Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66 results about "Ultrasonic shot peening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

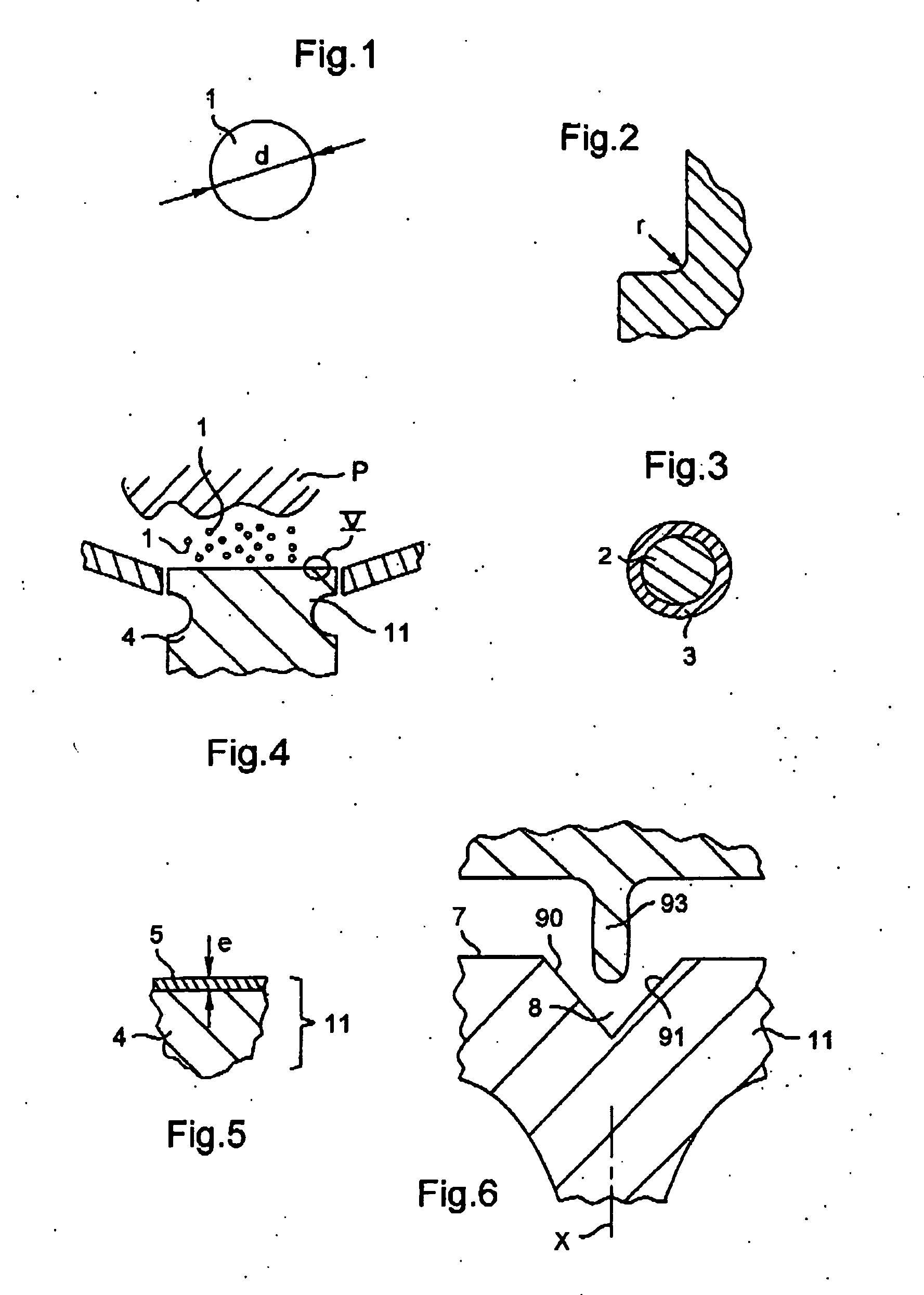

Shot, devices, and installations for ultrasonic peening, and parts treated thereby

InactiveUS20060021410A1Easy and quick to treatShorten treatment timeVibratory devicesMaximum dimensionMetallurgy

Shot for use in a peening installation, the shot having: hardness greater than or equal to 800 HV; density greater than or equal to 8 g / cm3; and pieces having a maximum dimension less than or equal to 1.5 mm.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

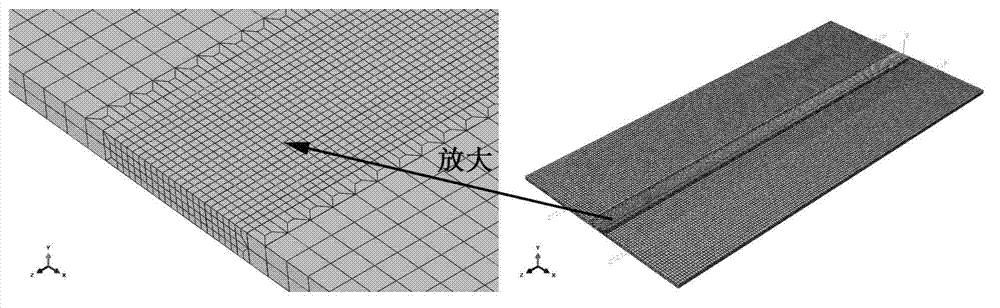

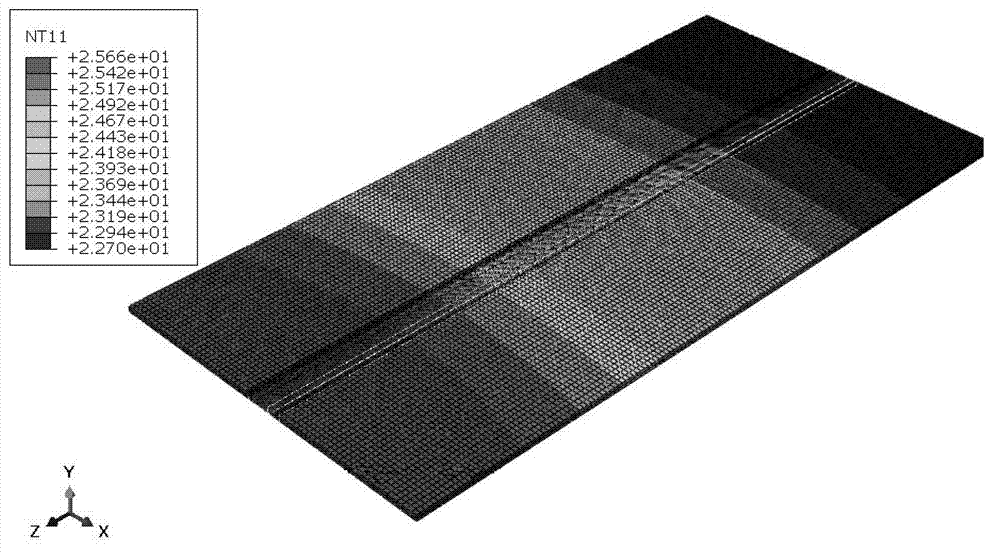

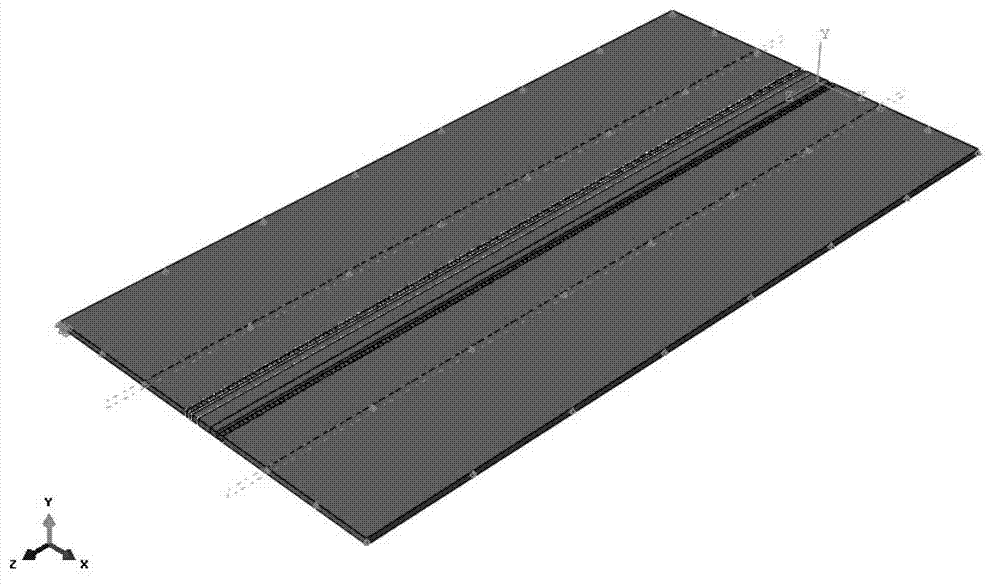

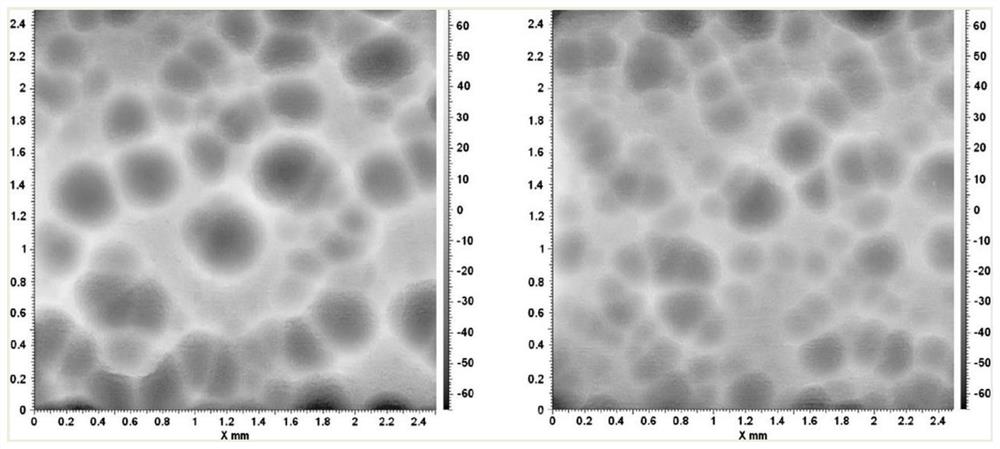

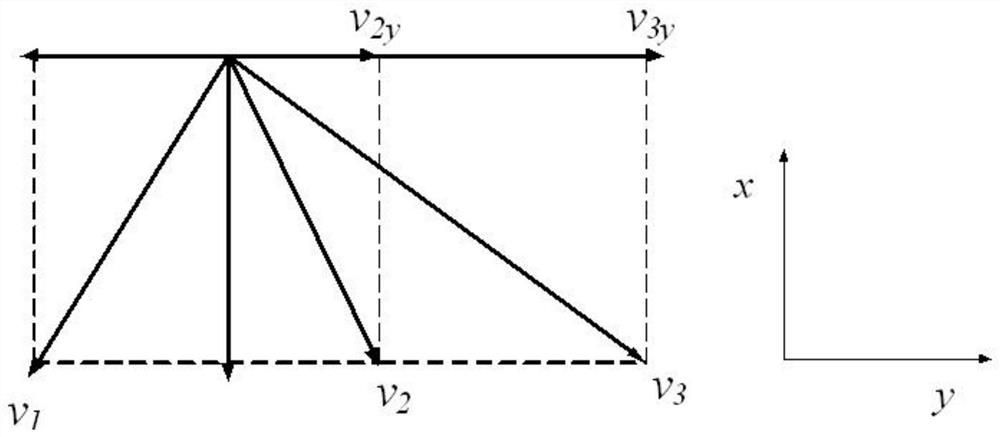

ABAQUS-based finite element simulation method of correcting welding deformation through ultrasonic shot-peening

The invention discloses an ABAQUS-based finite element simulation method of correcting welding deformation through ultrasonic shot-peening. The method includes: firstly, utilizing the finite element software ABAQUS to simulate the welding process of a certain-sized aluminum alloy sheet to obtain the distribution of the welding residual stress and the deformation;and secondly, reading in a stress force and deformation grid and performing the simulative computation of a shot-peening shape correction process on the basis of the welding stress and deformation. The ABAQUS-based finite element simulation method of correcting the welding deformation through the ultrasonic shot-peening takes the limits that the complexity of mechanism of the shot-peening process and the influence of various variable factors result in great difficulties in optimizing shot-peening process parameters and the method which purely relies on experimental data and experience consumes much time and money into consideration, so that the ABAQUS-based finite element simulation method is introduced to assist the selection of the ultrasonic shot-peening process parameters and the strain of the stress and the change of the deformation are analyzed to explain the mechanism of the shape correction.

Owner:TIANJIN UNIV

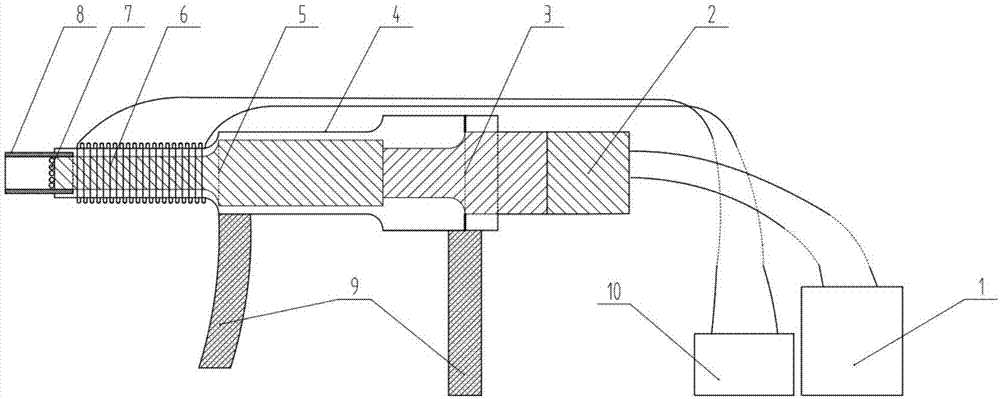

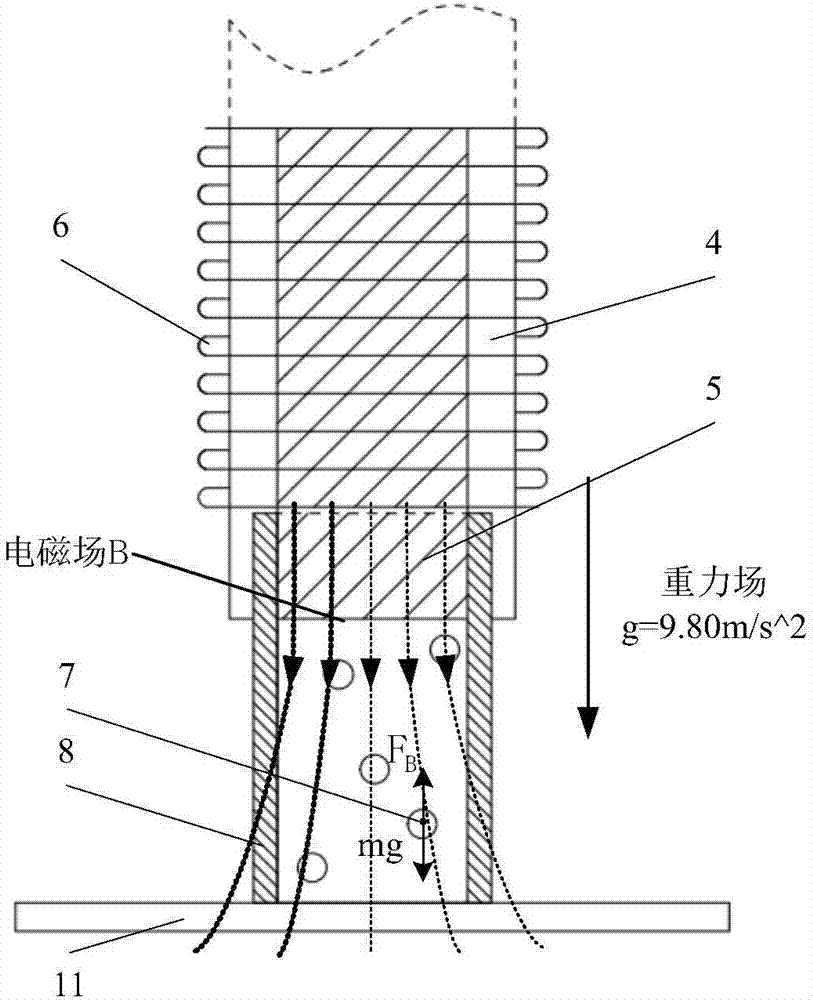

Electromagnetic-field-aided ultrasonic shot peening device and method

ActiveCN107336142AControl speedReduced strengthNon-mechanical blast generatorsAbrasive machine appurtenancesPower flowElectromagnetic field

The invention provides an electromagnetic-field-aided ultrasonic shot peening device and method. Through application of an electromagnetic field, shots are in a superimposed field of an electromagnetic field and a gravity field, and the intensity of the electromagnetic field is changed through change of the magnitude of a current so that the magnitude and direction of a resultant borne by the shots can be controlled; and in this way, the influence of the gravity field on the shots is eliminated according to different directions of a tool head relative to a workpiece, and the limitation that during conventional shot type ultrasonic shot peening treatment, the tool head can only be located below the workpiece to be treated and preferably over the workpiece to be treated is eliminated. The tool head can be located below the workpiece to be treated and can also located above the workpiece to be treated, and treatment of a workpiece in a complicated shape can be conveniently and flexibly achieved in any direction. Besides, through control over the magnitude of the electromagnetic force, the speed of the shots can be changed, and adjustment and control over the shot peening intensity can be achieved.

