Preparation Technology of Composite Nitride Coating on Tool and Die Surface

A surface compounding and preparation technology, which is applied in the coating process of metal materials, coating, superimposed layer plating, etc., can solve the problem of poor bonding strength between the coating and the substrate, high structural stress of the coating, and low ionization rate of atoms and other problems, to achieve the effect of good film-base binding force, good stability and high microhardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below through specific embodiments and examples.

[0047] The method of the present invention can be implemented in the following ways:

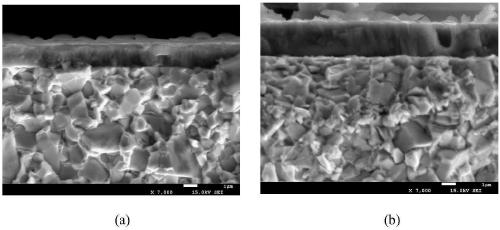

[0048] The preparation process of the composite nitride coating on the surface of the tool and die. When coating the film, a binary evaporation source technology combining vacuum ion evaporation plating and magnetron sputtering ion plating is used; 2 In a mixed atmosphere with Ar, the Ti element is evaporated by the electron beam evaporation source to form a traditional TiN film. While the TiN film is deposited and formed, the Me element is implanted by the magnetron sputtering source, and the surface of the tool and die is plated (Ti, Me) N layer; the Me is at least one of Ti, Al, Cr, and Si; specifically including the following steps:

[0049] (1) Pre-processing of tools and molds and equipment inspection;

[0050] (2) Vacuum and preheat;

[0051] (3) Electron beam heating; the pressure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com