A kind of preparation method of silicon carbide nanofiber film

A nanofiber membrane and nanofiber technology, applied in chemical instruments and methods, separation methods, membrane technology, etc., can solve the problem of mechanical strength of ceramic fiber membrane layer and membrane base binding force, short application life and filtration accuracy. Low-level problems, to achieve the effect of easy industrial production, easy operation, high separation precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

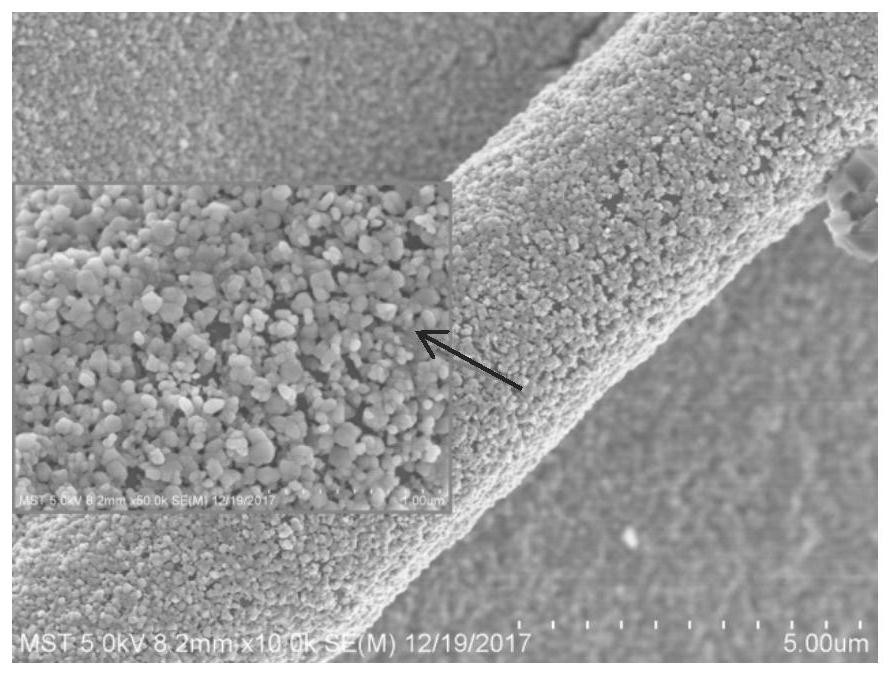

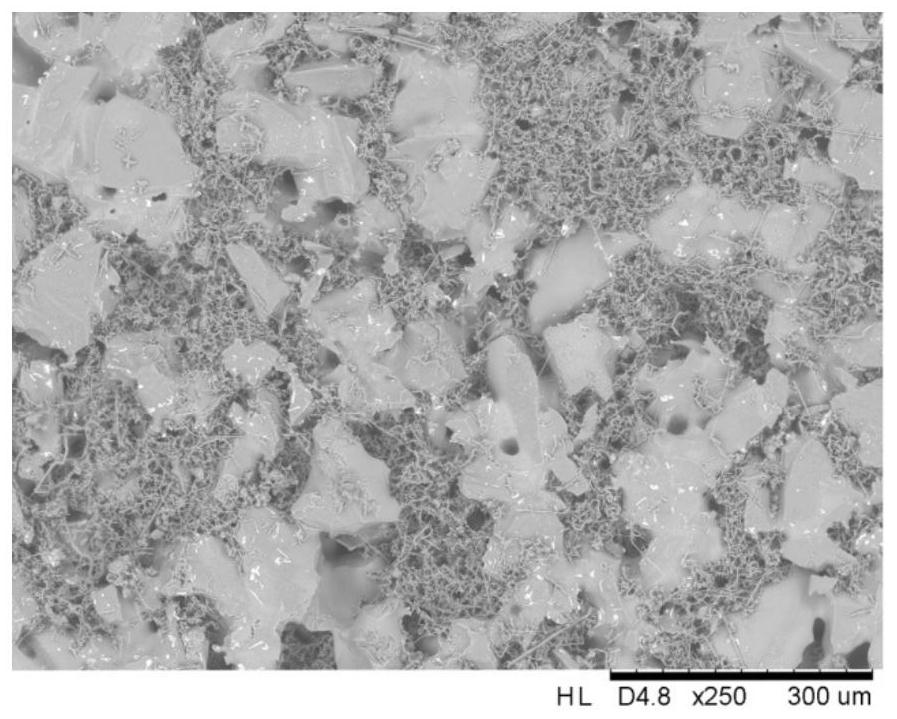

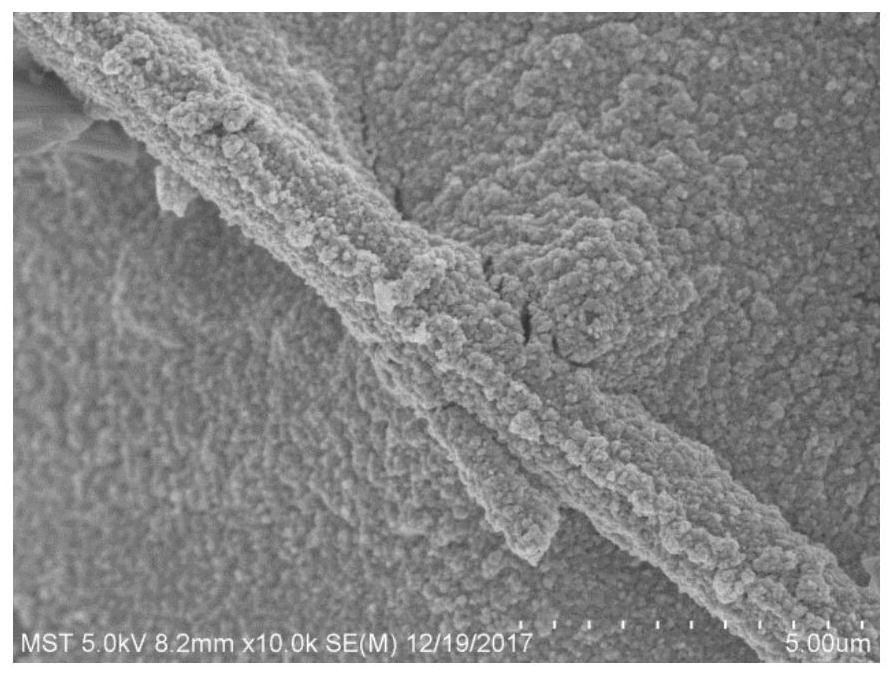

[0031] Add silicon carbide nanofibers with an average diameter of 0.1 μm and an aspect ratio of 50 into deionized water, and mix them uniformly by mechanical stirring. The stirring time is 0.5 h, the stirring speed is 1500 r / min, and the solid content of the film-forming solution is 0.5 wt%; then put the mixed film-making solution in an ultrasonic device for dispersion, the ultrasonic power is 50 W, and the ultrasonic time is 2 h; the silicon carbide substrate is coated by spraying method, and the porosity of the silicon carbide substrate is 30%, the average pore size is 60 μm, the spraying pressure is 0.2 MPa, the single spraying time is 0.2 s, and the number of spraying times is 8 times; the coated silicon carbide substrate is dried in a constant temperature drying oven at a drying temperature of 40 °C. The drying time was 4 h; then the coated substrate was submerged in alumina sol for negative pressure suction, so that the pores of the substrate were filled with sol solution...

Embodiment 2