Owner:SHANDONG UNIV

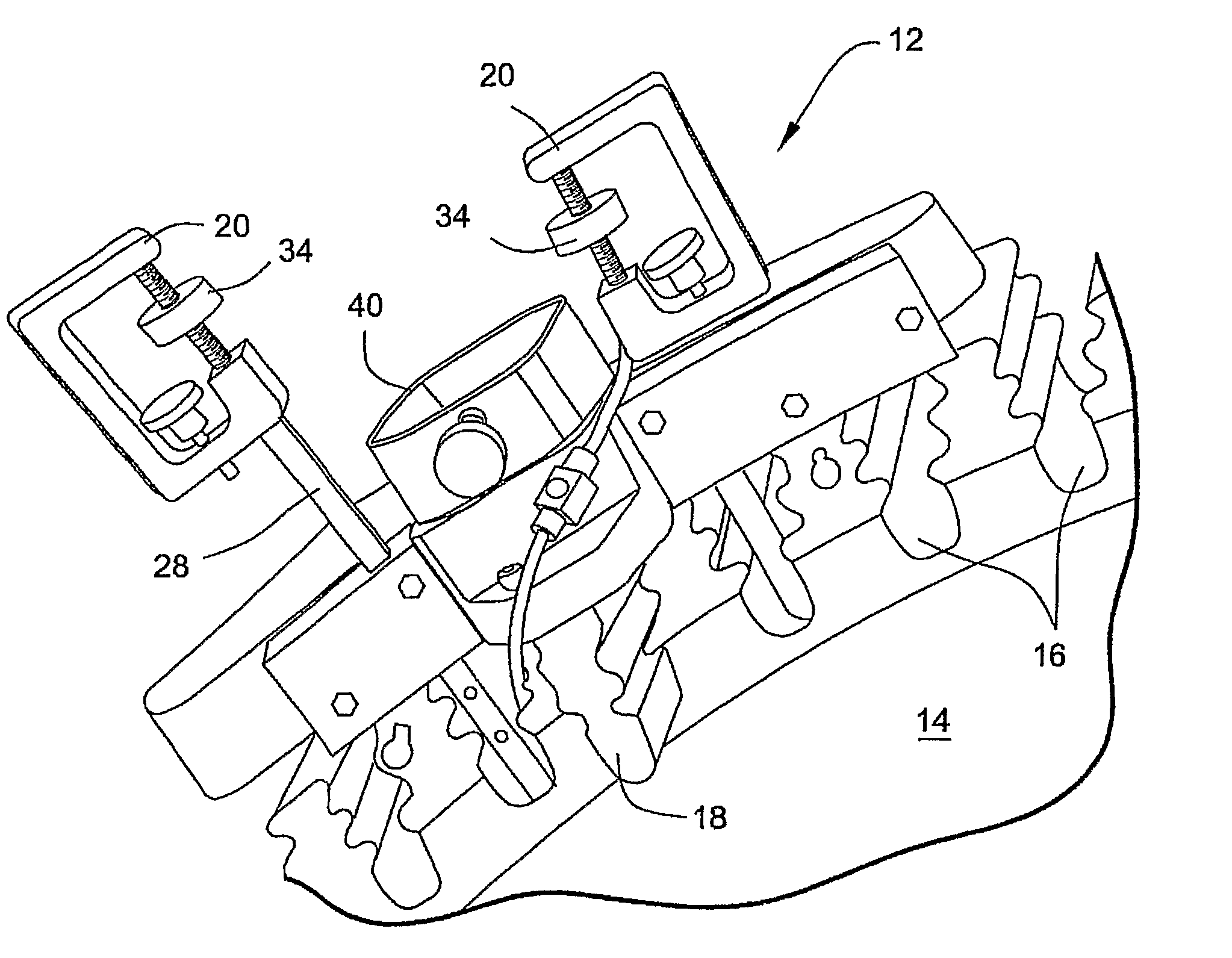

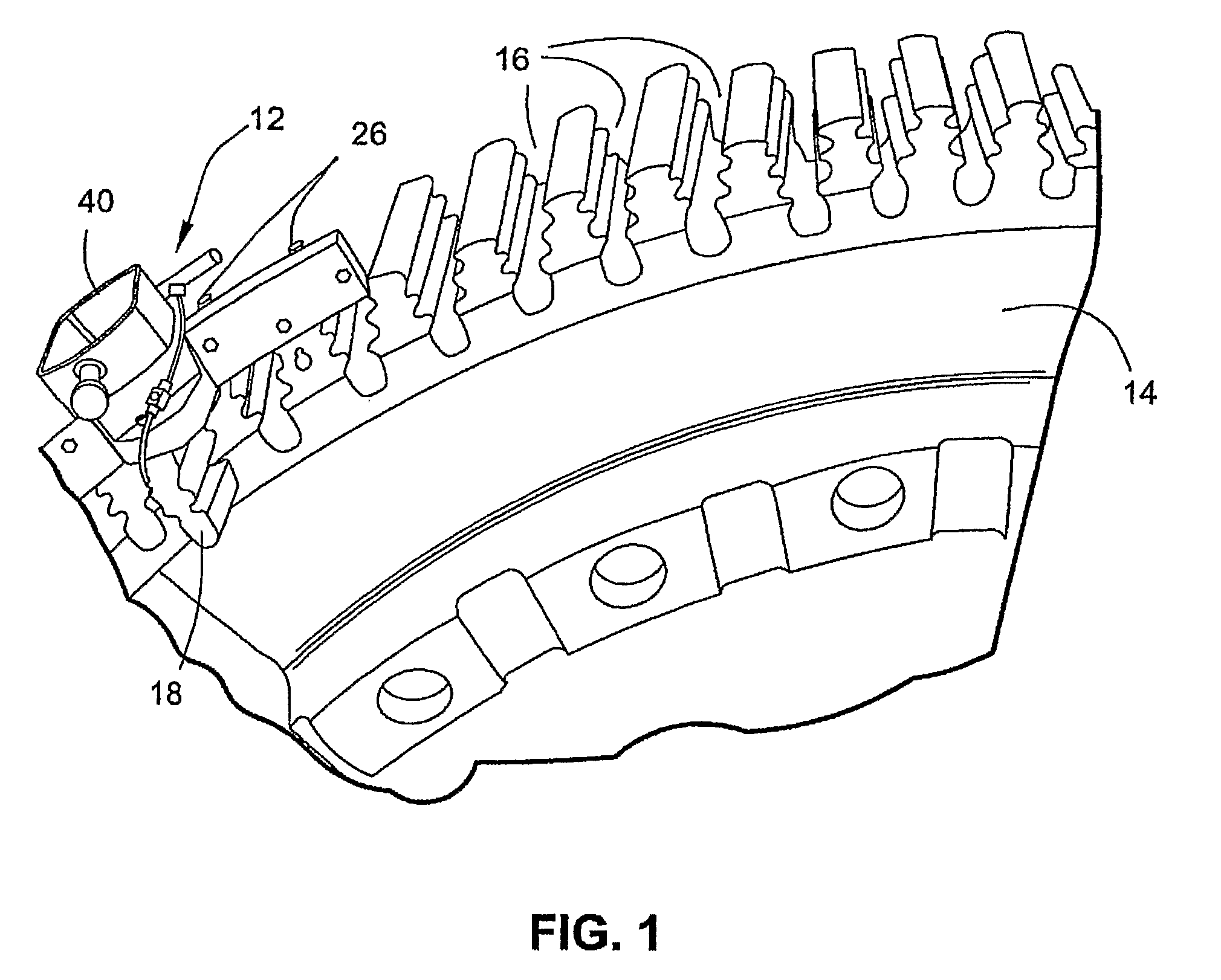

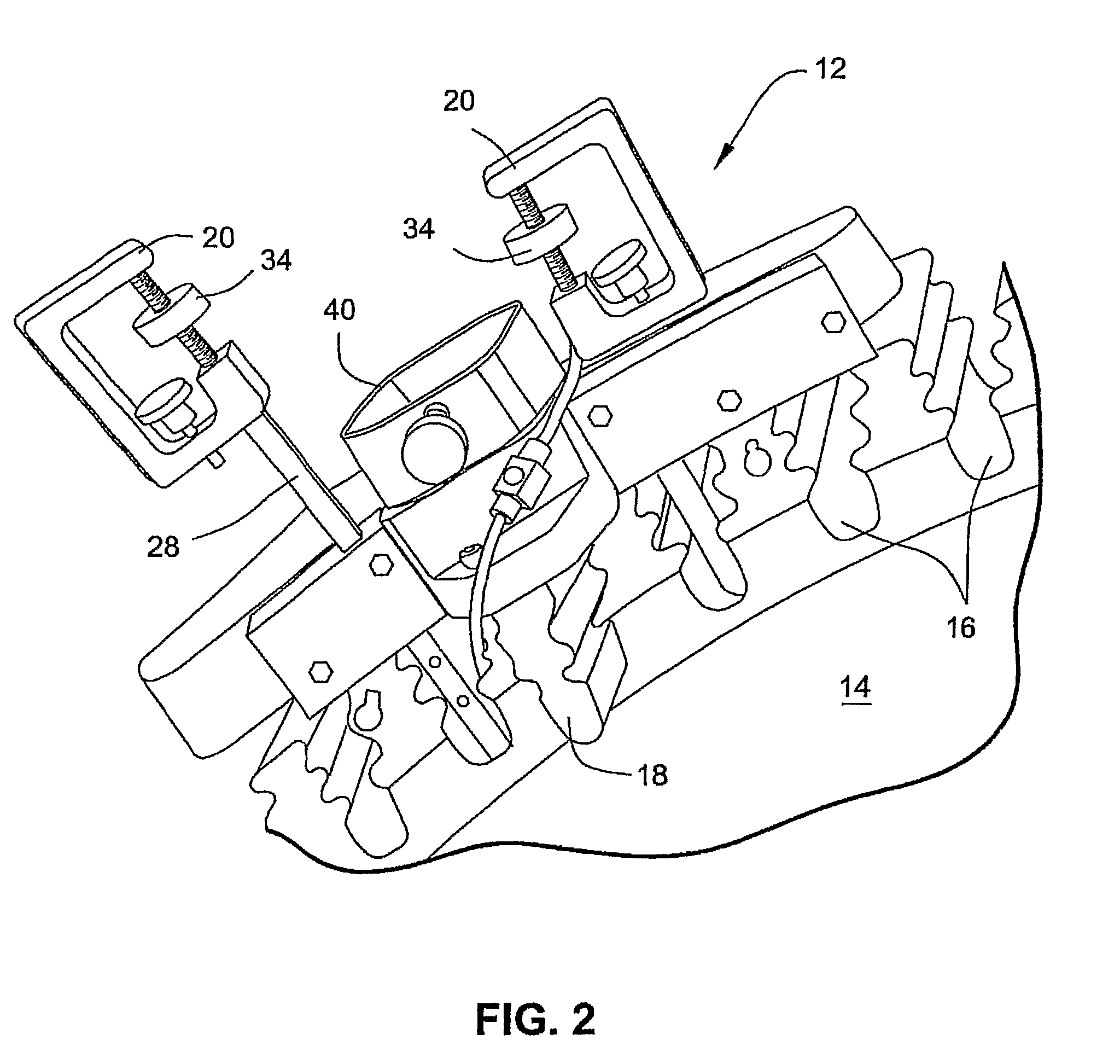

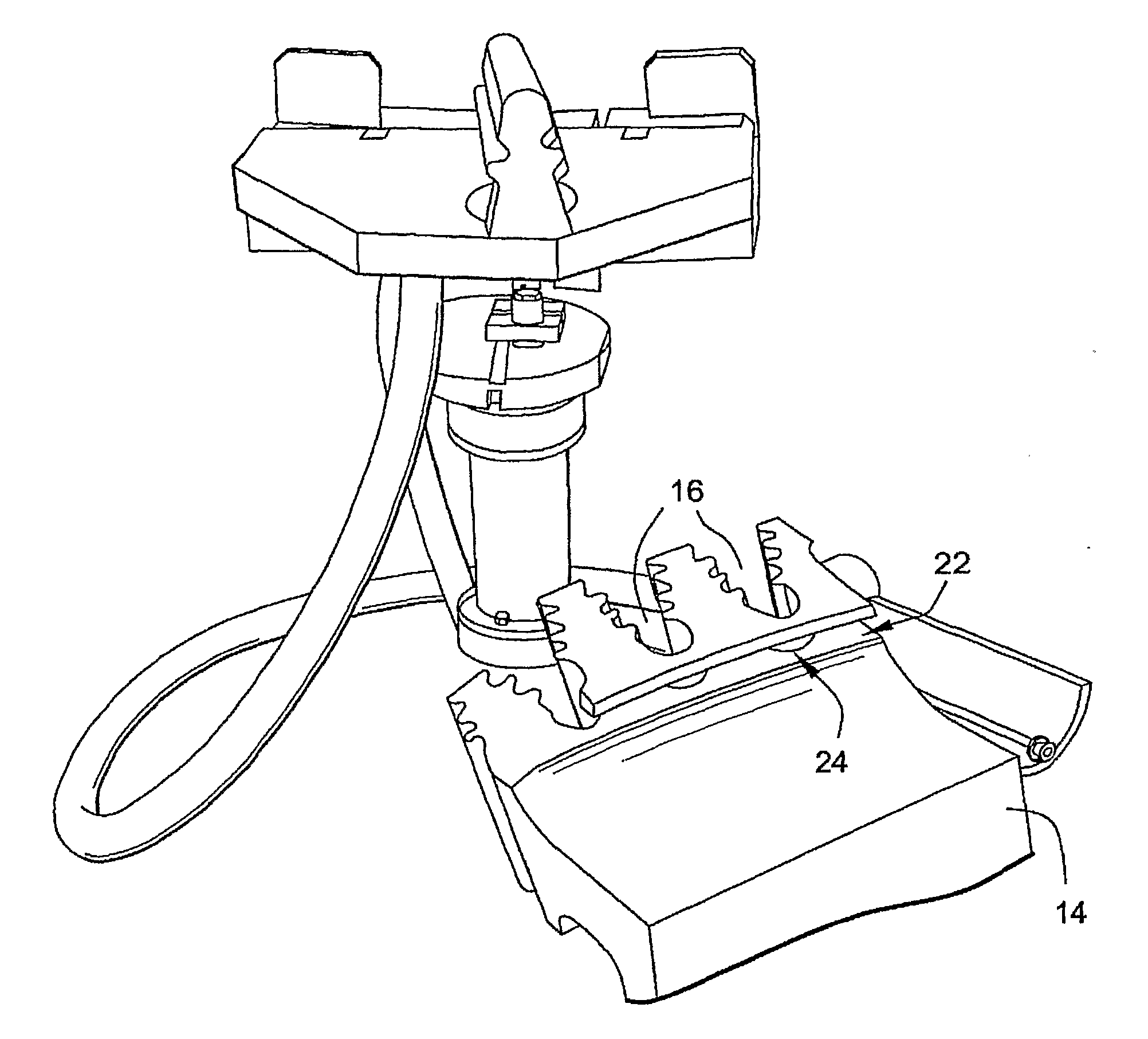

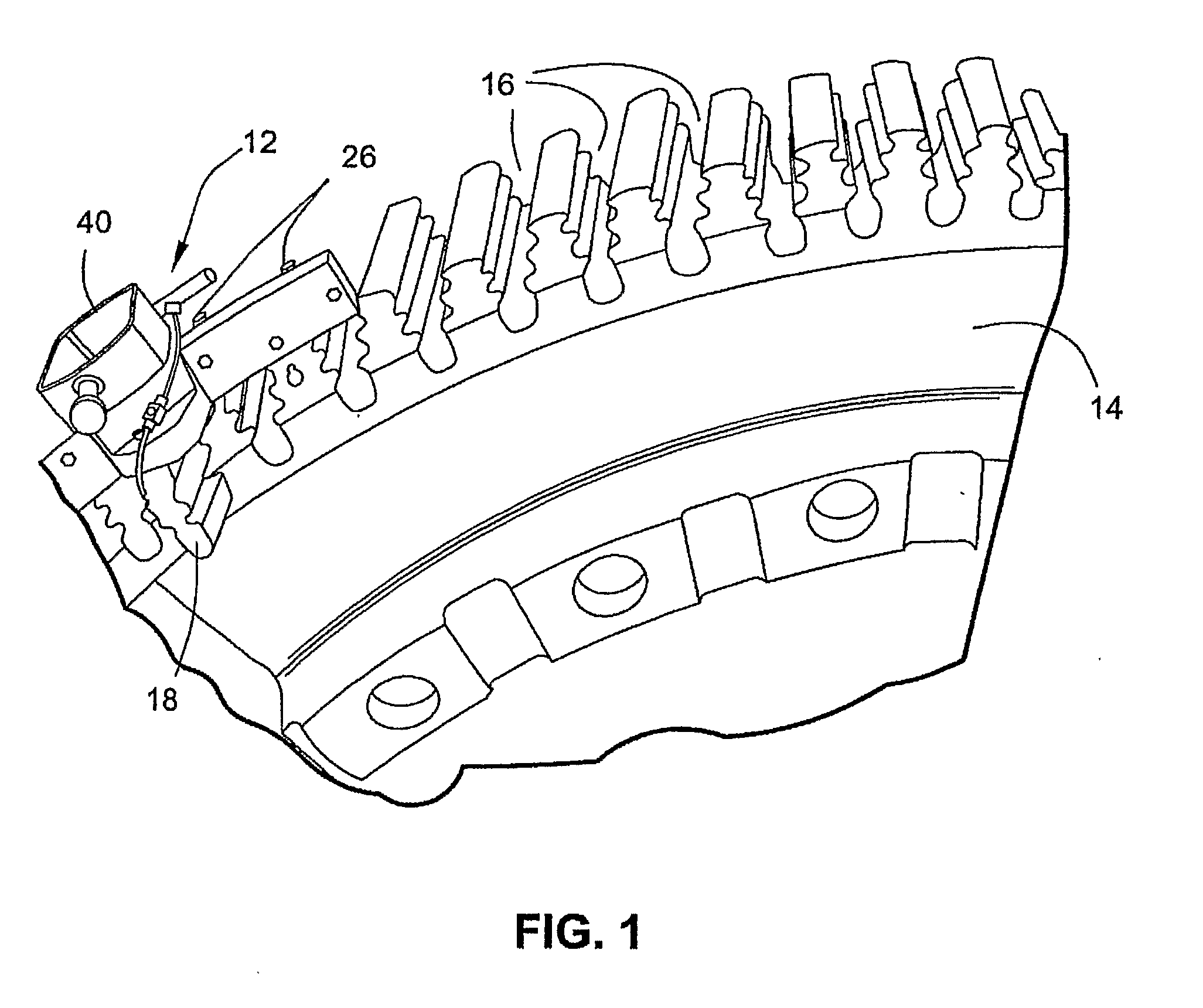

Ultrasonic peening treatment of assembled components

Ultrasonic peening treatment is desirable where an application of a compressive stress is helpful to reduce the incidence of crack formation on highly stressed parts. Ultrasonic peening treatment can be performed in field applications without requiring a rotor to be removed from the machine. The system includes an acoustic element that excites peening media within a peen chamber. A frame is attachable to an assembled turbine rotor component and includes support structure engageable with the acoustic element. The frame is cooperable with a chamber tooling that defines and encloses the peen chamber together with the turbine rotor component.

Owner:GE INFRASTRUCTURE TECH INT LLC

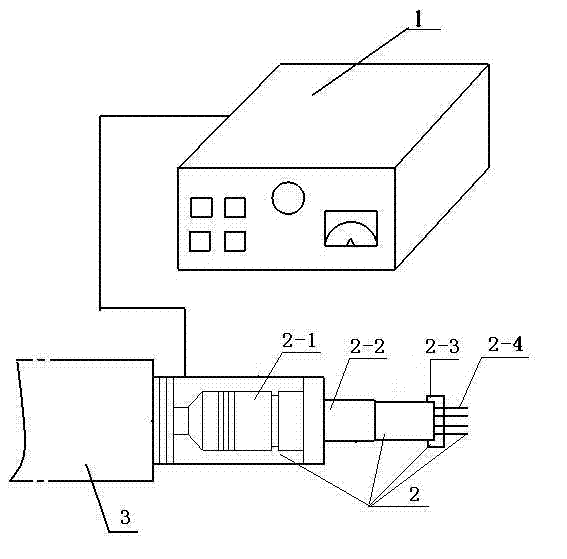

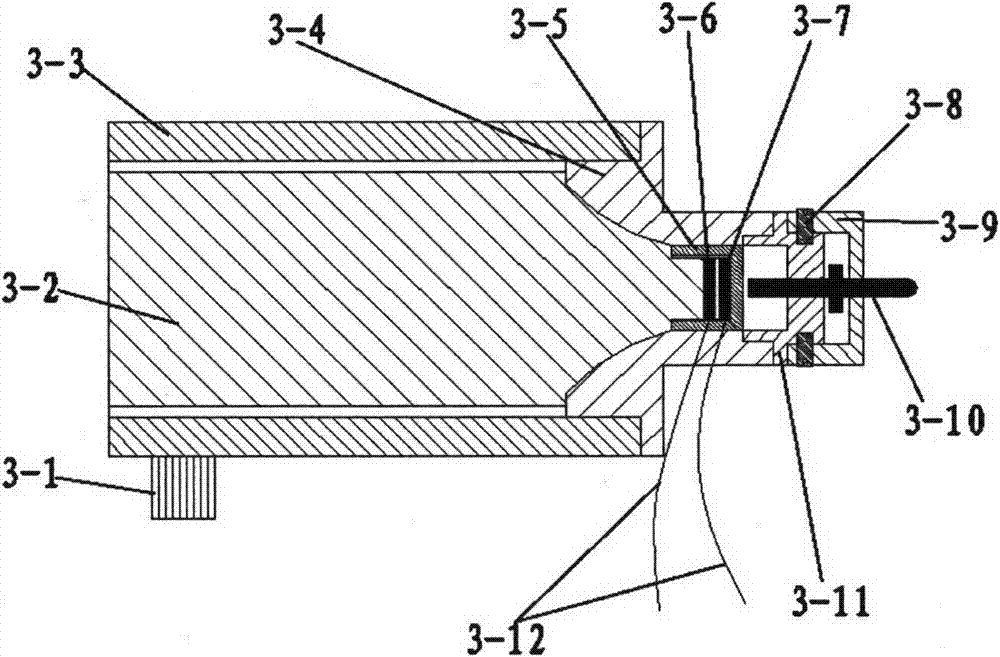

Supersonic shot-peening forming method for single or double curvature integral panels

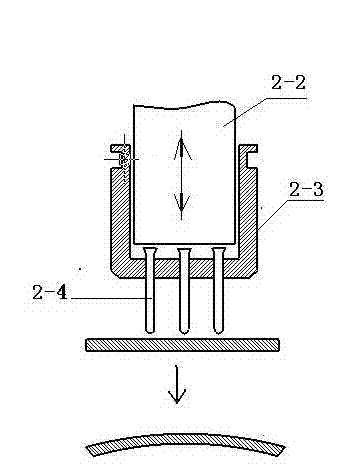

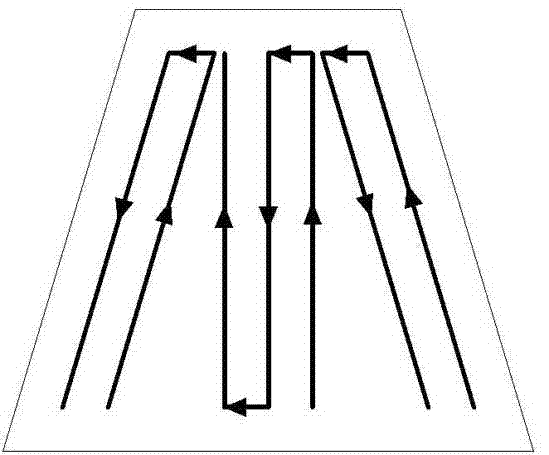

InactiveCN102513942AHigh precisionStable structureAbrasive blasting machinesNumerical controlTransformer

The invention discloses a supersonic shot-peening forming method for single and double curvature integral panels. According to the invention, a supersonic shot-peening forming device is utilized, different forming loci are set according to integral panel forming shape demands, and a numerical control program corresponding to the forming loci is compiled on a numerical control machine tool to make the main shaft of the machine tool move according to the compiled numerical control program and control the movement of an impact gun (2). A supersonic transducer (2-1) is utilized to transmit oscillation electric signals generated by a supersonic generator (1) to longitudinal wave mechanical oscillation with the frequency same as the frequency of the signals, minimal amplitudes are amplified through an amplitude transformer (2-2), panel surfaces are impacted by means of firing pins (2-4) on an oscillation tool head (2-3) according to the forming loci to make the panels project, be bent and be formed in the impact direction to obtain the single or double curvature integral panels with different curvatures. The method which has the advantages of strong maneuverability, high working efficiency, high forming precision and wide application range can be used for processing the single or double curvature integral panels with different curvatures, different shapes and highly required precision in the aerospace industry.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

