Optimized hydrogenation-catalytic cracking combination process

A catalytic cracking and catalyst technology, applied in hydroprocessing process, petroleum industry, hydrocarbon oil treatment, etc., can solve the problem of reducing the processing capacity of catalytic cracking unit and the yield of gasoline and diesel products, unsatisfactory cracking effect, increasing regenerator load, etc. problems, achieve flexible product solutions, reduce equipment investment and operating costs, and increase yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

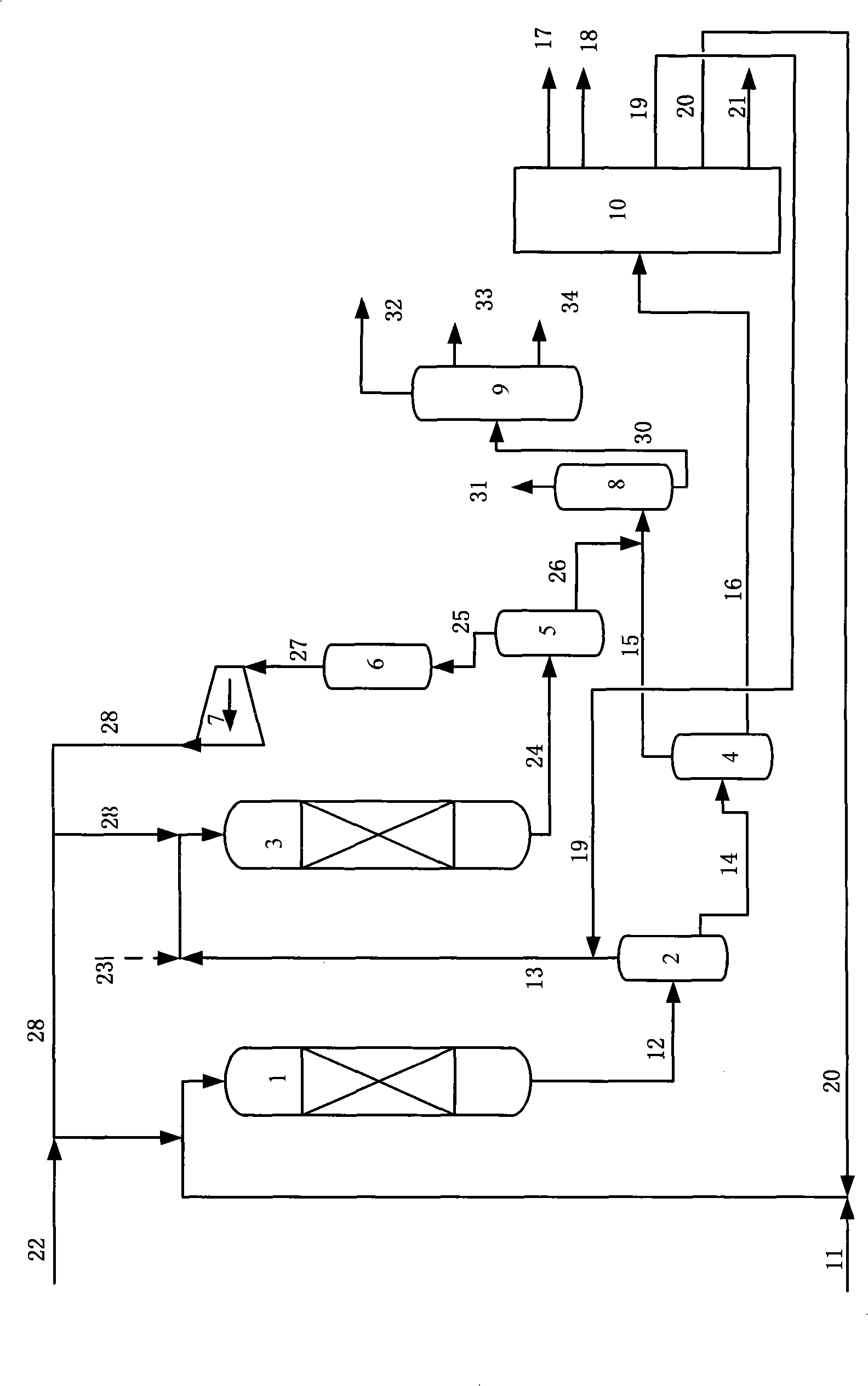

Method used

Image

Examples

Embodiment

[0054] The following examples will further illustrate the method provided by the present invention, but do not limit the present invention thereby.

