Degassing technique for liquid sulfur

A liquid sulfur degassing and process technology, applied in the field of degassing process, can solve the problems of clogging the bubbler, easy partial condensation of the bubbler, unstable degassing effect, etc. low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

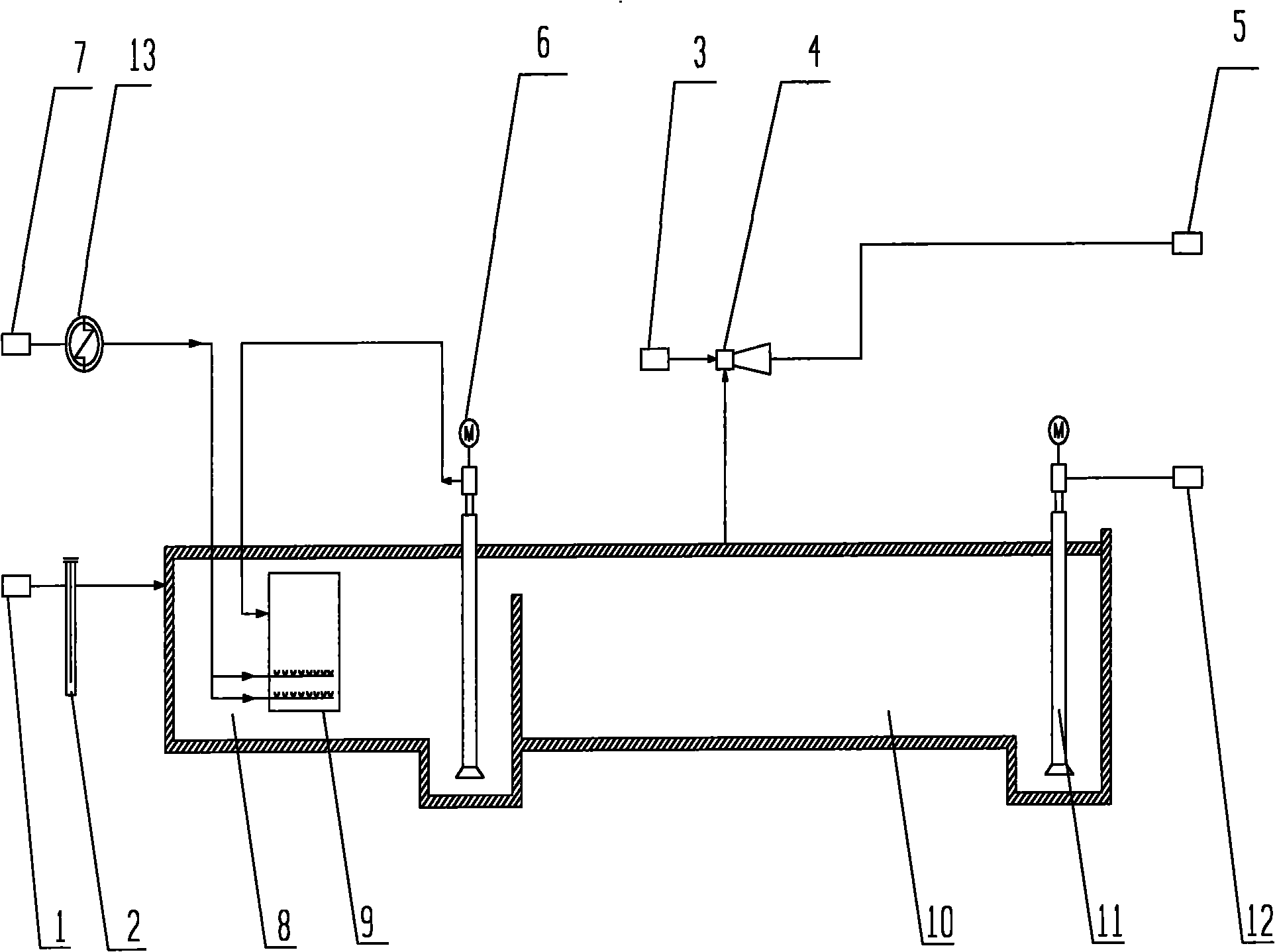

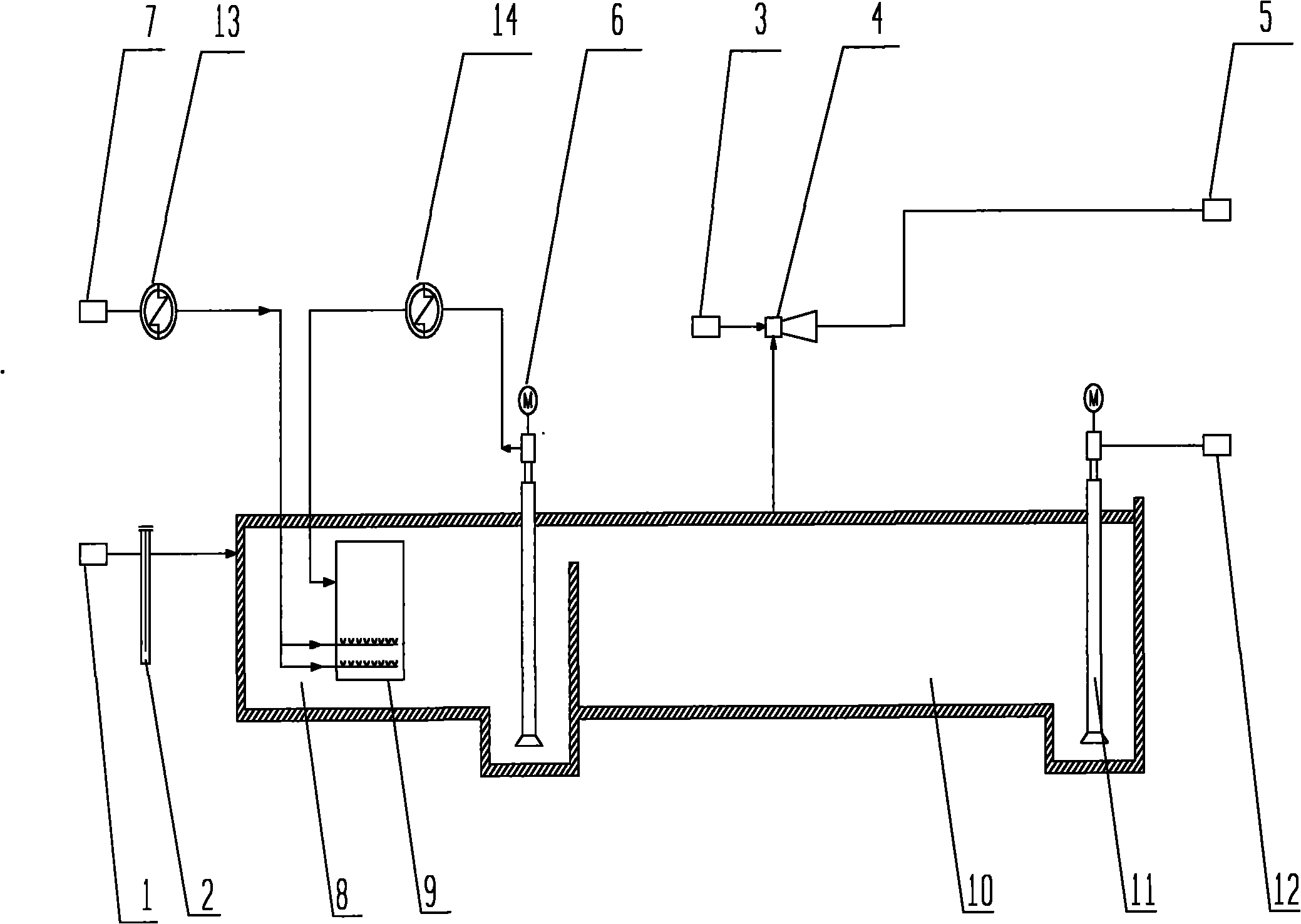

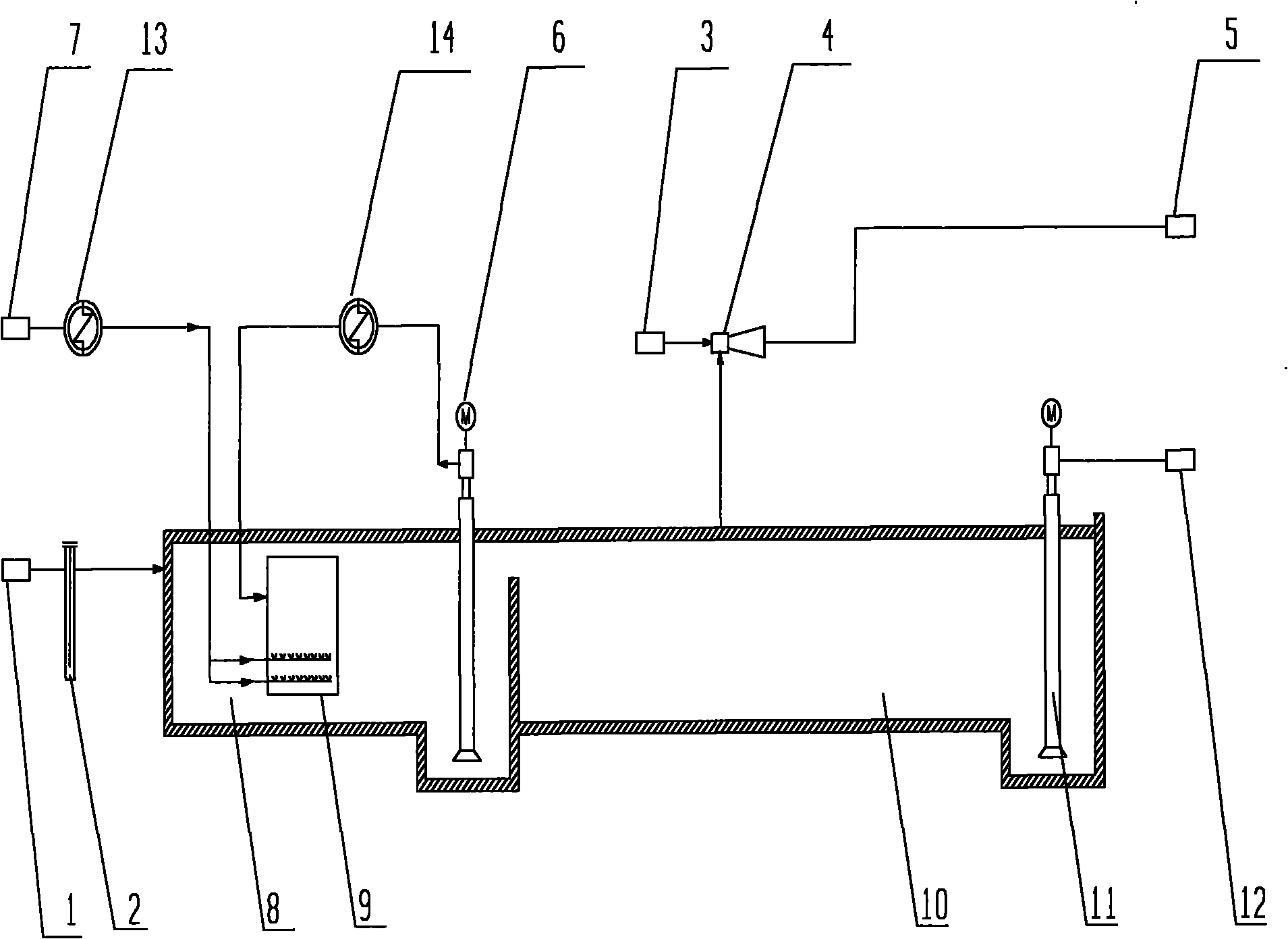

[0019] Combine below figure 1 The liquid sulfur degassing process of the present invention will be described in detail.

[0020] First, the liquid sulfur from the liquid sulfur inlet 1 enters the degassing section 8 through the sulfur seal 2, and the liquid sulfur in the degassing section 8 enters the upper part of the stripping degassing column 9 arranged in the degassing section 8 through the liquid sulfur degassing pump 6 .

[0021] The air enters the bubbling device at the bottom of the stripping and degassing column 9 after being heated to 130-140° C. from the air inlet 7 by the air preheater 13 . In the stripping and degassing column 9, the air lifts the liquid sulfur, and the liquid sulfur circulates inside and outside the stripping and degassing column 9, and the residual H 2 S x continue to convert to H 2 S, most of H 2 S is further oxidized to elemental S and H 2 O, H extracted from gas 2 S is pumped out through the steam evacuator 4 and sent to the tail gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com