Hydrocarbon oil desulphurization adsorbent, and preparation method and application thereof

A technology of adsorbent and hydrocarbon oil, which is applied in the field of hydrocarbon oil desulfurization adsorbent and its preparation and application, can solve the problem of lack of desulfurization activity of the adsorbent, and achieve high desulfurization activity and increase the effect of gasoline octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

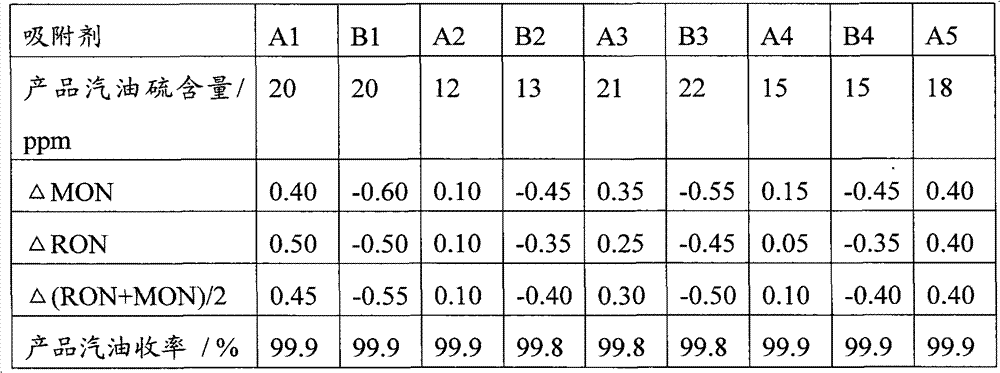

Examples

Embodiment 1

[0045] 4.43 kilograms of zinc oxide powder (Headhorse company, purity 99.7wt.%), 0.84 kilograms of β molecular sieves (Nanjing Catalyst Branch, containing 0.70 kilograms on a dry basis) and 4.57 kilograms of deionized water were mixed, and after stirring for 30 minutes, zinc oxide and β Molecular sieve mixed slurry.

[0046] Take 1.37 kg of alumina (produced by Shandong Aluminum Factory, containing 1.00 kg on a dry basis) and 2.10 kg of expanded perlite (including 2.06 kg on a dry basis) and mix them under stirring, then add 4.6 kg of deionized water and mix well, then add 360 ml 30wt.% hydrochloric acid (chemically pure, produced by Beijing Chemical Plant) was stirred and acidified for 1 hour, then heated to 80° C. and aged for 2 hours, then added zinc oxide and Beta molecular sieve slurry, mixed and stirred for 1 hour to obtain carrier slurry.

[0047] The carrier slurry uses Niro Bowen Nozzle Tower TM The model spray dryer is used for spray drying, the spray drying pressur...

Embodiment 2

[0055] Get 1.61 kilograms of pseudo-boehmite (produced by Shandong Aluminum Plant, containing 1.17 kilograms on a dry basis) and 1.54 kilograms of diatomite (containing 1.50 kilograms on a dry basis) and mix under stirring, then add 8.2 kilograms of deionized water and mix well, Add 260 milliliters of 30% hydrochloric acid (chemically pure, produced by Beijing Chemical Factory) and stir for acidification for 1 hour, then raise the temperature to 80° C. and age for 2 hours. After the temperature dropped, 5.52 kg of zinc oxide powder (Headhorse Company, purity 99.7%) and 0.36 kg of β molecular sieve (Nanjing Catalyst Branch, containing 0.30 kg on a dry basis) were added and stirred for 1 hour to obtain a carrier slurry.

[0056] Referring to the method of Example 1, the carrier was spray-dried and molded and the active component nickel was introduced to obtain the adsorbent A2. The chemical composition of the adsorbent A2 is: the content of zinc oxide is 55.2wt.%, the content of...

Embodiment 3

[0061] The adsorbent was prepared as follows: 4.93 kg of zinc oxide powder (Headhorse Company, purity 99.7%), 0.56 kg of USY (Qilu Catalyst Branch, containing 0.50 kg on a dry basis) and 5.57 kg of deionized water were mixed and stirred for 30 minutes to obtain Mixed slurry of zinc oxide and USY.

[0062] Take 1.85 kg of pseudo-boehmite (produced by Shandong Aluminum Plant, containing 1.35 kg on a dry basis) and 1.64 kg of diatomite (world mining company, containing 1.60 kg on a dry basis) and mix them under stirring, then add 4.6 kg of deionized water After mixing evenly, add 300 ml of 30% hydrochloric acid (chemically pure, produced by Beijing Chemical Factory) to make the pH value of the slurry 2.5, stir and acidify for 1 hour, then heat up to 80° C. and age for 2 hours. Zinc oxide slurry was added and stirred for 1 hour to obtain carrier slurry.

[0063] Referring to the method of Example 1, the spray drying of the carrier was carried out and the active components nickel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com