Hydrocracking method for producing high-octane petrol

A hydrocracking and hydrorefining technology, applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of high investment and operating costs, influence of catalyst service life, harsh operating conditions, etc., and achieve equipment investment. And the effect of low operating cost, wide applicability of raw materials and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

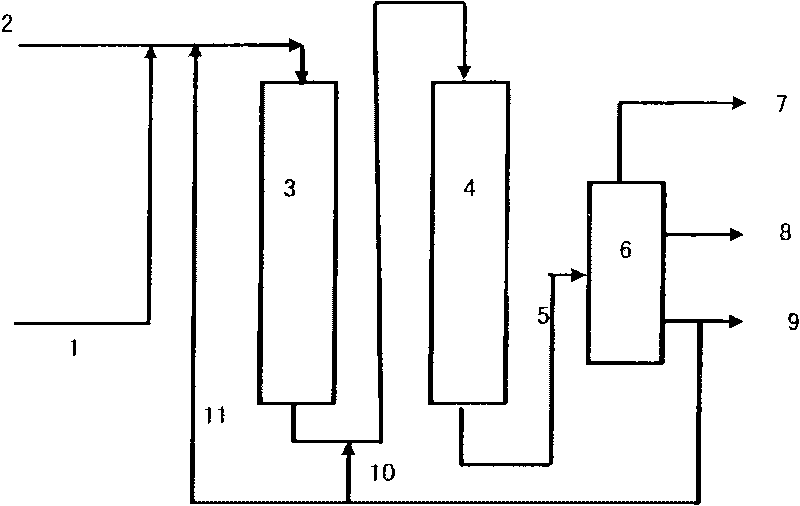

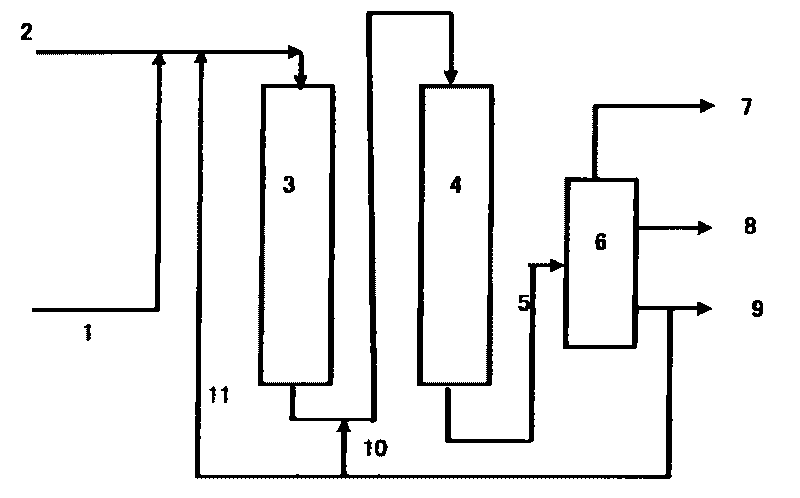

Method used

Image

Examples

Embodiment 1

[0032] Example 1 is an example of the feedstock once-through process, and the unconverted diesel fraction is not recycled. The conditions and results are shown in Table 1 below.

[0033] Table 1 raw material passes flow process embodiment and reference ratio once

[0034]

Example 1-1

Example 1-2

Reference example 1-1

Raw oil properties

Raw oil name

Inferior FCC

Inferior FCC

diesel oil

Inferior FCC

Density / kg·m -3

950.0

950.0

950.0

Distillation range / ℃

195~400

195~400

195~400

Sulfur content / wt%

0.79

0.79

0.79

Nitrogen content / μg·g -1

1109

1109

1109

Aromatic content / wt%

81.0

81.0

81.0

Hydrocracking process conditions

catalyst

FF-36 / FC-24

FF-36 / FC-24

FF-36 / FC-24

Pressure / MPa

8.0

8.0

8.0

temp...

Embodiment 2

[0041] Example 2 is an example of a partial circulation process, in which part of the unconverted diesel fraction is recycled back to the hydrocracking reactor. Conditions and results are shown in Table 2 below.

[0042] Table 2 Diesel Fraction Partial Circulation Process Embodiment

[0043] implementation plan

[0044] implementation plan

Embodiment 3

[0045] Example 3 is an example of the full circulation operation of the unconverted diesel fraction. The diesel fraction is fully recycled to the inlet of the hydrocracking reactor. The specific conditions and results are shown in Table 3 below.

[0046] Table 3 full cycle embodiment reaction conditions and product distribution

[0047] implementation plan

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com