[0055] In the examples, the feedstock for the reaction zone of the hydrotreatment of inferior wax oil is high-sulfur vacuum wax oil, and its properties are listed in Table 1. The raw material of fresh diesel oil in the hydroreforming reaction zone is straight diesel mixed oil, and its properties are listed in Table 2. The hydrotreating reaction zone is loaded with commercial catalyst combinations of RG-10A / RG-10B / RMS-1 / RN-32V respectively, and the loading volume ratio is 4:4:15:77. The hydrogenation-upgrading reaction zone is loaded with a commercial catalyst combination of RG-1 / RN-32 / RIC-2 / RN-32, and the loading volume ratio is 8:50:34:8. The grade of the catalyst used in the catalytic cracking process is CGP-2, and the above catalysts are all produced by Sinopec Catalyst Branch.

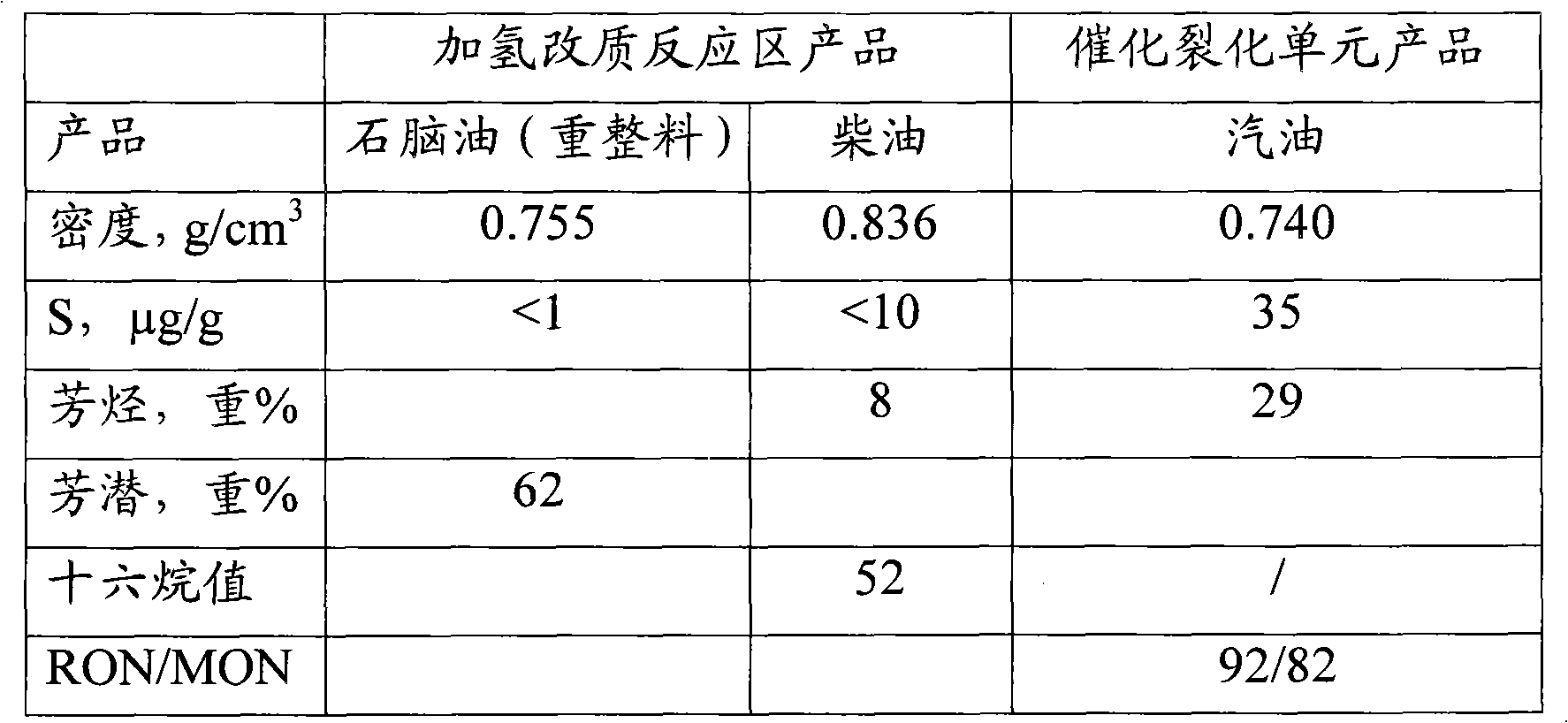

[0056] Tables 3 to 5 are the process conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com