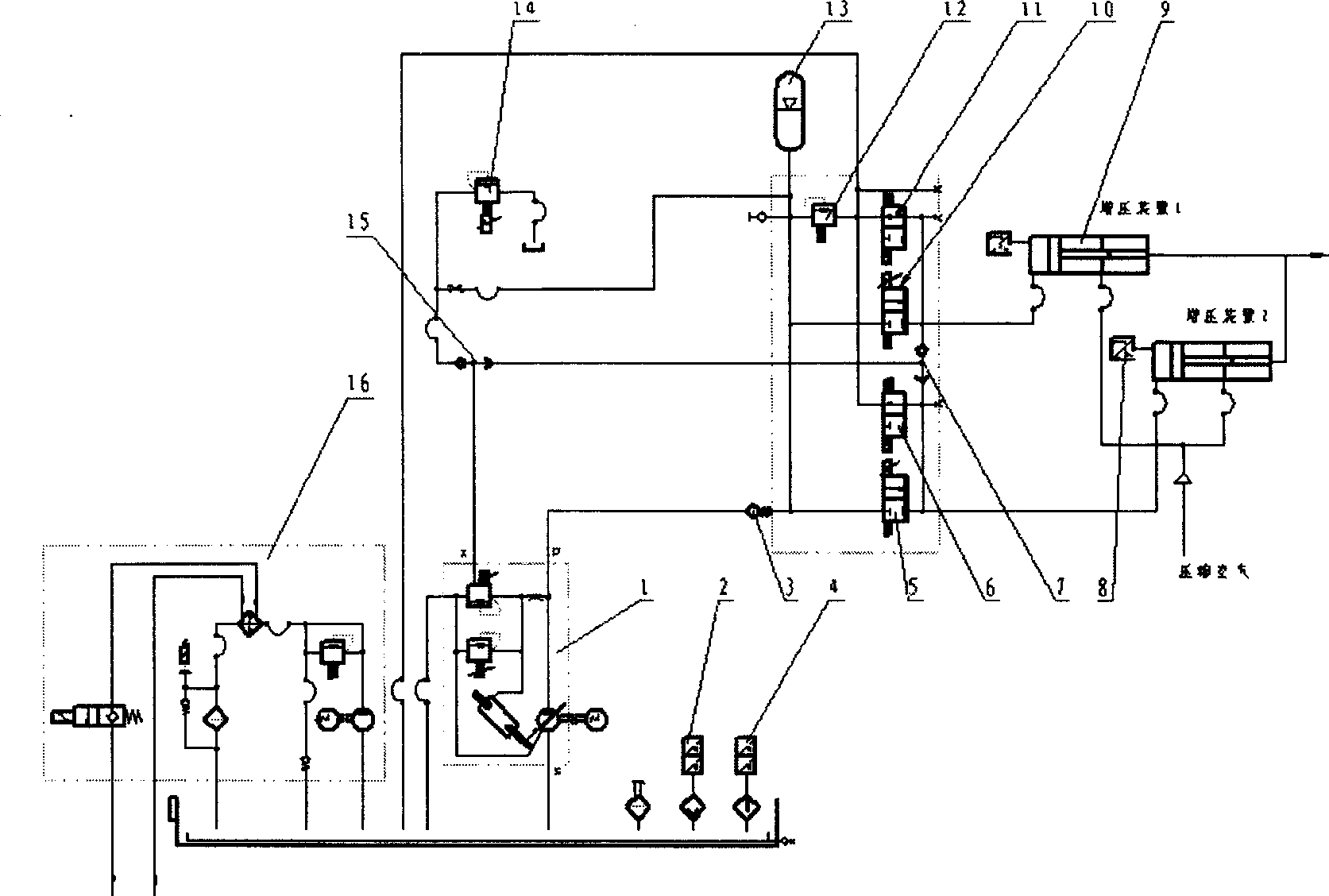

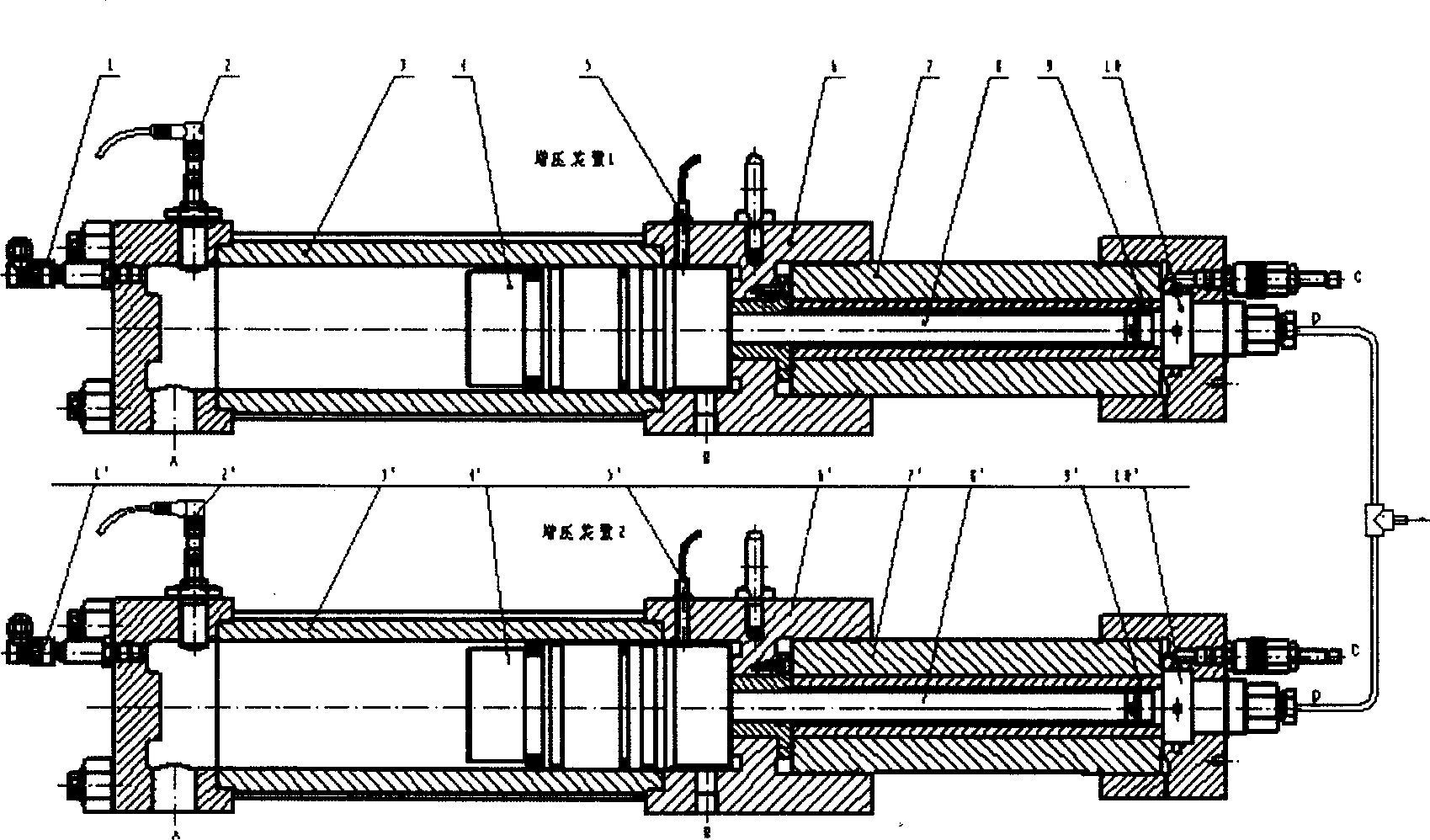

Phase-controlled constant pressure type ultra-high pressure water supercharger

InactiveCN101463842AImprove reliabilityExtend your lifeNon-mechanical blast generatorsFluid-pressure convertersUltra high pressureHuman–machine interface

The invention relates to an extra high pressure water pressure intensifier. The work mode of phase control and constant pressure is adopted, and two pressure devices are controlled by independent power and can be separately pressurized, wherein, each single pressure device pre-compresses high-pressure water before working, and a high-pressure cylinder body is formed by compounding high-tensile steel with titanium alloy. The pressure of the high-pressure water is constant and stable, the fluctuation of the water pressure is lower than 1.8 percent, and the phenomenon of 'water hammer' does not occur, thus the water pressure energy accumulator does not need to be used. The hydraulic pressure system generates the pressure by a variable plunger hydraulic pump with pressure and load compensation function, and the water pressure intensifier can work under variable pressure or fixed pressure. The entire system is intensively controlled by PLC, and is provided with various pressure, temperatures, liquid level sensors and human-computer interfaces, so as to guarantee the operational safety of the system; and the water pressure can be controlled to be constantly changed according to the external input order. The extra high pressure water pressure intensifier has the advantages of excellent performance, delicate design and convenient installation and especially the vulnerable part can be conveniently replaced.