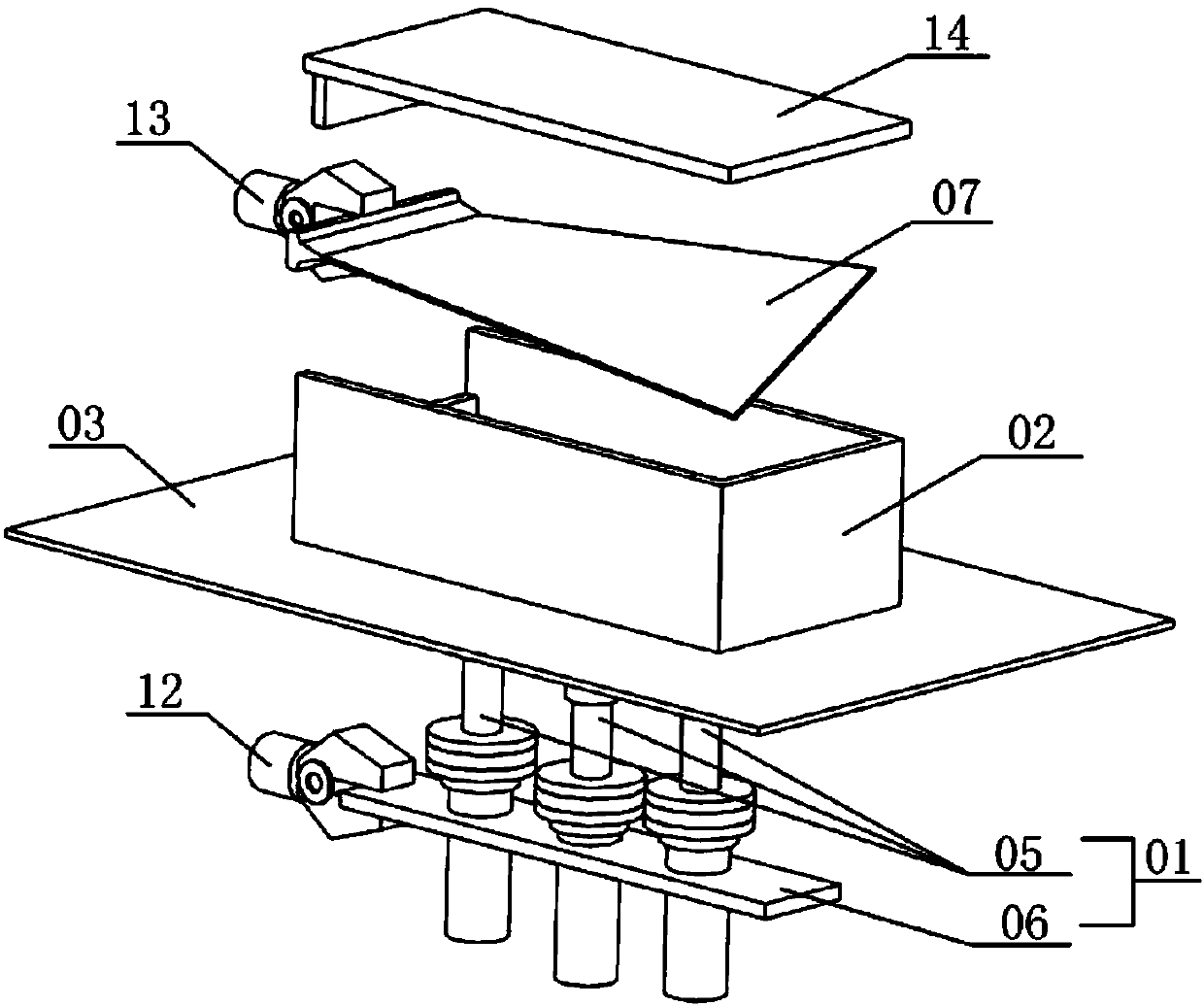

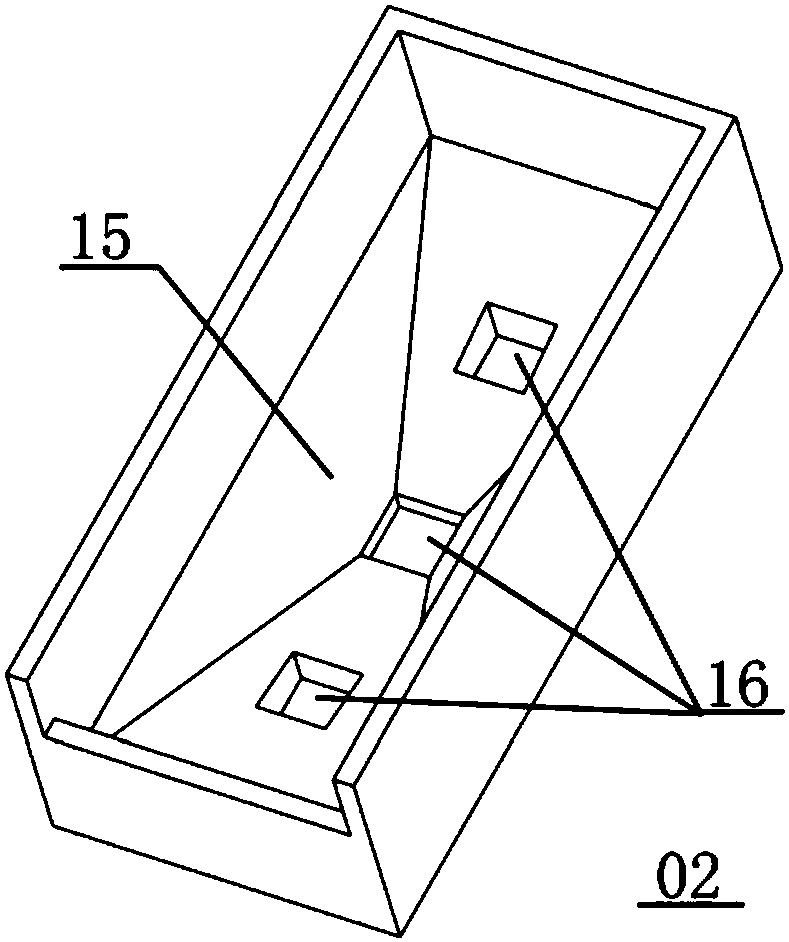

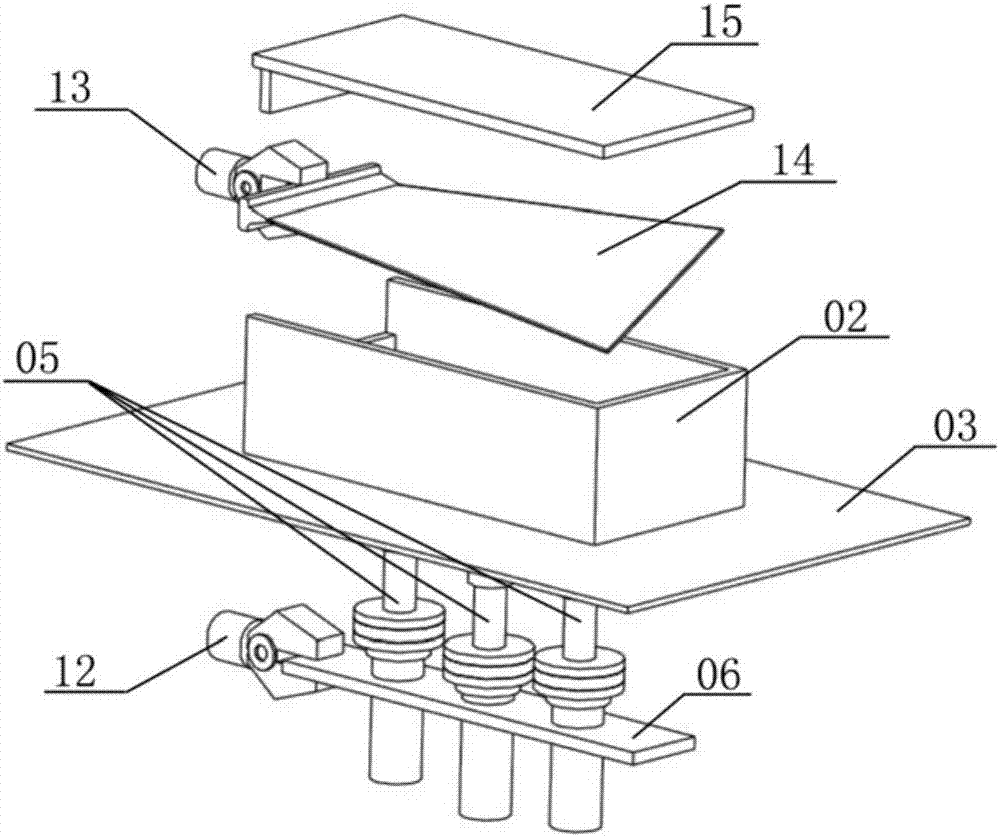

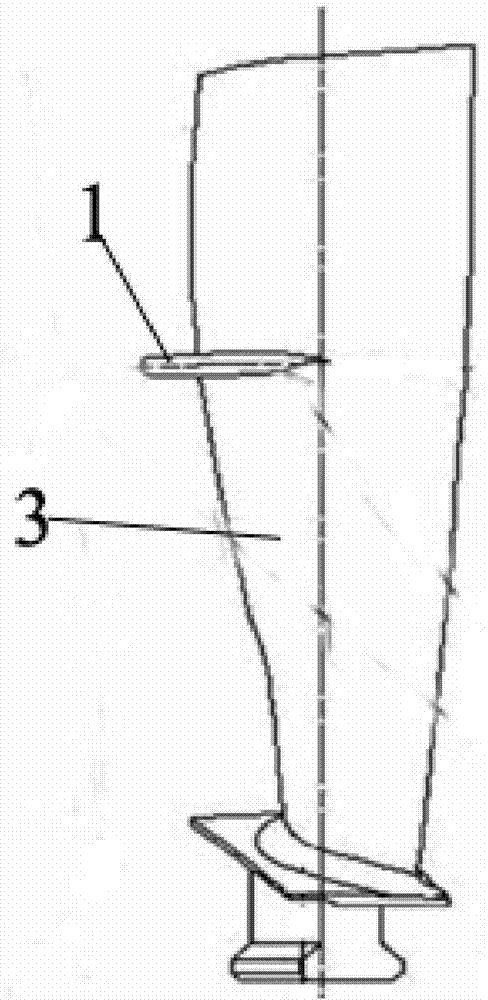

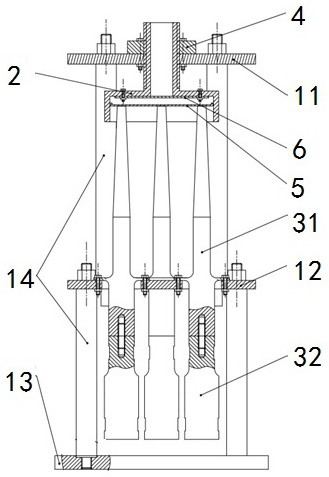

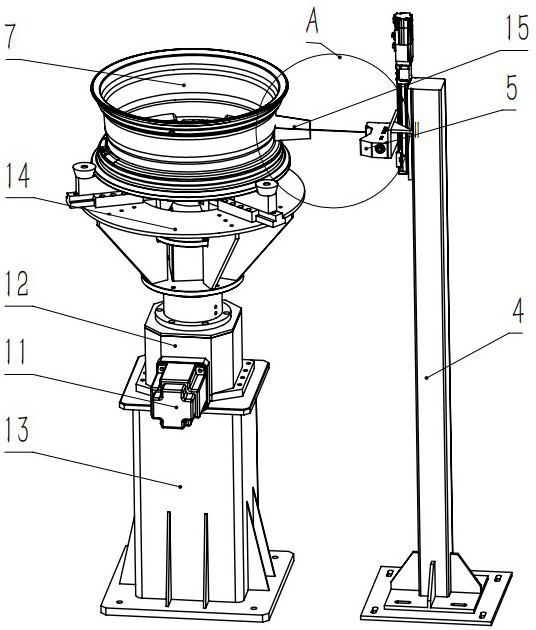

Fan blade step array type ultrasonic shot peening device and method

ActiveCN107630128ASolving Recycling ProblemsImprove strengthening efficiencyProcess efficiency improvementEngineeringUltrasonic vibration

The invention relates to a fan blade step array type ultrasonic shot peening device and method. The ultrasonic shot peening device comprises a step-shaped ultrasonic vibratory equipment array, a shotblasting cavity and a working table; the ultrasonic vibratory equipment array is composed of multiple ultrasonic vibratory equipment in an arranged manner, vibrating heads of the multiple ultrasonic vibratory equipment are arranged to be installed on a vibrating head clamping device in a step shape, and the heights of the vibrating heads are sequentially increased from the middle to the two sides;and the shot blasting cavity is installed on the working table, and the vibrating heads of the multiple ultrasonic vibratory equipment can move to penetrate the bottom of the working table and extends into the shot blasting cavity. According to the fan blade step array type ultrasonic shot peening device and method, the vibrating heads of the multiple ultrasonic vibratory equipment are adopted for forming an array for achieving one-time ultrasonic shot peening on larger surfaces; the box-shaped shot blasting cavity is designed, the bottom of the shot blasting cavity is designed to be in a hopper shape, and the problem about recovering of pills in the large-area ultrasonic shot blasting process is effectively solved; and the large fan blade ultrasonic shot peening efficiency can be effectively improved.

Owner:蔡晋

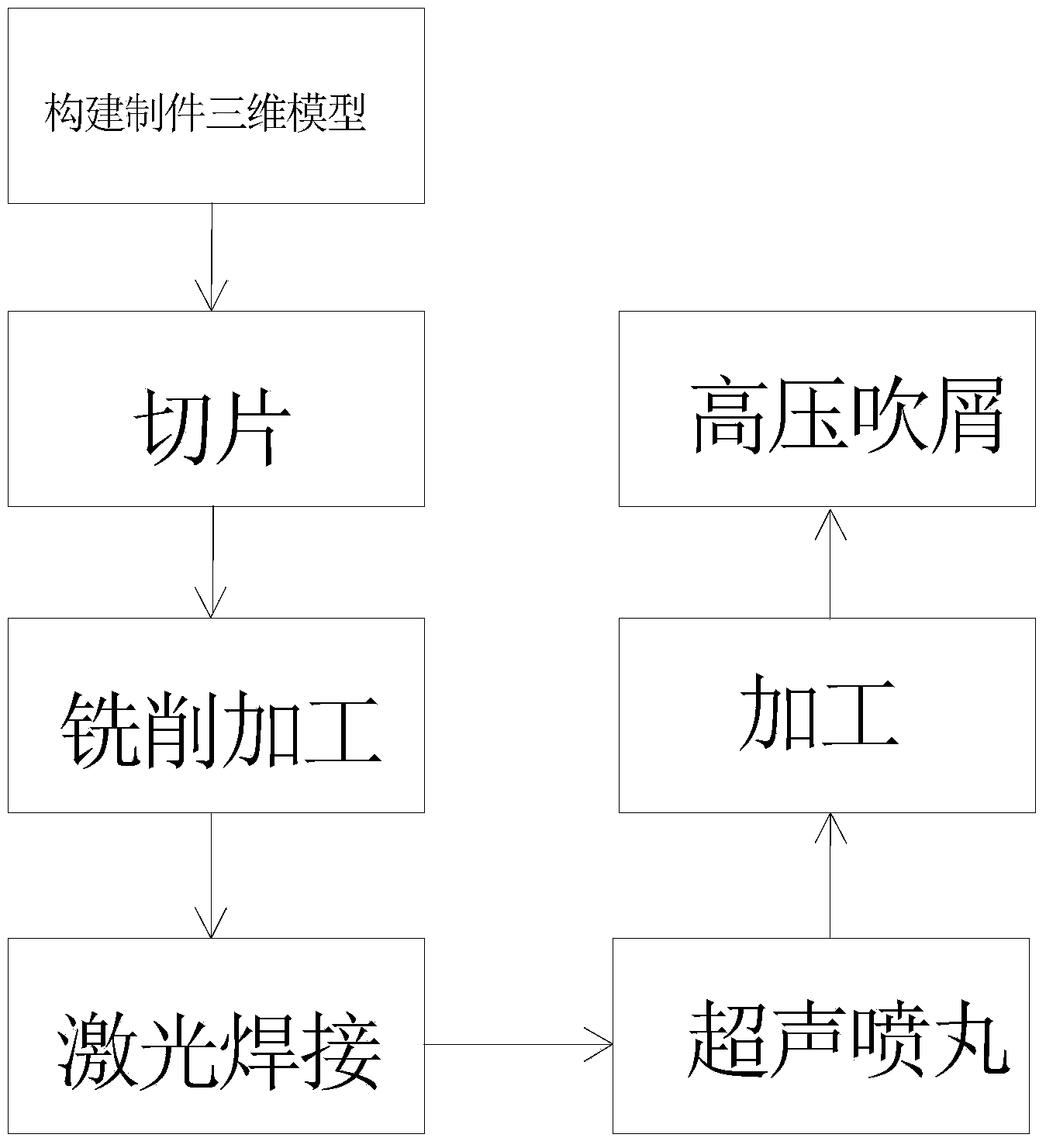

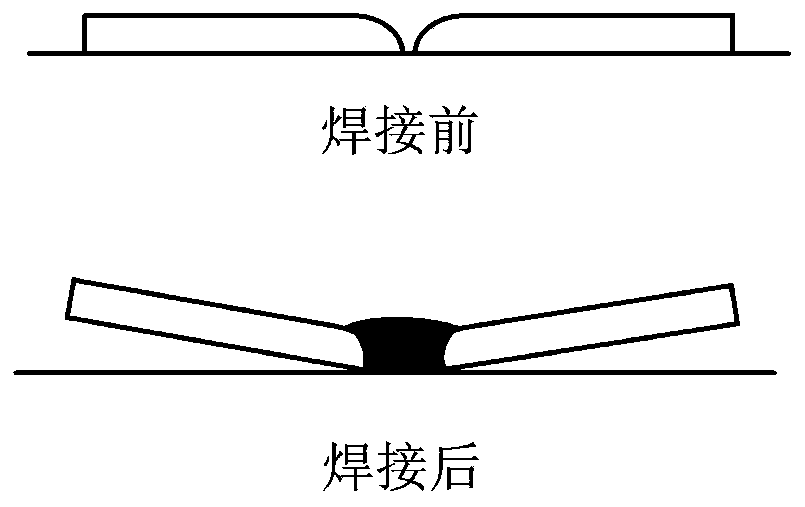

3D printing technology for ultrasonic shot-peening based on laser welding

The invention relates to a 3D printing technology for ultrasonic shot-peening based on laser welding. According to the 3D printing technology, a 3D model is built in a computer, then slicing is carried out on the 3D model according to the thickness of panel veneer to obtain the shape of each height section of a workpiece, and the needed sections are cut out from the panel veneer in a milling mode; in the overlapping and molding process, the sections of parts are scanned through high-energy laser beams according to a certain motion trail, materials on one section and materials on the prior section are welded together, high-energy shot-peening is carried out on the welding portion immediately after the welding is completed, and the textures and performance of the materials can be improved. According to the 3D printing technology for ultrasonic shot-peening based on laser welding, sheet metal is used for carrying out overlapped welding, and ultrasonic shot-peening is carried out on the welding portion immediately after the welding is completed so that local plastic deformation can happen to the welding portion, and consequently microstructures of the materials can be improved, mechanical properties of finished products can be improved, and the manufactured parts can meet the using requirements of some important strength-bearing portions.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

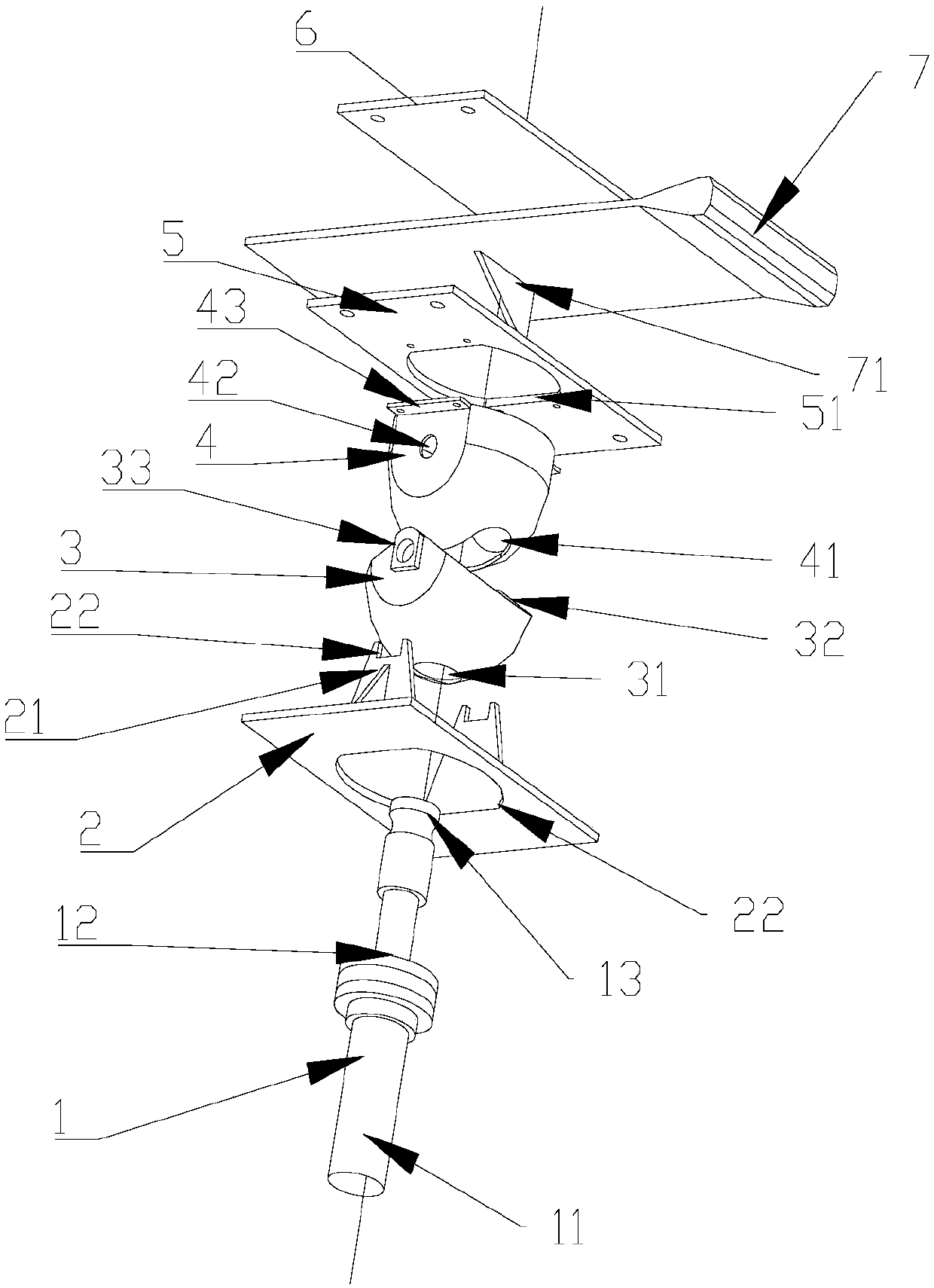

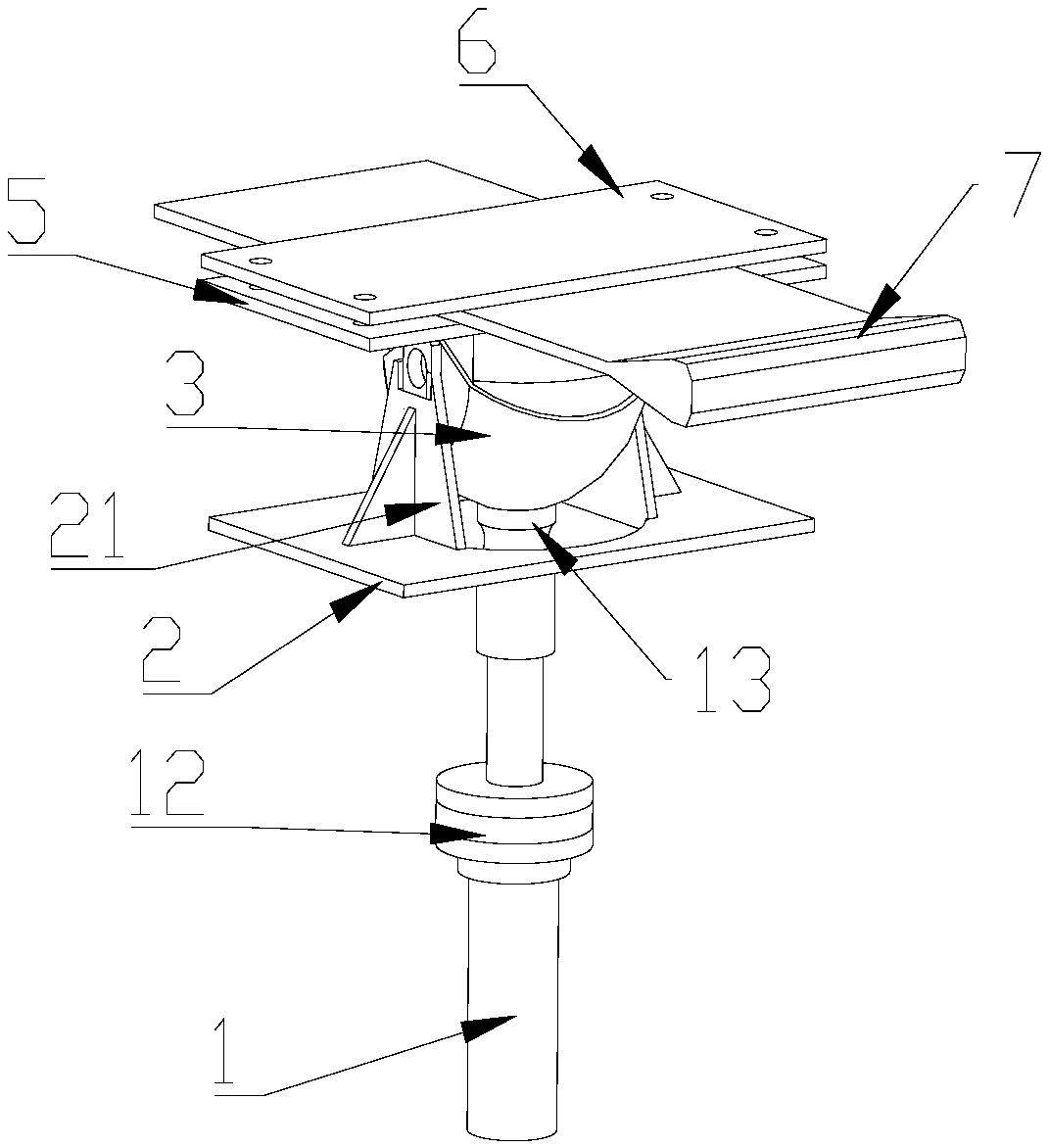

Swing type ultrasonic shot peening strengthening equipment

ActiveCN107630127AImprove strengthening efficiencyRealize multi-angle shot peeningEngineeringUltrasonic vibration

The invention discloses swing type ultrasonic shot peening strengthening equipment. The shot peening strengthening equipment comprises an ultrasonic vibrating device, a shot peening chamber and a blade clamping device, wherein the shot peening chamber comprises an outer chamber and an inner chamber for accommodating shots; the inner chamber is rotatably connected with the outer chamber; the ultrasonic vibrating device is fixedly connected with the outer chamber; and the inner chamber is fixedly connected with the blade clamping device. The shot peening device comprises the outer chamber and the inner chamber positioned in the outer chamber, the inner chamber can swing in the outer chamber to form a swing type shot peening chamber, the shortcoming of low shot peening efficiency is overcome,the problem that the angle of incoming of the shots is not adjustable is solved, the ultrasonic shot peening strengthening efficiency of a damping table can be improved effectively, multi-angle shotpeening strengthening on the damping table of blades of a fan is realized, and the real-time ultrasonic shot peening strengthening effect is enhanced.