[0034] Add silicon carbide nanofibers with an average diameter of 0.2 μm and an aspect ratio of 50 into deionized water, and mix them uniformly by mechanical stirring. The stirring time is 1.25 h, the stirring speed is 1250 r / min, and the solid content of the film-forming solution is 0.5 wt%; then put the mixed film-making solution in an ultrasonic device for dispersion, the ultrasonic power is 50 W, and the ultrasonic time is 2 h; the silicon carbide substrate is coated by spraying method, and the porosity of the silicon carbide substrate is 35%, the average pore size is 50 μm, the spraying pressure is 0.3 MPa, the single spraying time is 0.5 s, and the number of spraying times is 7 times; the coated silicon carbide substrate is dried in a constant temperature drying oven at a drying temperature of 45 °C. The drying time was 3 h; then the coated substrate was submerged in titanium oxide sol for negative pressure suction, so that the pores of the substrate were filled with sol ...

Embodiment 3

[0037] Add silicon carbide nanofibers with an average diameter of 0.5 μm and an aspect ratio of 25 into deionized water, and mix them uniformly by mechanical stirring. The stirring time is 2.5 h, the stirring speed is 1000 r / min, and the solid content of the film-forming solution is 2.5 wt%; then put the mixed film-making solution in an ultrasonic device for dispersion, the ultrasonic power is 250 W, and the ultrasonic time is 1 h; the silicon nitride substrate is coated by spraying, and the pores of the silicon nitride substrate The coating ratio was 40%, the average pore diameter was 40 μm, the spraying pressure was 0.4 MPa, the single spraying time was 1 s, and the number of spraying times was 5 times; the coated silicon nitride substrate was dried in a constant temperature drying oven at a drying temperature of 50 ℃, the drying time is 2 h; then submerge the film-coated substrate in the titanium oxide sol for negative pressure suction, so that the pores of the substrate are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com