Owner:崔玥

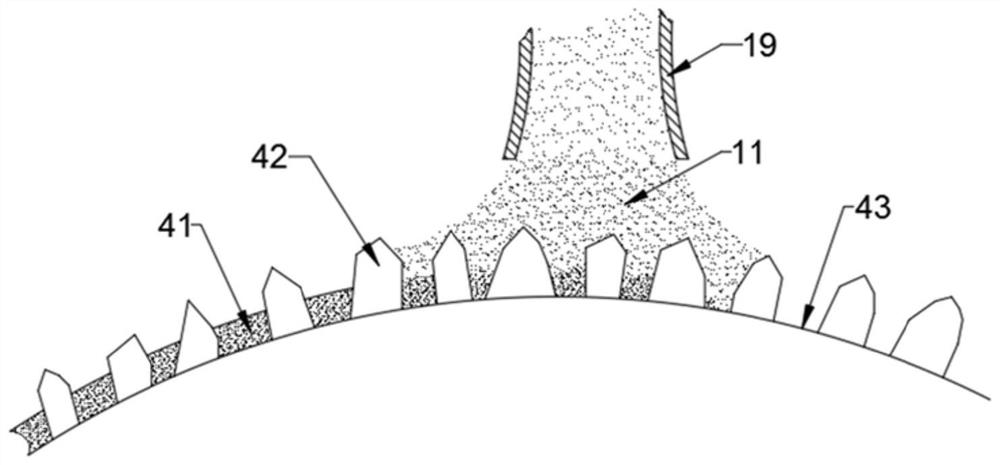

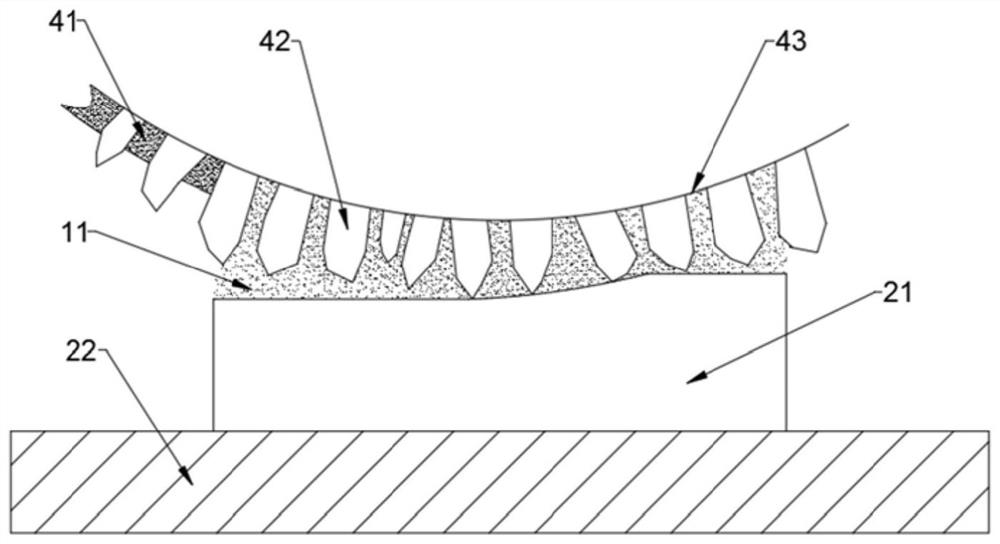

Nano layer lubrication diamond grinding wheel grinding method based on shock wave cavitation effect

ActiveCN112025554AImprove lubrication and coolingReduce grinding specific energyGrinding feed controlAbrasive surface conditioning devicesPhysicsDiamond grinding

The invention provides a nano layer lubrication diamond grinding wheel grinding method based on a shock wave cavitation effect. The method is characterized in that after an air pressure adjusting valve is opened, shock waves generated by an accelerating tube push nano particles to move forwards, and then the nano particles are accelerated by a small laval tube to obtain a high initial speed; meanwhile, a wave source of a shock wave accelerating module generates high-frequency and high-strength shock waves to impact the nano particles with the initial speed, so that the nano particles are continuously accelerated downwards in the axial direction of a large laval tube until the nano particles are embedded into the surface of a grinding wheel at the highest speed to form a nano layer; the other wave source is used for cleaning impurities on the surface of the grinding wheel; and in the machining process, the nano particles of the nano layer are autonomously released in a grinding core area, so that self-lubricating cooling in a grinding area is achieved. The method greatly enhances the lubricating cooling effect, and also conforms to the concept of green development.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Plasma subcritical/supercritical fluid generator and abrasive water jet cutting head comprising generator

InactiveCN103894937AImprove thermal efficiencyReduce volumeNon-mechanical blast generatorsEngineeringAbrasive water jet

The purpose of the invention is to provide a plasma subcritical / supercritical fluid generator and an abrasive water jet cutting head comprising the generator. The plasma subcritical / supercritical fluid generator comprises a protrusion electrode and an annular electrode, wherein the protrusion electrode and the annular electrode are connected through an insulation sealing ring; an electrode protrusion is formed in the middle of the protrusion electrode; holes are formed in the periphery of the electrode; a central hole is formed in the middle of the annular electrode; the electrode protrusion is opposite to the central hole; the protrusion electrode and the annular electrode are connected to a power supply; fluid flows into the generator through the holes at the periphery of the protrusion electrode and flows out of the generator through the central hole of the annular electrode; or the fluid flows into the generator through the central hole of the annular electrode and flows out of the generator through the holes at the periphery of the protrusion electrode; the electrode protrusion emits plasma beams, and the plasma beams pass through the fluid and then enter the annular electrode; or the annular electrode emits plasma beams, and the plasma beams pass through the fluid and then enter the protrusion electrode. By generating the plasma beams in the fluid, the inside of the generator is heated; the generator is applicable to small-scale integration and can be widely used in all systems and devices which need to generate subcritical / supercritical fluids.