Owner:蔡晋

Application of ultrasonic shot-peening to metal surface alloying

Owner:TIANJIN UNIV

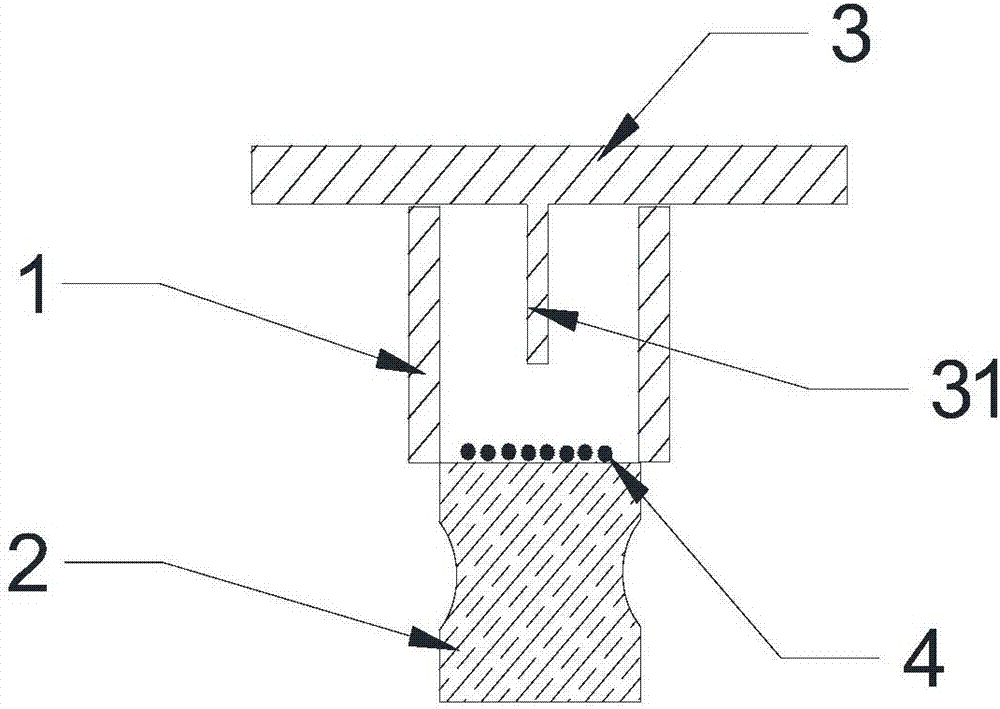

Reflection-type ultrasonic shot-peening strengthening device for inner hole surface

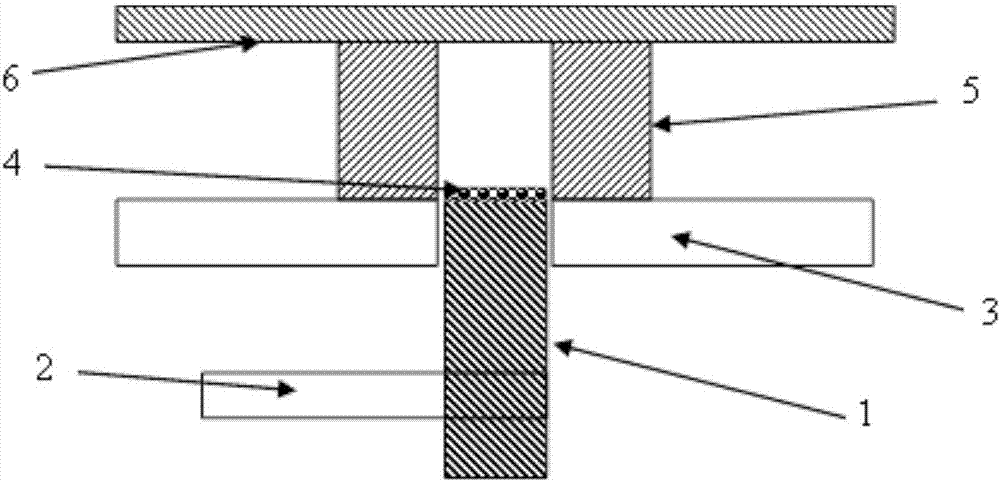

The invention relates to a reflection-type ultrasonic shot-peening strengthening device for an inner hole surface. The reflection-type ultrasonic shot-peening strengthening device for the inner hole surface comprises a cover plate, a workbench and an ultrasonic vibrating head. The workbench is provided with a positioning hole, and a to-be-processed part with a through hole is fixed to the workbench through a fixing part. The ultrasonic vibrating head is movably installed in the positioning hole. The through hole of the to-be-processed part corresponds to the positioning hole, so that the ultrasonic vibrating head penetrates through the positioning hole and then enters the through hole via a lower end opening of the through hole. The cover plate is fixed above the to-be-processed part. An upper end opening of the through hole can be blocked through the cover plate so that a closed cavity can be formed. A plurality of shot blasting bodies are placed in the cavity. A protruding part is arranged on the lower surface of the cover plate and further protrudes downwards to enter the through hole. The ultrasonic shot-peening strengthening device provided by the invention has the advantages that energy consumption is small, space can be saved, environmental pollution is low, the using quantity of the shot blasting bodies is small and the strengthening effect on the inner hole surface of the part is good.

Owner:SHENYANG AEROSPACE UNIVERSITY

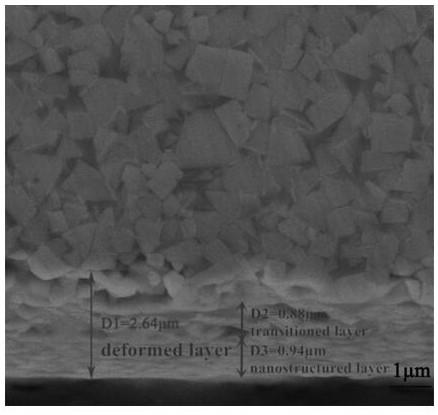

Coating preparation method based on hard alloy substrate surface nanocrystallization

ActiveCN110106468AHigh chemical activityEasy to useVacuum evaporation coatingSputtering coatingSputteringMegasonic cleaning

The invention discloses a coating preparation method based on hard alloy substrate surface nanocrystallization. The coating preparation method based on the hard alloy substrate surface nanocrystallization comprises the steps that S1, a substrate is prepared, specifically, a diamond frosted disk is adopted to grind and polish the surface of a coarse-grain hard alloy substrate; S2, the surface is cleaned; S3, surface nanocrystallization is carried out, specifically, the surface of the coarse-grain hard alloy substrate is subjected to the surface nanocrystallization, the method of the surface nanocrystallization is at least one of ultrasonic shot-peening, ultrasonic rolling or ultrasonic peening; and S4, a coating is prepared, specifically, after a substrate material is subjected to ultrasonic cleaning and is dried, the substrate material is put into a sputtering chamber, a TiAlN coating plating is carried out by a magnetron sputtering method, and the coating is obtained. According to thecoating preparation method based on the hard alloy substrate surface nanocrystallization, the mechanical properties and the film-substrate combined capacity of the substrate material are improved, the combination properties of the coating are improved, the preparation technology is simple, the cost is low, and the problems in the prior art are solved.

Owner:ZOLTRIX MATERIAL GUANGZHOU

Ultrasonic Peening Treatment of Assembled Components

Ultrasonic peening treatment is desirable where an application of a compressive stress is helpful to reduce the incidence of crack formation on highly stressed parts. Ultrasonic peening treatment can be performed in field applications without requiring a rotor to be removed from the machine. The system includes an acoustic element that excites peening media within a peen chamber. A frame is attachable to an assembled turbine rotor component and includes support structure engageable with the acoustic element. The frame is cooperable with a chamber tooling that defines and encloses the peen chamber together with the turbine rotor component.

Owner:GENERAL ELECTRIC CO

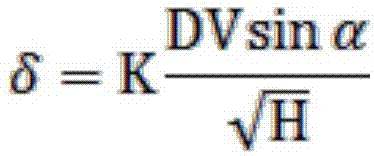

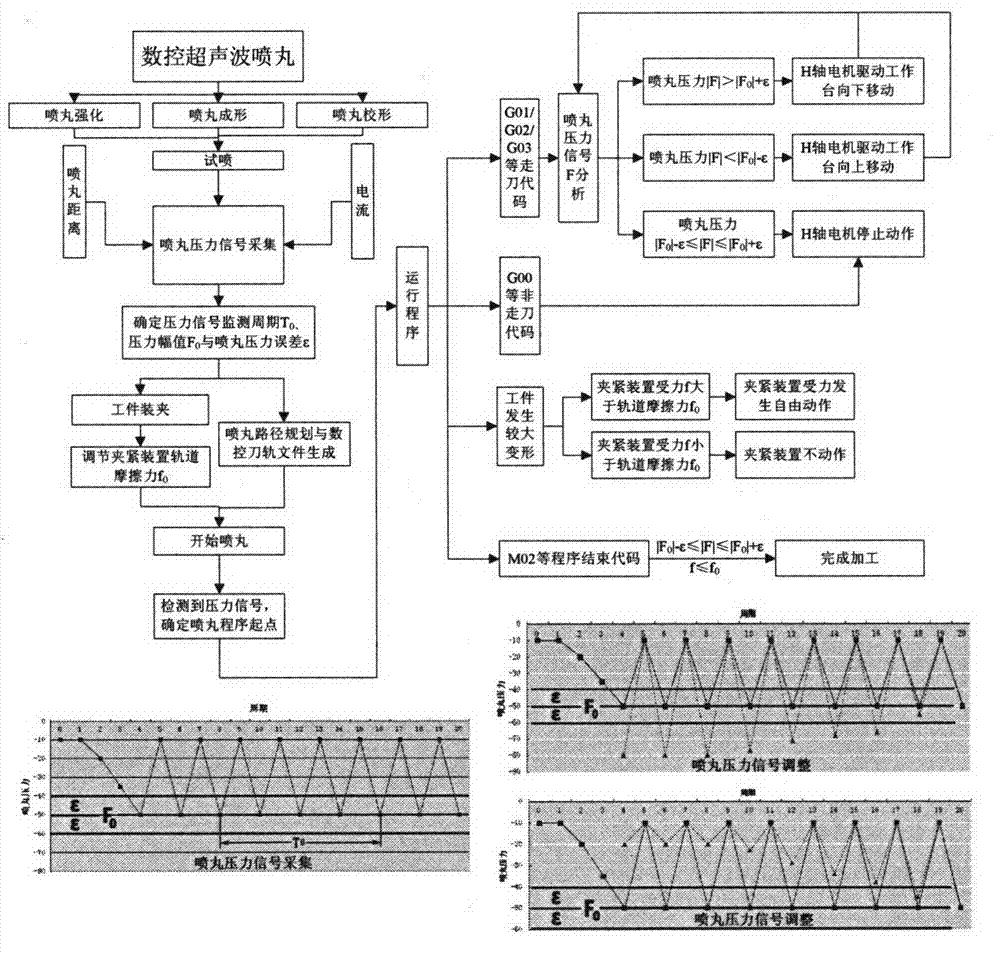

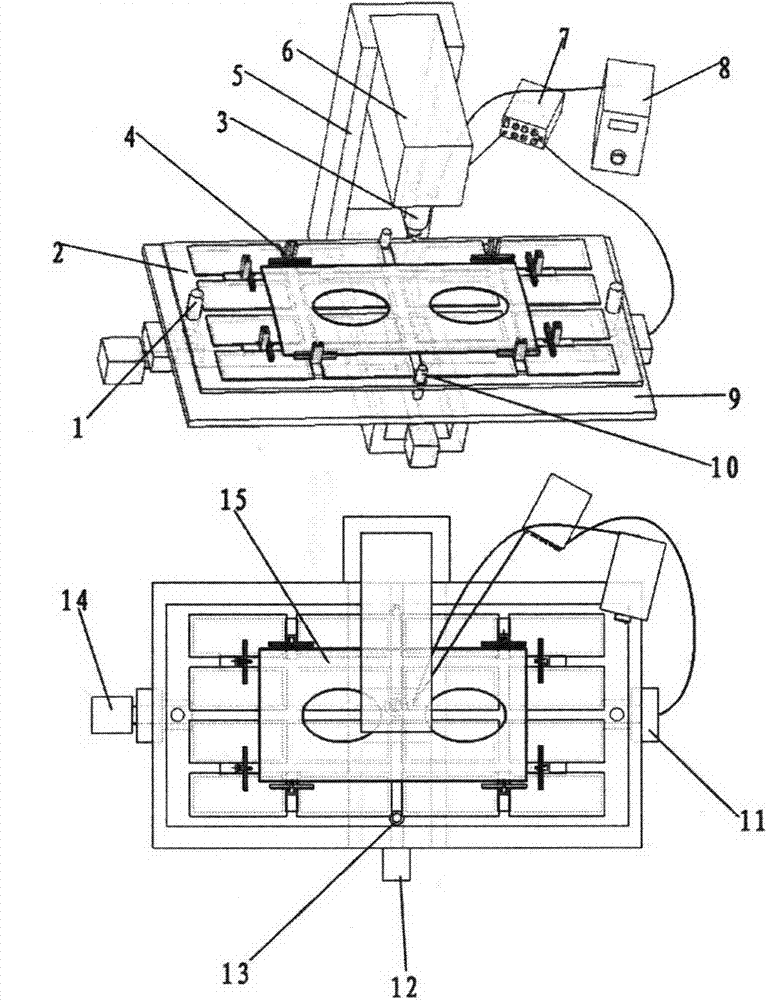

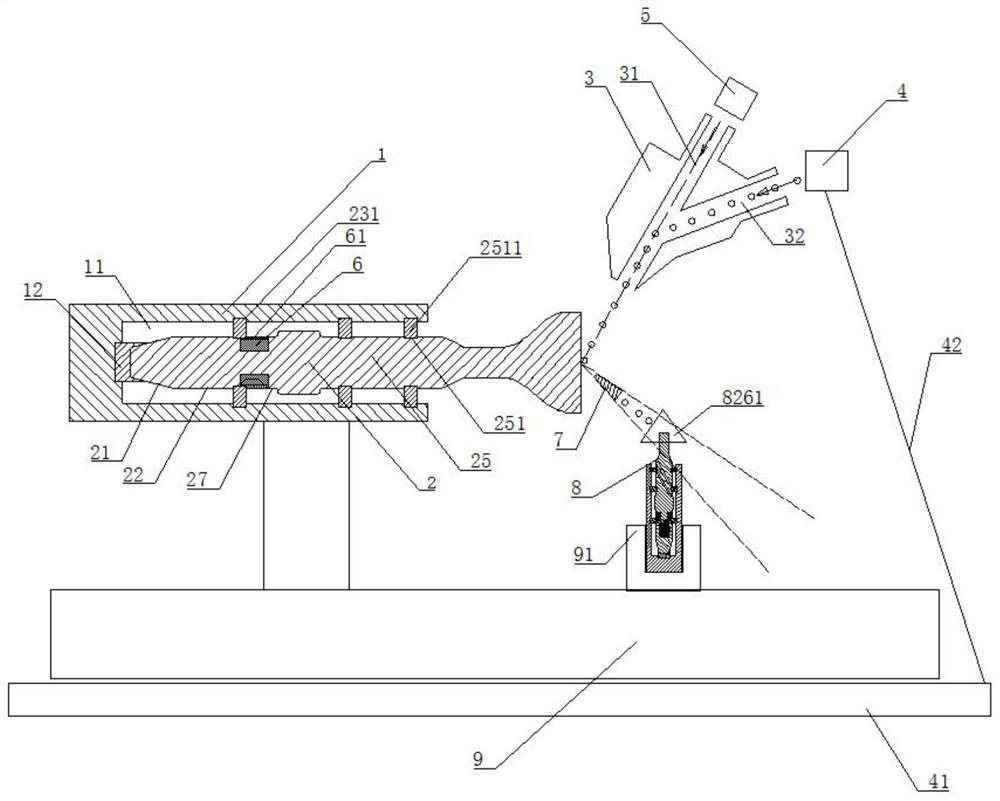

Numerical control ultrasonic shot peening process method based on dynamic pressure signal adjustment

The invention provides a numerical control ultrasonic shot peening process method based on dynamic pressure signal adjustment, and belongs to the technical field of shot peening machining. The method is based on a common three-axis numerical control machine tool, impact force formed after a striker impacts on the surface of a material and rebounds in the ultrasonic shot peening process serves as a monitoring signal, and the difference between a real-time pressure signal and a specific signal is analyzed by means of a ceramic capacitance pressure sensor and a pressure dynamic measuring system so that a lifting worktable servo motor is driven to move to enable the pressure signal to be close to the specific signal, and therefore the impact force borne by the material in a shot peening area keeps stable; in the deformation process of a workpiece to be peened, the workpiece overcomes extension or contraction of rubber friction needed by moving of a dynamic clamping device in the X direction, the Y direction and the Z direction, so that the clamping device is suitable for the spatial position of a clamping point of the workpiece to be peened in real time. According to the method, peening strength of each area is consistent with a theoretical value specified by the process, the high-precision peening forming and strengthening effects are achieved, and the method has high feasibility and practicality in peening machining of large aviation structural components.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

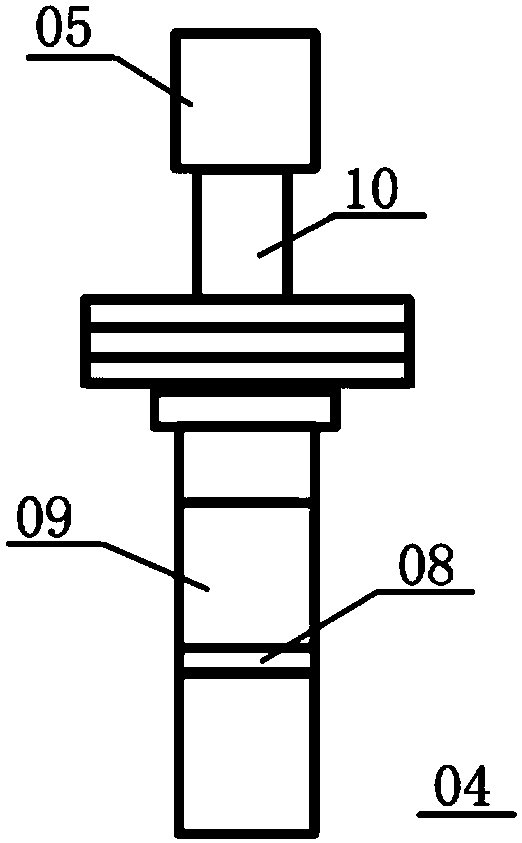

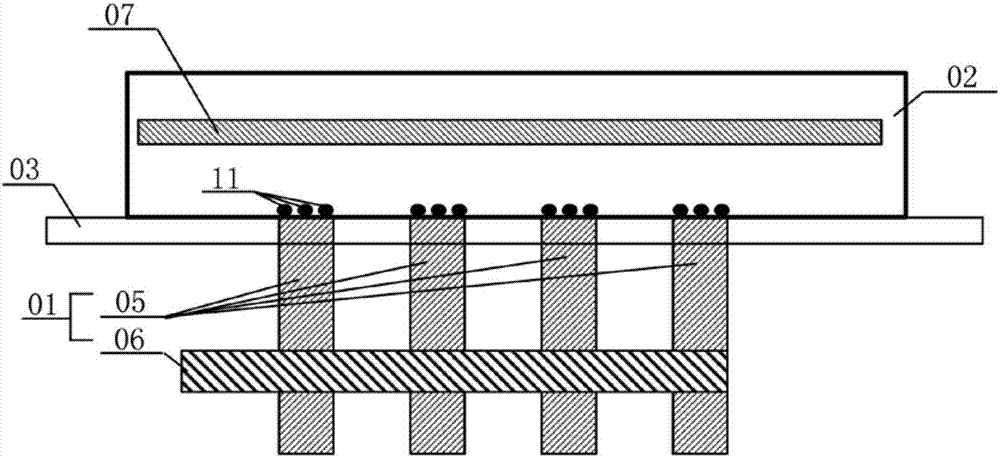

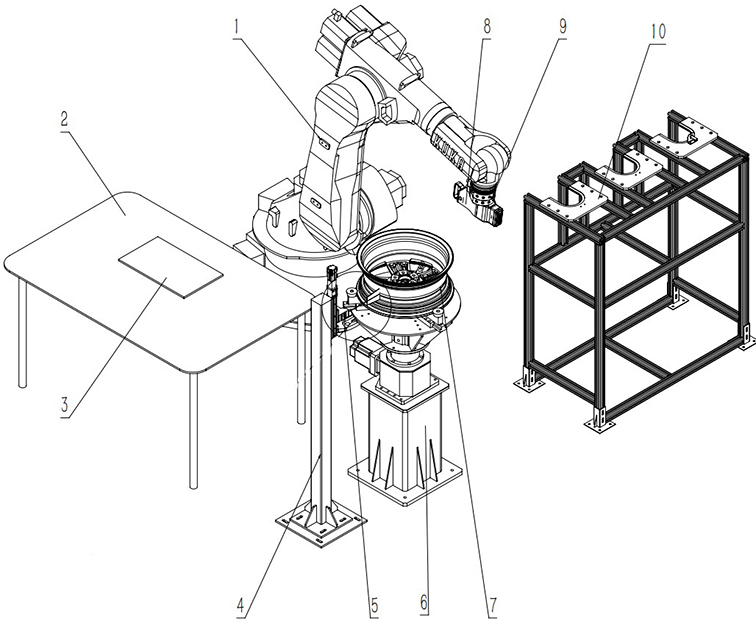

Planar array type ultrasonic shot-peening reinforcing device and method

The invention relates to a planar array type ultrasonic shot peening strengthening device and method. The ultrasonic shot peening strengthening device includes: an array of ultrasonic vibration equipment, a shot peening chamber and a workbench, and the array of ultrasonic vibration equipment is composed of a plurality of ultrasonic vibration equipment. The vibrating heads of multiple ultrasonic vibration equipment are arranged and installed on the vibrating head clamping device, the shot blasting chamber is installed on the workbench, and the vibrating heads of multiple ultrasonic vibrating equipment can move through the bottom of the workbench and extend into the blasting chamber. in the pill chamber. The present invention adopts the mode of forming an array of vibrating heads of a plurality of ultrasonic vibrating devices, which reduces the surface roughness of the strengthened parts, reduces the usage of projectiles, improves the efficiency of shot peening, and reduces energy consumption.

Owner:蔡晋

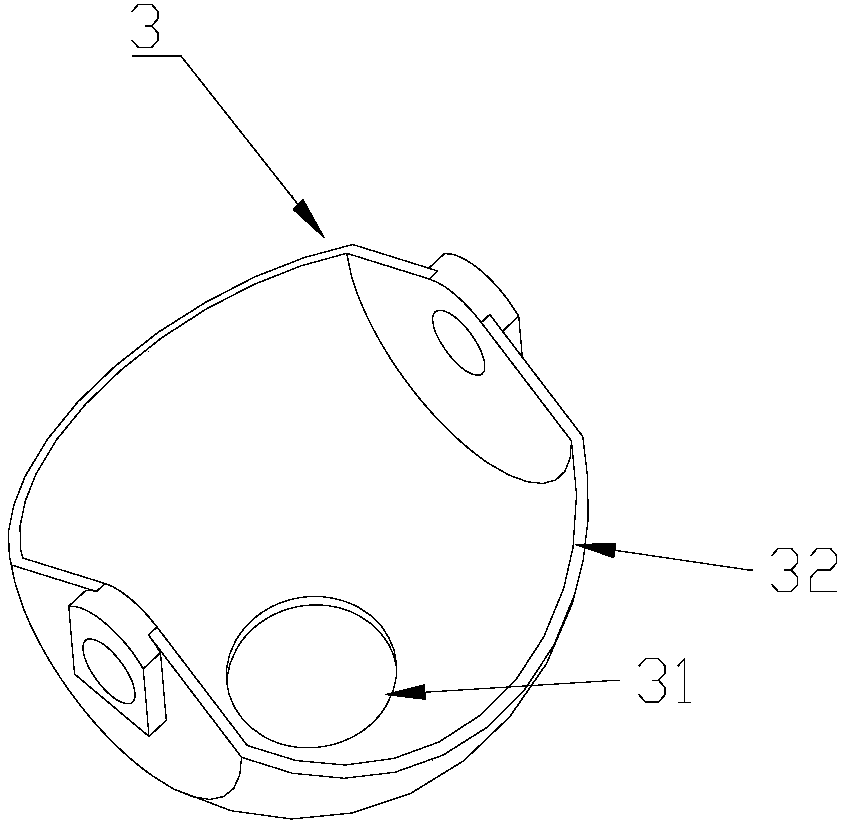

Ultrasonic shotblast strengthening equipment

The invention discloses an ultrasonic shot peening strengthening equipment, which comprises: an ultrasonic vibrating device, projectiles, and a shot peening chamber for containing the projectiles, wherein the shot peening chamber is a cylindrical structure, and the The vibration head of the ultrasonic vibration device is close to the lower port of the shot blasting chamber. When the ultrasonic shot peening strengthening equipment of the present invention is used for ultrasonic shot peening strengthening, fewer projectiles are used, the energy consumption is lower, and dust and noise pollution can be effectively reduced. Ultrasonic shot peening is used to strengthen the fan blade damping table, which overcomes the problem of projectile ejection and can effectively improve the efficiency of ultrasonic shot peening of the fan blade damping table.

