On-line non-contact laser stereo scanning detection device for internal screw threads of tubing coupling

A detection device and a three-dimensional scanning technology, which is applied to measurement devices, optical devices, measurement/indication devices, etc., can solve the problems of difficult correction, inability to achieve quality prediction, forecast, and difficulty in ensuring test accuracy, and improve the The effect of detecting accuracy and speed, reducing labor intensity and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

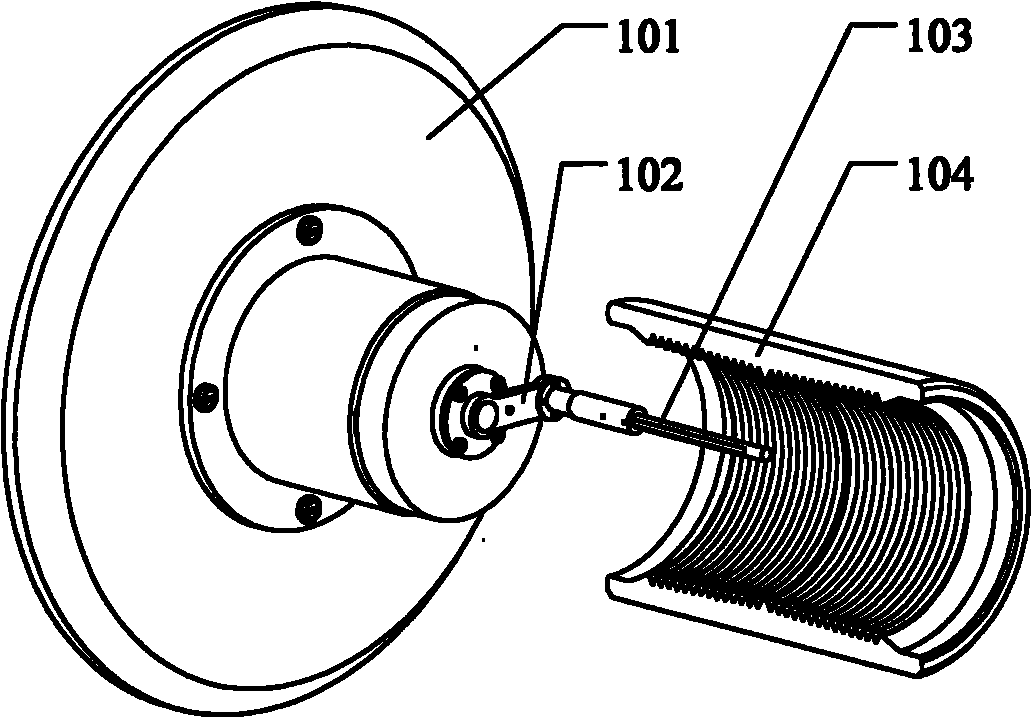

[0103] Please refer to the attached figure 1 , the present invention consists of an axial movement mechanism assembly 101, a radial rotation mechanism assembly 102, and a laser detection probe assembly 103.

[0104] Please refer to the attached Figure 2A , Figure 3A , Figure 4 , the present invention locates the outer circle 301A with a diameter of 220 mm in the installation base plate 201 and the three-jaw chuck of the threading machine tool, and presses the large end face 302A in the installation base plate 201 by the three-jaw chuck of the machine tool to realize this detection The fixed connection of the device to the machine tool.

[0105] After positioning the large outer circle 401 of the outer sleeve 202 and the large circular groove 303A on the installation base plate 201 , they are fixedly connected with thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com