Method for extracting butyraldehyde and butanol mixture and octenal and octanol mixture from waste liquid discharged by butanol-octanol device

A technology of mixture and octenal, which is applied in the field of resource utilization and treatment of waste liquid, can solve the problems of difficult comprehensive utilization technology, pollution of the environment and water sources, complex components, etc., and achieve low equipment investment, low operating cost, and efficient treatment. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

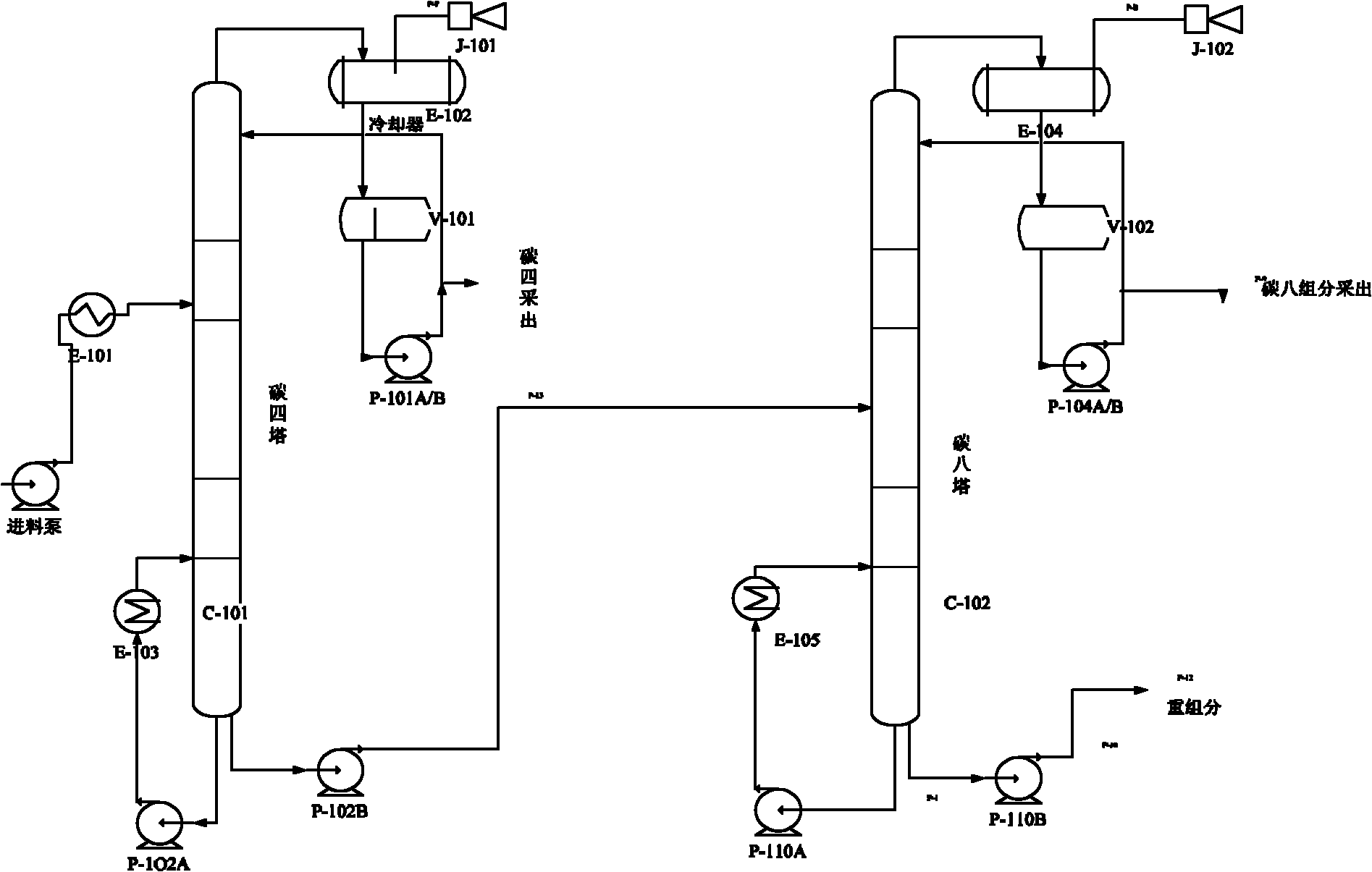

[0028] The waste liquid discharged from the butanol unit first passes through the carbon four fractionation tower system, and the butyraldehyde and butanol components contained in it are fractionated from the top of the carbon four tower, and the bottom components of the carbon four tower enter the carbon eight fractionation tower The device is used to fractionate the carbon eight components octenal and octanol contained in it from the top of the carbon eight column; the fractionated butyraldehyde and butanol are stored in the butyraldehyde and butanol mixture storage tank, and the octenal and octanol are stored In storage tanks for octenal and octanol mixtures.

[0029] The present invention is described in detail in conjunction with the accompanying drawings

[0030] The raw material of butanol waste liquid is heated to 100°C-120°C by the raw material preheater E-101 and enters the carbon four tower C-101. The heat required for the evaporation of the material in the tower is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com