Owner:HARBIN ENG UNIV

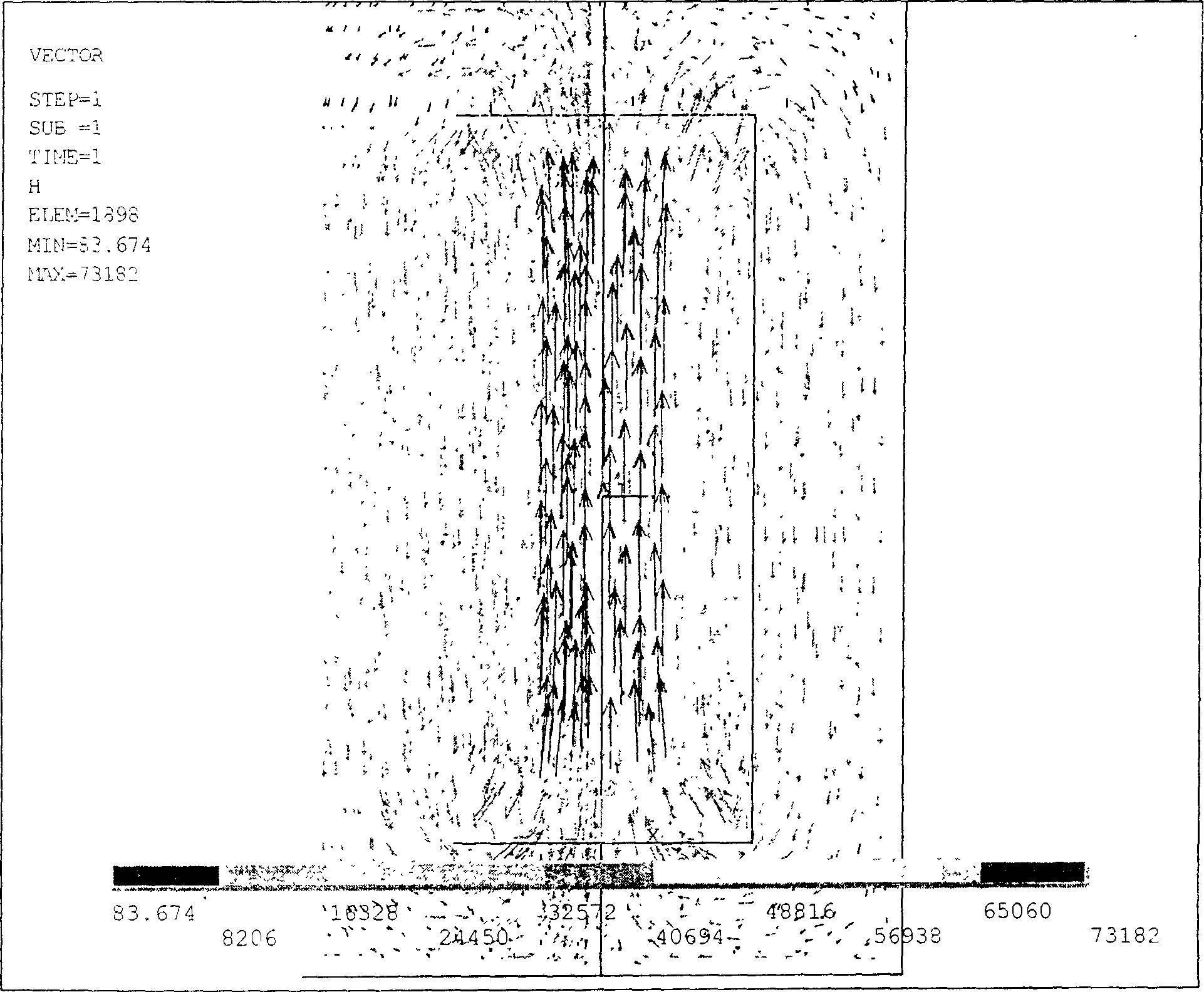

Deterministic magnetic jet-flow finishing method and apparatus

InactiveCN1231330CEasy to processIdeal stable removal functionNon-mechanical blast generatorsMagnetic liquidsLiquid mediumJet flow

A deterministic magnetic jet finishing method, which uses a magnetic field outside the nozzle that can spray magnetorheological fluid to form a jet, and controls the magnetorheological fluid by controlling the spatial movement position of the workpiece and the direction and size of the magnetic field around the nozzle. The rheological characteristics of the magnetorheological fluid are used to control the viscosity and jet angle of the magnetorheological fluid to form an anisotropic liquid medium, which is characterized in that the nozzle is placed in five coordinates composed of y-axis, v-axis, x-axis, z-axis and u-axis On the CNC platform, the v-axis that can place the workpiece is set on the y-axis. Above the v-axis is a nozzle and the u-axis connected to it. The z-axis that can move up and down is connected to the u-axis and connected to the x-axis. Magneto-rheological The liquid is composed of 30-40% carbonyl iron powder, 50-60% water, 4-8% abrasive and 1-5% stabilizer by volume. The invention combines jet technology and magnetorheological fluid viscosity controllable characteristics, by controlling the jet angle of magnetorheological fluid and the viscosity of external magnetorheological fluid, it can ensure that the polishing mold has a stable removal function, and realizes the definite amount of polishing of optical parts processing.

