Production method of environment-friendly water-soluble gum electrochemical aluminothermic transfer printing film

A technology of thermal transfer film and production method, which can be used in copying/marking methods, transfer ink from manuscripts, printing, etc., and can solve problems such as adverse human health, solvent residues, and non-compliance with the needs of the situation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, the present invention first mixes and stirs 3 parts of emulsified montanic acid montan wax, 40 parts of ethanol and 40 parts of water to make release layer coating; 10 parts of isocyanate resin, 4 parts of cellulose resin, 10 parts of acrylic resin, butyl 30 parts of ketone, 5 parts of pentanone, 5 parts of n-butanol, and 5 parts of metal complex dyes are mixed and stirred to make a color layer coating; 1 part of cellulose acetate, 1 part of vinyl cellulose, 1 part of polyvinyl butyral, Mix and stir 1 part of pulverized silicon dioxide, 3 parts of water and 15 parts of alcohol to prepare the adhesive layer coating.

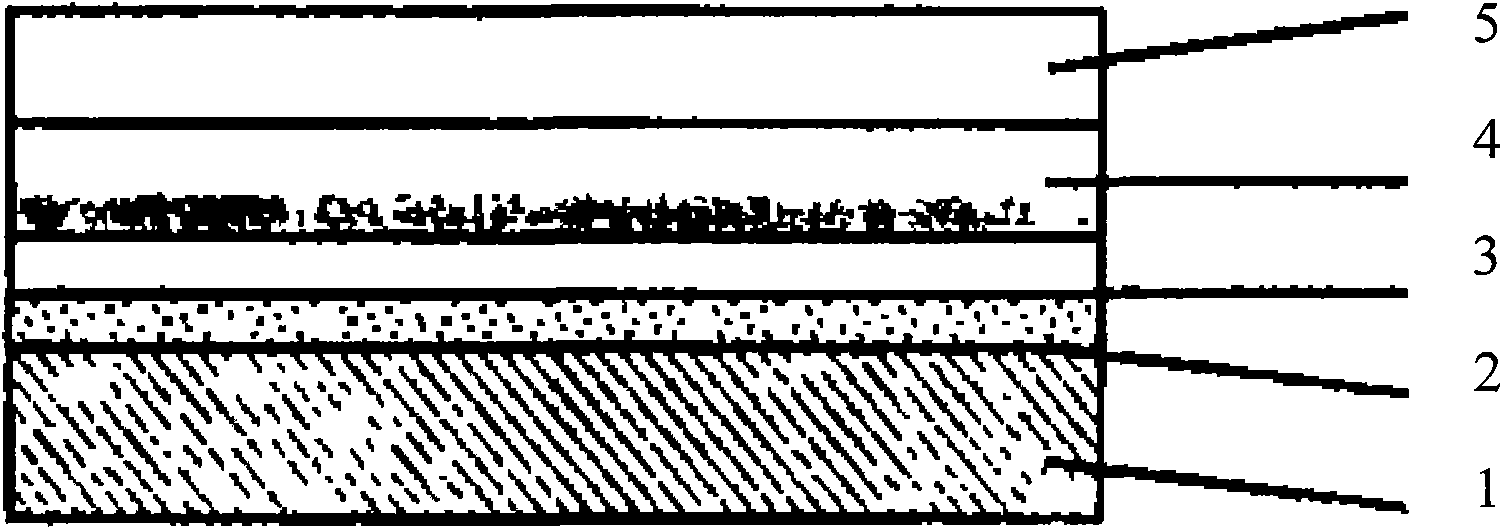

[0019] According to the production method of environmentally friendly water-soluble self-adhesive anodized aluminum thermal transfer film, 6-15 micron PET film is used as the carrier film, and the release layer coating is firstly coated by forward or reverse coating through a smooth roller or anilox roller On the PET base film substrate, after...

Embodiment 2

[0023] Embodiment 2, the present invention mixes and stirs 5 parts of OP wax, 95 parts of methyl ethyl ketone, and 5 parts of n-butanol to make a release layer coating; 20 parts of isocyanate resin, 10 parts of cellulose resin, 20 parts of acrylic resin, butanol 60 parts of ketone, 10 parts of amyl ketone, 10 parts of n-butanol, and 15 parts of metal complex dyes are mixed and stirred to make a color layer coating; 20 parts of cellulose acetate, 20 parts of vinyl cellulose, and 20 parts of polyvinyl butyral , 20 parts of pulverized silicon dioxide, 15 parts of water and 50 parts of alcohol are mixed and stirred to make an adhesive layer coating.

[0024] According to the production method of environmentally friendly water-soluble self-adhesive anodized aluminum thermal transfer film, 6-15 micron PET film is used as the carrier film, and the release layer coating is firstly coated by forward or reverse coating through a smooth roller or anilox roller On the PET base film substr...

Embodiment 3

[0028] Embodiment 3, the present invention first mixes and stirs 4 parts of emulsified montanic acid montan wax, 45 parts of ethanol and 45 parts of water to make a release layer coating; 15 parts of isocyanate resin, 6 parts of cellulose resin, 12 parts of acrylic resin, butyl 40 parts of ketone, 8 parts of amyl ketone, 7 parts of n-butanol, and 7 parts of metal complex dyes are mixed and stirred to make a color layer coating; 1 part of cellulose acetate, 1 part of vinyl cellulose, 1 part of polyvinyl butyral, Mix and stir 1 part of pulverized silicon dioxide, 3 parts of water and 18 parts of alcohol to prepare the adhesive layer coating.

[0029] According to the production method of environmentally friendly water-soluble self-adhesive anodized aluminum thermal transfer film, 6-15 micron PET film is used as the carrier film, and the release layer coating is firstly coated by forward or reverse coating through a smooth roller or anilox roller On the PET base film substrate, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com