Heating and drying device and seed screening device

A technology of a drying device and a screening device, which is applied in the field of separating solids from solids by the action of airflow on solid mixtures, which can solve the problems of high cost, complex structure of screening devices, and low drying efficiency of seeds, and achieve high efficiency and high drying efficiency. High drying efficiency and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

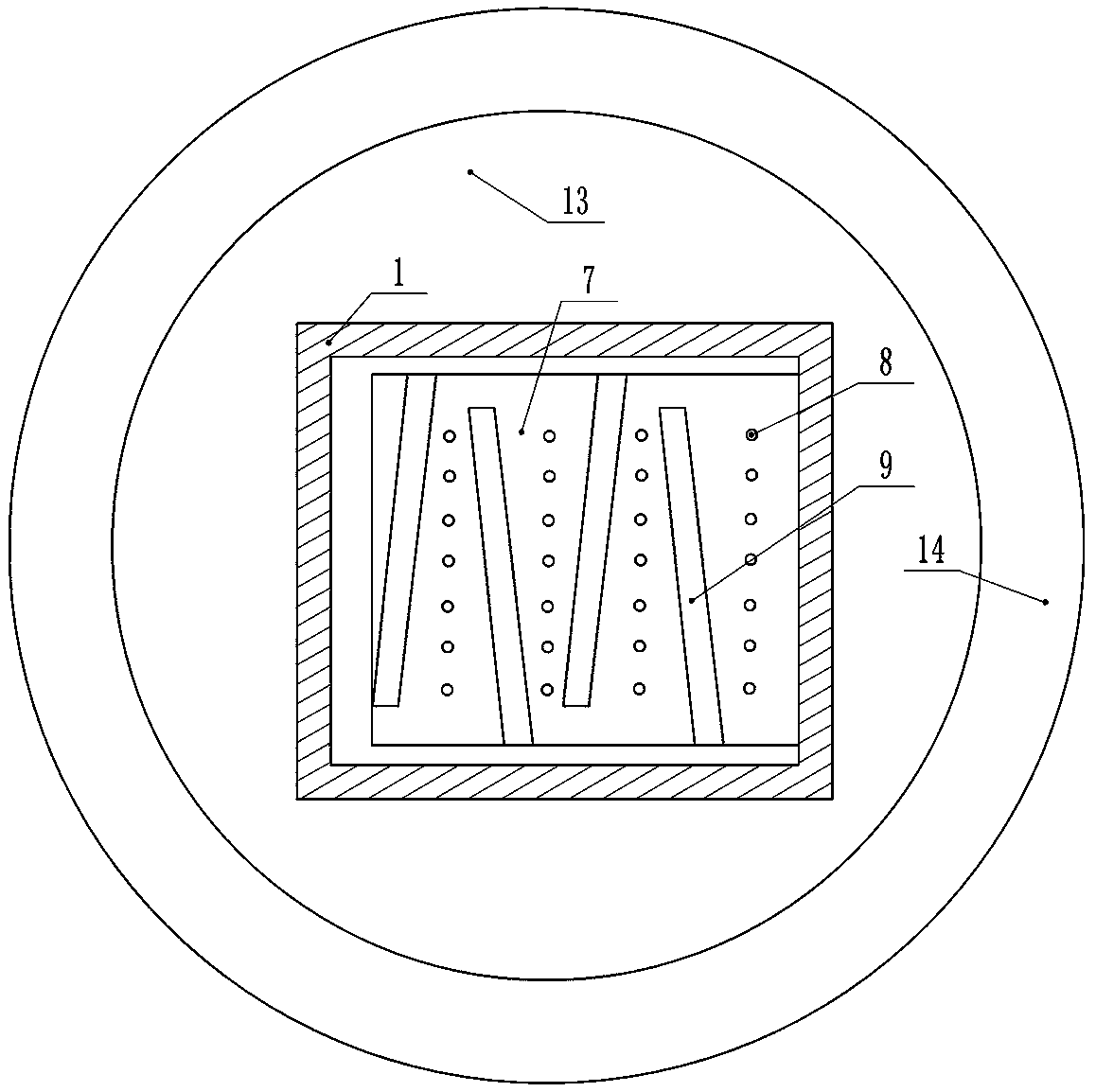

[0025] The preferred embodiments of the seed screening device of the present invention will be further described below with reference to the accompanying drawings.

[0026] The preferred embodiment of the seed screening device of the present invention, such as figure 1 with figure 2 As shown, the seed screening device includes a heating and drying device and a winnowing unit. The heating and drying device includes a housing 1. The top of the housing 1 is provided with a seed inlet for seeds to enter the interior of the housing 1, and the bottom of the housing 1 is provided with a supply The seed outlet through which the seeds inside the shell 1 flow out. The bottom of the casing 1 is also connected with a box 13 containing the winnowing unit.

[0027] The seed inlet is connected with a feed pipe 3, the feed pipe 3 is provided with a tapered feed funnel 5, and the feed pipe 3 is also provided with a feed valve 4 for controlling the inflow of seeds. A discharge pipe 33 for the seed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com