Preparation method for composite coating of cutter

A composite coating and cutting tool technology, which is applied in the coating, metal material coating process, ion implantation plating, etc., can solve the problems of poor bonding force of the membrane base, limited membrane application range, and low metal ionization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

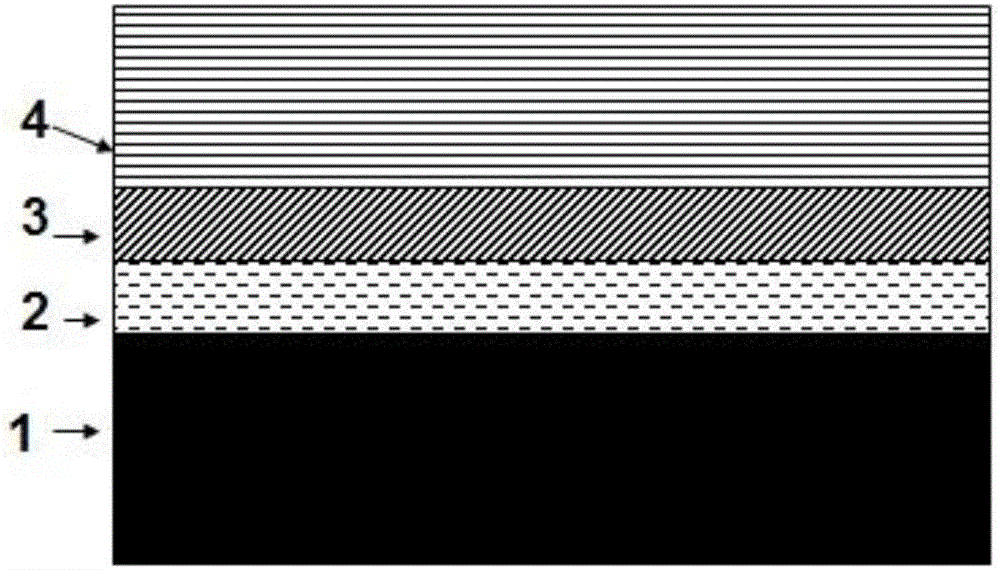

[0024] The embodiment of the invention discloses a method for preparing a tool coating, including the following steps:

[0025] A). Clamp the cleaned tool on the workpiece holder of the high-power pulsed magnetron sputtering apparatus, and vacuum, the vacuum degree of the cavity of the high-power pulsed magnetron sputtering apparatus is higher than (1~5)×10 -3 When Pa, turn on the heater to a temperature of 300~500℃, the rotation speed of the workpiece holder is 2~5rpm, when the vacuum degree is (1.2~5.5)×10 -3 When Pa, adjust the electric heater to a temperature of 200~400℃;

[0026] B) Pass inert gas into the cavity of the high-power pulse magnetron sputtering apparatus, turn on the bias power supply to perform glow cleaning on the tool, the vacuum degree is 0.3~0.9Pa, and the bias voltage is 800~1200V;

[0027] C) After the glow cleaning is finished, adjust the vacuum of the cavity of the high-power pulse magnetron sputtering apparatus to (1-9)×10 - 1 Pa, turn on the high-power pul...

Embodiment 1

[0037] Clean the hard alloy tool workpiece to be coated with alcohol and acetone, dry it with an air gun, and place it on the substrate holder in the cavity; start to pre-vacuum, when the vacuum degree is higher than 3×10 -3 At Pa, start to turn on the heater to remove the gas attached to the inner wall of the vacuum chamber and the workpiece holder. The temperature is controlled at 400℃, and the workpiece holder is kept at 3rpm. When the vacuum degree reaches 4×10 -3 At Pa, adjust the heater power supply voltage to stabilize it at 200°C, add Ar gas, turn on the bias power supply, and perform glow cleaning on the sample. The vacuum is maintained at 0.3Pa, the bias voltage is 1200V, and the glow time is 10 minutes;

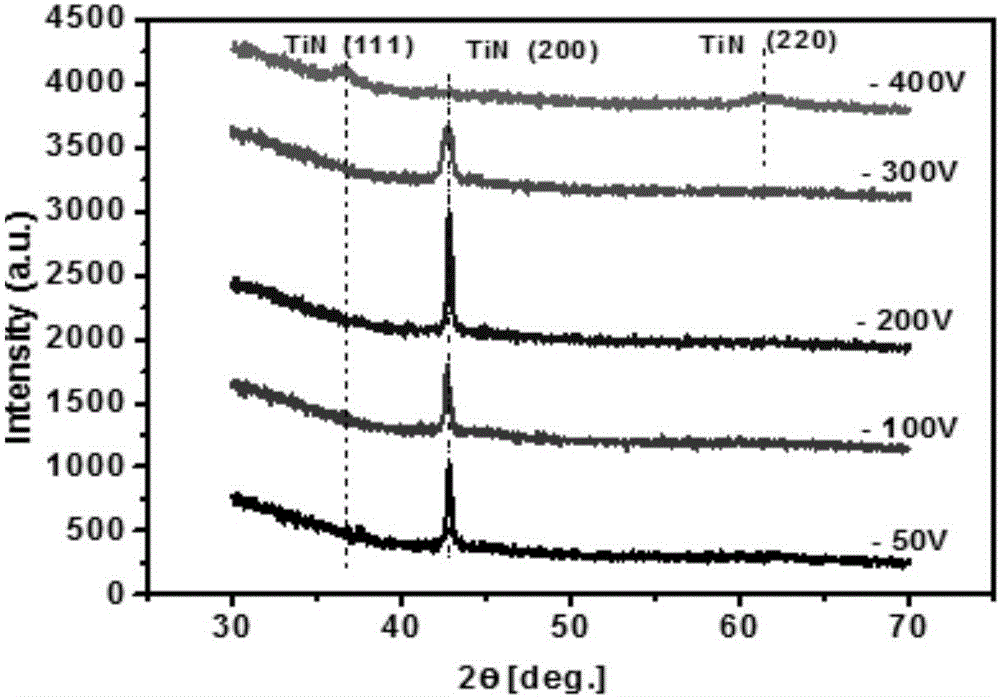

[0038] After the glow cleaning, the vacuum is adjusted to 3×10 -1 Pa, turn on the high-power pulsed magnetron sputtering power supply to sputter the Ti metal target, bombard the substrate for 20 minutes to grow a 120nm thick Ti bonding layer and TiN transition layer, the...

Embodiment 2

[0043] Clean the stainless steel tool workpiece to be coated with alcohol and acetone, dry it with an air gun, and place it on the substrate holder in the cavity; start pre-evacuating, when the vacuum degree is higher than 5×10 -3 At Pa, start to turn on the heater to remove the gas attached to the inner wall of the vacuum chamber and the workpiece holder. The temperature is controlled at 400℃, and the workpiece holder is kept at 5rpm. When the vacuum degree reaches 5.5×10 -3 At Pa, adjust the heater power supply voltage to stabilize at 300°C, then pass in Ar gas, turn on the bias power supply, and perform glow cleaning on the sample. The vacuum is maintained at 0.9Pa, the bias voltage is 1200V, and the glow time is 30 minutes. ;

[0044] After the glow cleaning, the vacuum is adjusted to 1×10 -1 Pa, the high-power pulsed magnetron sputtering power source is turned on to sputter the Ti metal target, and the substrate is bombarded for 40 minutes to grow a 200nm thick Ti bonding laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Internal stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com