Method for treating sulfur-containing waste water

A treatment method and technology for wastewater, applied in water/sewage treatment, natural water treatment, water/sludge/sewage treatment, etc., can solve the problems of large on-site odor, high energy consumption and high investment, and improve the treatment effect and process. Simple process and improved process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

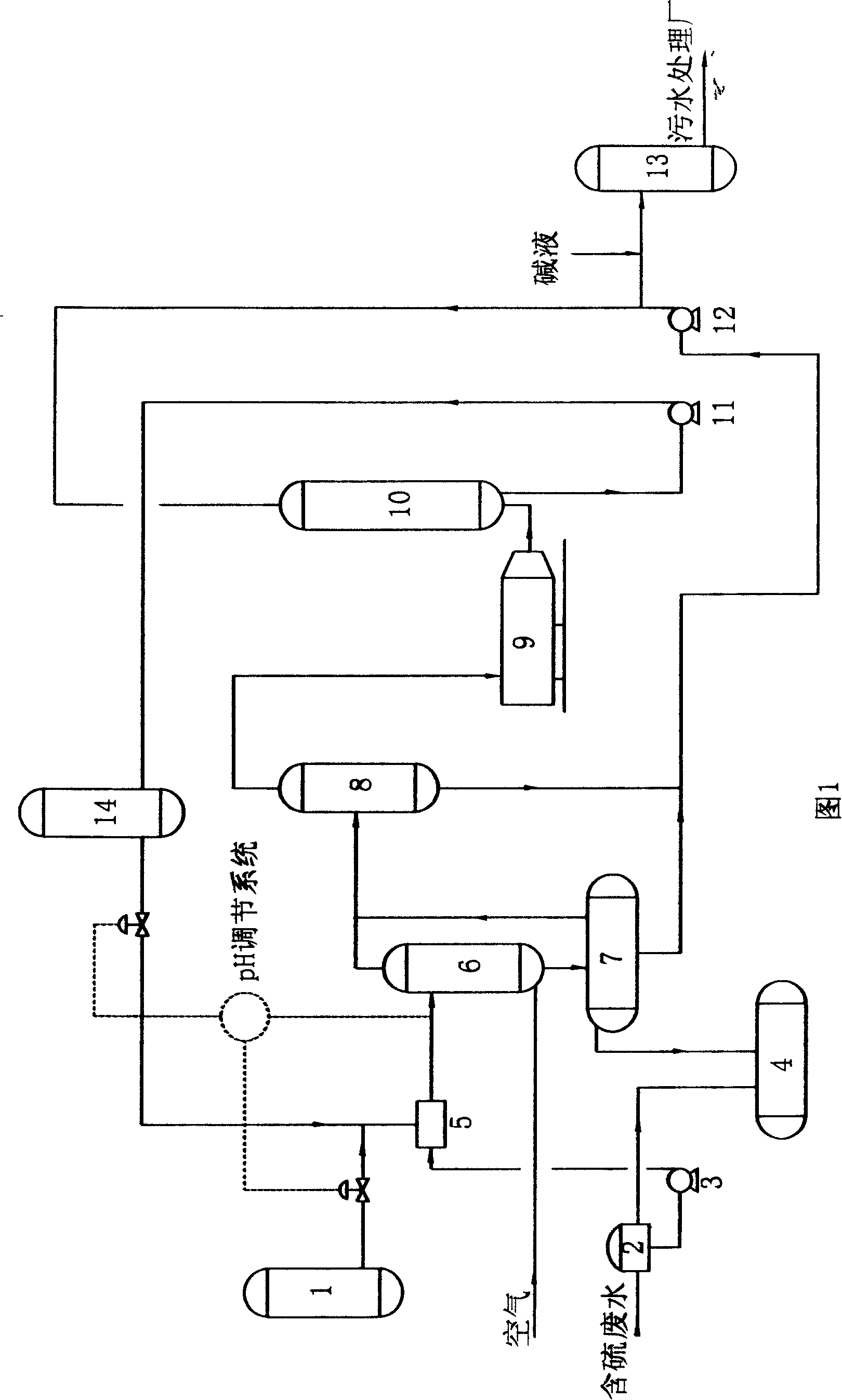

Image

Examples

Embodiment 1

[0045] A certain stream of sulfur-containing wastewater from a refinery has a sulfide content of 600mg / L and a pH value of 11.0. Add acid to adjust the pH value to 5. Stir with air aeration at 25°C. The residence time of the wastewater is 30 minutes. The catalyst carrier is catalytically incinerated. Using silica, the components are V 5%, Mn 1%, pt 0.2%, containing 5000μL / L H 2 After the tail gas of S is catalytically incinerated, H 2 S means not detected, H 2 S removal rate ≥ 99.9%, produce 0.1% dilute acid for reuse and adjust pH value to release H 2 S. The sulfide concentration of the effluent from the desulfurization unit is 25mg / L.

Embodiment 2

[0047] A certain stream of sulfur-containing wastewater from a refinery has a sulfide content of 2000mg / L and a pH value of 9.0. Add acid to adjust the pH value to 5. Stir with air aeration at 20°C for a residence time of 1 hour. The concentration of the substance is 16mg / L. Catalytic incineration of sulfur-containing gas The catalyst carrier is activated alumina, and the components are Fe 3%, Bi 4%, Ag 0.5%, containing H 2 After S 5000μL / L tail gas is catalytically incinerated, H 2 S removal rate ≥ 99.9%, after water absorption, 2% dilute acid can be obtained, which can be reused to adjust pH value of sulfur-containing wastewater to release H 2 S.

Embodiment 3

[0049] A certain stream of sulfur-containing wastewater from a refinery has a sulfide content of 20,000mg / L and a pH value of 12.0. Add acid to adjust the pH value to 4. Stir with air aeration at 30°C for a residence time of 3 hours. The concentration of the substance is 23mg / L. The carrier is titanium dioxide, the active component is Cu 3%, Pt 0.8%, Ag 1%, containing 2% H 2 After the tail gas of S is catalytically incinerated, H 2 S removal rate ≥ 99.9%, after water absorption, get 6% dilute acid, which can be reused in sulfur-containing wastewater, adjust pH value to release H 2 S.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com