Owner:蔡晋

Shape correction and strengthening method for postwelding prestressing force of moderately thick light alloy plate

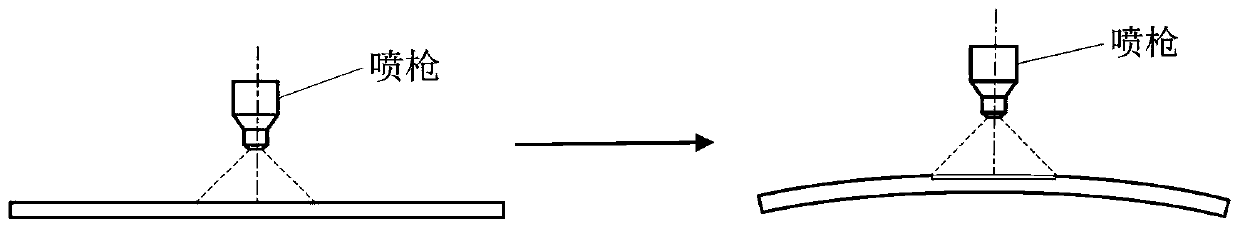

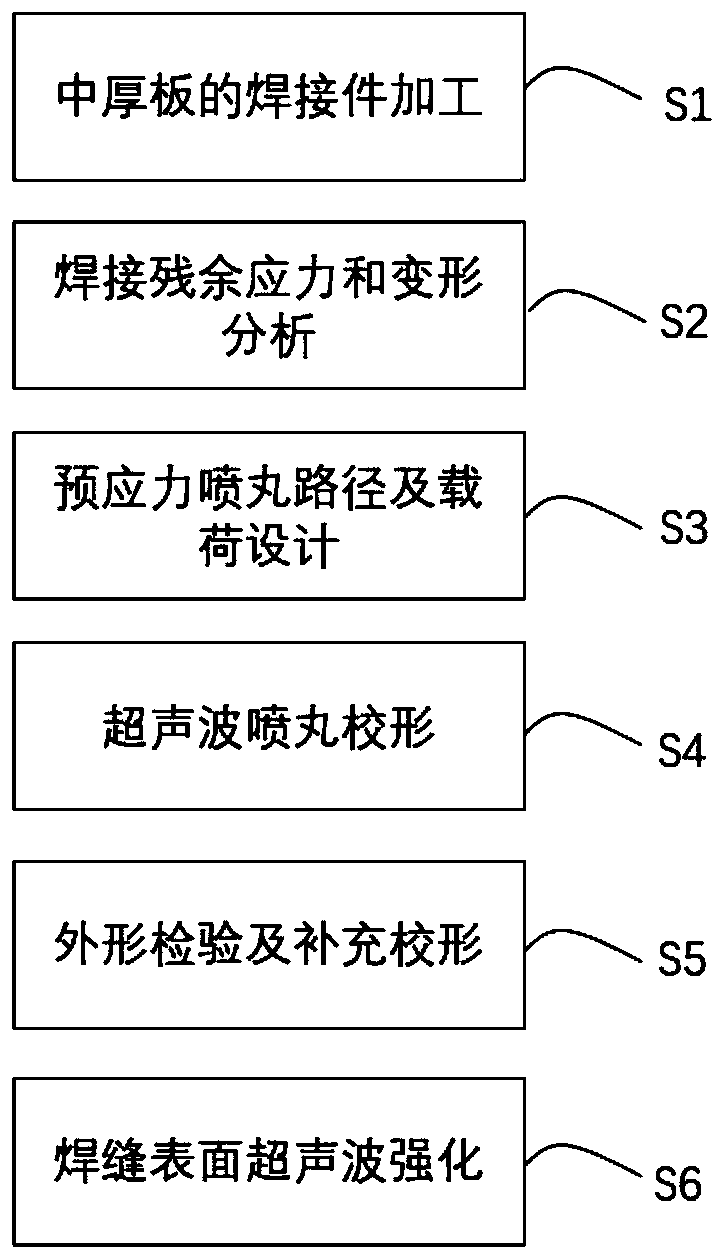

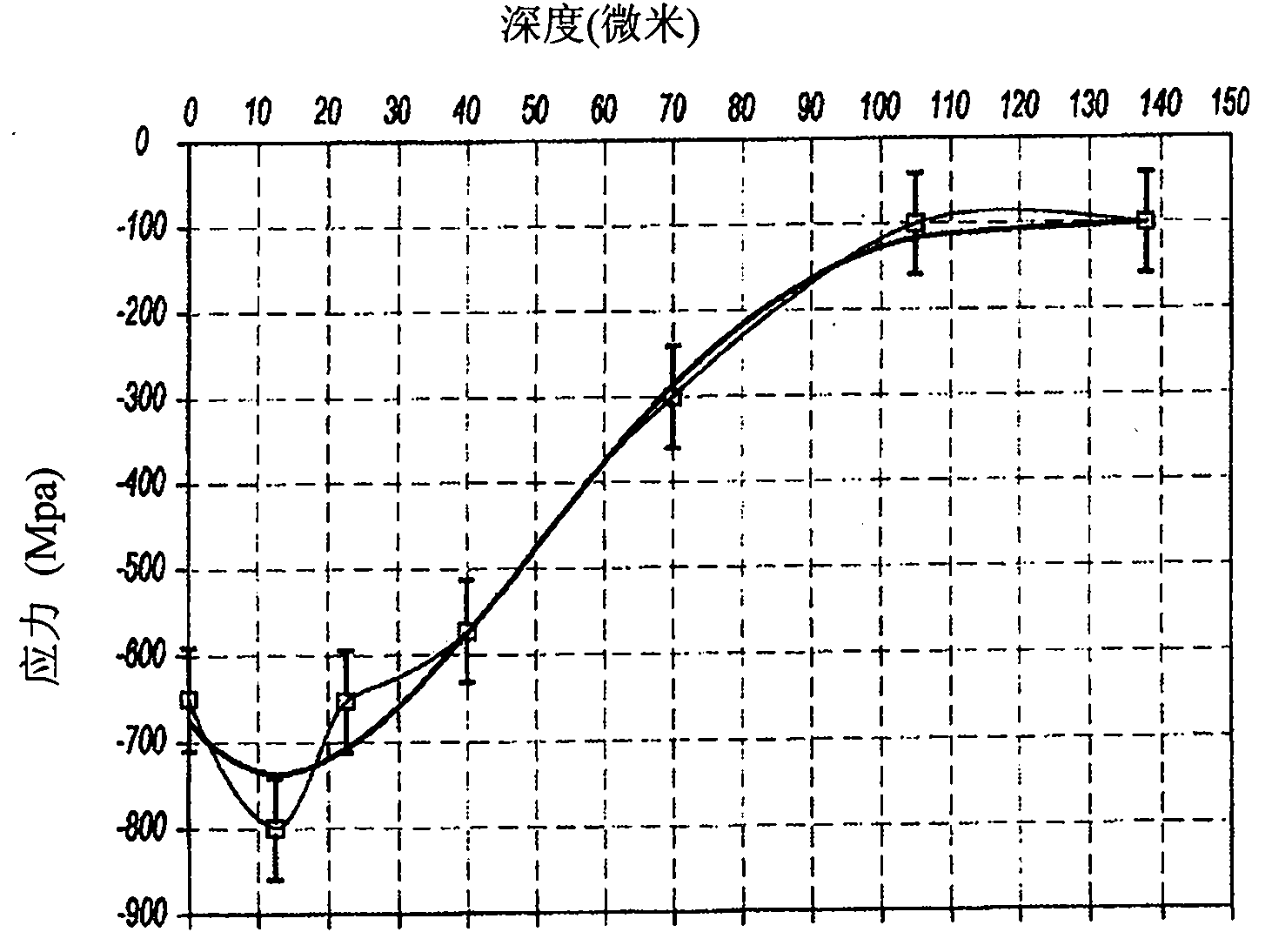

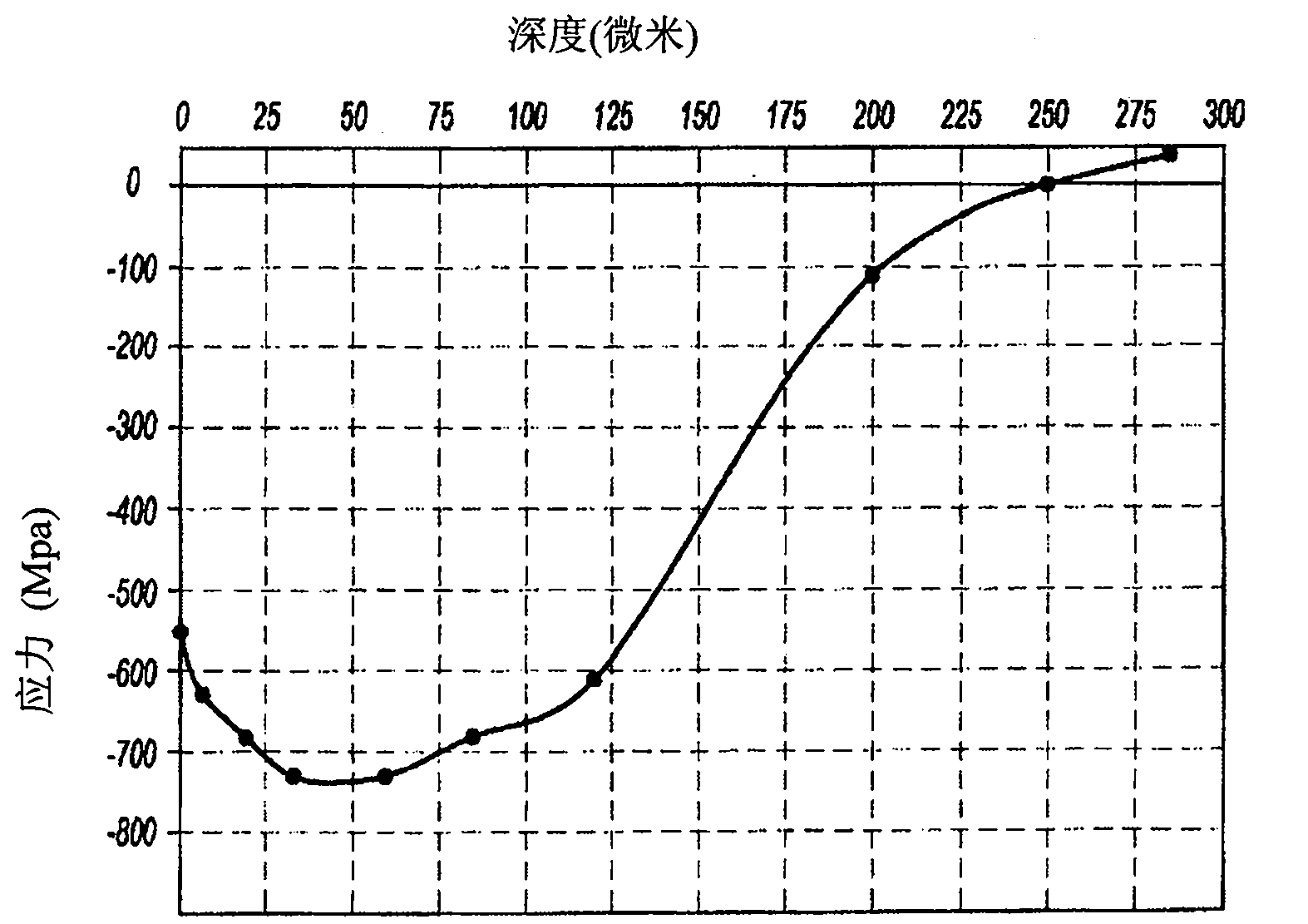

ActiveCN111546017ARealize the correctionRealize functionVibratory devicesGrinding/polishing apparatusWelding residual stressPre stress

The invention discloses a shape correction and strengthening method for postwelding prestressing force of a moderately thick light alloy plate. The method comprises steps as follows: S1), machining ofa welding part; S2), welding residual stress and deformation analysis; S3), design of a shot-blasting path and load of prestressing force; S4), ultrasonic shot-blasting shape correction; S5), outlineinspection and supplementary shape correction; and S6), ultrasonic strengthening for a weld surface. The method has main advantages as follows: an existing welding technology and process of a productare not changed, firing pin type ultrasonic shot-blasting equipment is utilized for shape correction and strengthening, shape correction and strengthening functions are realized by replacing workingheads of different sizes, and the operation is convenient and efficient. According to the method, after the welding part is cooled, residual stress which is not released is utilized as prestressing force load to be applied, so that energy required for shape correction can be greatly reduced, and meanwhile, damage of the material surface due to high-temperature-state shape correction is avoided. The method is particularly suitable for control treatment of welding deformation of a light high-strength material which is strengthened by heat treatment.

Owner:SHANGHAI UNIV OF ENG SCI

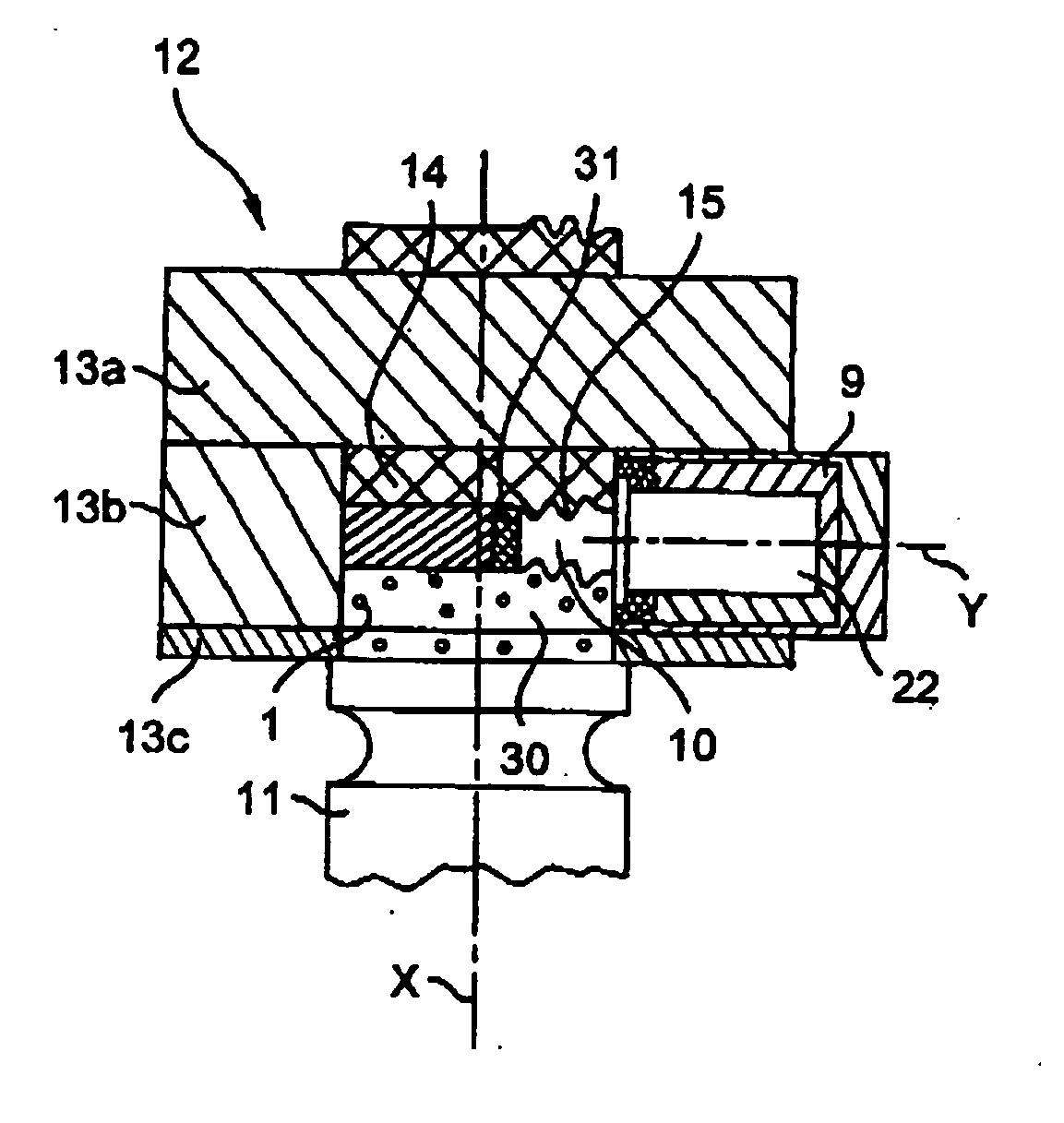

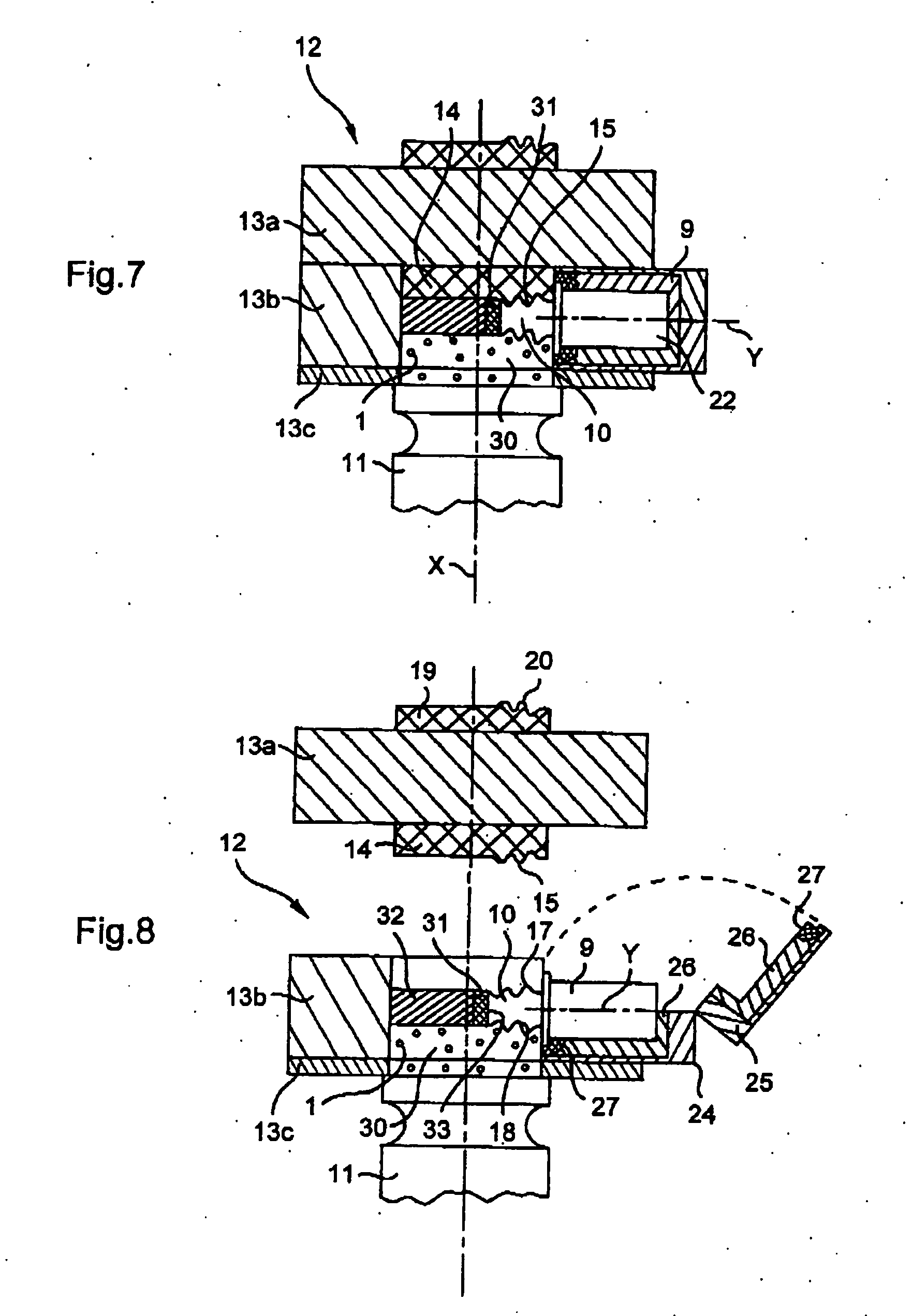

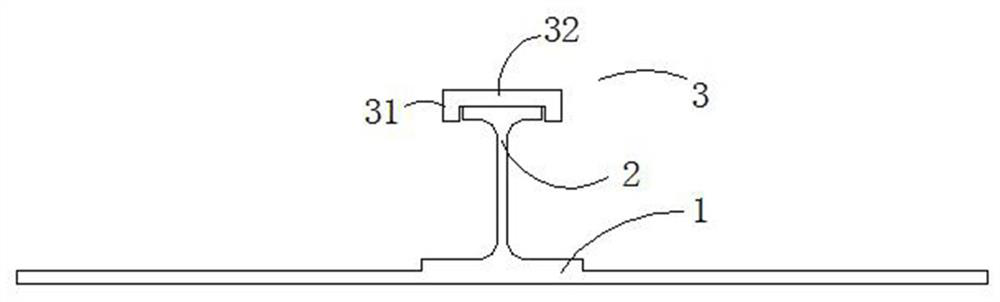

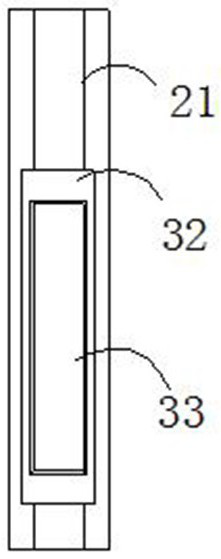

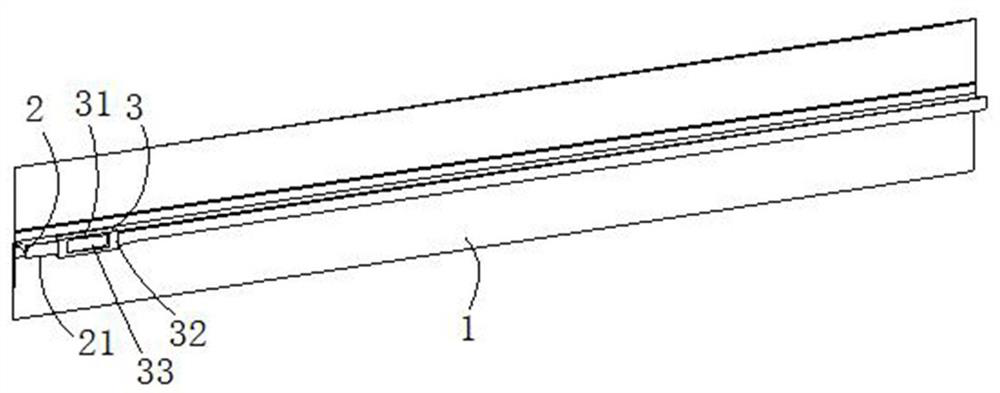

Method for ultrasound shot-blasting of turbomachine parts

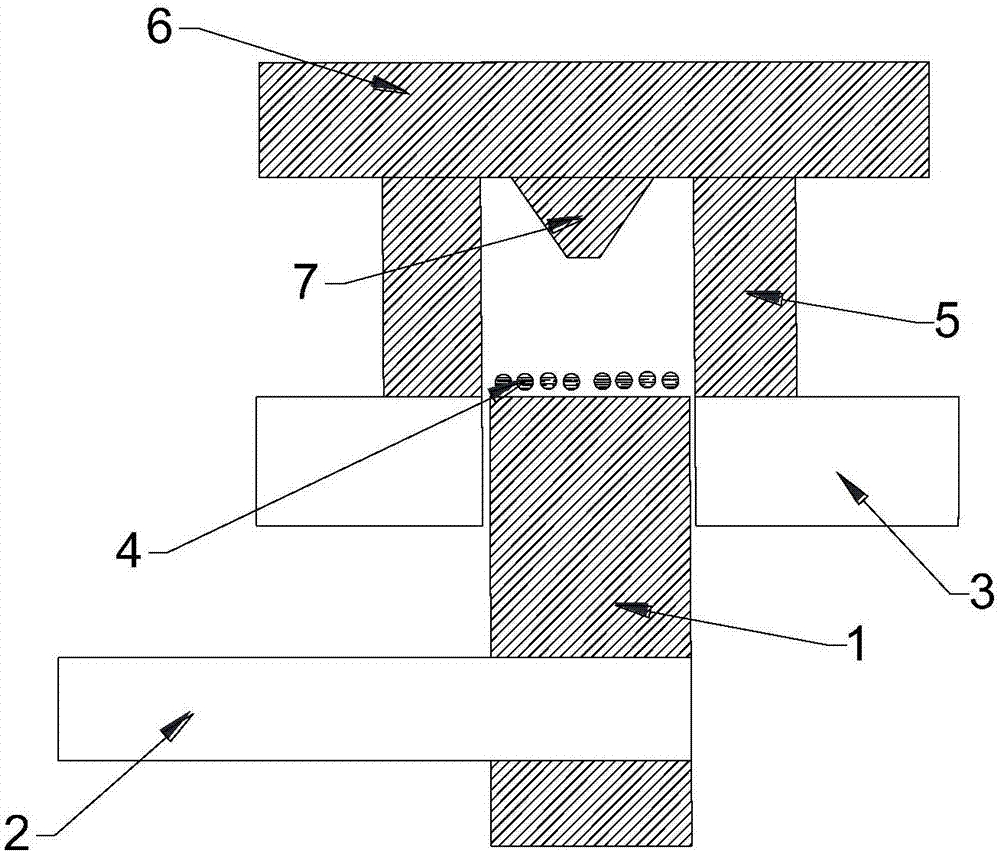

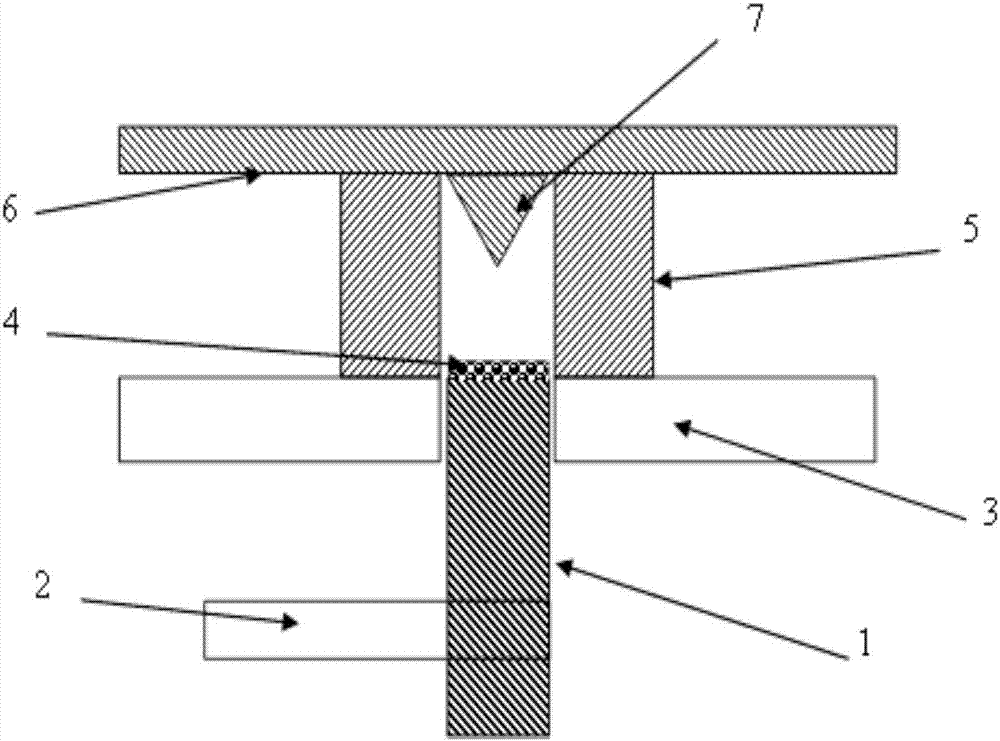

ActiveCN102123828AImprove surface conditionVibratory devicesBiomedical engineeringUltrasonic shot peening