Owner:NAT UNIV OF DEFENSE TECH

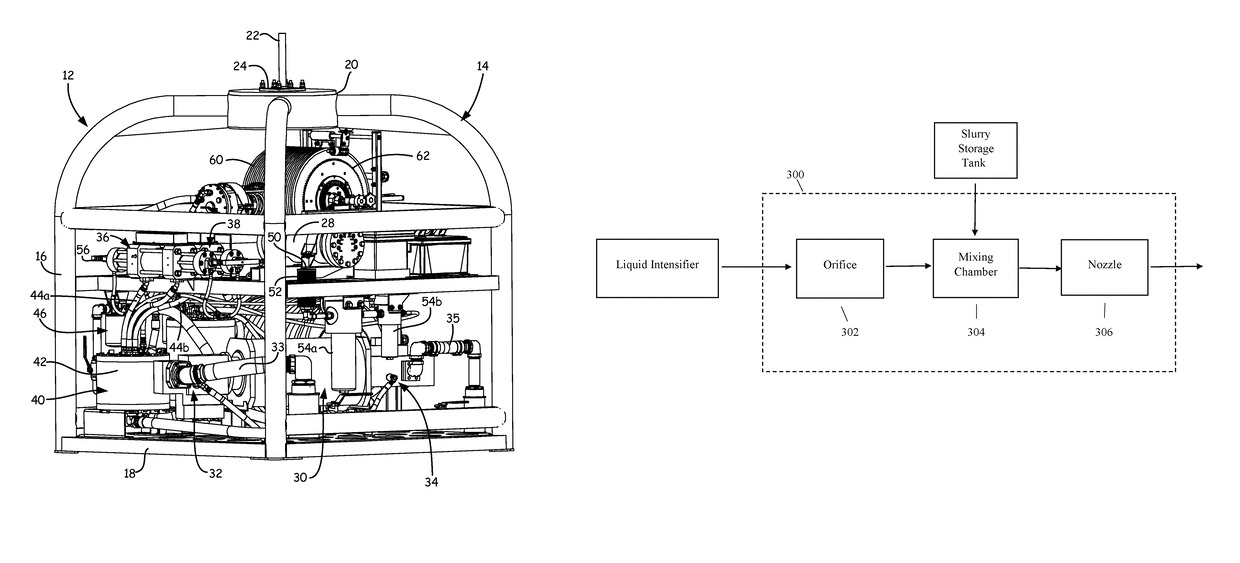

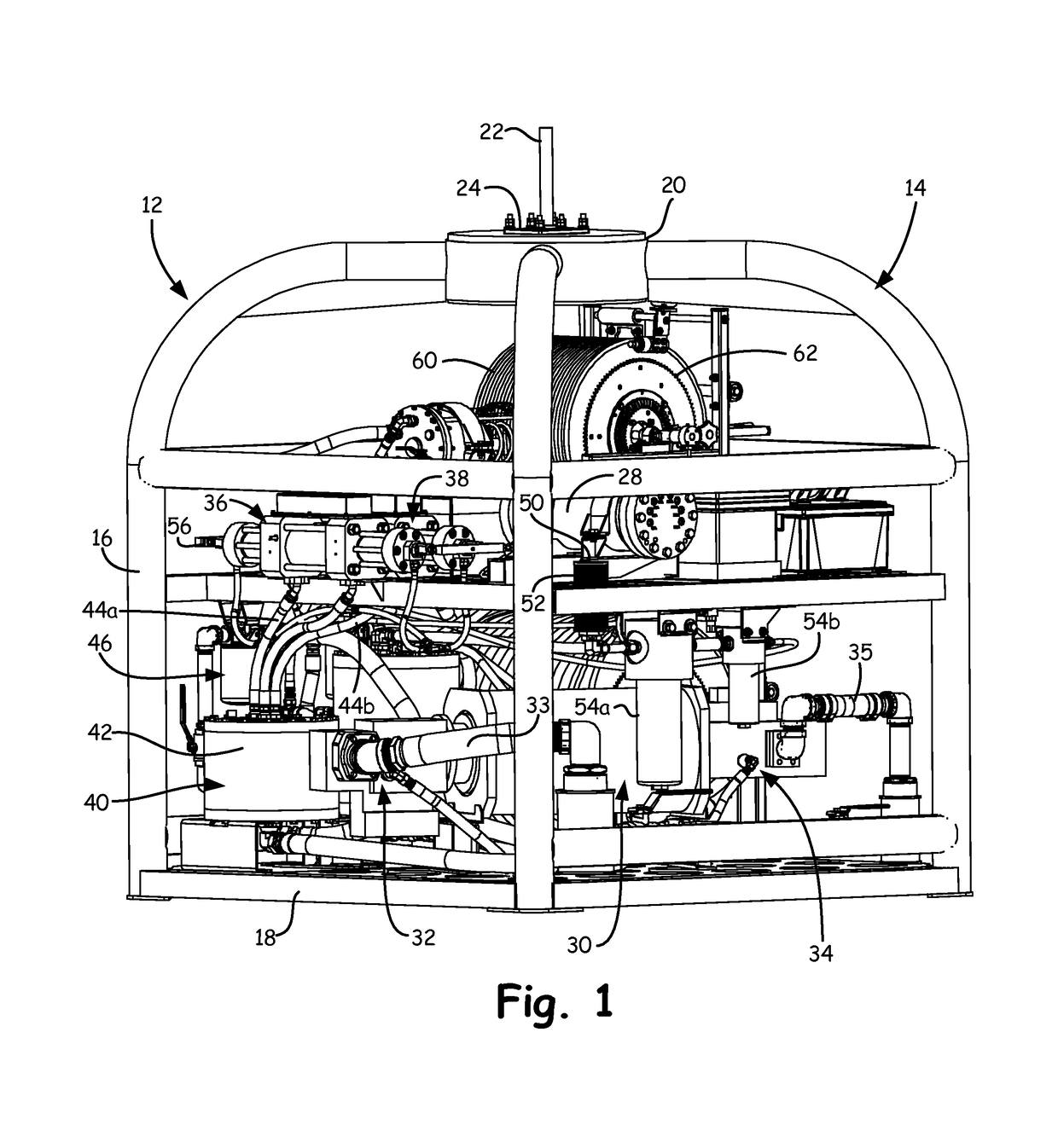

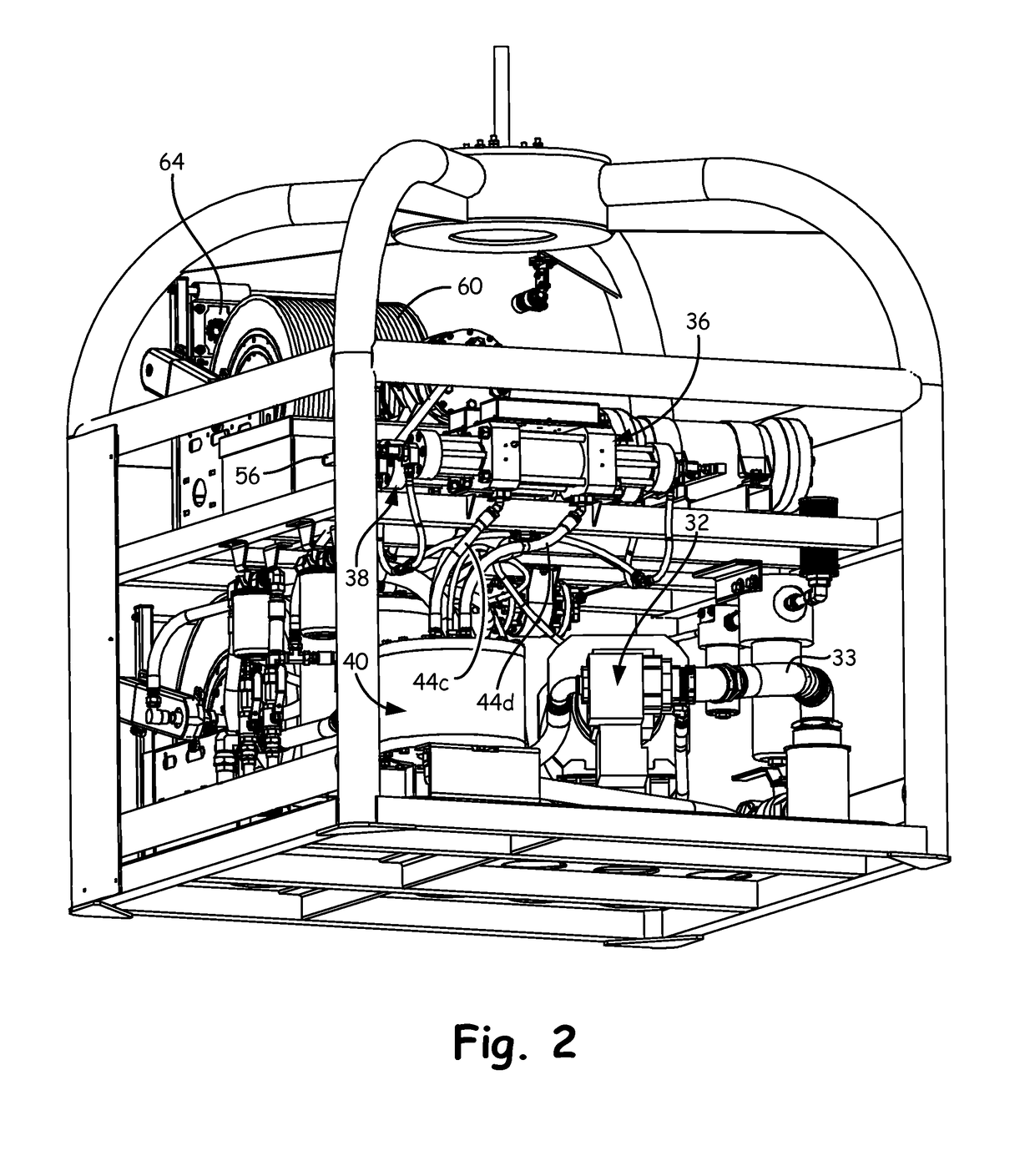

Submersible liquid jet apparatus

InactiveUS10086497B1Wide range of movementSufficiently portableNon-mechanical blast generatorsAbrasive feedersLiquid jetEngineering

A submersible liquid jet apparatus is provided for a system with a portable liquid jet tool that may be handled by human divers or remotely operated vehicles (ROV). The present apparatus facilitates the portability of a liquid jet tool with a support unit supplying high pressure working liquid and pressurized hydraulic fluid. The apparatus further provides portable delivery of an abrasive suspension to enhance the effectiveness of the high pressure working liquid.

Owner:CHUKAR WATERJET

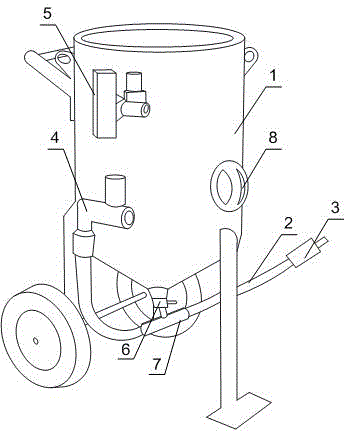

Movable sand blowing polishing machine achievement method

InactiveCN105619263AReduce work intensityConvenient for hoistingNon-mechanical blast generatorsGrinding/polishing apparatusSand blastingEngineering

The present invention discloses a movable sand blowing polishing machine achievement method. The movable sand blowing polishing machine comprises a box, a sand blasting pipe and a blasting nozzle, wherein the box is provided with a gas inlet control valve and a gas discharge control valve, the sand outlet position on the bottom portion of the box is provided with a butterfly sand adjustment valve, one end of the sand blasting pipe is connected to the box through the gas inlet control valve, the other end is respectively connected to the butterfly sand adjustment valve and the blasting nozzle through a thickened sand outlet three-way valve, the movable sand blowing polishing machine further comprises two foot wheels and a support foot, the foot wheels and the support foot are arranged on the bottom portion of the box and are distributed in a triangular manner, the thickened sand outlet three-way valve and the butterfly sand adjustment valve are independently arranged, the thickened sand outlet three-way valve is improved to increase the bottom portion wall thickness so as to increase the wear time, and the 90 DEG vertical sand falling port inside the three-way valve is changed into the 45 DEG inclined sand falling port so as to form the co-directional gas flow path with the gas flow from the back, such that the effective power of the sand inside the sand valve is increased, the bounce and the convolution of the abrasive material on the bottom portion of the sand valve are reduced, the wear on the sand outlet three-way valve and the sand blasting pipe is reduced, and the equipment use rate is enhanced.

