Equal-diameter roller type fresh tea grading device and method

A grading device and technology of fresh tea leaves, applied in chemical instruments and methods, solid separation, tea treatment before extraction, etc., can solve problems such as extensive working methods, low grading efficiency, and non-adjustable drum speed, and reduce labor intensity of workers , Improving the degree of mechanization and improving the utilization rate of the drum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

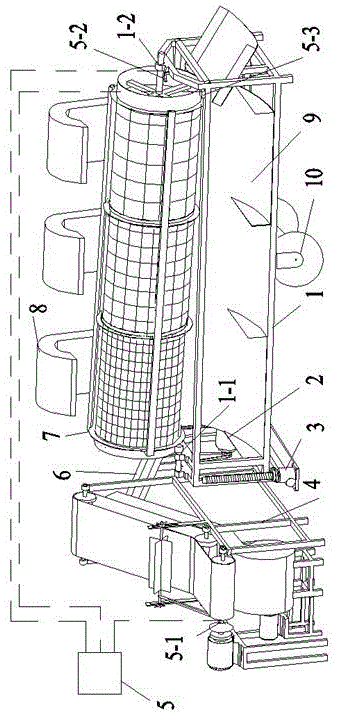

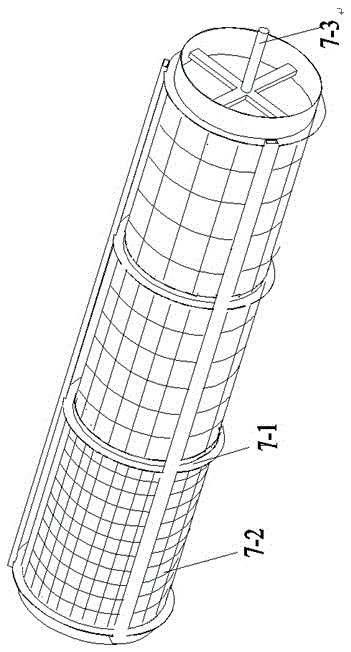

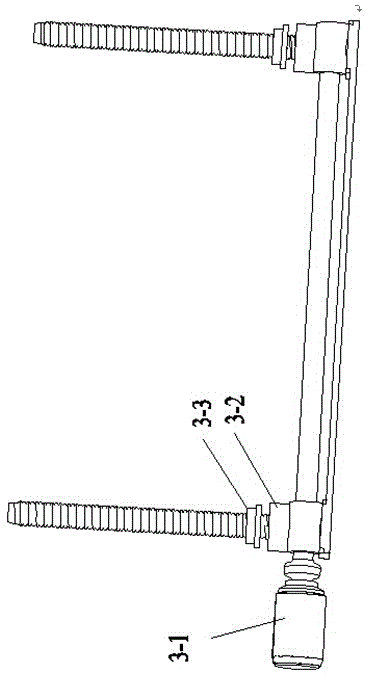

[0050] Grading of fresh hand-picked tea leaves: Before grading the fresh tea leaves, first select 3 sections of screens according to the size and grade quantity of the target fresh tea leaves, the sizes are: 6mm×6mm, 10mm×10mm, 13mm×13mm, and install them on the drum frame 7-1. According to the kind of the fresh tea leaves and the composition of the fresh tea leaves at all levels, the drum inclination angle when setting the classification is 6°, the drum rotating speed is 8r / min, and the feed rate is 2.0kg / min by the controller 5. After setting, the lifting mechanism 3 starts to adjust the inclination angle of the drum to the set value; after a 10s delay, the power source 2 starts to accelerate the drum 7 to the set value; After the conveying speed of belt 4-3 accelerates to the set value, air separation fan 4-4 and cleaning fan 8 start. After a delay of 10s, the controller gives an alarm, and the workers start loading materials. The worker puts the fresh tea leaves on the ...

example 2

[0052] Grading of machine-picked fresh tea leaves: Before grading the fresh tea leaves, first select 3 sections of screens according to the size and grade quantity of the target fresh tea leaves, the sizes are: 10mm×10mm, 15mm×15mm, 20mm×20mm, and install them on the drum frame 7-1. According to the kind of the fresh tea leaves and the composition of the fresh tea leaves of all levels, the drum inclination angle 6°, the drum rotating speed 16r / min, and the feed rate 1.5kg / min when setting the classification are set by the controller 5. After setting, the lifting mechanism 3 starts to adjust the inclination angle of the drum to the set value; after a 10s delay, the power source 2 starts to accelerate the drum 7 to the set value; After the conveying speed of belt 4-3 accelerates to the set value, air separation fan 4-4 and cleaning fan 8 start. After a delay of 10s, the controller gives an alarm, and the workers start loading materials. Workers put the fresh tea leaves on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com