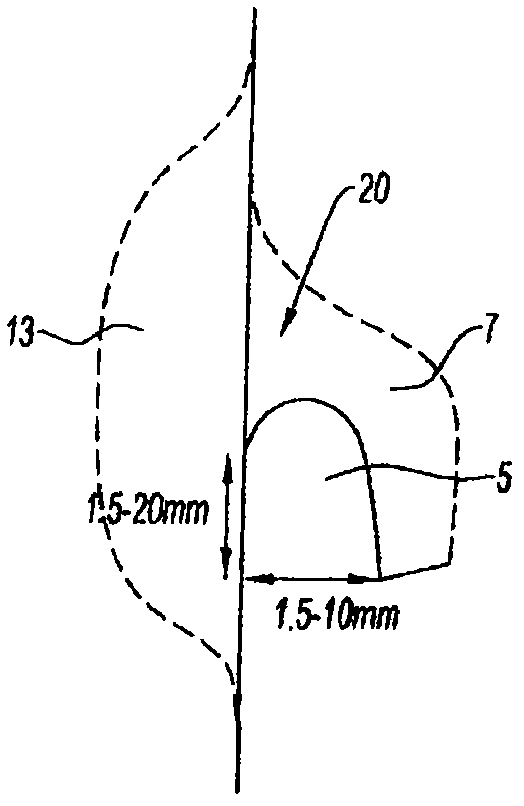

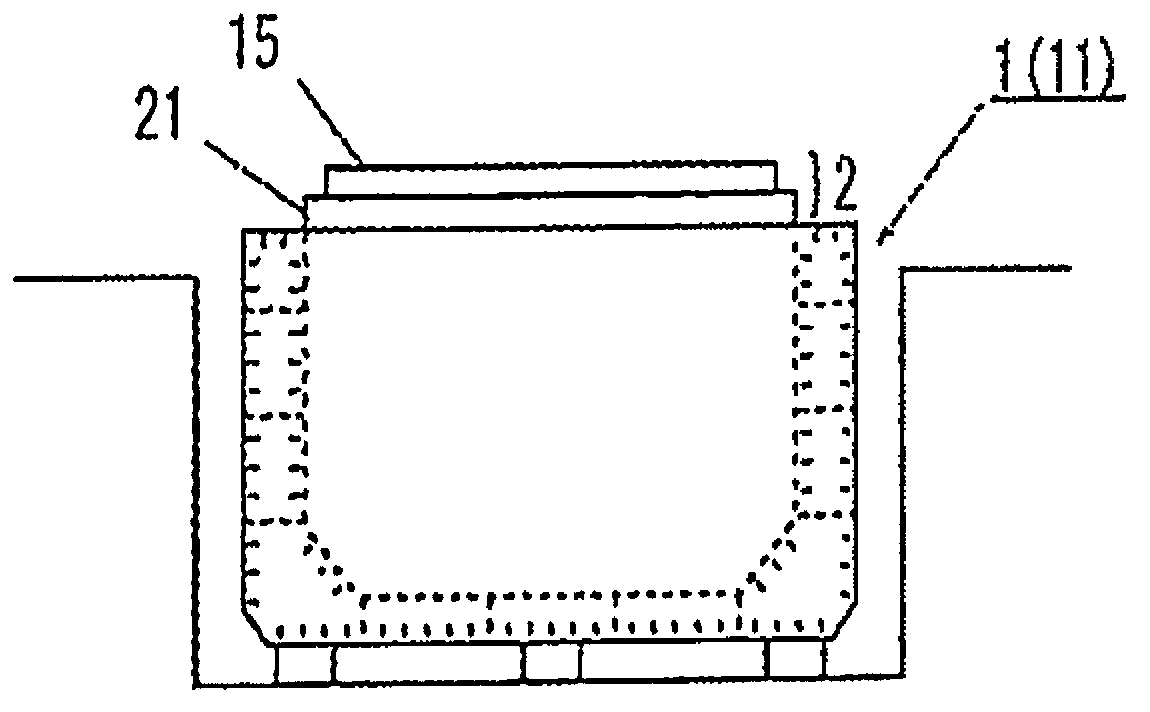

The present invention relates to a method for ultrasound shot-blasting by means of a cloud of balls set in motion through contact with a sonotrode having one metallic surface including an area of difficult access. It is characterized in that the surface is that of a hook axially restrained on a turbomachine blade including a groove (5) provided between the hook and the base of the blade, and a surface portion (7) outside said groove, and the cloud of balls is contained in a chamber (25) encompassing said groove and said surface portion (7) outside said groove.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

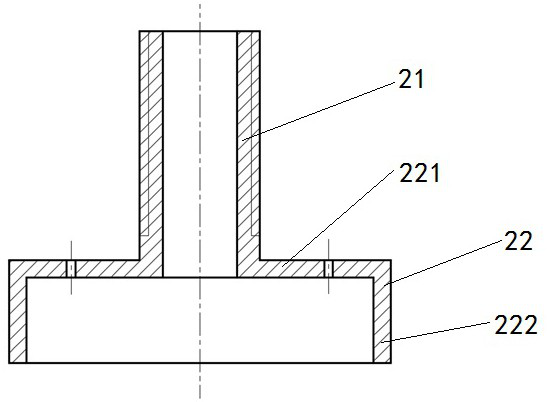

Inner hole surface ultrasonic shot peening strengthening device

The invention relates to an ultrasonic shot peening strengthening device for the surface of an inner hole. The ultrasonic shot peening strengthening device for the inner hole surface includes a cover plate, a workbench and an ultrasonic vibrating head. The workbench is provided with a positioning hole and has a through hole The part to be processed is fixed on the workbench by a fixture, the ultrasonic vibration head is movably installed in the positioning hole, the through hole of the part to be processed corresponds to the positioning hole, so that the ultrasonic vibration After the head passes through the positioning hole, it enters the through hole from the lower port of the through hole. The cover plate is fixed above the part to be processed, and the upper port of the through hole is blocked by the cover plate to form a closed cavity. Several shots are placed. The ultrasonic shot-peening strengthening device of the inner hole surface of the present invention has the advantages of low energy consumption, space saving, low environmental pollution, less shot peening consumption and good strengthening effect on the inner hole surface of parts.

Owner:SHENYANG AEROSPACE UNIVERSITY

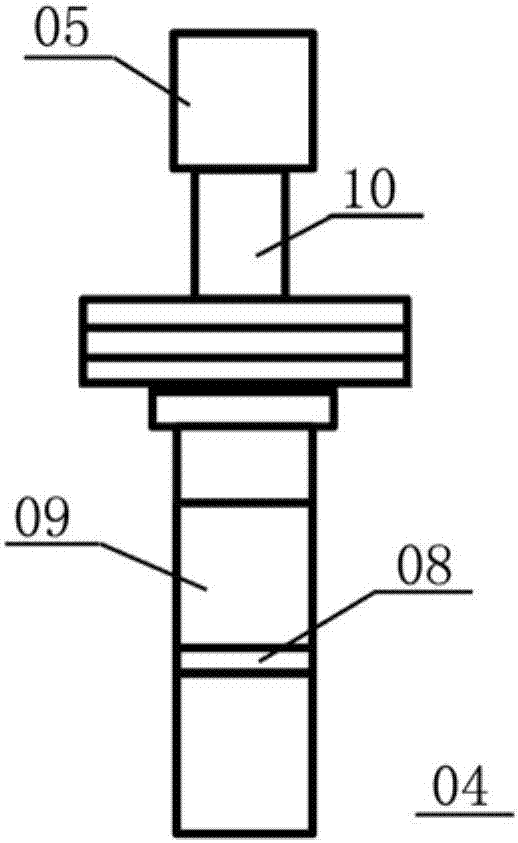

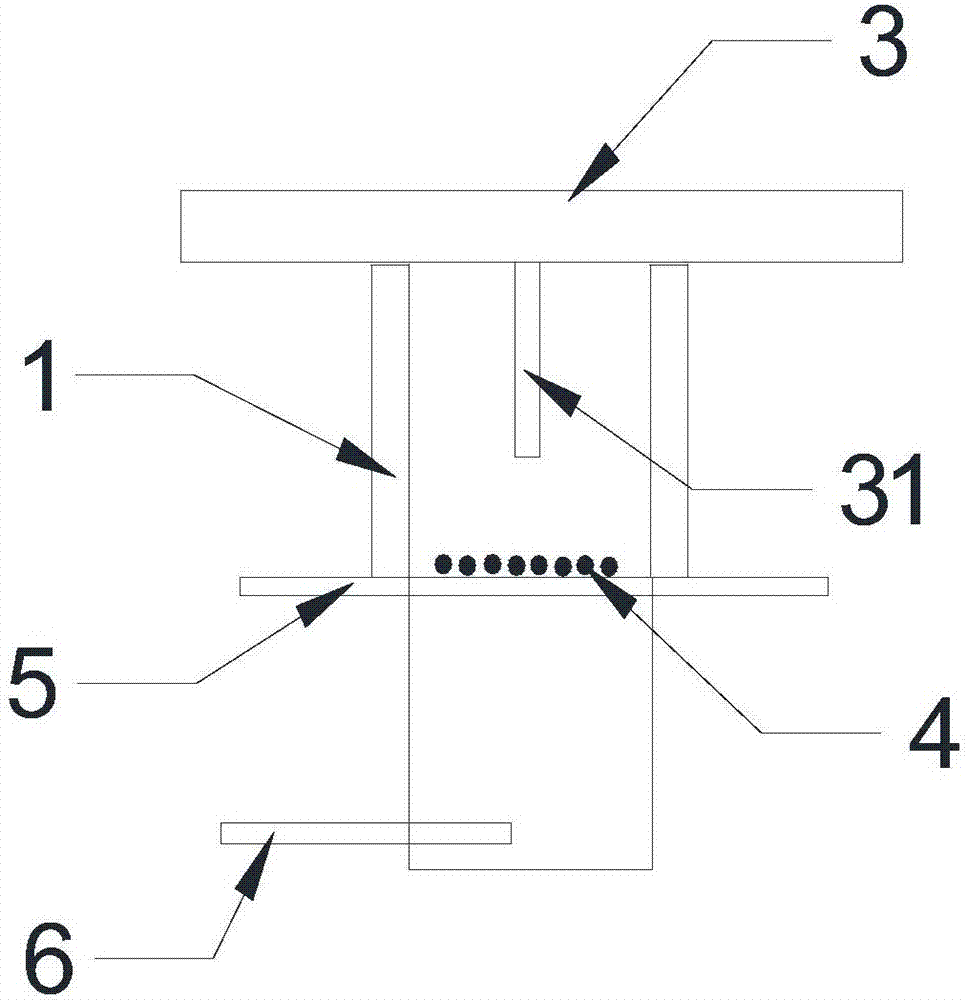

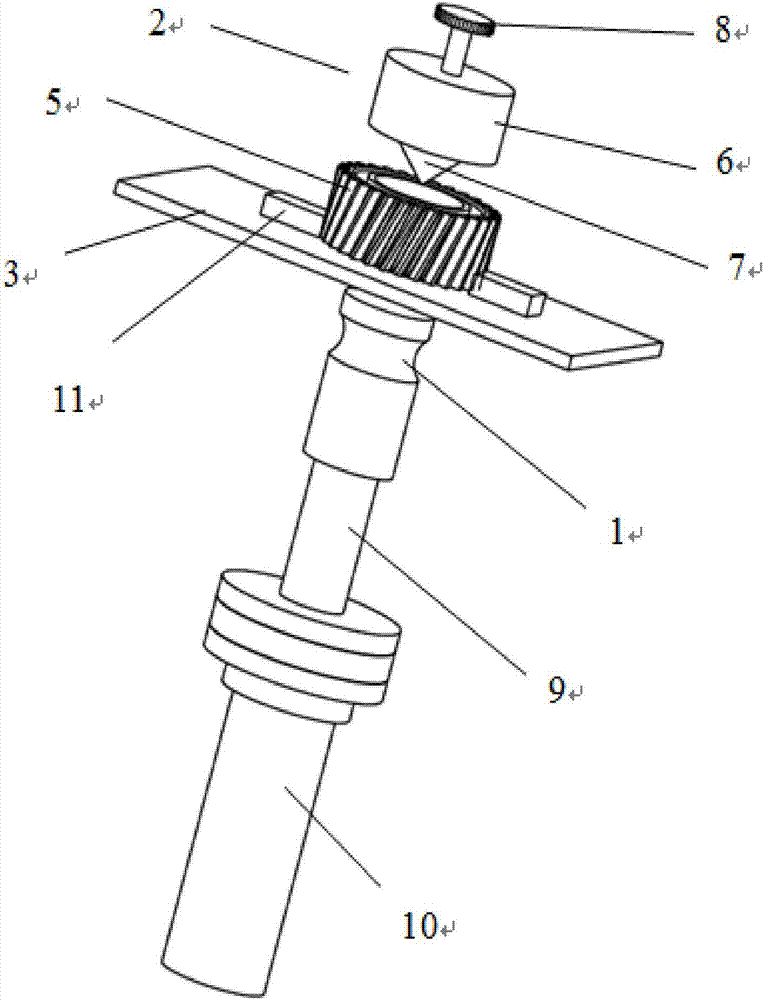

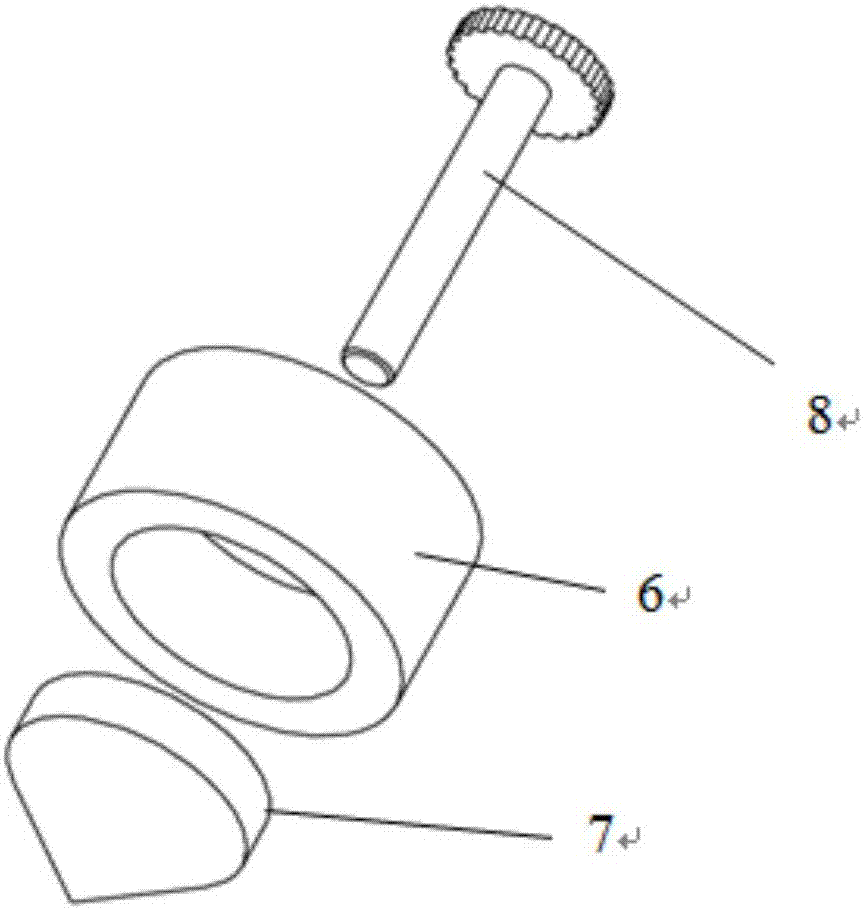

Adjustable reflection type ultrasonic shot peening strengthening device for surface of inner hole

PendingCN107471118AReduce energy consumptionSave spaceAbrasive machine appurtenancesVibratory devicesEngineeringUltrasonic vibration

The invention relates to an adjustable reflection type ultrasonic shot peening strengthening device for the surface of an inner hole. The ultrasonic shot peening strengthening device comprises a reflection assembly, a workbench and an ultrasonic vibration head; a positioning hole is formed in the workbench; a part to be machined is fixed to the workbench through a fixing part; a through hole corresponds to the positioning hole so that the ultrasonic vibration head can penetrate through the positioning hole and then enter the through hole from a lower port of the through hole and can be matched with the through hole in a clearance mode; the reflecting assembly comprises a convex part, a supporting cover and an adjusting screw; the supporting cover is fixed to the position above the part to be machined and plugs an upper port of the through hole; the supporting cover, the part to be machined and the ultrasonic vibration head define a closed cavity; an adjusting hole is formed in the supporting cover; the adjusting screw is arranged in the adjusting hole; the convex part is connected to the front end of the adjusting screw; and the lower end of the convex part protrudes downwards. The ultrasonic shot peening strengthening device has the advantages that the energy consumption is low, the space can be saved, the environmental pollution is low, the shot consumption is low, and the strengthening effect on the surface of the inner hole of the part is good.

Owner:SHENYANG AEROSPACE UNIVERSITY

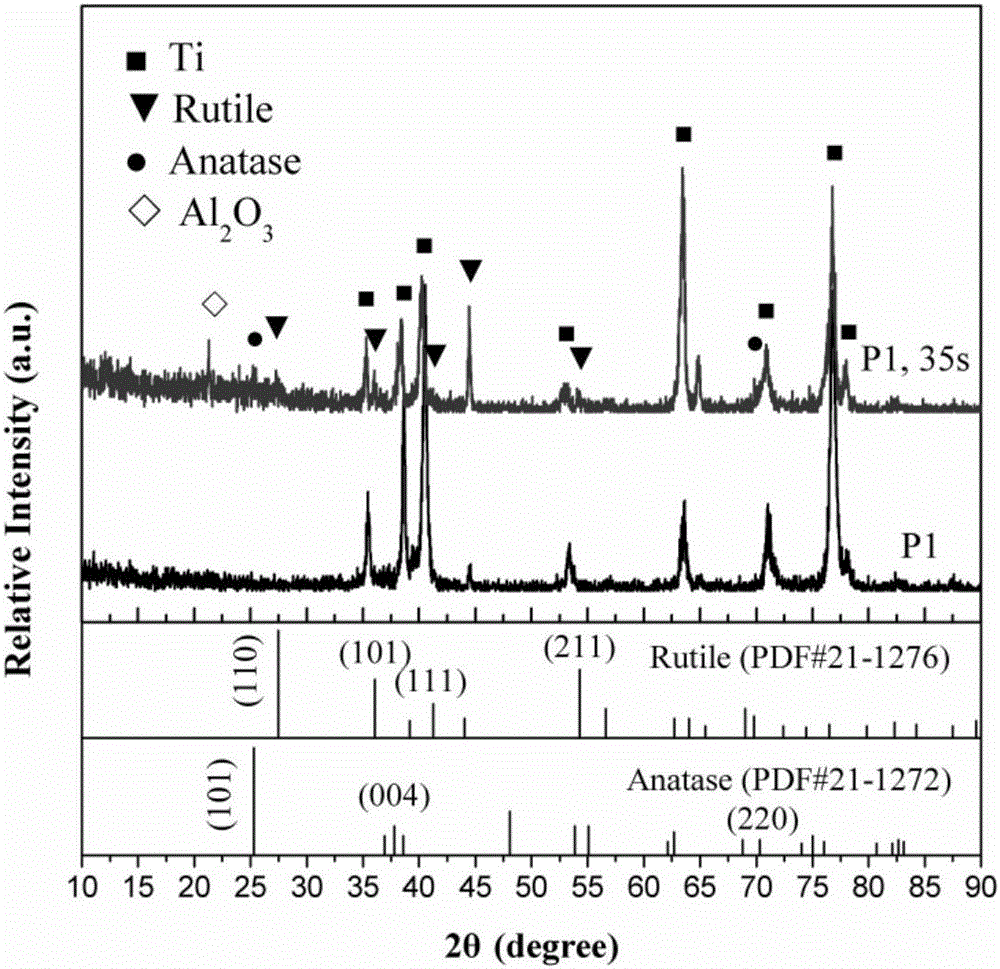

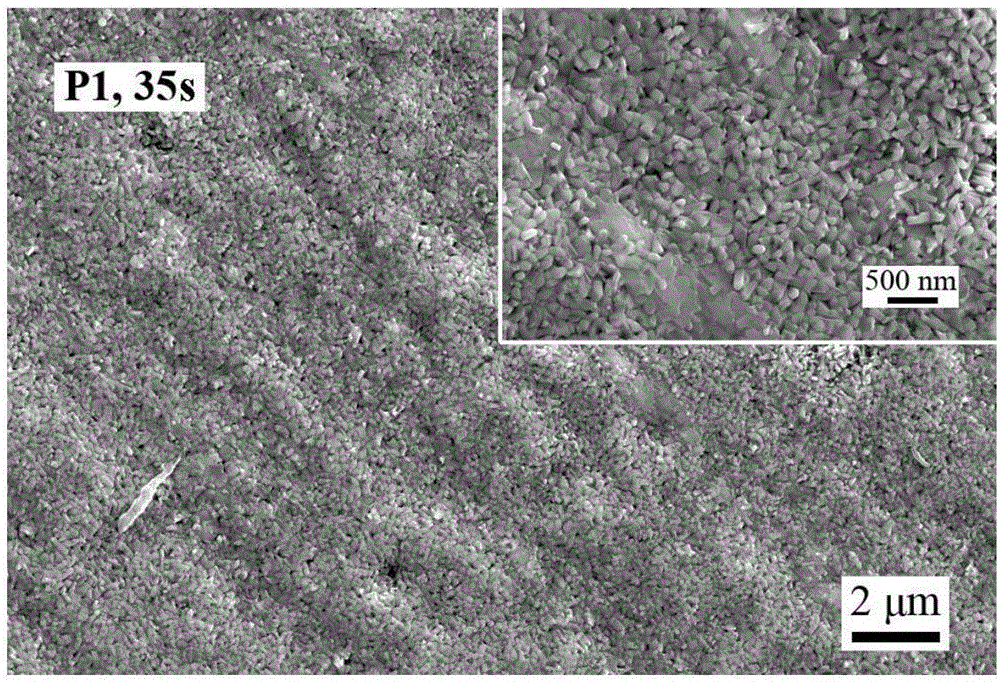

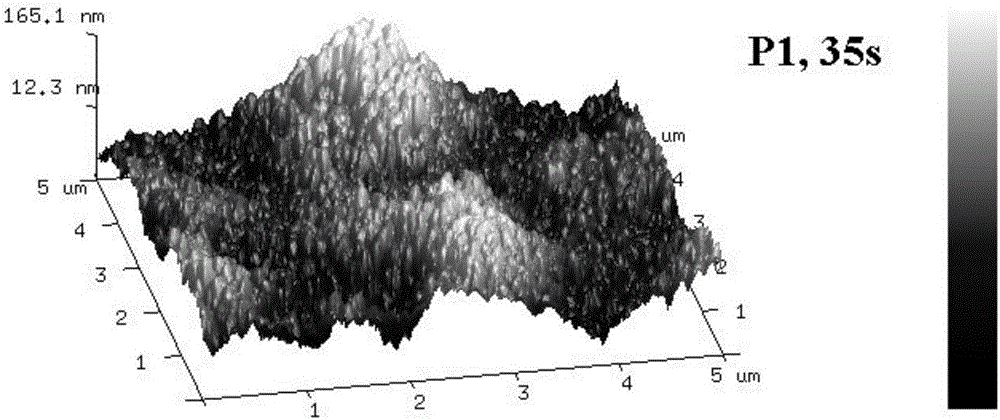

Method for preparing nanostructured bioactive oxide film on titanium alloy surface

ActiveCN106480387AImprove biological activityGood biocompatibilitySolid state diffusion coatingTissue regenerationBiocompatibility TestingTitanium

The invention discloses a method for preparing a nanostructured bioactive oxide film on the titanium alloy surface. The method comprises the steps of ultrasonic shot peening of titanium alloy and induction heating oxidation treatment, wherein ultrasonic shot peening of the titanium alloy is characterized in that the titanium alloy is treated for 97-103 s by ultrasonic shot peening equipment with power of 1800 W under conditions that the amplitude is 30 mu m and the frequency is 20 KHz, or the titanium alloy is treated for 97-103 s by the ultrasonic shot peening equipment with power of 2200 W under conditions that the amplitude is 30 mu m and the frequency is 20 KHz; the induction heating oxidation treatment is performed at follows: the titanium alloy after ultrasonic shot peening treatment is subjected to supersonic frequency induction heating for 20-35 s. The nanostructured bioactive oxide film prepared with the method can remarkably improve the bioactivity, biocompatibility and cell responsiveness of titanium and the titanium alloy implanted in vivo.