Owner:王丰利

Apparatus and method for spiral polishing with electromagnetic abrasive

InactiveUS7938716B2Improve liquidityNon-mechanical blast generatorsGrinding machinesEngineeringElectromagnet

An apparatus and method for spiral polishing with electromagnetic abrasive has adopted the principle of electromagnetic and magnetic abrasive along with a lead screw to polish the inner or outer surface of a precise screw or a complicated part. The apparatus includes a clamp, a lead screw, a first electromagnet, and a second electromagnet assembled in an airtight space, wherein the airtight space is filled with magnetic abrasive which is driven by the rotation of the lead screw and the electromagnetic function to polish a processed part in a regular shape or in an irregular shape.

Owner:SOUTHERN TAIWAN UNIVERSITY OF TECHNOLOGY

Apparatus and method for spiral polishing with electromagnetic abrasive

InactiveUS20110070809A1Improve liquidityNon-mechanical blast generatorsGrinding machinesEngineeringElectromagnet

An apparatus and method for spiral polishing with electromagnetic abrasive has adopted the principle of electromagnetic and magnetic abrasive along with a lead screw to polish the inner or outer surface of a precise screw or a complicated part. The apparatus includes a clamp, a lead screw, a first electromagnet, and a second electromagnet assembled in an airtight space, wherein the airtight space is filled with magnetic abrasive which is driven by the rotation of the lead screw and the electromagnetic function to polish a processed part in a regular shape or in an irregular shape.

Owner:SOUTHERN TAIWAN UNIVERSITY OF TECHNOLOGY

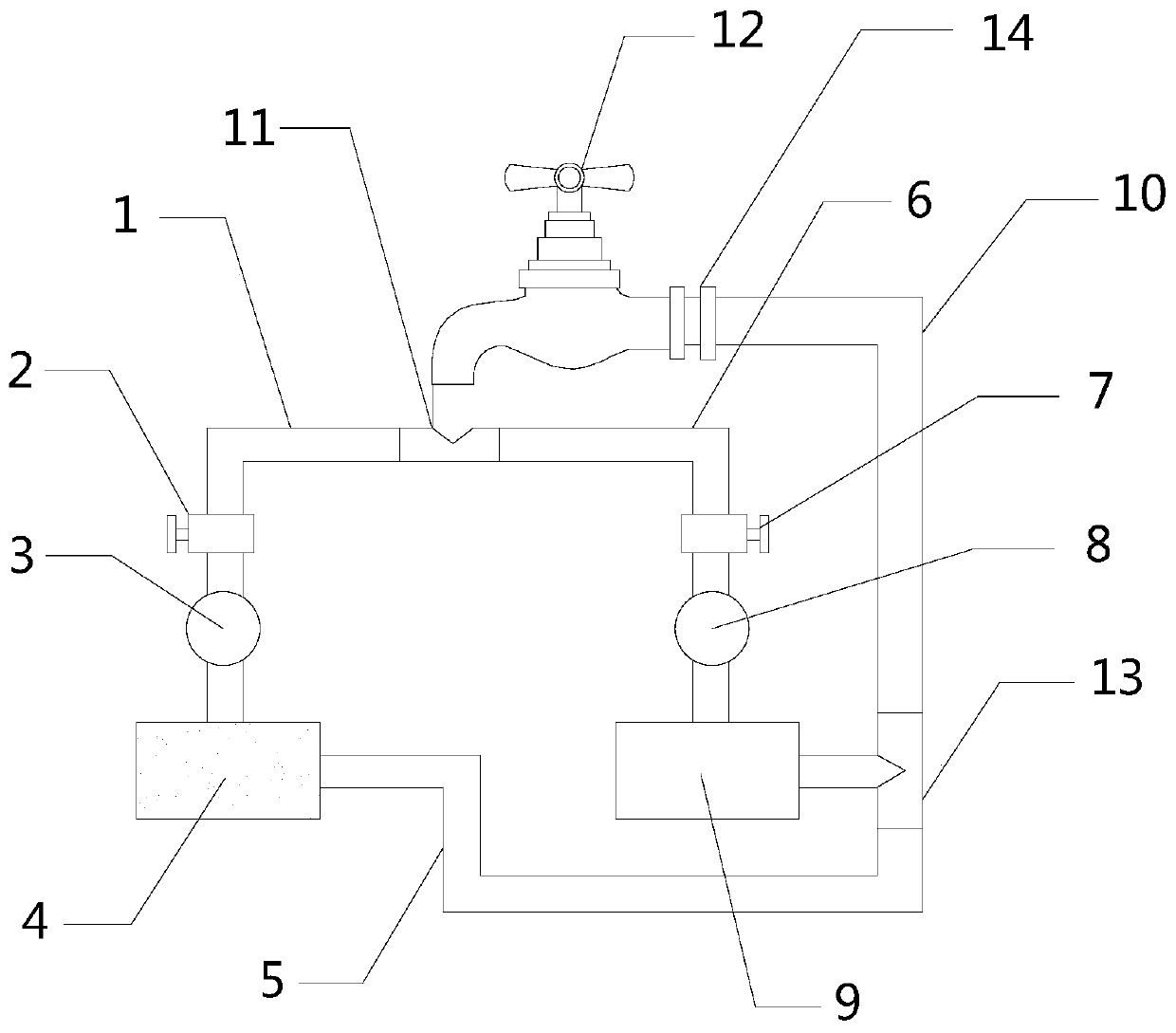

Household faucet cleaning device

InactiveCN111531472ASuitable for useQuick peelNon-mechanical blast generatorsAbrasive feedersSolenoid valveEnvironmental engineering

The invention provides a household faucet cleaning device which includes a first water inlet pipe, a first solenoid valve, a backwash pump, a water tank, a first water outlet pipe, a second water inlet pipe, a second solenoid valve, a high pressure pump, a chemical box, a second water outlet pipe, a power supply and a controller. The chemical box is internally equipped with an incrustation removing agent, the water tank is internally equipped with water quartz sand; hydroxypropionic acid is safe and non-toxic, and suitable for household users; a backwash loop formed by the first water inlet pipe, the second solenoid valve, the backwash pump, the clean water tank and the first water outlet pipe drives quartz sand particles to move at a high speed, the incrustation on the inner wall of a faucet is quickly peeled off, and the incrustation removing effect is further improved; and a first three-way pipe, a second three-way pipe can be quickly installed and disassembled, and the incrustationon the inner wall of the faucet can be quickly removed without removing the faucet.

Owner:SUZHOU ZHIJIAKEYAN TECH CO LTD

Aero-engine bearing inner ring electromagnetic composite field micro-nano targeted repairing device and device

ActiveCN113305743AImprove the surface hardness of the working surfaceImprove wear resistanceNon-mechanical blast generatorsBlade accessoriesRotational axisElectric machine

The invention relates to an aero-engine bearing inner ring electromagnetic composite field micro-nano targeted repairing device. The device comprises a driving device, an ultrasonic shot blasting device, a pulse current generator and a magnet yoke coil device. The driving device comprises a motor and a rotating shaft, and the motor drives the rotating shaft to drive a bearing inner ring to synchronously rotate. The ultrasonic shot blasting device comprises an ultrasonic shot blasting cavity, an ultrasonic probe and a steel ball, the ultrasonic probe extends into the ultrasonic shot blasting cavity from a lower end opening, and the steel ball is arranged on the ultrasonic probe. An upper end opening of the ultrasonic shot blasting cavity is formed in the lower end of the to-be-machined bearing inner ring. The pulse current generator generates pulse currents on the bearing inner ring. The magnet yoke coil device is used for exciting a magnetic field around the bearing inner ring. According to the device, in-situ surface micro-nano damage formed in the ultrasonic peening surface nanocrystallization process or after the ultrasonic peening surface nanocrystallization process is repaired, and therefore homogenization of deformation phase change and internal energy distribution of a nanolayer is achieved, the problem of matrix micro-nano scale damage defect control in macroscale manufacturing is solved, and the existing aero-engine bearing service performance and service life limits are broken through.

Owner:WUHAN UNIV OF TECH

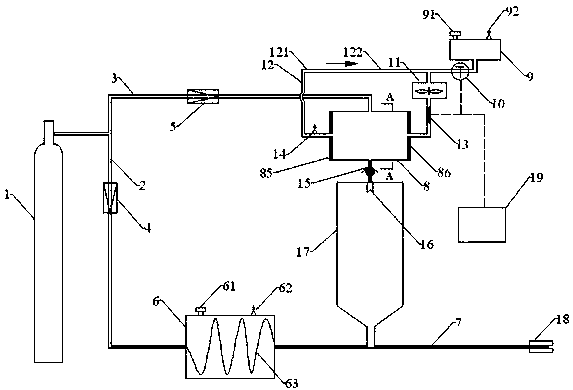

Apparatus and method for preparing ice particle gas jet from supercooled water

PendingCN109262474AMake up for the phenomenon of easy blockingHigh speedNon-mechanical blast generatorsAbrasive machine appurtenancesLine tubingGas cylinder

A method for preparing ice particle gas jet from supercooled water includes the steps of (1), preparing supercooled water; (2), preparing ice particles and completing gas jet; (3), recycling raw materials. The invention further provides an apparatus for preparing ice particle gas jet from supercooled water, comprising a high-pressure air bottle connected with an air current circulating system through a second branch pipeline, wherein the high-pressure air bottle is connected with a first liquid nitrogen box through a first branch pipeline, the other end of the first liquid nitrogen box is connected with a nozzle through a manifold, an atomizing box is arranged on the manifold between the first liquid nitrogen box and the nozzle, the air current circulating system comprises a heat exchanger, the upper end of the heat exchanger is connected with the second branch pipeline, the left end of the heat exchanger is connected with the second liquid nitrogen box and an air blower through a pipeline and a tee joint, the other end of the heat exchanger is connected with the right end of a heat exchange box, and the bottom of the heat exchange box is connected with an atomizing nozzle of the atomizing box through a pipeline. With the apparatus and the method, ice particles can be prepared and ice particle gas jet can be formed rapidly.

Owner:HENAN POLYTECHNIC UNIV

A fluid shear type metal parts surface derusting device

ActiveCN111531470BSimple surface treatmentImprove rust removal effectNon-mechanical blast generatorsAbrasive feedersFluid shearGas bubble

The invention discloses a fluid shearing type metal parts surface derusting device, which belongs to the technical field of metal derusting. The bubbles are continuously introduced into the fluid shearing and derusting cylinder to achieve high-speed shearing of the fluid through the dense shunting screen, and at the same time drive some magnetic impurity spheres to drive upwards to drive the impact, floating in the magnetic field of the fluid shearing and derusting cylinder. The impurity balls capture the air bubbles in the water body, and after colliding with the metal parts, the air bubbles are compressed to generate impact force, destroying the rust and oxidized impurities on the metal surface, and the magnetic flotation derusting mechanism has a certain magnetic attraction effect, which is good for floating The magnetic impurity spheroids have the function of magnetotropic movement, which further increases the contact and collision probability between some magnetic impurity spheroids and metal parts, and is easy to carry out surface treatment on metal parts with smaller specifications.

Owner:NANJING JUCHENG ZHIYUAN FINANCIAL CONSULTANT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com