Owner:SHANDONG UNIV

Ultrasonic impact strengthening device and method for rotary workpiece

ActiveCN114107633AImprove carrying capacityImprove fatigue resistanceProcess efficiency improvementRotational axisElectric machinery

The invention relates to an ultrasonic impact strengthening device for a rotary workpiece. The ultrasonic impact strengthening device comprises an ultrasonic shot blasting device, a rotating device and a sealing box body, the ultrasonic shot peening device comprises an ultrasonic probe, a steel ball, a shot peening cavity and a shot peening chamber base, the lower end of the shot peening cavity is mounted on the shot peening chamber base, the upper end of the shot peening cavity is open and arranged below the rotary workpiece, the ultrasonic probe extends into the shot peening cavity, and the steel ball is flatly laid on the surface of the ultrasonic probe; the rotating device comprises a motor, a rotating shaft, a pinnacle shaft, a first bearing and a second bearing; one end of the rotating shaft is connected with the motor, the other end of the rotating shaft is connected with the pinnacle shaft, a rotary workpiece is installed on the rotating shaft, and the pinnacle shaft positions the rotating shaft and clamps the rotary workpiece. And the shot blasting chamber is positioned in the sealed box body. The rotating device driven by the speed-adjustable motor is coupled with the ultrasonic shot blasting device, so that the ultrasonic shot blasting technology is applied to the actual production and application of the rotary workpiece, and the service performance and the service life limit of the rotary workpiece at present are broken through.

Owner:WUHAN UNIV OF TECH

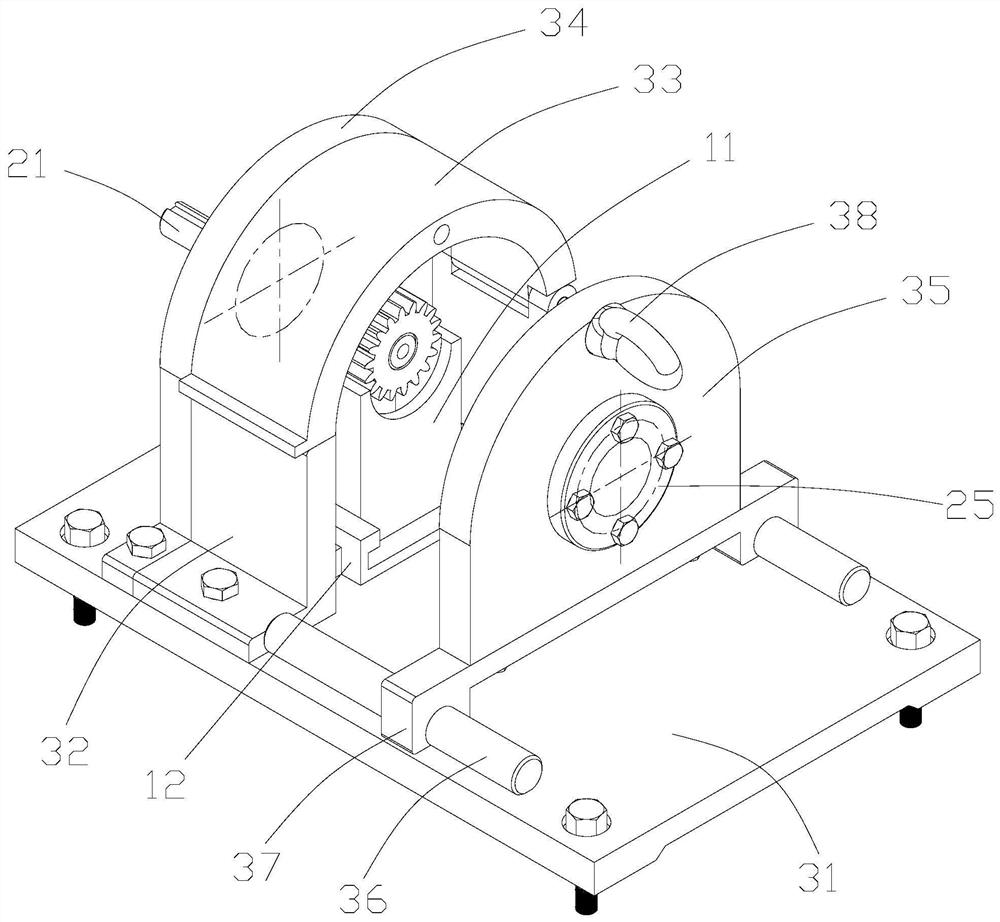

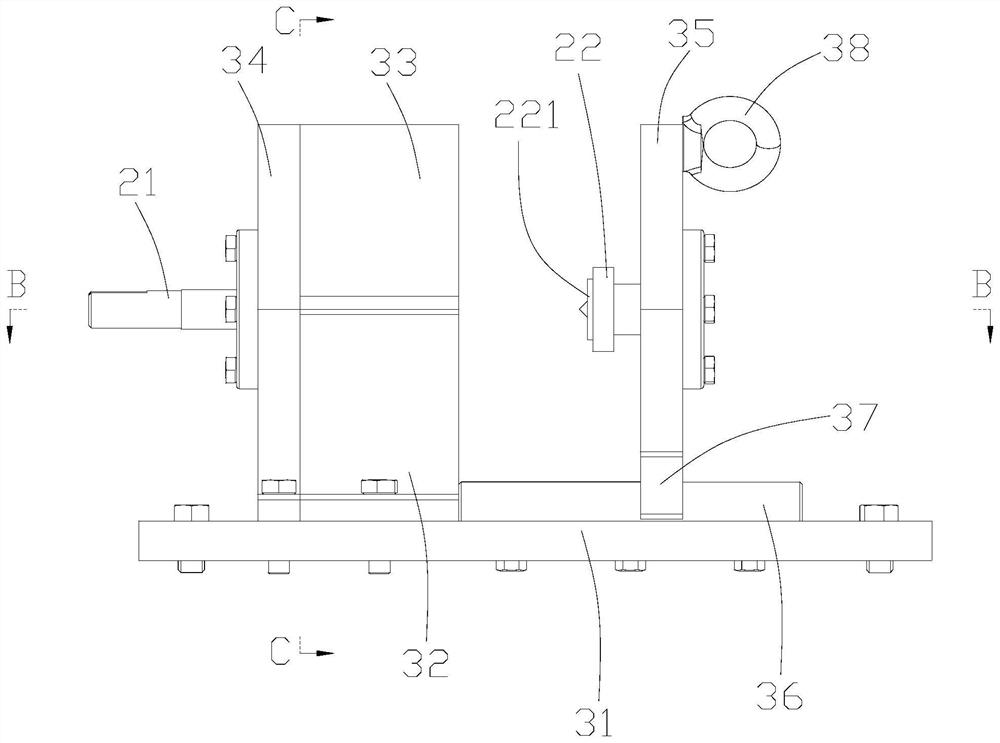

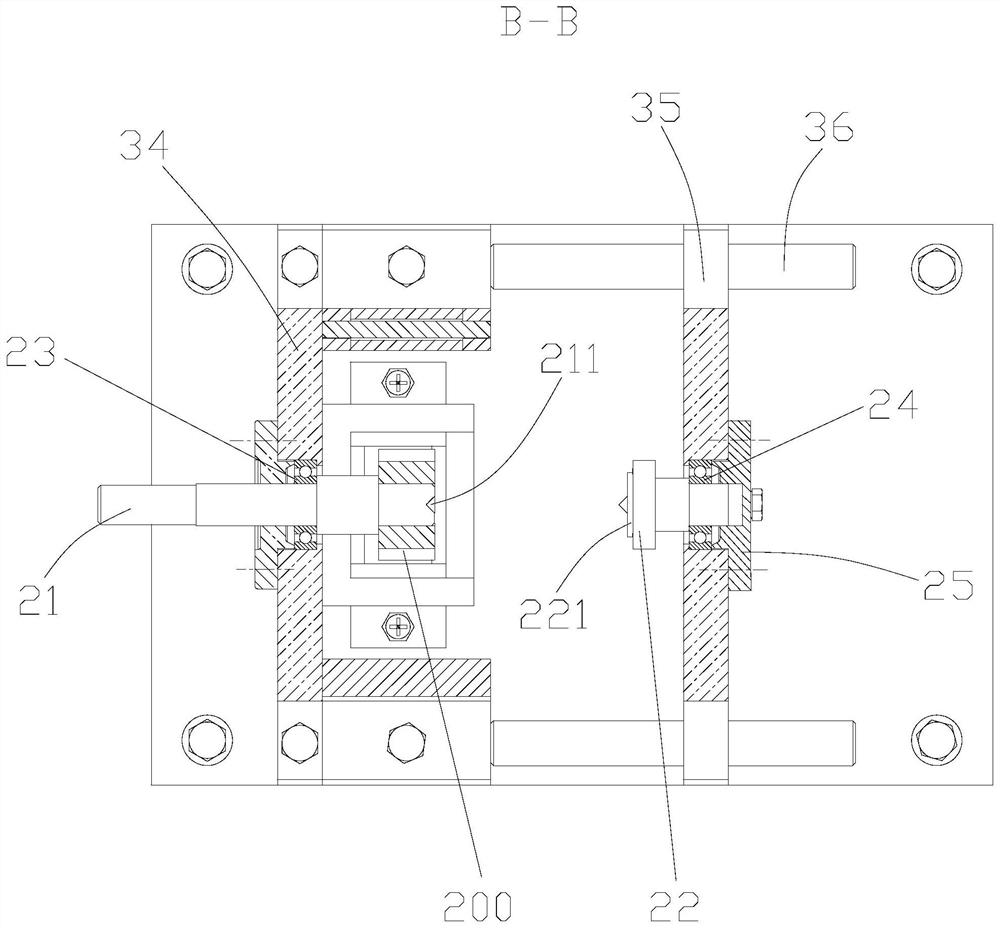

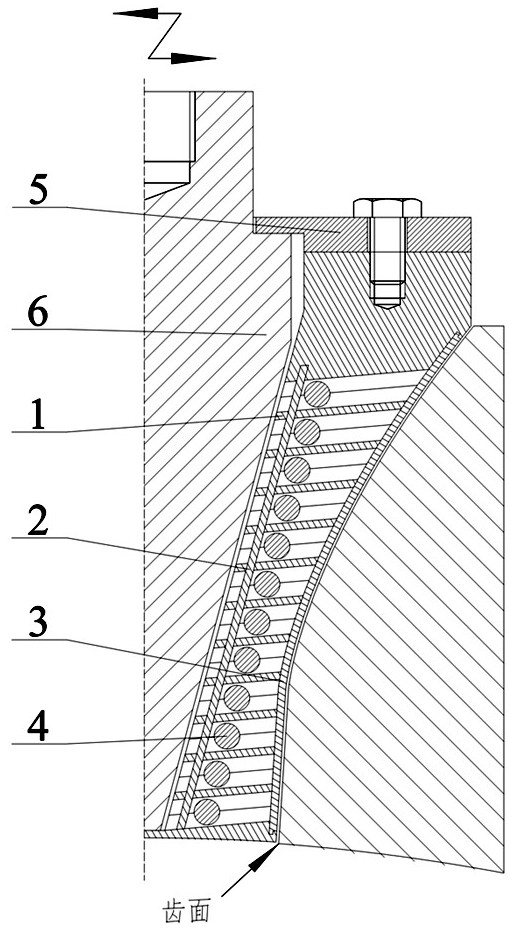

Shot type gear ultrasonic shot peening strengthening device

A shot type gear ultrasonic shot peening strengthening device comprises an ultrasonic vibration device and a shot impact mechanism, the ultrasonic vibration device is composed of an ultrasonic generator, a transducer, an amplitude-change pole and a vibration head, the section of the working end of the vibration head is trapezoidal, and the vibration mode is radial vibration. The shot impact mechanism is composed of a shell, an upper cover plate, inner baffles, outer baffles and shots, a cavity in the same shape as the vibration head is formed in the shell, the contour shapes of the two sides, matched with a machined gear, of the shell are involutes, honeycomb-shaped orthohexagonal shot paths are arranged at the two sides of the shell, and inner baffle grooves are formed in the ends, close to the vibration head, of the shot paths; and outer baffle grooves are formed in the end, close to the machined gear, and a shot is installed in each shot path. According to the shot type gear ultrasonic shot peening strengthening device, the radial vibration generated by the vibration head is used for driving the shots to move in the shot paths and impact the surface of the gear, so that ultrasonic shot blasting is achieved, and the problem that because the distance between an ultrasonic tool head and the tooth surface of the machined gear is large, an ideal processing effect is difficult to achieve is solved.

Owner:HUNAN UNIV OF SCI & TECH

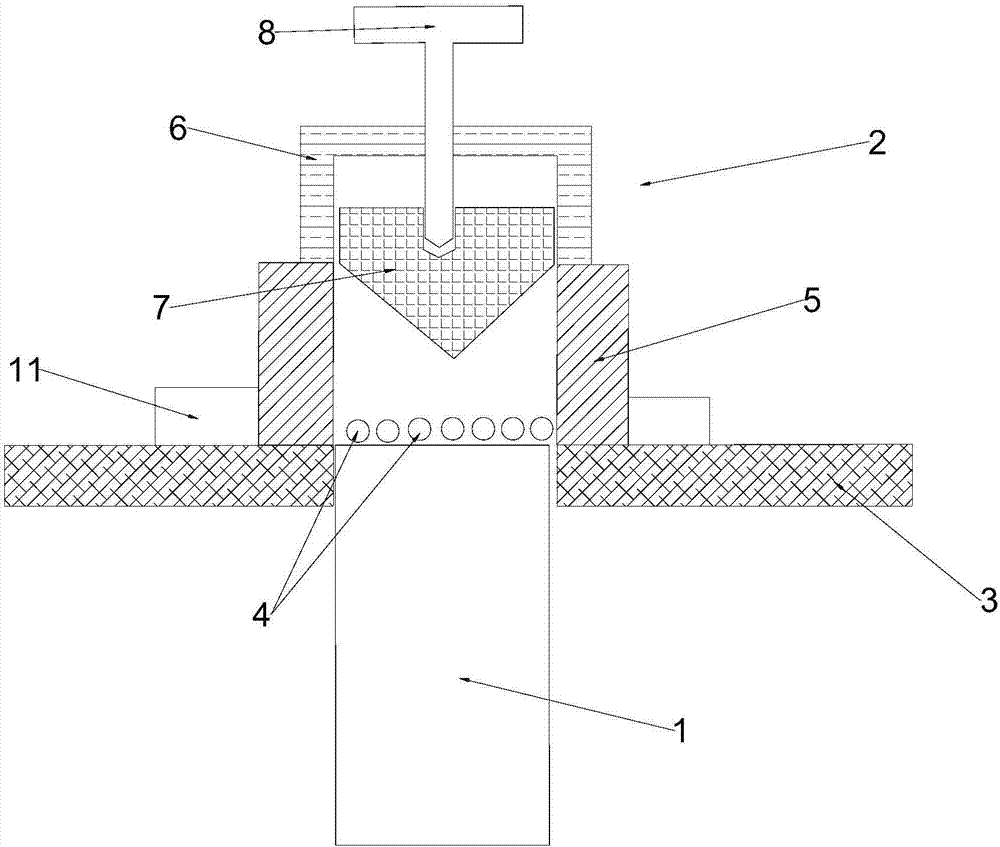

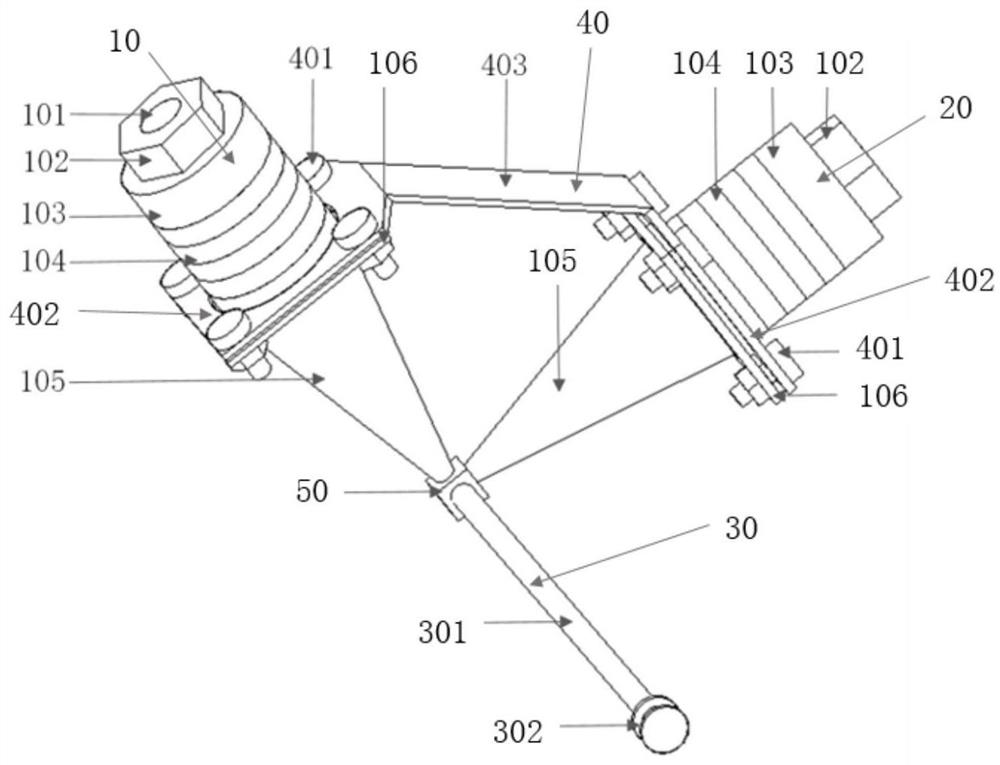

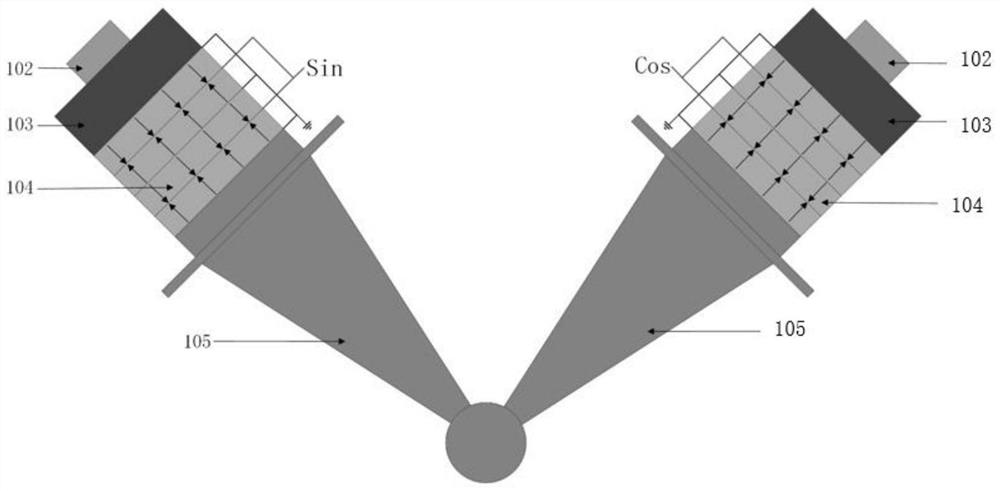

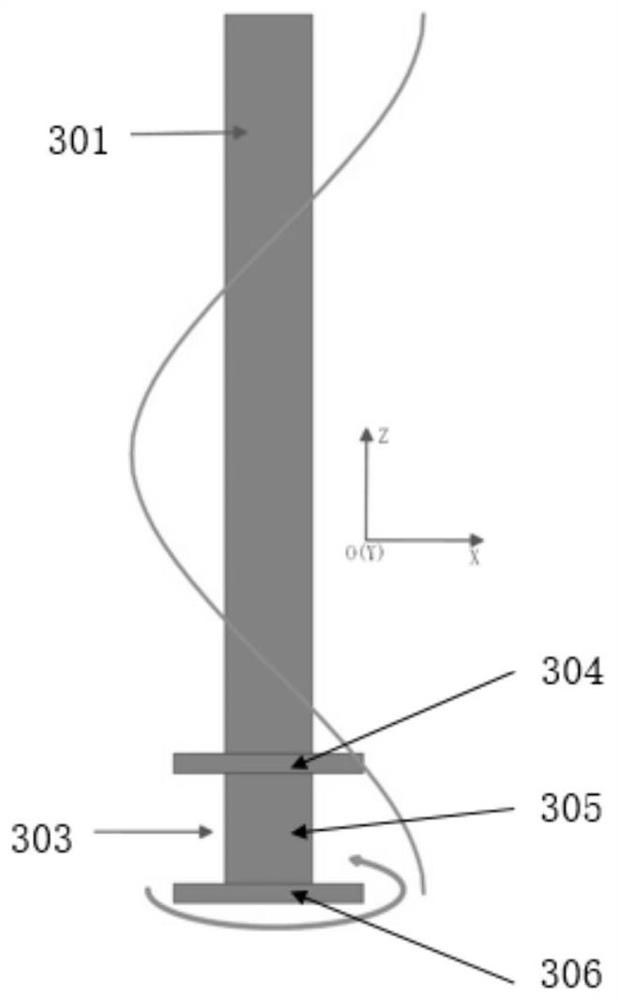

Deep-hole V-shaped ultrasonic shot blasting device

ActiveCN112975765AAchieving shot peeningReduce power consumptionAbrasive machine appurtenancesAcousticsUltrasonic shot peening

The invention relates to a deep-hole V-shaped ultrasonic shot blasting device which is provided with a first transducer and a second transducer. Main body parts of the first transducer and the second transducer are connected through a transducer connecting piece, the included angle between the axis of the first transducer and the axis of the second transducer is 90 degrees, and the first transducer and the second transducer are the same in structure; amplitude-change poles are arranged at the front parts of the first transducer and the second transducer, the end parts of the two amplitude-change poles are connected through a connecting block, the connecting block is connected with a slender tool head, the axis of the slender tool head is orthogonal to the axis of the first transducer and the axis of the second transducer, a shot blasting part is arranged at the front end of the slender tool head, and the shot blasting part is provided with an annular groove; and the annular groove and the inner wall of a deep hole form a shot blasting cavity. The deep-hole V-shaped ultrasonic shot blasting device can realize uniform shot peening strengthening of the inner wall of the deep hole in the whole circumferential direction, effectively improves the efficiency of ultrasonic shot peening strengthening, is remarkable in effect, and can be widely applied to surface strengthening of various metal deep holes.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

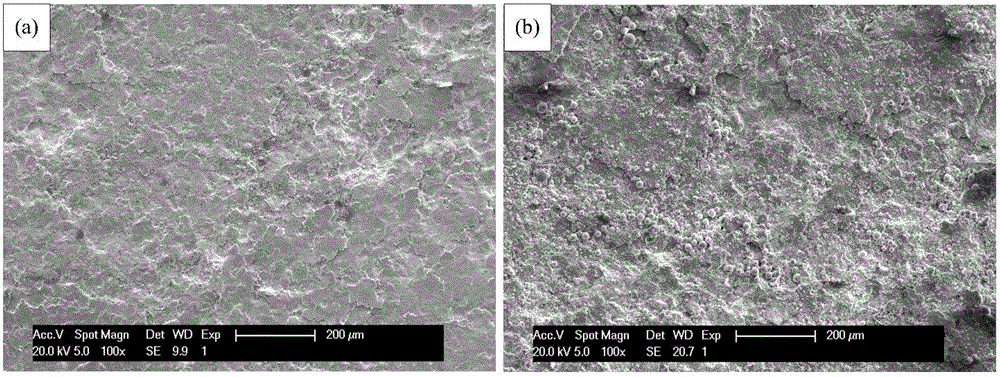

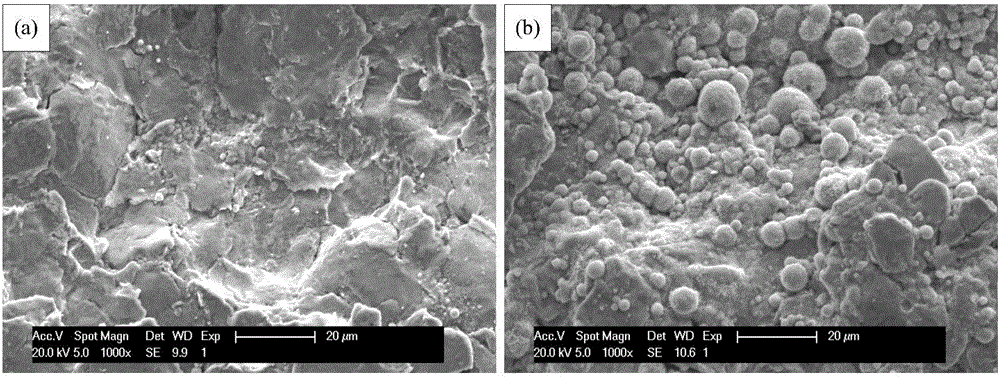

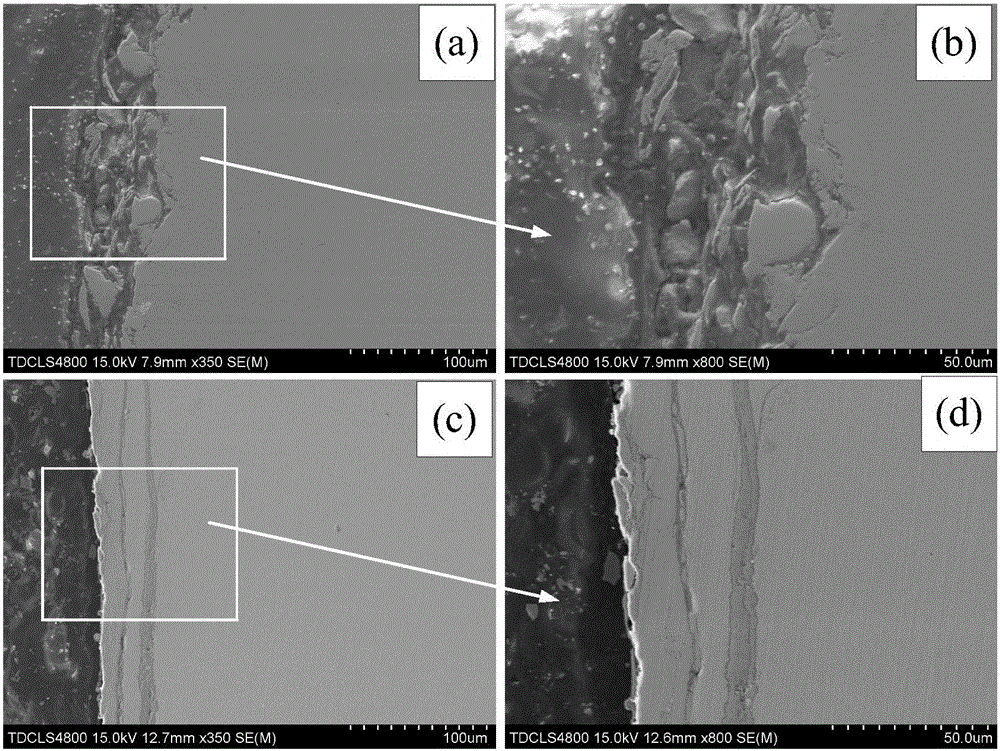

Microstructure and mechanical property testing method for ultrasonic shot peening induced nano-alloying

InactiveCN110133030AEasy to operateGood alloying performanceMaterial strength using tensile/compressive forcesInvestigating material hardnessSpecific testScanning electron microscope

The invention discloses a microstructure and mechanical property testing method for ultrasonic shot peening induced nano-alloying. The testing method comprises the specific steps that first, a test technician writes test steps, grasps test matters needing attention and prepares test materials and equipment; second, Q235 steel plate samples are prepared and tested in groups, wherein the tests include that a, the Q235 steel plate sample 1 is maintained; b, the Q235 steel plate sample 2 is subject to ultrasonic shot peening under 30kHz power for 5min; c, Cr powder is added, and then the Q235 steel plate sample 3 is subject to ultrasonic shot peening under 30kHz power for 20min; d, Cr powder is added, and then the Q235 steel plate sample 4 is subject to ultrasonic shot peening under 30kHz power for 10min; and e, Cr powder is added, and then the Q235 steel plate sample 5 is subject to ultrasonic shot peening under 20kHz power for 10min; and third, a scanning electron microscope is utilizedto perform ray scanning on sample surface regions in the five tests performed in the second step respectively. The microstructure and mechanical property testing method for ultrasonic shot peening induced nano-alloying is simple, practical and convenient to operate, the obtained conclusion is representative, and the method is suitable for wide application and popularization.

Owner:XINGHUA TIANTAI ALLOY PROD TECH CO LTD

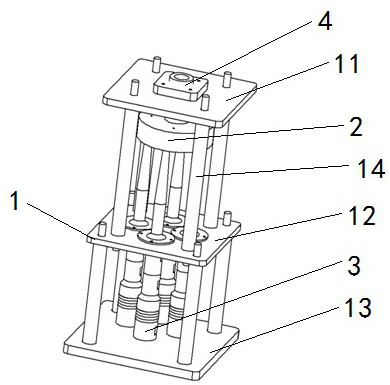

Piezoelectric vibrator array type ultrasonic shot peening strengthening device

ActiveCN112518594AQuality improvementImprove efficiencyAbrasive machine appurtenancesAbrasive blasting machinesTransducerEngineering

The embodiment of the invention relates to a piezoelectric vibrator array type ultrasonic shot peening strengthening device. The piezoelectric vibrator array type ultrasonic shot peening strengtheningdevice comprises a supporting device, a shot peening chamber, piezoelectric ultrasonic vibrators and a vibration excitation sheet, wherein the supporting device comprises a shot peening chamber clamping plate, a transducer clamping plate, a bottom plate and a supporting rod; the transducer clamping plate is connected with the shot blasting chamber clamping plate and the bottom plate through supporting rods so as to provide sufficient space for mounting of the shot blasting chamber and the piezoelectric ultrasonic vibrators; the output ends of the piezoelectric ultrasonic vibrators extend intothe shot blasting chamber; an vibration excitation sheet is connected to the output ends of the piezoelectric ultrasonic vibrators; and a plurality of shots are laid on the side, far away from the output ends of the piezoelectric ultrasonic vibrators, of the vibration excitation sheet. The piezoelectric ultrasonic vibrators convert an ultrasonic frequency electric oscillation signal input by an ultrasonic power supply into a mechanical vibration signal with the same frequency, and acts on the vibration excitation sheet after the amplitude is amplified; and the vibration excitation sheet vibrates at high frequency to drive the shots to repeatedly impact the surface of a workpiece to be machined, so that the shot blasting quality and the shot blasting efficiency of an ultrasonic shot peening device are improved.

Owner:SICHUAN UNIV

A system and application method for efficient and uniform processing of various profiles by ultrasonic shot peening

ActiveCN109249317BAvoid sharp anglesUniform surface treatmentAbrasive feedersAbrasive machine appurtenancesVibration amplitudePiezoelectric actuators

The invention discloses an ultrasonic shot blasting efficient and uniform processing system for various molded surfaces. The system comprises a workpiece clamping mechanism, a working table and a first connecting member arranged on the working table, a first vibration amplitude transformer, a mixer, a shot blast filling device, a jet mechanism, a driving mechanism, and a control system; a pair ofoppositely positioned first piezoelectric actuators are arranged at the first vibration amplitude transformer; the mixer is located above the first vibration amplitude transformer, and is used for mixing the compressed gas and the shot blast, the shot blast is sprayed to the end surface of the first vibration amplitude transformer, and the shot blast is accelerated by end surface rebounding to process a workpiece at a lower part; The workpiece clamping mechanism includes a second connecting member, a second vibration amplitude transformer, the second vibration amplitude transformer is mountedwith a second piezoelectric actuator, and is capable of generating axial-bending-torsional coupling vibration. The system can improve the speed of shot blast processing, under the action of the vibration of the second vibration amplitude transformer, the workpiece is uniformly processed at a high speed, and efficient processing of the workpiece is realized.

Owner:CENT SOUTH UNIV

Shot peening forming method for prolonging fatigue life of ribbed integral panel

ActiveCN114011958AImprove surface qualityImprove fatigue lifeAircraft componentsMachining processUltrasonic shot peening

The invention relates to a shot peening forming method for prolonging the fatigue life of a ribbed integral panel. Barrier strips at the two sides of a rib top are clamped, groove bodies are formed on the barrier strips, and shot peening forming is cairred out on shots in an area limited by the groove bodies by using shot peening equipment with the shot diameter of 1-6mm; the barrier strips are detached, metal sliding blocks are clamped to the two sides of the rib top, and sliding block grooves are formed in the metal sliding blocks; ultrasonic shot blasting equipment with the diameter of a spray needle being 2-6 mm is used, and the spray needle is sprayed and shaped in an area limited by the sliding block groove; and in the machining process, the metal sliding blocks are moved in the length direction of the rib top till the shape of the area to be subjected to shot peening forming machining on the rib top is corrected. According to the method, the surface quality of the rib top is effectively protected, reasonable shot peening strengthening parameters are combined, the fatigue life of the rib can be greatly prolonged, and application of the shot peening forming technology to the complex ribbed integral wall plate is expanded.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

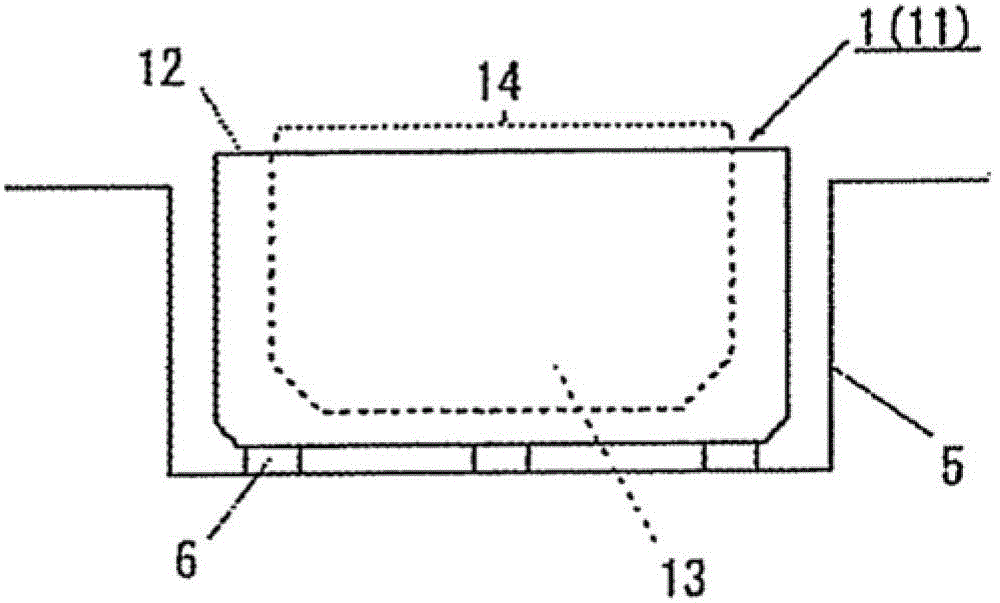

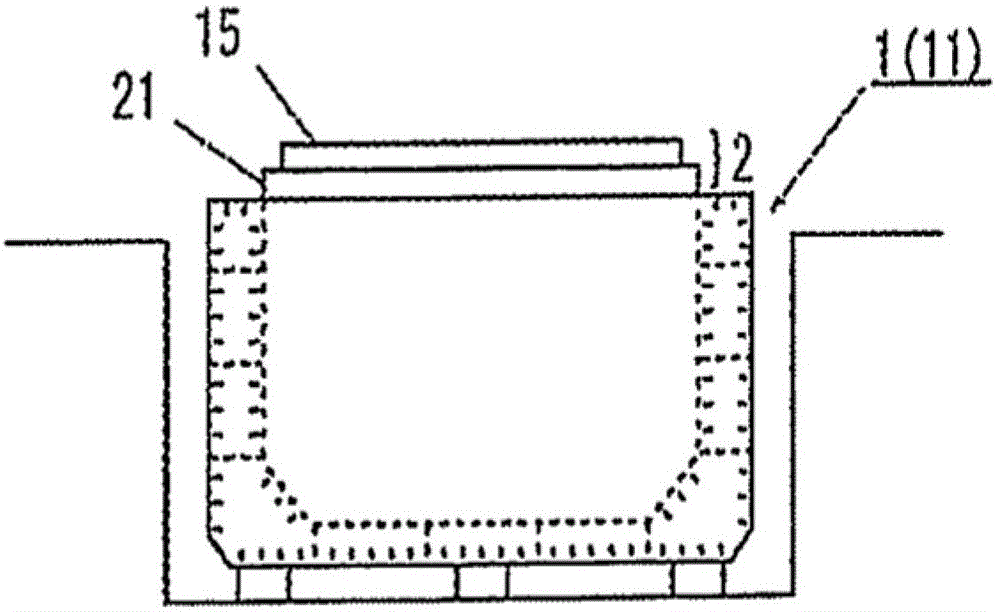

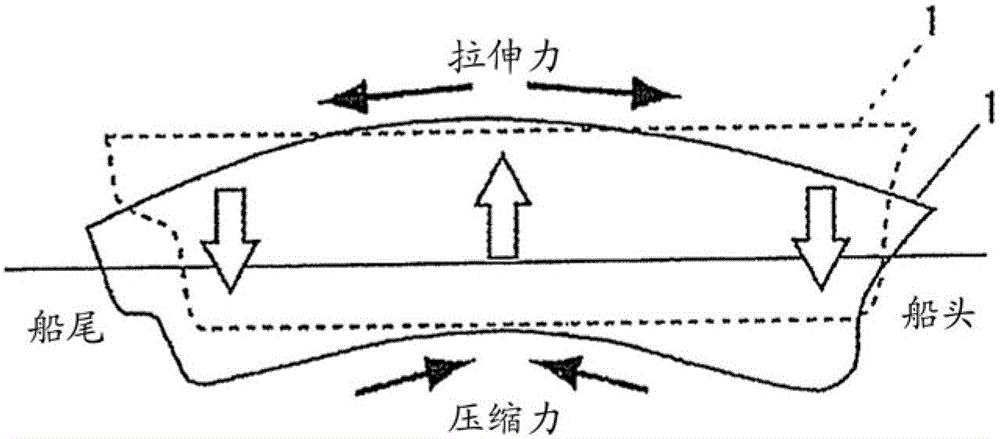

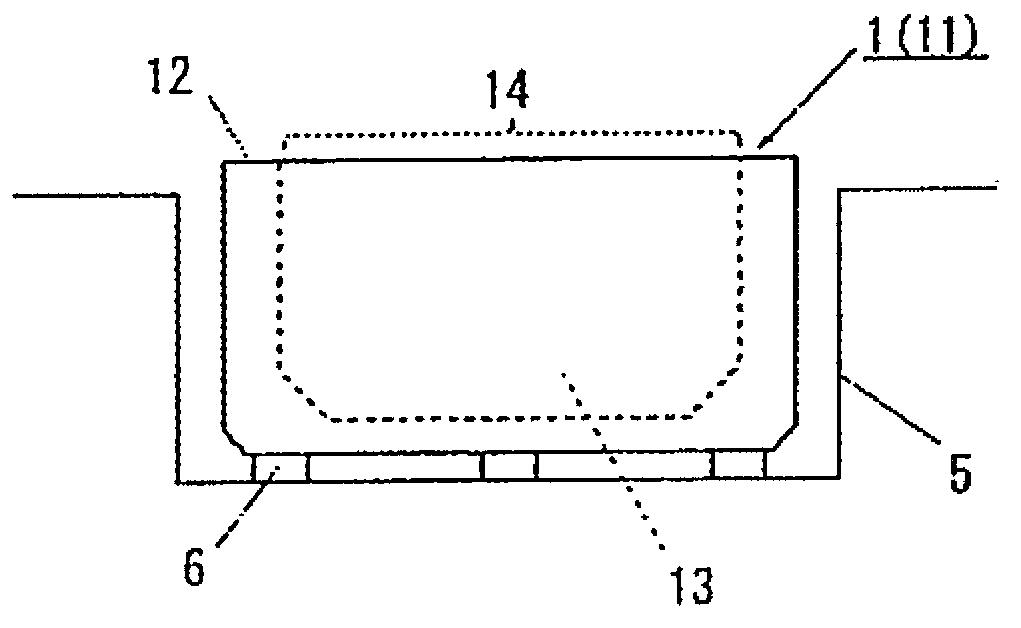

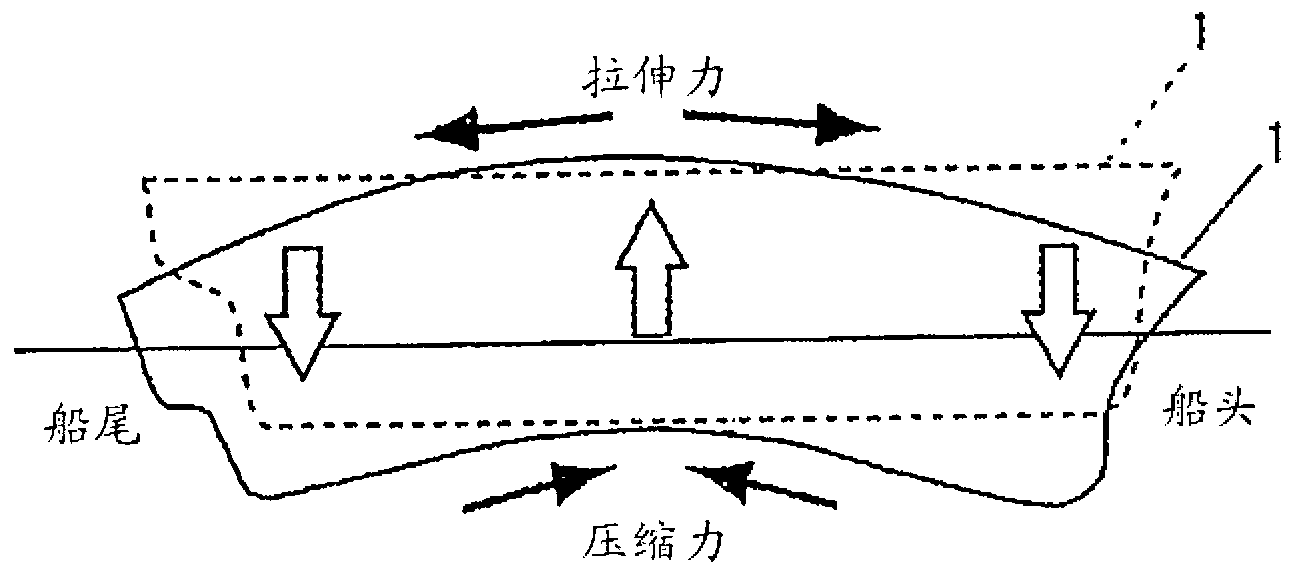

Ultrasonic peening method and floating building

ActiveCN102844147BEfficient constructionReduce inhibitionVessel partsFurnace typesBuoyancyUltrasonic shot peening

An ultrasonic peening method which, in order to improve the fatigue strength of the weld (3) between a floating building (1) and a structure (2) welded to the floating building (1), applies an impact to the weld (3) by a pin (4) vibrated by an ultrasonic wave. The ultrasonic peening method comprises: a building construction step for constructing the floating building (1); a structure welding step for attaching the structure (2) to the floating building (1) by welding; a building launching step for lowering the floating building (1), to which the structure (2) has been attached, into water; and an ultrasonic peening step for applying ultrasonic peening to the weld (3) of the floating building (1) having buoyancy.

Owner:JAPAN MARINE UNITED CORP +2

Ultrasonic peening method and floating building

ActiveCN102844147AEfficient constructionReduce inhibitionVessel partsFurnace typesBuoyancyUltrasonic shot peening

An ultrasonic peening method which, in order to improve the fatigue strength of the weld (3) between a floating building (1) and a structure (2) welded to the floating building (1), applies an impact to the weld (3) by a pin (4) vibrated by an ultrasonic wave. The ultrasonic peening method comprises: a building construction step for constructing the floating building (1); a structure welding step for attaching the structure (2) to the floating building (1) by welding; a building launching step for lowering the floating building (1), to which the structure (2) has been attached, into water; and an ultrasonic peening step for applying ultrasonic peening to the weld (3) of the floating building (1) having buoyancy.

Owner:JAPAN MARINE UNITED CORP +2

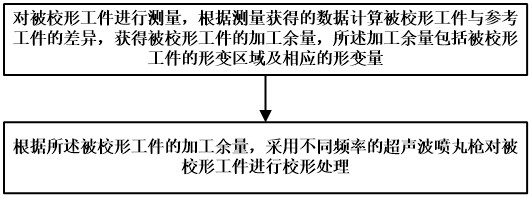

Workpiece shape correcting method and workpiece shape correcting device

ActiveCN113042577AAccurate deformation informationAvoid damageBlast gunsMetal working apparatusStructural engineeringMachining

The invention discloses a workpiece shape correcting method and a workpiece shape correcting device. The workpiece shape correcting method comprises the steps that a to-be-corrected workpiece is measured, the difference between the to-be-corrected workpiece and a reference workpiece is calculated according to data obtained through measurement, the machining allowance of the to-be-corrected workpiece is obtained, and the machining allowance comprises a deformation area of the to-be-corrected workpiece and the corresponding deformation amount; according to the machining allowance of the to-be-shaped workpiece, ultrasonic shot blasting guns with different frequencies are adopted for conducting shape correction treatment on the to-be-shaped workpiece; and the steps are repeated until the corrected workpiece meets the correction standard. According to the device, a to-be-machined metal plate and a to-be-shaped hub can be subjected to shape correction treatment, the hub shape correction precision is improved, meanwhile, damage to the hub is avoided, and the application range is wide.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com